Development and Characterization of Jatropha Oil as Innovative

Bio-sourced Phase Change Material for Thermal Energy Storage

Made Rasta

1a

, Nyoman Suamir

1b

, Wayan Adi Subagia

1c

, Adi Winarta

1

,

Ketut Bangse

1d

and Gusti Ketut Puja

2e

1

Mechanical Engineering Department, Bali State Polytechnic, Bali-80364, Indonesia

2

Mechanical Engineering Department, Sanata Dharma University, Yogyakarta-55002, Indonesia

Keywords: Jatropha Oil, Bio-phase Change Material, Thermal Energy Storage.

Abstract: Thermal energy storage (TES) using phase change materials (PCM) is very promising to meet future energy

needs because of its high storage capacity and low cost. This study aims to develop Jatropha oil as a new

candidate for solid-liquid latent heat energy storage for cold storage applications. The characteristics of

Jatropha oil as a candidate for PCM were tested experimentally using T-history methods. The test results

show that Jatropha oil as a PCM candidate does not undergo super-cooling or super-cooling is very small

compared to tap water and mineral water of 10 K and 15 K. The phase transition temperature of Jatropha oil

ranges from -14 ºC to -16 ºC, lower than with tap freezing point and mineral water at 0 ºC. Thus, the candidate

PCM has good thermal properties that can meet the thermal energy storage requirements for cold storage

applications.

1 INTRODUCTION

Along with the increase in the economy and

population development, the need for energy is

increasing. Energy is a vital need in development.

Energy is still sourced from fossil fuels which can

cause climate change and environmental degradation.

Therefore, it is important to save energy and use new

and renewable energy sources that are

environmentally friendly for sustainable

development. Energy storage (ES) systems play an

important role in supporting energy security. Energy

can be stored in electrical, mechanical and thermal

energy.

One of the important ES systems for storing and

retrieving energy for energy conversion systems is

thermal energy storage (TES). The use of a TES

system based on latent heat technology can save

energy use from fossil fuels and conserve energy.

TES helps rational use of thermal energy and has the

a

https://orcid.org/0000-0002-9610-3738

b

https://orcid.org/0000-0003-0594-7511

c

https://orcid.org/0000-0001-9261-3549

d

https://orcid.org/0000-0003-0220-056X

e

https://orcid.org/0000-0002-6025-3865

advantage that it allows the transfer of peak loads

beyond peak loads, is significant in energy savings

and mitigation of CO

2

that causes pollution to the

environment.

Latent heat thermal energy storage (LHTES) is an

attractive technique because it can provide a higher

energy storage density than conventional TES

systems. Has the ability to store the heat of fusion at

a constant (relatively constant) temperature

corresponding to the phase transition temperature of

the phase change material (PCM).

One of the typical applications of PCM is for the

storage of solar thermal energy which is considered

the most abundant renewable energy. Utilization of

PCM for TES can overcome the intermittency of solar

energy, thus providing a better solution to rationalize

the utilization of solar thermal energy, compared to

the sensible heat TES system.

ES is a promising power management method to

obtain sustainable energy utilization. ES using

716

Rasta, M., Suamir, N., Subagia, W., Winarta, A., Bangse, K. and Puja, G.

Development and Characterization of Jatropha Oil as Innovative Bio-sourced Phase Change Material for Thermal Energy Storage.

DOI: 10.5220/0010952000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 716-720

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

LHTES is currently receiving a lot of attention to

reduce grid energy requirements.

TES schemes using PCM are categorized into

organic, inorganic and organic-inorganic mixtures.

Organic PCMs, such as paraffin and fatty acids, have

little super-cooling properties (no super-cooling

occurs) because they have self-nucleation but lower

thermal conductivity and higher cost. Inorganic

PCMs, such as hydrated salts, are readily available

and less expensive, but occurs phase separation, and

corrosive (Rasta and Suamir, 2019). Therefore, it is

important to select the optimal PCM in a given

application to meet operating and cost requirements.

The main problem of TES technology is

developing effective PCM for energy storage (Wang

& Lu, 2013). The main criteria in determining the

selection of PCM material types for TES applications

are to have a phase change temperature in the

practical application range, have high latent heat and

good thermal conductivity, as they involve the energy

storage and thermal stability characteristics of the

PCM.

By far the most famous PCM is water because it

has good thermal properties, but has the disadvantage

of high super-cooling (Rasta and Suamir, 2018). In

this study, Jatropha oil was developed as a PCM

material. Oil is a complex fatty acid/fatty acid ester.

Oils or fatty acids are a new class of organic PCM

materials and the thermal data available in the

literature are still limited (Aydin & Okutan, 2011).

Oils or fatty acids are derivatives of materials easily

found in nature and are labelled as bio-based

ingredients (Cellata, et al., 2015; Sharma, et al.,

2015). Another advantage is that vegetable oils are

available continuously (Sharma, et al., 2014; Fauzi, et

al., 2015; Suamir, et al., 2019).

Given the complexities of LHTES problems,

developing an effective PCM for energy storage in a

suitable form is still a big challenge and many

methods have been sought (Yingbo, et al., 2014). The

aim of this paper is to develop new bio-materials for

low temperature thermal energy storage below 0 ºC

for refrigeration system applications.

2 MATERIAL AND METHOD

The material used as Latent Heat Thermal Energy

Storage in this research is Jatropha oil. Jatropha oil

was chosen because of its sufficient availability in the

field and cultivated by farmers to increase their

income. The Jatropha oil tested here has undergone a

hydrolysis process. Jatropha oil contains various fatty

acids, both saturated and unsaturated fatty acids

(PUFA).

The thermal properties of Jatropha oil will be

compared with the thermal properties of tap water and

mineral water. Water is an excellent PCM material,

but has the disadvantage of high super-cooling and a

freezing point of 0 ºC. The results of the Jatropha oil

test will be compared with water, to explain the

characteristics of Jatropha oil.

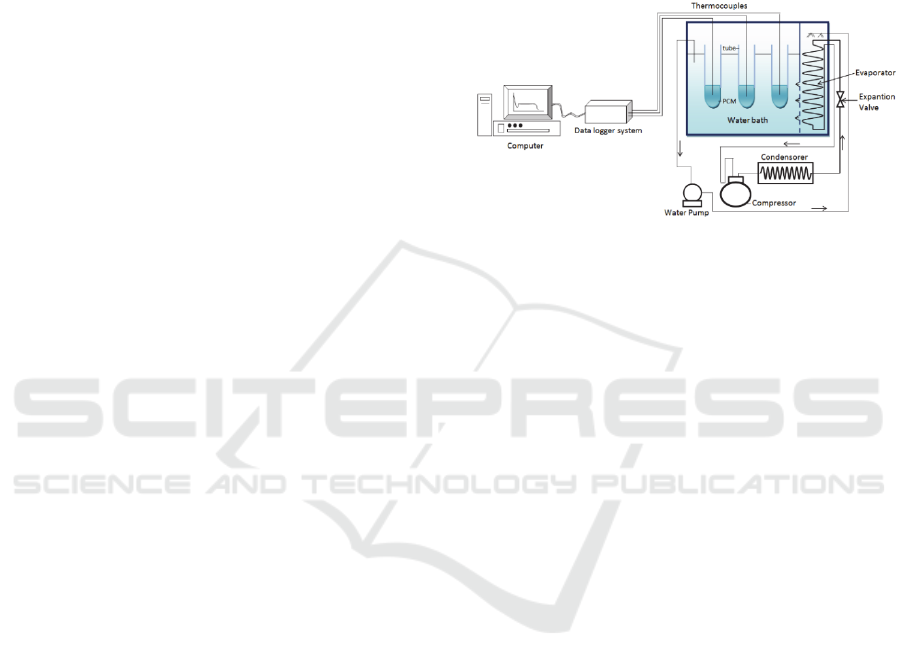

Figure 1: Schematic diagram of the experimental test

equipment T-history method (Rasta, et al., 2016a).

Figure 1 shows that the prospective PCM Jatropha

oil in various volumes is put into a glass tube and

immersed in a water bath as a cooling medium. The

cooling medium is a mixture of 40% (volume)

polypropylene glycol with tap water. The cooling

medium is circulated by pump through the evaporator

of the system. The temperature of the cooling medium

can be as low as -25 ºC. However, for testing, the

temperature of the cooling medium was maintained

stable at -20 ºC by using a digital thermostat with an

accuracy of ±0.2 ºC.

The data recording system shown in Figure 1 is

equipped with a data acquisition module and a

computer for recording or display systems. The data

acquisition module utilizes the Data scan 7000 series

from MSL (Measuring Systems Ltd) which includes

the Data scan 7320 measurement processor and the

7020 expansion module. Type T thermocouples are

used to measure the temperature of the PCM

candidate and cooling medium. The thermocouple

has a temperature measurement range of -250 ºC to

350 ºC with an error of ± 0.5 ºC. The thermocouple

was calibrated using a water bath calibration and the

uncertainty of the thermometer precision was ± 0.04

ºC. In the test temperature range is -25 ºC to 50 ºC

(Rasta, et al., 2016b).

3 RESULT AND DISCUSSION

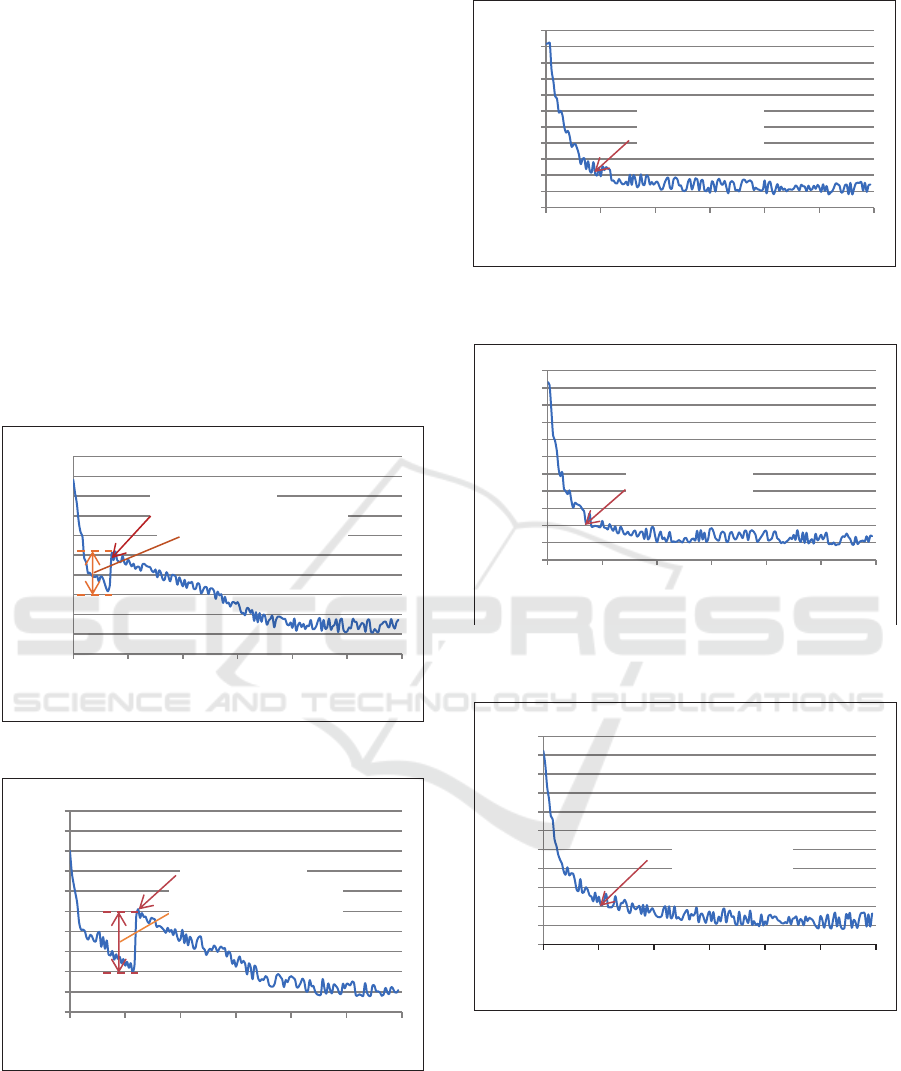

Super-cooling degree is an important parameter in

LHTES technology using PCM. Figures 2 and 3 show

Development and Characterization of Jatropha Oil as Innovative Bio-sourced Phase Change Material for Thermal Energy Storage

717

that tap water and mineral water have high super-

cooling, namely 10 K and 15 K. Super-cooling is a

condition that indicates the presence of tap water and

mineral water still in liquid form below the freezing

point of 0 ºC. A LHTES technology with high super-

cooling, will result in a much lower evaporation

temperature required when applied in the cooling

system. Thus will reduce the performance of the

system. In addition, before tap water and mineral

water freeze, the energy stored is only in the form of

sensible heat, causing a very small energy storage

capacity. In order for tap water and minerals to store

energy in the form of latent heat, more energy is

needed to change the state from liquid to solid. The

greater energy requirements in PCM technology are

in direct conflict with thermal energy storage

technology. So high super-cooling is a disadvantage

in LHTES technology

Figure 2: Cooling process and super-cooling tap water.

Figure 3: Cooling process and super-cooling mineral water.

Figure 4: Cooling process and Jatropha oil freezing point

for sample 4 ml.

Figure 5: Cooling process and Jatropha oil freezing point

for sample 8 ml.

Figure 6: Cooling process and Jatropha oil freezing point

for sample 12 ml.

-25

-20

-15

-10

-5

0

5

10

15

20

25

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Tap water

-25

-20

-15

-10

-5

0

5

10

15

20

25

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Mineral water

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 4 ml

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 8 ml

‐25

‐20

‐15

‐10

‐5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 12 ml

Freezing point

Freezing point

Freezing point

Su

p

e

r

-coolin

g

de

g

ree

Su

p

e

r

-coolin

g

de

g

ree

Freezing point

Freezin

g

p

oint

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

718

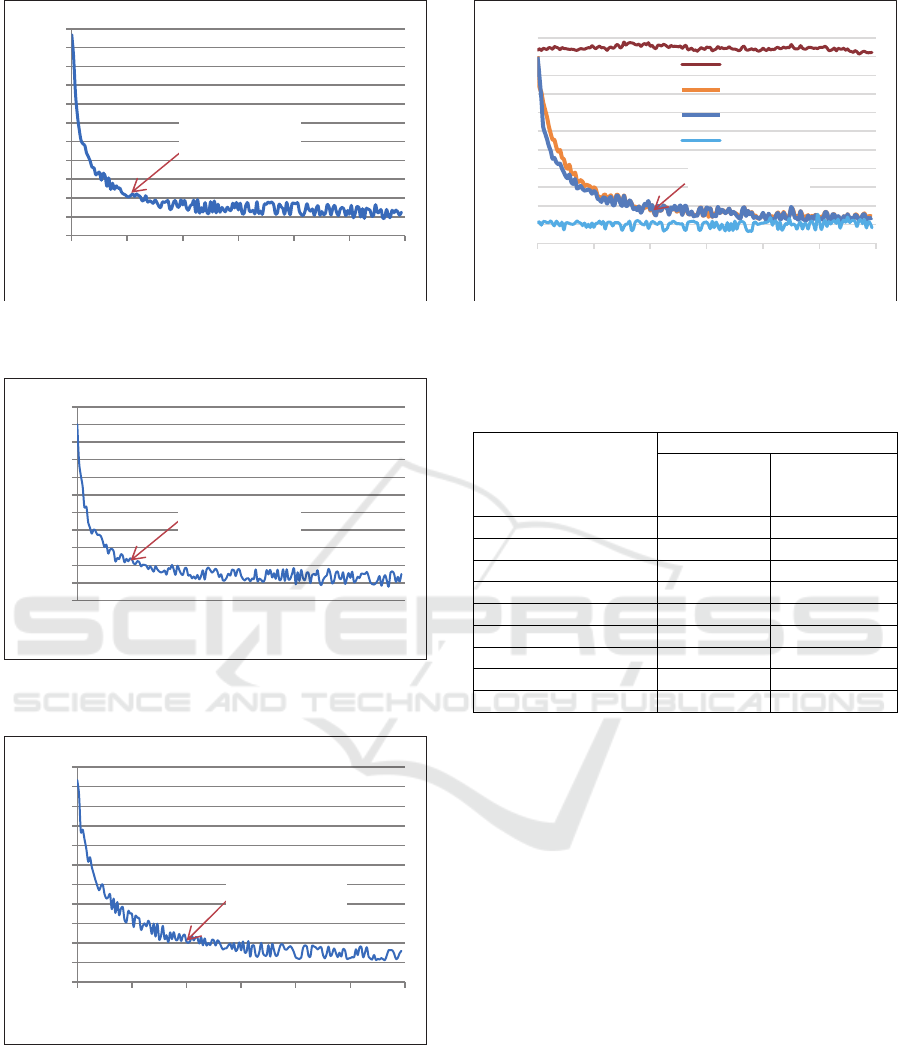

Figure 7: Cooling process and Jatropha oil freezing point

for sample 16 ml.

Figure 8: Cooling process and Jatropha oil freezing point

for sample 20 ml.

Figure 9: Cooling process and Jatropha oil freezing point

for sample 30 ml.

Figure 10: Cooling process and Jatropha oil freezing point

for sample 40 ml.

Table 1: Thermal energy storages properties of tap water,

mineral water and Jatropha oil.

Samples

(Volume, ml)

Cooling process

Freezing

temperature

(

ºC

)

Super-cooling

degree

(

K

)

Ta

p

water, 20 ml 0 10

Mineral water, 20 ml 0 15

Jatropha oil, 4 ml 14 0

Jatropha oil, 8 ml 14 0

Jatro

p

ha oil, 12 ml 15 0

Jatro

p

ha oil, 16 ml 15 0

Jatro

p

ha oil, 20 ml 15 0

Jatropha oil, 30 ml 16 0

Jatropha oil, 40 ml 16 0

Figures 4-10 shows the cooling process of each

volume variation of the Jatropha oil sample

developed as PCM. The test results of the T-history

method show that in the early stages of the cooling

process, there is a very rapid decrease in temperature

to the initial limit of the transition phase temperature

process. At the beginning of the phase transition

process until it ends there is no significant or constant

temperature change. When a phase transition occurs

from the beginning to the end, this is where the

storage of latent heat energy occurs. After that the

freezing process takes place, the temperature

decreases towards the final test temperature setting.

Overall, all samples developed with different

volume fractions of Jatropha oil are summarized in

Table 1. The freezing point of the PCM candidate

developed is lower than that of tap water and mineral

water. The freezing point of Jatropha oil in various

volumes of 4 ml, 8 ml, 12 ml, 16 ml, 20 ml, 30 ml and

40 ml, ranged from -14 ºC to -16 ºC. The results

showed that increasing the volume of the sample

tested did not significantly affect the change in

freezing point. Thus, the advantages of Jatropha oil

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 16 ml

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 20 ml

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (ºC)

Time (minute)

Volume = 30 ml

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Temperature (

o

C)

Time (minute)

Volume = 40 ml

Ambient temperature

Sample-1

Sample-2

Water bath

Freezing point

Freezing point

Freezing point

Freezing point

Development and Characterization of Jatropha Oil as Innovative Bio-sourced Phase Change Material for Thermal Energy Storage

719

do not occur super-cooling, have stable properties, are

not corrosive and environmentally friendly. These

properties make Jatropha oil a potential PCM material

for energy storage for latent heat thermal energy

storage applications in low temperature refrigeration

systems below 0 ºC, compared to water (tap water and

mineral water).

4 CONCLUSIONS

An investigation of Jatropha oil as a candidate for the

development of a new phase change material (PCM)

has been carried out. T-history thermal analysis was

applied in the investigation and it was found that

Jatropha oil has a phase transition temperature or

freezing point ranging from -14 ºC to -16 ºC. The

results of the investigation also found that the

candidate PCM under test conditions had a minimum

or even none (negligible) super-cooling level. In

addition, Jatropha oil has a continuous supply, is non-

corrosive and non-toxic. Meanwhile, tap water and

mineral water have high super-cooling, which are 10

K and 15 K, respectively, with a freezing point or

phase transition temperature of 0 ºC. This makes

Jatropha oil applicable as a new PCM for cold storage

applications below 0 ºC.

ACKNOWLEDGEMENTS

The authors would like to thank the financial support

received from the Ministry of Education, Culture,

Research, and Technology of the Republic of

Indonesia. This fee is charged to the Bali State

Polytechnic DIPA Number: SP DIPA-

023.18.2.677608/2021 dated November 23, 2020.

which has been submitted to the head of the research

as stated in the DIPA Fund Research Implementation

Agreement Letter No.: 887/PL8/PG/2021, April 6,

2021.

REFERENCES

Aydın, A.A., Okutan, H. (2011). High-chain fatty acid

esters of myristyl alcohol with even carbon number:

Novel organic phase change materials for thermal

energy storage-1. Solar Energy Materials and Solar

Cells 95, 2752-2762.

Aydın, A.A., Okutan, H. (2011). High-chain fatty acid

esters of myristyl alcohol with odd carbon number:

Novel organic phase change materials for thermal

energy storage-2. Solar Energy Materials and Solar

Cells 95, 2417-2423.

Cellata, K., Beyhana, B., Güngörb, C., Konukluc, Y.,

Karahand, O., Dündare, C., Paksoya, H. (2015).

Thermal enhancement of concrete by adding bio-based

fatty acids as phase change materials. Energy and

Building 106, 156-163.

Fabiani, C., Pisello, A.L., Barbaneraa, M., Cabeza, L.F.

(2020). Palm oil-based bio-PCM for energy efficient

building applications: Multipurpose thermal

investigation and life cycle assessment. Journal of

Energy Storage 28 (2020) 101129

Fauzi, H., Hendrik, S.C., Metselaar, Mahlia, T.M.I,

Silakhori, M., Chyuan-Ong, H. (2015). Thermal

characteristic reliability of fatty acid binary mixtures as

phase change materials (PCMs) for thermal energy

storage applications. Applied Thermal Engineering 80,

127-131.

Rasta, I.M., Suamir, I.N. (2018). The role of vegetable oil

in water based phase change materials for medium

temperature refrigeration. Journal of Energy Storage

15, 368-378.

Rasta, I.M., Suamir, I.N. (2019). Study on Thermal

Properties of Bio-PCM Candidates in Comparison with

Propylene Glycol and Salt Based PCM for sub-Zero

Energy Storage Applications. IOP Conference Series:

Materials Science and Engineering 494, 012024.

Rasta, I.M., Wardana, I.N.G., Hamidi, N., Sasongko, M.N.

(2016a). The role of heterogeneous nucleation in water

based Phase change material for medium temperature

Refrigeration. ARPN journal of engineering and

applied sciences

11(2), 978-985.

Rasta, I.M.,

Wardana I.N.G.,

Hamidi, N.,

Sasongko M.N.

(2016b). The Role of Soya Oil Ester in Water-Based

PCM for Low Temperature Cool Energy Storage.

Journal of Thermodynamics, Volume 2016, Article ID

5384640, 8 pages.

Suamir,

I.N., Rasta, I.M., Sudirman, Tsamos, K.M. (2019).

Development of Corn-Oil Ester and Water Mixture

Phase Change Materials for Food Refrigeration

Applications. Energy Procedia 161, 198-206.

Sharma, A., Shukla, A., Chen, C.R., Wu, T.N. (2014).

Development of phase change materials (PCMs) for

low temperature energy storage applications.

Sustainable Energy Technology Assessment 7, 17-21.

Sharma, R.K., Ganesan, P., Tyagi, V.V., Metselaar, H.S.C.,

Sandaran, S.C. (2015). Developments in organic solid-

liquid phase change materials and their applications in

thermal energy storage. Energy Conversion and

Management 95, 193-228.

Wang, H.Y., Lu, S.S. (2013). Study on thermal properties

of phase change material by an optical DSC system.

Applied Thermal Engineering 60, 132-136.

Yingbo, C., Shifeng, Z., Qi, Z., Yusheng, C., Yufeng, Z.

(2014). Composite phase change materials prepared by

encapsuling paraffinin PVC macrocapsules.

Thermochimica Acta 578, 10-14.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

720