Development of Hydrogen Gas Generator Prototype Model for

Vehicle Fuel with Electrolysis Method

I Putu Darmawa

a

, Ikeh Wiryanta

b

and I Nyoman Sutarna

c

Department of Mechanical Engineering, Politeknik Negeri Bali Badung, Bali, Indonesia

Keywords: Generator, Hydrogen, Electrolysis, Emission.

Abstract: The problem of energy needs in Indonesia is a serious problem in human life. The increase in consumption

of fossil fuels is not matched by the availability of natural resources, therefore alternative energy is needed to

reduce dependence on fossil fuels. One alternative energy that has been found is the electrolysis of water to

produce HHO gas. In this study, the model of a prototype hydrogen gas generator was developed using the

electrolysis method. The HHO generator aims to reduce emissions in vehicle exhaust gases. From the results

of the hydrogen gas generator development, it is found that the dimensions of the generator are length x width

x height = 210 mm x 130 mm x 300 mm, using aluminium plate and polycarbonate mica as the cover. The

electrolyte used is KOH with a percentage of 4%, the test results on the performance of the HHO generator

show that exhaust gas emissions in vehicles will decrease compared to the use of fossil fuels with octane 90,

a decrease in CO emission gas levels of 67% from 1.35% has decreased to 0.47% then the reduction in HC

emission gas levels was 34% from 645.33 ppm, decreased to 422.66 ppm.

1 INTRODUCTION

The problem of energy needs in Indonesia is a serious

problem in human life. Energy is an important

component for human survival because almost all

activities of human life are highly dependent on the

availability of sufficient energy, national energy

needs are still met by petroleum. Indonesia's oil

reserves are predicted to remain at around 3.6 billion

barrels. The reserves are estimated to be exhausted in

the next 12 years (viva.co.id, September 2013). The

cause of this problem is because petroleum is a non-

renewable natural resource, so it takes hundreds of

millions of years to get it back. In terms of controlling

the sustainability of national energy, the Indonesian

government also helps the use of energy composition

by issuing Presidential Regulation no. 5 of 2006

concerning the Goals and Targets of the National

Energy Policy states that the composition of energy

types in Indonesia in 2025 is coal 33%, natural gas

30%, petroleum 20%, and renewable energy 17%.

Included in this 17% are 5% biofuels, 5% geothermal,

a

https://orcid.org/0000-0001-7621-6420

b

https://orcid.org/0000-0002-1501-569X

c

https://orcid.org/0000-0003-2615-1854

biomass, nuclear, hydro, solar and wind 5%, and 2%

liquefied coal."

Hydrogen research and development continues to

be developed very intensively to welcome the era of

hydrogen-based energy which is predicted to be

achieved in the decade of 2050. Research and

development of energy in developed countries agrees

that future energy must have the following

characteristics (Crosbie, L. M., 2003):

1. Future energy technology must be developed,

because energy demand will continue to

increase

2. Future energy sources must be environmentally

Friendly.

3. An effective distribution system must be able to

be created, so that energy can really be widely

affordable and improve people's living

standards.

4. Must be safe both in terms of production,

transportation, storage, and use.

5. Energy technology must be economical.

Darmawa, I., Wiryanta, I. and Sutarna, I.

Development of Hydrogen Gas Generator Prototype Model for Vehicle Fuel with Electrolysis Method.

DOI: 10.5220/0010949400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 581-586

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

581

6. As an energy carrier, hydrogen is quite

promising and fulfills the characteristics of

future energy.

Hydrogen is a chemical element on the periodic

table that has the symbol H and atomic number 1. At

standard temperature and pressure, Hydrogen is a

colorless, odorless, non-metallic, single-valent, and a

highly flammable diatomic gas. Hydrogen is the

lightest element in the world. Most hydrogen exists in

a compound state with other elements such as

hydrocarbons and water. One way to produce

Hydrogen is through the process of electrolysis with

the help of electrical energy. Hydrogen gas is also

known as HHO gas (Brown Gas).

Several previous studies on the development of

hydrogen gas as an alternative fuel have been carried

out. Study on hydrogen gas production using the PEM

Water Electrolysis method has been conducted. The

review discusses recent developments in PEM water

electrolysis including the high performances low cost

HER and OER electrocatalysts and the challenges

associated with electrocatalysts and PEM cell

components (Kumar, S. Shiva, 2019). Study on the

effect of using a hydrogen gas mixture in internal

combustion engines, both gasoline and diesel

engines. Research shows that hydrogen gas mixtures

can be easily used in internal combustion engines

without the expense of modifying existing engine

configurations (SR. Premkartikkumar, 2015). One

form of innovation to improve energy efficiency in

vehicles is to add or inject HHO (Brown gas) gas into

the internal combustion engine. This HHO gas is

produced from the electrolysis of water with the

addition of a KOH catalyst. The addition of HHO gas

in an internal combustion engine can improve the

quality of combustion because this gas has a high

calorific value and octane, hydrogen fuel is able to

reduce NOx and HC gas emissions (R.F. Horng,

2008). The hydrogen-injected engine eliminates

knock and backfiring. The effect of using hydrogen in

a spark ignition (SI) engine can increase thermal

efficiency by 14% and NOx emissions can be reduced

by up to 95% (T. Suzuki, 2006). From previous

research, it has been compared hydrogen injection in

a spark ignition engine with a carburetor and an

engine with an injection system. The result is that the

fuel injection engine with the addition of hydrogen

has greater power and less backfiring risk (S.

Verhelst, 2005). Another research about hydrogen

gas as a fuelfor combustion also done by Mujebuu,

MA, 2016 and Chi, Jun, 2018. Both of them made a

gas hydrogen by electrolyze water.

From this description, on this research will design

and apply an electrolyser to produce sufficient HHO

(Brown Gas) gas for motorcycles engines by making

a prototype hydrogen gas generator which will later

be used for environmentally friendly vehicle fuel.

2 RESEARCH METHODOLOGY

The development of hydrogen gas generator prototype

model for vehicle fuel were divided into two sections.

The first was creates a design of the HHO generator.

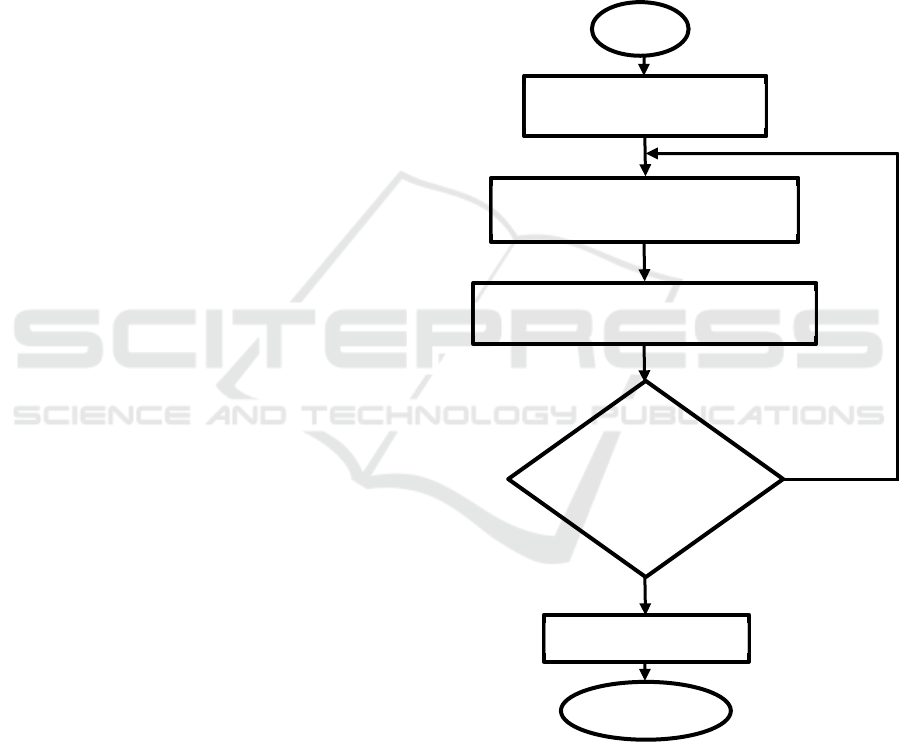

The flowchart of the research are shown in Figure 1.

Figure 1: Flowchart of the research.

By using CAD the design of the micro hydro

power screw Archimedes turbines were shown in

Figure 2.

Yes

N

o

Start

Design prototype of HHO

g

enerator model

Material selection for the generator

and the catalyst solution

Build and fabrication of HHO generator

Experimental report

Testing of

HHO

generator

Finish

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

582

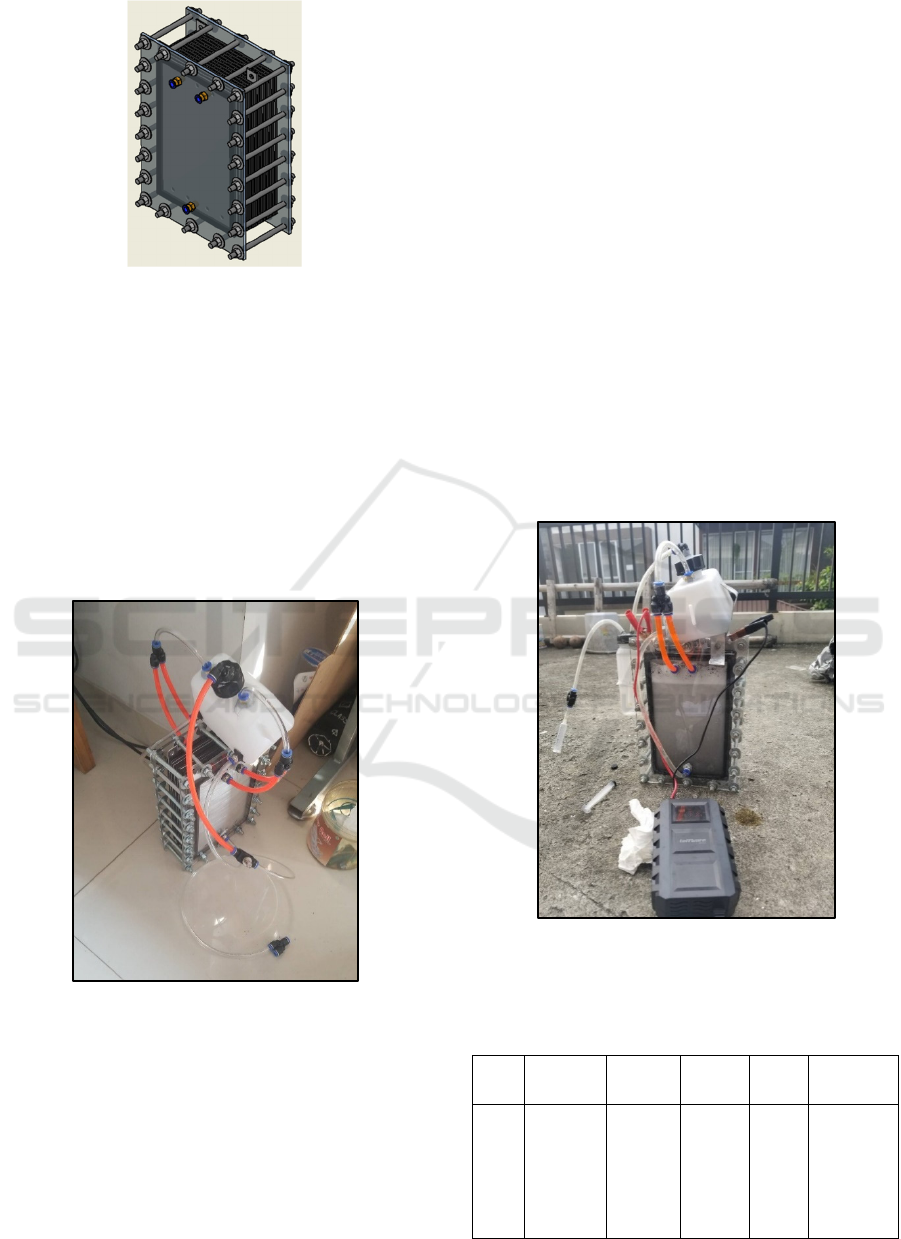

Figure 2: Design of HHO generator.

3 RESULT AND DISCUSSION

From the geometry design using CAD in Fig.2, then

the prototype of HHO generator were built and

developed. The hydrogen generator made has the

following sizes, length x width x height = 210 mm x

130 mm x 300 mm, number of plates = 13 sheets,

number of cells = 12 cells, plate material =

aluminium. The prototype of HHO generator were

shown in Figure 3 below:

Figure 3: Prototype HHO generator engine.

In this HHO generator engine, there are several

types of components, including:

1. Aluminium plate with a thickness of 2 mm. The

generator made is divided into 3 plates, namely:

a. Positive plate, positive plate is a plate that

carries positive current. The positive plate has

the following sizes, the negative plate size is

270 mm high, 160 mm wide and 2 mm thick,

2 pieces.

b. Negative plate, negative plate is a plate that

carries negative current. The negative plate

size is 270 mm high, 160 mm wide, and 2mm

thick, 1 piece.

c. Neutral plate, neutral plate is a plate that limits

the negative plate and positive plate. The

neutral plate has the following dimensions,

250 mm high, 160 mm wide and 2 mm thick

with a total of 10 plates.

2. Polycarbonate mica, using polycarbonate mica

with a length of 210 mm x a width of 297 mm with

a thickness of 5 mm.

3. The rubber gasket used has a height of 270 mm, a

width of 160 mm and a thickness of 5mm.

The HHO generator that has been developed then

tested in a 100cc four stroke gasoline engine. The test

was conducted to determine the flow rate and

efficiency of the dry cell type HHO generator, with

the main ingredient in the form of water and

additional KOH catalyst with a mass percentage of

4% of the water volume of 2000 ml.

Figure 4: Performance test of HHO generator.

The result from the test shown in table 1 below:

Table 1: Test Result.

No Catalyst Voltage

(V)

Curren

t (A)

Time

(s)

𝒙

𝟎

∆𝒙

1 KOH 14.8 20 3.56

5.30

4.58

2.05

3.36

3.772.72

Development of Hydrogen Gas Generator Prototype Model for Vehicle Fuel with Electrolysis Method

583

3.1 P HHO Generator

From the result above it can be seen that the KOH

catalyst requires a voltage of 14.8 volts with a current

of 20 amperes, which has an average time of

3.77±2.72 seconds to produce 10 ml of HHO gas.

The power used in HHO generator then can be

known:

P = V.I

P = 14.8 V. 20 A

P = 296 watt

3.2 HHO Gas Flow Rate

From the result in table 1, the flow rate of HHO gas

can be known:

𝑉

=

𝑣𝑜𝑙𝑢𝑚𝑒

𝑡

V

=

10 ml

3.77 s

= 2.56 ml/s

3.3 HHO Gas Flow Rate

Based on the results of the calculation of the HHO

generator power consumption and HHO gas flow rate,

it can be calculated to find the efficiency of the HHO

generator tool that uses a KOH catalyst with a

percentage of 4%, with an additional value of the

density of HHO gas of 0.491167 gr/l and a value of

0.491167 gr/l. from the LHV of HHO gas of 13.25

kJ/gr.

Ƞ

=

×

×

× 100%

Ƞ

=

2.56 × 0.491167 × 13.25

296

× 100%

Ƞ

=5.6 %

The ratio of hydrogen gas and oxygen gas in

Brown's gas is the same, so the density of HHO and

LHV HHO does not affect the cause of the increase

or decrease in the efficiency of the generator. While

the amount of power greatly affects the increase and

decrease in efficiency in this study. The higher the

power used, the lower the efficiency, it can be seen

that the greater the current, the higher the

productivity, but not proportional to the greater the

energy used so that the efficiency will decrease. A lot

of the energy used is turned into heat and not used to

break the bonds of water, so a lot of energy is wasted

and the efficiency will decrease.

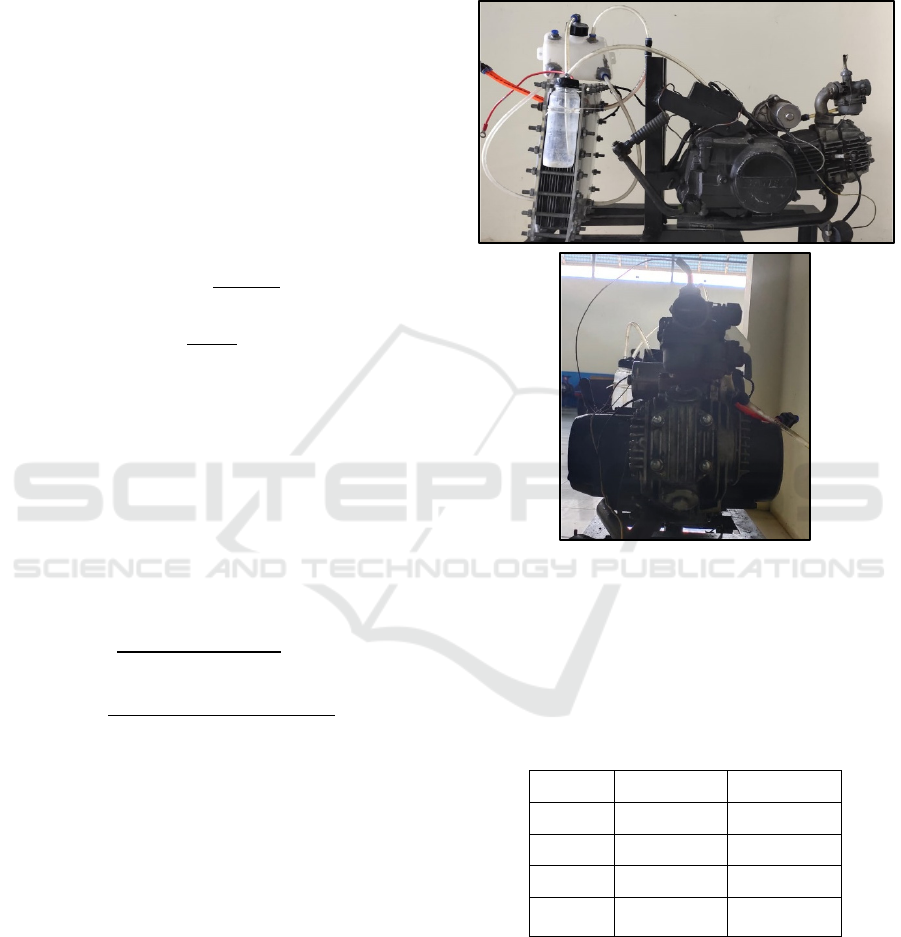

3.4 Exhaust Emission Testing

The exhaust testing was conducted in a single

cylinder 4 stroke engine, 110 cc. The experimental set

up was shown in Figure 5 below:

Figure 5: Engine set-up.

The results from the emission test (CO and HC)

without using a hydrogen generator shown in table 2

below. The results from the CO emission test are in

percentage (%) and the results from the HC test are

parts per million (ppm)

Table 2: Emission test without hydrogen generator.

No CO (%) HC (ppm)

1 0.93 677

2 1.44 629

3 1.79 630

Average 1.35 645.33

The results from the emission test (CO and HC) using

dry cell type hydrogen generator, and water – KOH

as the catalyst shown in table 3 below. The results

from the CO emission test are in percentage (%) and

the results from the HC test are parts per million

(ppm).

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

584

Table 3: Emission test with hydrogen generator (water-

KOH catalyst).

No CO (%) HC (ppm)

1 0.46 433

2 0.50 403

3 0.45 432

Average 0.47 422.66

Figure 6: Emission test of CO (%).

Figure 7: Emission test of HC (ppm).

From Figure 6 it can be seen that the ratio of CO

gas when not using an HHO generator is much greater

than using an HHO generator. The use of a hydrogen

generator causes differences in exhaust gas emissions

in CO gas (carbon monoxide) which is quite far,

compared to the standard which uses RON 90 fuel,

the average concentration of CO gas without HHO

generator was 1.35% then in using HHO generator,

the average concentration decreasing into 0.47%.

The emission test of HC gas with and without

using HHO generator were shown in Figure 7. The

result showed that the use of HHO generator also can

decreasing the emission of HC gas compared to the

standard which uses RON 90 fuel. The average

emission of HC gas were 645.33 ppm and the average

emission of HC using HHO generator were 422.6

ppm, which the decreasing was about 34.5%.

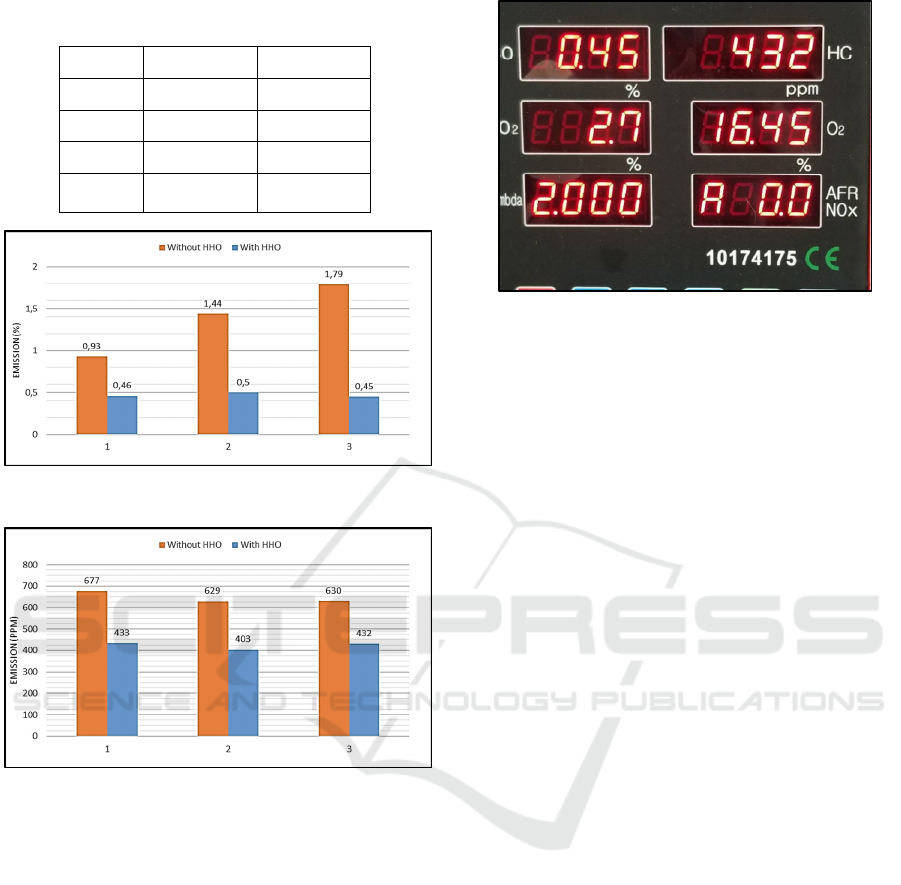

Figure 8: Emission test using gas analyser.

4 CONCLUSIONS

From the discussion above, it can be concluded that

the HHO generator that has been made can work

properly. The generator can produce enough HHO

gas that can be use in motorcycle engine. The test

result of uses HHO gas to the engine showed that the

use of HHO generator can reduce the emission of

exhaust gas (CO and HC) compared to the standard

which uses RON 90 fuel. The average concentration

of CO gas decreasing about 0.47%, and the average

emission of HC decreasing about 34.5%.

ACKNOWLEDGEMENTS

The authors would like to thank the Director and the

Head of P3M Politeknik Negeri Bali for funding this

research. Authors also like to thanks to all the staff of

mechanical engineering department of PNB for all

their hands.

REFERENCES

Chi, Jun, Hongmei Yu, (2018). Water electrolysis based on

renewable energy for hydrogen production. Chinese

Journal of Catalysis. 39, p. 390–394.

Crosbie, L. M., Chapin, Douglas, (2003). Hydrogen

Production by Nuclear Heat. GENES4/ANP2003. Sep.

15-19, 2003, Kyoto, JAPAN.

Kumar, S. Shiva, V. Himabindu, (2019). Hydrogen

production by PEM water electrolysis – A review.

Materials Science for Energy Technologies. Vol. 2, p

442–454.

Mujebuu, MA., (2016). Hydrogen and syngas production

by superadiabatic combustion – A review. Applied

Energy. 273, p. 210-224.

Development of Hydrogen Gas Generator Prototype Model for Vehicle Fuel with Electrolysis Method

585

R.F. Horng, et al, (2008). Driving characteristics of a

motorcycle fuelled with hydrogen-rich gas produced by

an onboard plasma reformer. Int. Journal of hydrogen

energy. 33, p. 7619 – 7629.

SR. Premkartikkumar, AR. Pradeepkumar, (2015). Effect

of using hydrogen mixed gases as a fuel in internal

Combustion engines – A Review. International Journal

of Innovative Research in Advanced Engineering

(IJIRAE). Vol. 2, p. 29 – 31.

T. Suzuki, Yoshihito Sakurai, (2006). Effect of Hydrogen

Rich Gas and Gasoline Mixed Combustion on Spark

Ignition Engine. Powertrain & Fluid Systems

Conference & Exhibition, Toronto, Canada, October

16-19.

Verhelst, S., R. Sierens, (2001), Aspects concerning the

optimisation of a hydrogen fueled engine. Int. Journal

of hydrogen energy. 26, p. 981 – 985.

viva.co.id, September 2013.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

586