Preliminary Study of Solar PV Characteristics Cooled by Water

Spray

Putu Wijaya Sunu

1a

, Daud Simon Anakottapary

1b

, I Dewa Made Susila

1c

,

I Dewa Gede Agus Triputra

1d

, I Nyoman Edi Indrayana

2

, Asrori

3e

, Andoko

4f

, Ketut Suarsana

5

and C. Bambang Dwi Kuncoro

6g

1

Mechanical Engineering Department, Bali State Polytechnic, Badung, Bali, Indonesia

2

Electrical Engineering Department, Bali State Polytechnic, Badung, Bali, Indonesia

3

Mechanical Engineering Department, Malang State Polytechnic, Malang, Jawa Timur, Indonesia

4

Mechanical Engineering Department, Malang State University, Malang, Jawa Timur, Indonesia

5

Mechanical Engineering Department, Udayana University, Badung, Bali, Indonesia

6

Refrigeration, Air Conditioning and Energy Engineering Department, National Chin-Yi University and Technology,

Taiwan

ediindrayana@pnb.ac.id, asrori@polinema.ac.id, andoko.ft@um.ac.id, suarsana@unud.ac.id, bkuncoro@ncut.edu.tw

Keywords: Solar PV, Automatic Cooling, Water Spray, Nominal Power.

Abstract: The efficiency of the solar PV array will decrease significantly as the temperature of the surface module

exceeds a certain limit a nominal value. To handle the efficiency problem, it is important to control the surface

temperature of solar PV. This study investigated the effect of the surface temperature of solar PV array

modules due to automatic water spray cooling installed on the top roof of a residential structure in the

Denpasar area. The performance indicator were then compared to that of the case without a water spraying

cooling system. A thermostat is an automatic controlling system of cooling mechanism to keep the surface of

solar PV temperature nearly to the ambient temperature. In this experiment, the surface temperature was kept

at approximately around 33

0

C with the active cooling system by the water spraying technique focus on the

front surface of the PV module. The result presented an increase of PV voltage by 4.69% on average.

Consequently, the output power produced by the cooled PV array module increase is 107.14 W against 94.01

W for the non-cooled PV array.

1 INTRODUCTION

To limit the use of fossil fuels and reduce the carbon

footprint of the global electricity system requires

comprehensive policies on production and incentives

to stimulate growth in renewable energy use.

Electricity generation from solar energy resources

which is utilizing solar radiation with solar panels as

alternative energy offers many advantages namely

cheap, pollutant-free, and environmentally friendly

a

https://orcid.org/0000-0002-6915-0475

b

https://orcid.org/0000-0001-7856-6512

c

https://orcid.org/0000-0002-2567-9932

d

https://orcid.org/0000-0002-9422-7876

e

https://orcid.org/0000-0002-9414-3015

f

https://orcid.org/0000-0003-1923-2445

g

https://orcid.org/0000-0002-5054-2794

energy. Solar PV is a very promising energy

instrument for the sustainability of energy

development (Jager-Waldau, 2019; Meral et al.

2011). Power generated by solar energy is a function

of the PV module efficiency, and several other factors

i.e., cell materials, photovoltaic system devices,

environmental factors. Special attention is paid to

environmental factors, hot climatic conditions, long

periods of sunshine, and high ambient temperatures

which is given a very dominant factor influence on

Wijaya Sunu, P., Simon Anakottapary, D., Dewa Made Susila, I., Dewa Gede Agus Triputra, I., Nyoman Edi Indrayana, I., Asrori, ., Andoko, ., Suarsana, K. and Bambang Dwi Kuncoro, C.

Preliminary Study of Solar PV Characteristics Cooled by Water Spray.

DOI: 10.5220/0010947000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 429-433

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

429

the efficiency and power of PV module. With

environmental conditions as described above, there is

a reduction in the quantity of energy that is converted

into useful energy by about 31%. The rest of it will be

changed into heat energy which will affect the surface

temperature of the PV panel. This condition will

decrease the PV module lifespan and energy

conversion efficiency (Idoko et al., 2018).

Several introductory articles regarding the solar

PV cooling method as a solution to the overheating of

PV surface temperatures describe below. It is well

recognized that the number of efficiency can be

reached by keeping the surface panel temperature.

(Moharram et al., 2013) the investigation was made

to reveal the phenomena of cooling the PV module

using water spraying, this study also revealed how

long to decrease the temperature of the surface

temperature to 35

0

C. From the data, it specifies the

PV energy output was highest when surface

temperature commenced around 45

0

C. In the study by

(Schiro et al., 2017), for controlling the temperature

and reaching the maximum module performance, the

researcher studied the opportunity of a cooling system

method without varying the original PV structure.

They observed the specified methods to maintain the

temperature of the front panel with watering. The

result shows, the method applied in this experiment

could recover both the economic and performance

aspect of the PV system. (Sajjad et al. 2019) expected

to increase the efficiency and performance. A special

cooling system developed by placing PV modules in

the refrigerated duct of a buildings. The performance

was made for one PV module cooled by refrigerated

air and the other one was non-cooled. The cooled PV

performance reaches 6% higher compared to that of

the without cooling system. Also, the efficiency

reached 7.2% better. In another research an

investigation of applied water as cooling medium by

(Abdolzadeh and Ameri, 2009). The aims of the study

were to decrease the PV module surface temperature.

In the case of spraying, it is usual use a water pump.

The experiment data shows a significant electrical

power increase of the solar PV. Off course this

phenomenon will causes the efficiency of the system

better. An investigation by (Kordzadeh, 2010), a thin

water film layer generated by spraying water at

surface area of PV to reduce the PV array

temperature. In this test rig, the pump flows the

cooling water to the surface of PV module. The

results confirmed that the improvement of PV module

efficiency.

To increase the efficiency of the PV module array,

another active cooling was preserve using a heat

exchanger. (Ceylan et al., 2014) an approach was

agreed out to deliver active cooling using a spiral heat

exchanger. The HX was stationed on the module. The

result designates 13% module efficiency increased

with this HX cooling approach. A HX use as a precool

the ambient air. This is an alternative cooling system

employs. This method is used to cool the back surface

of a PV panel. A good agreement was found to

decrease the temperature from 55

0

C to 42

0

C

(Elminshawy et al., 2019). Another active cooling

method that is applicate from the back surface of PV

modules using HX proposed by (Bahaidarah et al.

2013). The result found 9% of efficiency. This

method assisted to decrease the module temperature

significantly. For residential PV, another alternative

cooling system method was proposed using channels

which is placed under the flat of solar panel. In this

schema, the thermal power exchanging take place

between water circulation in/out from a tank for

domestic hot water applications in England by (Peng,

2017). (Irwan et al. 2013) proposed a cooling system

with the force convection system applied using a fan

for air cooling. A good agreement on the amount of

energy saving was accomplished. Another progress in

fan cooling to reduce the temperature of PV modules

by (Teo et al. 2012). In this experiment, the back side

of the PV panel was tailored with an arrangement of

air channel and found around 14% efficiency.

It can be summarized from the literature study

done by many researchers that using water as a

cooling media, found to be effective to increase the

solar PV power. Therefore, the objective of this study

is to build a cooling system using the spraying

technique to controlled the surface of solar cells

temperature from overheating problematic.

2 EXPERIMENTAL METHODS

A water tank with a capacity of 120L is considered to

provide a supply cooling system of a PV panel

(Figure 1). Water is pumped through the pipe system

by a centrifugal pump. Ten nozzles were placed on

the edge of solar PV which is spraying the water to

the surface of solar PV. The solar PV was cooled

during the optimum solar irradiance intensity of a day

period of 2.5 hours, from 11:00 a.m. to 01:30 p.m., in

May 2021 at Denpasar city, Bali, Indonesia. The

experimental setup comprises two solar PV units.

Every solar PV unit has 72 monocrystalline silicon

cells. The load is about 50 W. The unit’s specification

is presented in Table 1.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

430

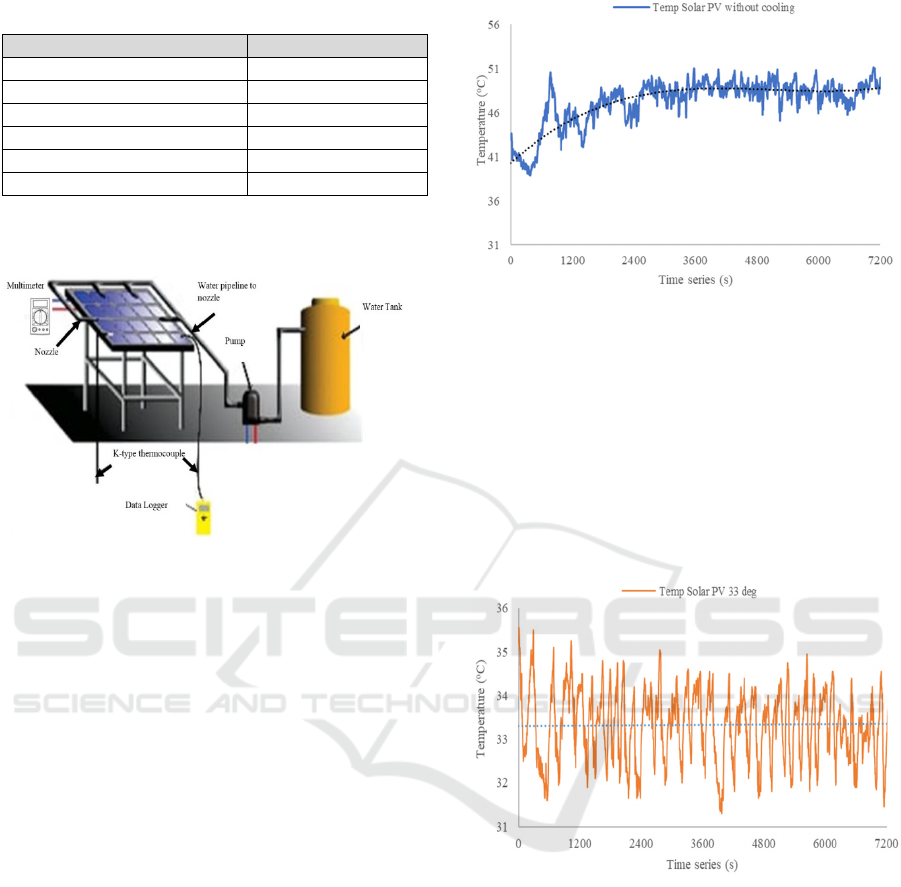

Table 1: Spesification of the PV panel.

Parameter of PV panel Spesification

Cell type Monocrystalline Si

Number of cells 72

Maximum power (Pmax) 220 W

Current at P max/ Isc 5.73A

Voltage at P max/ Voc 47.00V

Dimensions of module (mm) 1320 x 992 x 40

The graphic of the test experimental setup is

shown in Fig.1.

Figure 1: Sketch of water spray cooling system of the solar

PV.

The PV panel is placed at a proclivity angle around

15

0

to the flat surface. The positioning of solar PV

depends on geographical conditions. Besides that in

the meantime of spraying, this inclination will

prevent puddles on the surface of solar PV. The

experiments were carried out for cut-off surface

temperature around 33

0

C. Temperature

measurements were taken every second from some

point in the surface of the PV module with K-type

thermocouples and logged with a data logger.

Meanwhile, electrical parameters were taken via

Bluetooth communication for every 30 s.

3 RESULT AND DISCUSSION

Firstly, the data were conducted under relatively high

radiation intensities at noon. The increase of PV-

surface temperature was logged under these solar

irradiances without any cooling system. The data was

then compared to that of the surface temperature of

solar PV 33

0

C. The water flow rate considered for the

spray cooling is 4 l/min of all PV surface area.

Figure 2: The time series of PV surface temperature (for

without-cooled).

Figure 2 shows the temperature of the PV surface as

a function of time. It can be seen, that the temperature

increased gradually by increased of time. The

temperature of the PV panel surface for the uncooled

PV system is varied and reached a maximum of about

51.5

0

C. The panel cooled down by the spray water

cooling systems and maintain the surface temperature

around 33

0

C with a deviation of about 2

0

C as shown

in Fig 3.

Figure 3: The time series of PV surface temperature (for

33

0

C conditions).

The spray technique is effective to reduce the PV

surface temperature by reducing the reflection of

electromagnetic radiations and the efficiency of solar

PV are strongly correlated with the solar spectrums.

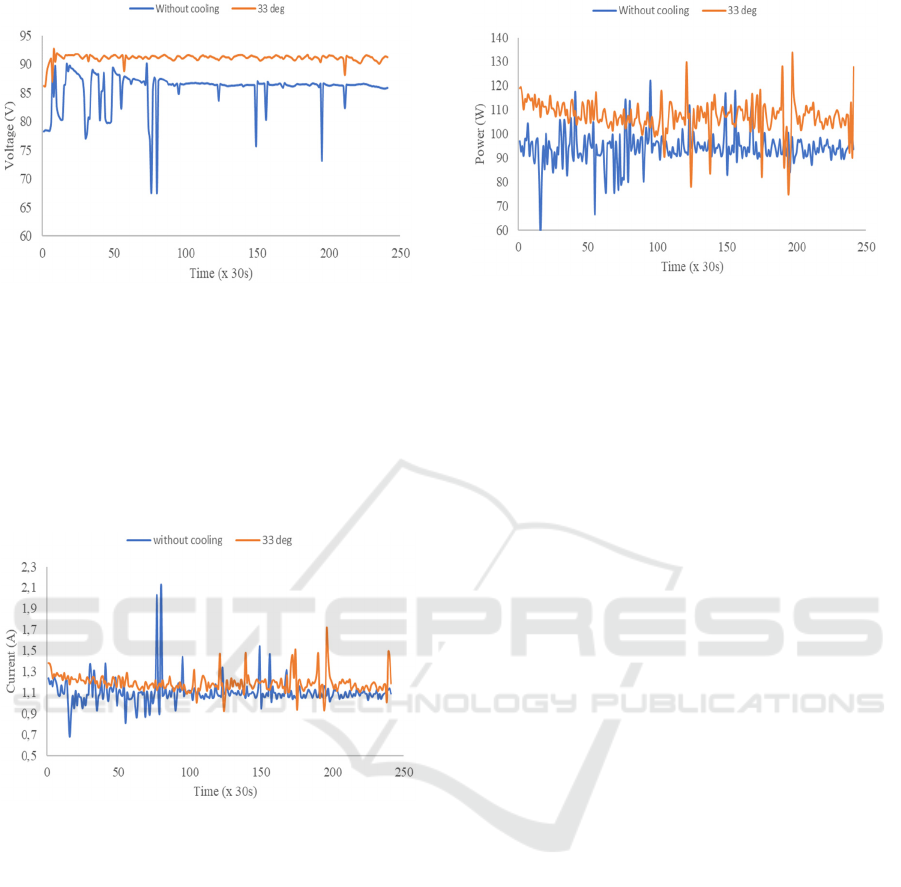

(Hadipour, 2021). Fig. 4 shows the time series of

voltage values of the duty cycle on the experiment

period. As shown in fig.4, by decreasing the surface

temperature of PV, the voltage produced by the solar

PV increase.

Preliminary Study of Solar PV Characteristics Cooled by Water Spray

431

Figure 4: The time series of PV voltage (for without-cooled

and 33

0

C conditions).

The maximum electrical voltage significantly

increases, by decreasing the surface solar PV

temperature. The changes in the maximum current of

the PV panel can be observed in Fig.5. It is also

revealed, the water spraying cooling technique is

more effective to increase the current in a high solar

irradiation environment.

Figure 5: The time series of PV current (for without-cooled

and 33

0

C conditions).

Fig. 6 described the time series of the electrical power

generated by solar PV for all variables in this

research. As described in this figure, the average

electrical power output of 94.01 W. On the other

hand, the average electrical power output is 107.29 W

for the cooled PV panel can be achieved by using a

steady water spraying cooling system. The more

decreases of the surface PV temperature, the more

increases power output.

Figure 6: The time series of PV power (for without-cooled

and 33

0

C conditions).

The spray cooling technique has the better

performance on the electrical parameter but they're

still need to investigate about the electrical

efficiencies for both cases. So, it is strongly suggested

to use the water spraying technique for maintaining

the PV panel's temperature.

4 CONCLUSIONS

To cool the PV panels, this research proposed a

technique using spray water. The experimental setup

has been arranged to find the correlation of cooling

the PV surface on the electrical parameter. It can be

determined from the results that:

1. The application of a cooling system by means

of spray cooling is very possible.

2. Based on the concern operating conditions

the average power for cooled PV surface is

107.29 W, and 94.01 W for non-cooled PV

surface. It has a strong correlation between

the output electrical energy and surface PV

temperature.

ACKNOWLEDGEMENTS

The authors would like to express sincere gratitude to

Kemdikbud-Ristek, Republic of Indonesia for

research fund, No. 180/E4.1/AK.04.PT/2021. Also

Politeknik Negeri Bali with research project number

is No. 31/PG/PL8/2021.

REFERENCES

Abdolzadeh, M., Ameri, M., 2009. Improving the

effectiveness of a photovoltaic water pumping system by

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

432

spraying water over the front of photovoltaic cells. In

Renew. Energy.

Bahaidarah, H., Subhan, A., Gandhidasan, P., Rehman, S.,

2013. Performance evaluation of a PV (photovoltaic)

module by back surface water cooling for hot climatic

conditions. In Energy.

Ceylan, I., Gürel, A.E., Demircan, H., Aksu, B., 2014.

Cooling of a photovoltaic module with temperature

controlled solar collector. In Energy Build.

Elminshawy N.A.S., Mohamed A.M.I., Morad K.,

Elhenawy Y., Alrobaian A.A., 2019. Performance of

PV panel coupled with geothermal air cooling system

subjected to hot climatic. In Appl Therm Eng.

Hadipour Amirhosein, Mehran Rajabi Zargarabadi, Saman

Rashidi., 2021. An efficient pulsed-spray water cooling

system for photovoltaic panels: Experimental study and

cost analysis. In Renewable Energy.

Idoko Linus, Olimpo Anaya-Lara, Alasdair McDonald,

2018. Enhancing PV modules efficiency and power

output using multi-concept cooling technique. In

Energy Reports.

Irwan, Y.M., Daut, I., Safwati, I., Irwanto, M., Gomesh, N.,

Fitra, M., 2013. A new technique of photovoltaic/wind

hybrid system in Perlis. In Energy Proc.

Jager-Waldau A., 2019. Snapshot of photovoltaics. In

Energies.

Kordzadeh, A., 2010. The effects of nominal power of array

and system head on the operation of photovoltaic water

pumping set with array surface covered by a film of

water. Renew. In Energy.

Meral, M.E., Diner, F., 2011. A review of the factors

affecting operation and efficiency of photovoltaic based

electricity generation systems. In Renew. Sustain.

Energy Rev.

Moharram, K.A., Abd-Elhady, M.S., Kandil, H.a., El-

Sherif, H., 2013. Enhancing the performance of

photovoltaic panels by water cooling. In Ain Shams

Eng. J.

Sajjad U. et al., 2019. Cost effective cooling of photovoltaic

modules to improve efficiency. In Case Studies in

Thermal Engineering.

Schiro F., A. Benato, A. Stoppato, N. Destro, 2017.

Improving photovoltaics efficiency by water cooling:

Modelling and experimental approach. In Energy.

Teo, H.G., Lee, P.S., Hawlader, M.N., 2012. An active

cooling system for photovoltaic modules. In Appl.

Energy.

Peng Z, Herfatmanesh MR, Liu Y., 2017. Cooled solar PV

panels for output energy efficiency optimisation. In

Energy Convers Manag.

Preliminary Study of Solar PV Characteristics Cooled by Water Spray

433