Experimental Study of the Effect of Reactor Temperature

Reconstruction on Fuel Consumption and Distillate Quantity

Ida Bagus Puspa Indra

a

, I Made Anom Adiaksa

b

and Gusti Ngurah Ardana

c

Mechanical Enginering Departement, Bali State Polytechnic, Mangupura, Bali, Indonesia

Keywords: Temperature, Transfer, Heat, Energy, Distillate.

Abstract: Temperature is a measure or degree of hotness or coldness of an object or system, temperature is defined as a

physical quantity that is shared between two or more objects that are in thermal equilibrium. The second law

of thermodynamics is based on the fact that there is no reversible process in which heat flows naturally from

a high-temperature object to a low-temperature object, and not vice versa. Heat is energy that is transferred

due to a temperature difference. The concept of this law of thermodynamics will always occur and the process

will stop until the concept of thermal equilibrium occurs. It can be concluded that an object or fluid will have

a temperature and naturally that temperature can flow from a high temperature to a lower temperature until

the concept of thermal equilibrium is formed. Heat treatment through certain media can increase the

temperature or the temperature of the existing fluid. In the distillation column the high temperature distillate

fluid will tend to be at the top and the bottom will tend to be cooler even though heat treatment is carried out

at the bottom. Equilibrium temperature will be achieved in a relatively long time because the system used for

distillation is open. Temperature reconstruction by providing additional tools aims to achieve thermal

equilibrium more quickly. The process is carried out for 60 minutes using 25 liters of raw materials of the

same quality and the temperature is set at 90 degrees Celsius. The results obtained are the average temperature

difference in the reactor is 86.11%, the decrease in fuel consumption is 30.3%, and the distillation quantity

increases by 16.67% between the reactor without a pump compared to the reactor with a pump.

1 INTRODUCTION

Distillation is a process of separating two or more

components of a liquid based on the boiling point. In

simple terms, distillation is done by

heating/evaporating the liquid and then the steam is

cooled back to become liquid with the help of a

condenser. The reactor is tightly closed so that no

steam comes out of the lid gap or connection pipe.

The temperature increases gradually until the

maximum can evaporate water and other dissolved

materials which then flow through the connecting

pipe and undergo a process of condensation/phase

change from vapor to liquid.

Temperature is a measure or degree of hotness or

coldness of an object or system, temperature is

defined as a physical quantity that is shared between

two or more objects that are in thermal equilibrium

(Putra, 2007). If heat is transferred at the temperature

of the object, then the temperature of the object will

decrease if the object in question loses heat. The

relationship between the heat unit and the temperature

unit is not a constant, because the magnitude of the

increase in temperature due to receiving a certain

amount of heat will be influenced by the heat capacity

of the receiving object (Lakitan, 2002). Heat is energy

that is transferred due to a temperature difference.

Another definition of heat / heat is something that

moves between the system and its environment due to

changes in temperature (Zemansky, 1986). The

second law of thermodynamics is based on that there

is no reversible process. This law is a statement about

the processes that occur in nature. One of the

statements expressed by R.J.E Clausius is that heat

flows naturally from objects at high temperature to

objects at low temperature, not the other way around.

The development of the second law of

thermodynamics is based on the study of heat

engines, namely devices that can convert thermal

energy into mechanical work, such as steam engines

(Giancoli, 2005). Heat is energy that is transferred

due to a temperature difference. Another definition of

heat / heat is something that moves between the

system and its environment due to changes in

Indra, I., Adiaksa, I. and Ardana, G.

Experimental Study of the Effect of Reactor Temperature Reconstruction on Fuel Consumption and Distillate Quantity.

DOI: 10.5220/0010949600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 595-599

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

595

temperature (Zemansky, 1986). This concept of the

law of thermodynamics will always occur and the

process will stop until the concept of thermal

equilibrium occurs (Ninik, 2019). It can be concluded

that an object or fluid will have a temperature and

naturally that temperature can flow from a high

temperature to a lower temperature until the concept

of thermal equilibrium is formed. This flow of

temperature is often referred to as heat transfer.

Heat transfer is the science of predicting the

transfer of energy that occurs due to temperature

differences between objects or materials. Where the

energy transferred is called heat. Heat is known to be

able to move from a higher place to a lower

temperature (Evalina, 2019). Heat transfer is the

process of transferring energy from one place to

another due to differences in temperature in these

place, heat transfer can also take place in several ways

by convection, conduction and radiation (Indriatma,

2016). Conduction is the transfer of energy from a

particle with a high concentration of an adjacent

substance to a particle with a lower concentration as

a result of the interaction between the particles.

Convection is a model of energy transfer between a

solid surface and an adjacent gas or liquid motion,

and it involves a combination of the effects of

conduction and fluid motion. Radiation is the

emission of energy from matter in the form of

electromagnetic waves (photons) as a result of

changes in the electronic form of molecules or atoms

(J.P Holman, 6th Edition). Theoretically, the heat

transfer can occur through solid, liquid or gas due to

the treatment.

The existence of a distillation column as one of

the vital tools in the separation place, is an almost

always part of the complete process design. A special

understanding of this tool is considered very

important (Komariah, 2009), so in planning a

distillation reactor, it is very important to pay

attention to the manufacture of the reactor. Heat

treatment through certain media can increase the

temperature or the temperature of the existing fluid.

Looking at the second law of thermodynamics, the

heat that occurs will tend to move or flow to a place

that has a lower temperature. This process will occur

continuously until thermal equilibrium is established.

In the distillation column (reactor) the high

temperature distillate fluid will tend to be at the top

and the bottom will tend to be cooler even though heat

treatment is carried out at the bottom. Equilibrium

temperature will be achieved in a relatively long time

because the system used for distillation is open. This

time will greatly affect energy consumption which in

turn will increase the cost of distillate production.

This research will be carried out on the treatment

of the temperature that occurs in the reactor tube.

Temperature reconstruction by providing additional

tools with the aim of thermal equilibrium can be

achieved more quickly. The hope is that as soon as

this equilibrium is reached, it will affect the energy

consumption in the production process. The fixed

variables in this study are temperature and fluid flow

rate, while the independent variables are energy

consumption and distillate quantity.

Based on the background of the problem, the

problem is how to design a distillation reactor with

the addition of a temperature reconstruction tool and

whether the temperature reconstruction treatment can

affect energy consumption and the quantity of

distillate produced.

The problem will be limited by applying existing

applied science to design an appropriate

technological tool that can speed up production time

to reduce production costs that affect energy

consumption. The problem discussed in this study is

the design of a distillation reactor using a 1.5 mm

thick stainless steel plate with dimensions of 40 cm

base and 60 cm height wrapped with heat cover (glass

wool and burlap sacks). The heater uses an LPG stove

with a temperature setting to adjust the flame to suit

the needs of the reactor tube temperature. Steam

outlet using stainless steel pipe. Temperature data is

recorded between 15 menit. LPG weight is measured

in a certain time to get the amount of energy use. The

distillate quantity will be measured after the

distillation process runs at a predetermined time.

2 RESEARCH METHODS

2.1 Research Design

The application of traditional distillation equipment

is to make alcoholic beverages with coconut tree sap

or palm tree sap as raw materials. To obtain 1 liter of

alcoholic beverage it takes at least 16 liters of palm

juice, while the time required to heat the raw

materials to become steam is about 3 to 4 hours, this

takes a relatively long time to reach equilibrium.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

596

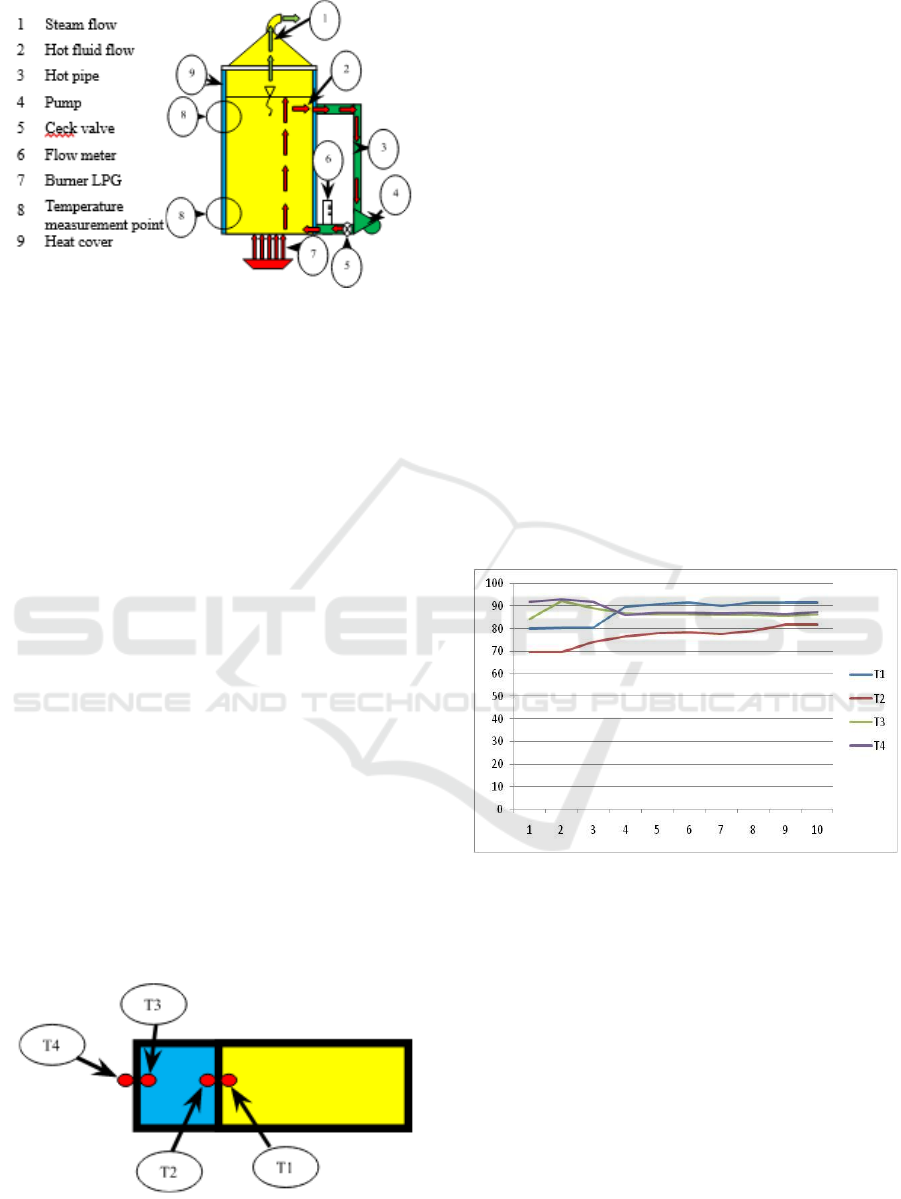

Figure 1: Distillation reactor design with temperature

reconstruction.

The addition of a pump in a device designed to flow

hot fluid that tends to be on the surface back to the

bottom of the reactor. The hope is that with this

circulation, the heat balance will occur more quickly.

The faster the increase in temperature is achieved, the

faster the evaporation of alcohol that occurs and thus

the energy consumption will decrease.

Previous research has been carried out with the

addition of heat cover to prevent heat losses causing

energy requirements to be relatively high. The spread

of heat in the reactor tube still adopts the natural law

where the highest heat will be on the surface of the

fluid.

The addition of a fluid pump in this study is to

obtain thermal equilibrium so that the evaporation

process will be faster and affect energy consumption.

2.2 Research Instruments

The instrument used in the research with the title of

experimental study is the effect of temperature

reconstruction on fuel consumption and distillate

quantity. Collecting data in the test using a

thermocouple by measuring the temperature at

several locations on the distillation tube as shown in

Figure 2.

Figure 2: Location of data retrieval.

The test is carried out based on the data that has

been taken and the variables that have been set. Fixed

variables are heating temperature and fluid flow rate.

The independent variables are fuel consumption and

distillate quantity. The test will be limited to only 5

trials and then find the average.

3 RESULT

The test was carried out 5 times with raw materials of

the same quality for each treatment. The volume

of raw materials is 25 liters. Preheating is done to

reach a temperature of 90 degrees Celsius according

to the temperature setting. Data collection on the

internal temperature and weight of the fuel begins

when the distillation reactor temperature has reached

90 degrees Celsius and the circulation pump is

started. Data were taken every 15 minutes for 60

minutes of heating. The distillate quantity and final

fuel weight were measured after 60 minutes of

processing. The data is displayed according to graph

1.

Figure 3: Test result data.

Figure 1 shows a very significant difference

between a reactor using a pump and a reactor without

a pump. T1 and T2 are the temperatures in the reactor

without a pump. T3 and T4 are the temperatures in

the reactor using a circulation pump. Understanding

the pump in general is a tool used to move fluid from

one place to another (Hirt, 1986). In principle, the

pump converts the mechanical energy of the motor

into fluid flow energy, the energy received by the

fluid will be used to increase the pressure and

overcome the losses that occur in the line.

In this reactor are use a centifugal pump. They use

a rotating impeller to increase the pressure of a fluid.

Centrifugal pumps are commonly used to move

liquids through a piping system. The fluid enters the

Experimental Study of the Effect of Reactor Temperature Reconstruction on Fuel Consumption and Distillate Quantity

597

pump impeller along or near to the rotating axis and

is accelerated by the impeller, flowing radially

outward into a diffuser or volute chamber (casing),

from where it exits into the downstream piping

system. Centrifugal pumps are used for large

discharge through smaller heads. The principle work

of the pump is driven by a motor. Power from the

motor is given to the pump shaft to rotate the impeller

attached to the shaft. The liquid in the impeller will

also rotate due to the impetus of the blades. Because

the centrifugal force arises, the liquid flows from the

center of the impeller out through the channel

between the blades and leaves the impeller at high

speed. The liquid that comes out of the impeller at

high speed will then come out through a channel

whose cross section is getting bigger (volute/diffuse)

so that there is a change from the velocity head to the

pressure head. Suction occurs because after the liquid

is thrown by the impeller, the space between the

blades becomes lower in pressure so that the liquid

will be sucked in. The pump in the reactor is useful

for draining the fluid on the surface to the bottom. The

hot fluid on the surface is returned to the bottom of

the reactor. Pumps used with a capacity of 10 liters

per minute.

The temperature of the reactor without a pump

(T1 and T2) shows a very significant difference

where there is an average temperature difference of

11.09 degrees Celsius. This temperature

difference affects the fuel consumption used. The

initial fuel weight is on average 6.980 kg and after the

process becomes an average of 6.585 kg there is a

decrease in weight of 0.395 kg. That’s an average of

5 times off/on burner with a very short time span from

off burner into on burner to maintain a stable

temperature. The quantity of distillation during the

process obtained an average of 1,250 ml after one

hour of process.

The reactor temperature with the pump (T3 and

T4) looks almost the same where there is only an

average temperature difference of 1.54 degrees

Celsius. This almost small difference indicates that

the temperature in the reactor becomes more even

with the addition of a pump for fluid circulation. This

affects the fuel consumption used only 0.275 kg from

an average initial weight of 6.950 kg to an average of

6.675 kg. That’s average 2 times off/on burner with a

long time span from off to on. The quantity of

distillation results during the process obtained an

average of 1,500 ml after one hour of process.

4 CONCLUSIONS

The conclusions of this study are:

1. The difference in temperature is 86.11%

between the reactor without a pump compared

to the reactor with a pump.

2. Decrease in fuel consumption by 30.3%

between reactors without pumps compared to

reactors with pumps.

3. An increase in the quantity of distillation results

by 16.67% between reactors without pumps

compared to reactors with pumps.

ACKNOWLEDGEMENTS

Thank you to the Bali State Polytechnic Research and

Community Service Center for providing full support

for the implementation of this research.

REFERENCES

Intang, A., & Darmansyah, D. (2018). Analisa

termodinamika laju perpindahan panas dan

pengeringan pada mesin pengering berbahan bakar gas

dengan variabel temperatur lingkungan. FLYWHEEL:

Jurnal Teknik Mesin Untirta, 1(1), 34- 38.

Chen, Y., & Athienitis, A. K. (1998). A three-dimensional

numerical investigation of the effect of cover materials

on heat transfer in floor heating systems. Ashrae

Transactions, 104, 1350.

Krasnoshlykov, A. S. (2016). Analysis of Influence of Heat

Transfer Conditions on the Upper Cover to Heat

Transfer in Thermosyphon. In MATEC Web of

Conferences. Vol. 72: Heat and Mass Transfer in the

System of Thermal Modes of Energy–Technical and

Technological Equipment (HMTTSC-2016).— Les

Ulis, 2016. (Vol. 722016, p. 1052). [sn].

Budiman, A. (2009). Penghematan energi pada menara

distilasi. Reaktor, 12(3), 146-153.

Budiyanto, A., Fadiawati, N., Tania, L., & Syamsuri, M.

M. F. (2015). Alat Distilasi Sederhana Berbasis Barang

Bekas. Jurnal Pendidikan dan Pembelajaran Kimia,

4(3), 1137-1150.

Bergman, T. L., Bergman, T. L., Incropera, F. P., Dewitt,

D. P., & Lavine, A. S. (2011). Fundamentals of heat and

mass transfer. John Wiley & Sons.

Adams, E. E., & Sato, A. (1993). Model for effective

thermal conductivity of a dry snow cover composed of

uniform ice spheres. Annals of Glaciology, 18, 300-304.

Ferahta, F. Z., Bougoul, S., Médale, M., & Abid, C. (2012).

Influence of the air gap layer thickness on heat transfer

between the glass cover and the absorber of a solar

collector. Fluid Dynamics & Materials Processing,

8(3), 339-351.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

598

Kros, S. J. (1986). Elemen Mesin, edisi kedua. Erlangga,

Jakarta.

Holman, J. P. (1986). Heat transfer, 1986. Mc Gran–Hill

Book Company, Soythern Methodist University.

Supu, S. I., Usman, U. B., & Basri, B. S. (2016). Sunarmi,”.

Pengaruh Suhu Terhadap Perpindahan Panas Pada

Material Yang Berbeda” Pogram Studi Fisika,

Fakultas Sains Universitas Cokroaminoto Palopo.

Indriatma. (2016). “Heat Analisis at Rotary Kiln Unit Iii Pt.

Antam, Tbk ( Persero ),” Ubpn Sultra, Enthalpy Jurnal

Mechanical Enginering. e-ISSN:2502-8944, Vol. 2,

No.2.

Syaichurrozi, I., Karina, A. M., & Imanuddin, A. (2014).

Study of Plate and Frame Heat Exchanger Performance:

The Effects of Mass Flow Rate, Inlet Temperature and

Type of Flow Againts The Overall Heat Transfer

Coefficient. Eksergi, 11(2), 11-18.

Mursito, J. A., Sukadana, I. G. K., & Tenaya, I. G. N. P.

(2017). Perancangan Dan Pengujian Alat Distilasi

Minyak Dari Limbah Sampah Plastik. Jurnal Ilmiah

Teknik Desain Mekanika, 6(4), 311-17.

Walangare, K. B. A. (2016). Design of a Seawater

Conversion Tool into Drinking Water Using a

Distillation Process. Journal of Electrical and

Computer Engineering, Department of Electrical

Engineering-Ft. Unsrat Manado.

Lakitan, B. (2002). Dasar-dasar klimatologi. PT. Raja

Grafindo Persada. Jakarta.

Komariah, L. N., Ramdja, A. F., & Leonard, N. (2009).

Tinjauan Teoritis Perancangan Kolom Distilasi untuk

Pra-Rencana Pabrik Skala Industri. Jurnal Teknik

Kimia, 16(4).

Noufal, M., Kusuma, I. G. B. W., & Suarnadwipa, I. N.

(2017). Analisa Perpindahan Panas Pada Heater Tank

FASSIP-01. Jurnal Mettek: Jurnal Ilmiah Nasional

dalam Bidang Ilmu Teknik Mesin, 3(1), 1- 10.

Evalina, N., Riza, M. K., Arfis, A., & Rimbawaty, R. (2019,

May). Pemanfaatkan Bahan Bakar Sampah Plastik

Dengan Menggunakan Pembangkit Listrik Hot Air

Stirling Engine. In Seminar Nasional Teknik

(SEMNASTEK) UISU (Vol. 2, No. 1, pp. 71-76).

Akhyar, O., & Mashuri, M. T. (2016). Perancangan Dan Uji

Kualitas Alat Destilasi Sederhana Sebagai Langkah

Kreatif Mewujudkan Kemandirian Laboratorium. AL

ULUM JURNAL SAINS DAN TEKNOLOGI, 1(2).

Putra, S., & Kelana, M. (2007). Rancangan Bangunan dan

Analisa Perpindahan Panas pada Ketel Uap Bertenaga

Listrik. Medan: USU.

Khurmi, R. S., & Gupta, J. K.(2008). Text Book of Machine

Design Eurasia. Ram Nagar ltd, New Dehli, 68.

Zemansky, M. F. (1986). Social Support and Burden In

Adult Child Caregivers of Physically Ill Elderly.

Giancoli, D. C. (2005). Physics: Principles with

applications (Vol. 1). Pearson Educación.

Ninik, T. S., Zaenal, A., Dyah, I., & Nurhidayat, N. (2019).

Sensitive and stable ethanol biosensor development

based on Acetobacter aceti biofilm for halal detection

of food and beverages.

Hirt, P. I. E. R. R. E., Hiller, G., & Wittek, R. (1986).

Localization and fine structure of a vaccinia virus gene

encoding an envelope antigen. Journal of Virology,

58(3), 757-764.

Experimental Study of the Effect of Reactor Temperature Reconstruction on Fuel Consumption and Distillate Quantity

599