Effect of Different Type Catalyst on Biodiesel Production from

Jatropha Curcas Oil via Transesterification using Ultrasonic Assisted

Muh. Irwan

1,2

, Ramli

1,2

, Mardhiyah Nadir

1,2

,

Marlinda

1,2

and Arief Adhiksana

1,2

1

Politeknik Negeri Samarinda, Jalan Dr. Ciptomangunkusumo Kampus Gunung Lipan, Samarinda, Indonesia

2

Department of Chemical Engineering, Politeknik Negeri Samarinda, Samarinda, Indonesia

Keywords: Biodiesel, Catalyst, Jatropha, Oil, Transesterification, Ultrasonic.

Abstract: Biodiesel as an alternative energy can be produced through transesterification reaction from different

vegetable oils such as palm oil, coconut oil, jatropha oil and other sources. Jatropha oil has 4.61% free fatty

acids (FFA<5%) so the biodiesel production can be done directly by the transesterification reaction. The

purpose of this study is to determine the effect of transesterification time and the type of catalyst on the yield

of biodiesel obtained. The catalysts used are sodium hydroxide (NaOH), potassium hydroxide (KOH), and

sodium methoxide (CH

3

ONa) with a concentration of 1% mass of oil dissolved into methanol using of 1:6

molar ratio. Transesterification reaction assisted by ultrasound 35 kHz with different time of reaction (10, 15,

20, 25, and 30 minutes). The highest biodiesel yield was obtained at 30 minutes with 89,531% using KOH as

catalyst. The results of physical properties such as viscosity of 5.71 cSt, density of 860.17%, and moisture

content of 0.0136% have met SNI 7182-2015 standard.

1 INTRODUCTION

The depletion of fossil fuels in the near future makes

the world community look for alternative energy

sources (Mohandass. et al, 2016). Indonesia is one of

the world's petroleum-producing countries, but to

date is still importing fuel oil to meet fuel needs in the

transport and energy sectors. Thus, the government is

trying to reduce the amount of imported fuel oil by

increasing the use of biodiesel to be mixed in fossil

oils as diesel fuel. One of them is biodiesel used as a

substitute of petroleum fuel (Kementerian ESDM,

2013). The Government of Republic Indonesia issued

a Minister of Energy and Mineral Resources

Regulation No. 25 of 2013 on supply, utilization and

trading biofuel, which requires increased use of

biodiesel in the transportation, industrial, commercial

and power sectors. It is targeted that in 2013 it saved

1.3 million kilo liter of diesel fuel and 4.4 million kilo

liter in 2014, in the next year there will be a decrease

in diesel fuel imports by 5.6 million kilo liter

(Kementerian ESDM, 2013). Biodiesel, is a fuel that

is potentially used as a substitute for petroleum fuel.

This is because of being from renewable, non toxic

and biodegradable like vegetable oil . (Ji. et al, 2006;

Deng et al, 2010). In addition, biodiesel / biofuel is

also environmentally friendly fuels, it does not

contain sulfur to reduce the environmental damage

caused by acid rain (Azis, 2010). Biodiesel can be

produced by the transesterification process or

alcoholysis of vegetable oil or animal fats. The cost

of biodiesel production is mainly influenced by the

system used and the cost of raw materials. Currently,

waste oil or fats are used in biodiesel production

because 70 to 90 % of production costs are due to raw

materials. Alternatively, overall production costs can

also be reduced by optimizing the efficiency and the

catalyst used (Talha and Sulaiman, 2016). The aim

this process to reduce the viscosity of vegetable oil

or animal fats can be applied in regular combustion

engine (Prabaningrum et al, 2014). The alcoholysis

process is the reaction between short-chain alcohol

with triglyceride from vegetable oil to produce fatty

acid alkyl ester (biodiesel) and glycerol as by-product

(Hoque and Gee, 2013). The presence of catalysts in

this process is very necessary to enhance the reaction

rate and ultimately the biodiesel yield. The

alcoholysis reaction is reversible and excess alcohol

shifts are equilibrium to the product side (Rahmah et

al, 2013). Many different type of alcohol can be used

in this reaction, including methanol, ethanol,

propanol and butanol. The general equation of

412

Irwan, M., Ramli, ., Nadir, M., Marlinda, . and Adhiksana, A.

Effect of Different Type Catalyst on Biodiesel Production from Jatropha Curcas Oil via Transesterification using Ultrasonic Assisted.

DOI: 10.5220/0010946700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 412-415

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

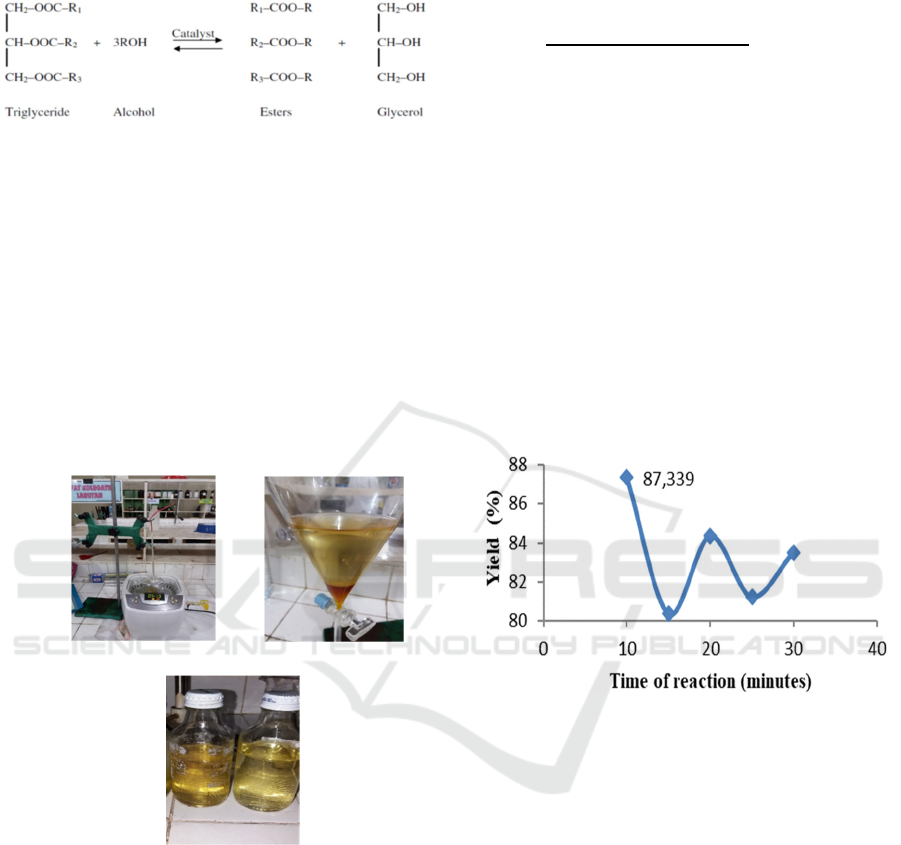

transesterification reaction can be shown in Figure 1

below :

Figure 1: General equation of transesterification reaction.

Figure 1 above shown the comparison of molar

ratio between triglyceride and alcohol to produce of

ester (biodiesel) and also glycerol as by product.

2 METHOD

The ultrasonic apparatus as source of energy was

performed to production of biodiesel in a batch

reactor (Rahmah et al, 2013; Rahmaniah et al, 2013;

Suryanto et al, 2015). The design of equipment used

in this work shown in Figure 2a below :

(a) (b)

(c)

Figure 2: (a). Ultrasonic equipment; (b). two phase layer

product; (c). product of biodiesel.

Figure 2a shown the jatropha curcas oil as raw

materials were transesterified using ultrasonic reactor

assisted. In this work, KOH, NaOH and CH

3

ONa was

dissolved each with methanol. Jatropha curcas oil as

feedstocks was taken at following reaction time 10,

15, 20, 25 and 30 minutes. Once the reaction is

complete, the samples is immediately quenched in

water to stop the reaction until two phases are formed.

The next process, sample is washed using distilled

water 3-4 times until the water layer became clear

(figure 2b). The last, is the heating process to remove

a lot of water in the ester as product. Finally, biodiesel

can be stored (figure 2c). To calculate the percentage

of yield can use the following formula:

Yield =

x 100 %

(1)

3 RESULT AND DISCUSSION

The most commonly used alkaline or base catalyzed

transesterification are NaOH, KOH and CH3ONa.

Alkaline catalyzed transesterification is more rapid

than acid catalyzed and is used in the commercial

production of biodiesel. Event at ambient

temperature, the alkaline catalyzed reaction proceeds

faster usually reaching more than 80 % a few minutes

using ultrasonic assisted (Rahmaniah et al, 2013).

This is the yield comparison of the three types of

catalyst used in this work. When using NaOH as

catalyst, the yield can be shown in Figure 3 as

follows:

Figure 3: The yield of biodiesel using the NaOH as catalyst.

Figure 3 shown the high biodiesel yield using

NaOH as catalyst, namely 87.339 % at 1 : 6 molar

ratio of jatropha curcas oil to methanol and 1 %

concentration of NaOH to raw materials. In this

experiment, only three types of catalyst were used

they were sodium hydroxide (NaOH), potassium

hydroxide (KOH), and sodium methoxide (CH

3

ONa).

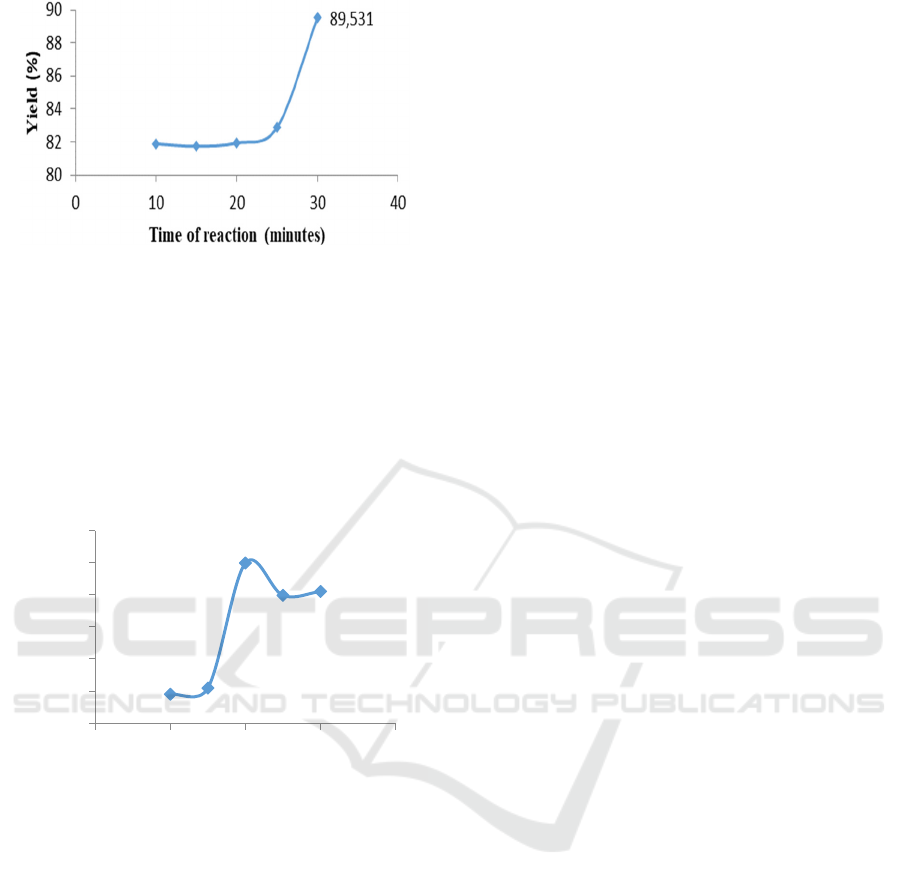

For the biodiesel production using KOH as

catalyst, the yield can be shown in Figure 4 as

follows:

Effect of Different Type Catalyst on Biodiesel Production from Jatropha Curcas Oil via Transesterification using Ultrasonic Assisted

413

Figure 4: The yield of biodiesel using the KOH as catalyst.

Figure 4 shown the high biodiesel yield using

KOH as catalyst, namely 89.531 % at 1 : 6 molar ratio

of jatropha curcas oil to methanol and 1 %

concentration of KOH to raw materials. The results

showed that KOH gave the better yield, compared

with NaOH.

For the biodiesel production using CH

3

ONa as the

third catalyst in this work, the yield can be shown in

Figure 5 as follows:

Figure 5: The yield of biodiesel using the CH

3

ONa as

catalyst.

Figure 5 shown the high biodiesel yield using

CH

3

ONa as catalyst, namely 85.986 % at 1 : 6 molar

ratio of jatropha curcas oil to methanol and 1 %

concentration of CH

3

ONa to raw materials.

There are no significant different between these

three catalyst in term of biodiesel yield. There are also

no clearly reason to explain why KOH is better than

other catalyst. But, there are many researchers found

that types of catalyst performance are strongly

dependent on raw materials used. Besides, catalysts

performances were also affected by the reaction

conditions.

4 CONCLUSIONS

From the results of this study, it was found that of the

three types of catalyst used, KOH produced the

highest yield of 89.53 %, while the use of ultrasonic

assisted in the transesterification reaction give the

impact of reaction time reduction compared of

conventional process which can take between 2-4

hours. Results of the physical biodiesel properties

namely of the 5.71 cSt viscosity, density of 860.17 %

and moisture content of 0.0136 % has met SNI 7182-

2015 standard.

ACKNOWLEDGEMENTS

This study was financially supported by the Centre of

Research and Community Service, Politeknik Negeri

Samarinda with the scheme grand Hibah Penelitian

Doktor 2021.

REFERENCES

Azis, (2010). Uji Performance Mesin Diesel Menggunakan

Biodiesel Dari Minyak Goreng Bekas.

Deng X, Fang Z, Liu Yh, (2010). “Ultrasonic

transesterification of jatropha curcas L. oil to biodiesel

by a two-step process”, Journal of Energy Conversion

and Management., Vol.51, pp 2802-2807.

Hoque, M.E, Gee, L.P, (2013). “Biodiesel from Plant

Resources-Sustainable Solution to Ever Increasing

Fuel Oil Demands”, Journal of Sustainable Bioenergy

System., Vol.5, pp.163- 170.

Ji J, Wang J, Li Y, Yu Y, Xu Z, (2006). “Preparation of

biodiesel with the help of ultrasonic and hydodynamic

cavitation”, Journal of Ultrasonic., Vol.44, pp. 411-414.

Kementerian ESDM. (2013). Program Percepatan

Pemanfaatan Bahan Bakar Nabati (BBN).

Mohandass, R, Ashok, K, Selvaraju, A. Rajagopan, S

(2016). “Homogeneous Catalysts used in Biodiesel

Production: A Review”, International Journal of

Engineering Research & Technology (IJERT)., Vol.5,

Issue.5, pp. 264-268.

Prabaningrum, N, Ismail, L.B, Subbarao, (2014). “In-Situ

Methanolysis of Jatropha curcas Seeds in Soxhlet

Extractor”, Journal of Advanced Materials Rexearch.,

Vol.917, pp. 72-79.

Rahmah, N, Sulaiman, H, Hazwani, N. (2013). “Process to

Produce Biodiesel Using JatrophaCurcas Oil (JCO)”,

International Journal of Materials Science and

Engineering., vol.1, no.2, pp. 100-103.

Rahmaniah, O, Ju, Y.H, Vali, S.R, Tjondronegoro, I,

Musfil, A.S. (2015). “A Study on Acid-Catalyzed

Transesterification of Crude Rice Bran Oil for

Biodiesel Production”,

85,986

81

82

83

84

85

86

87

0 10203040

Yield (%)

Time of reaction (minutes)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

414

Suryanto, A, Suprapto, Mahfud. (2015). “The production of

Biofuels from Coconut Oil Using Microwave”, Journal

of Modern Applied Science., Vol.9, no.7, pp. 93-98.

Talha, N.S, Sulaiman, S. (2016). “Overview of Catalysts in

Biodiesel Production”, ARPN Journal of Engineering

and Applied Science., Vol.11, No.1, pp. 439-448.

Effect of Different Type Catalyst on Biodiesel Production from Jatropha Curcas Oil via Transesterification using Ultrasonic Assisted

415