Mini Pile Foundation Construction Design on Soft Soil Due to Box

Traffic Loads based on Standard Penetration Test

Liliwarti, Dwina Archenita and Sandra Faurina

Civil Engineering Department, Politeknik Negeri Padang, Limau Manis, Padang, Indonesia

Keywords: Box Traffic Loads, Mini Pile Foundation, Foundation Construction Design.

Abstract: Box traffic is an underpass structure in the form of a tunnel under the ground that functions as a transverse

road under other roads that serves as a liaison between separate areas due to the construction of toll roads.

The construction of Padang – Sicincin Toll Road has separated several surrounding areas so that public access

is limited. To solving this problem, a traffic box is built at STA 2+175. Based on the Standard Penetration

Test (SPT) data, the location has deep soft soil, so that it cannot support the loads. This paper discusses the

used of mini pile foundations to increase the bearing capacity of the soil. The foundation was used with a size

of 0.25 m x 0.25 m, the distance between the piles (s) 1m, with variations in the penetration depth of 10m,

12m, and 14m. Bearing capacity analysis was carried out based on SPT data. The analysis results show that

the sub-grade settlement without using a mini pile foundation is 0.34 m – 0.35 m BH-01 and 0.59 m – 0.62 m

on BH-02, where the settlement exceeds the allowable settlement limit. While, by using a mini pile foundation

with a depth of 10 m, the settlement is 0.02 – 0.05 cm. This settlement is smaller than the allowable settlement

for pile foundation. The bearing capacity of the mini pile group foundation increases with increasing pile

penetration depth, but it does not apply to single piles.

1 INTRODUCTION

Pile foundation is one of the important aspects of road

construction. It functions as a successor to the load

that works on it and is channeled to the subgrade. Pile

foundations are generally divided into two sizes,

namely large size (maxi pile) and small size (mini

pile)(Yu & Wang, 2019). The foundation must

withstand the loads that work on it (Yu & Wang,

2019), (Purwanto, 2019). One of these loads can be a

box traffic load.

Box traffic is an underpass structure in a tunnel

under the ground that functioned as a transverse road

under the road (Desai & Desai, 2017). In its role as an

underpass, this traffic box carries both gravity and

lateral loads. The gravity load includes dead loads and

live loads. In comparison, the lateral load includes

earth pressure and earthquake loads (Wrana, 2015),

(de Sanctis et al., 2021). Carry out the working load

needs the subgrade must have allowable bearing

capacity to withstand the load.

In the construction of the Padang-Sicincin Toll

Road, there is a location with soft soil that is quite

deep based on the Standard Penetration Test results

(SPT). This condition leads to the soil not being able

to withstand the load, such as box traffic. Therefore,

efforts are needed to increase the bearing capacity of

the soil.

This paper discusses a mini pile foundation design

due to box traffic load to solve the problem. This

foundation design will strengthen the subgrade of the

structure. Thus, it has sufficient permit-bearing

capacity to withstand the load.

This paper is organized as follows: In Section 2,

the proposed construction design is explained.

Section 3 contains the results and discussion of the

methods that have been implemented. Lastly, section

4 concludes the paper.

2 METHODS

2.1 Data Collection

The mini pile foundation construction design is built

from secondary data, i.e., the soil data from field and

laboratory tests, box traffic structure specification,

and mini pile specification data.

358

Liliwarti, ., Archenita, D. and Faurina, S.

Mini Pile Foundation Construction Design on Soft Soil Due to Box Traffic Loads based on Standard Penetration Test.

DOI: 10.5220/0010945800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 358-364

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2.1.1 Soil Data

Field testing: boring and SPT tests of two

drilling points (BH-01 and BH-02) with a depth

of 50 m

Laboratory test: from 4 undisturbed sample

(UDS1 to UDS4) which varies in-depth, as

shown in Table 1.

Table 1: Undisturbed Samples for Soil Laboratory Test.

Sam

p

le ID De

p

th

UDS1 5 m and 13

m

UDS2 19 m an

d

29

m

UDS3 39

m

UDS4 49

m

2.1.2 Box Traffic Specification

The traffic box specifications used are shown in Table

2. With concrete quality, the density of concrete and

steel quality is 20 MPa, 24 kN/ m

3

, and 390 MPa.

Table 2: Box Traffic Specification.

Dimension

Len

g

th 32,70

m

Width 970 or 974 m (skew)

Height 6.95

m

Top plate thickness 0.80

m

Wall

p

late thickness 0.85

m

Bottom

p

late thickness 0.95

m

Materials

Concrete qualit

y

20 MPa

Density of concrete 24 kN/ m

3

Steel

q

ualit

y

390 MPa

2.1.3 Mini Pile Specification

The mini pile is 0.25x 0.25 m in size. It is calculated

with the condition of the head of the pile being

pinched. It is because the thickness of the bottom

plate of the box is directly used as a pile cap.

2.2 Box Traffic Loads

The box traffic load for the foundation construction

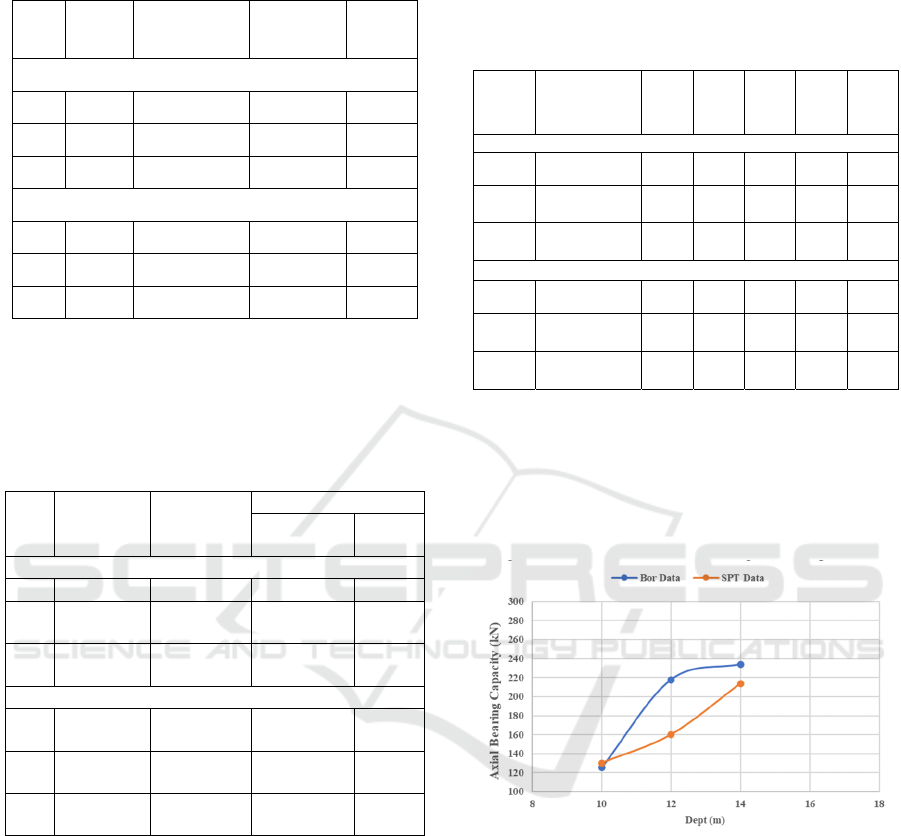

design is shown in Table 3. While R

A

is reaction at

point A, R

D

is reaction at point B, and Q is load.

Table 3: Box Traffic Load.

R

A

R

D

Q

(kN)

Vertical

(kN)

Horizontal

(kN)

Vertical

(kN)

Horizontal

(kN)

6927.51 -3.02 8109.50 0

1503

7.01

Figure 1: Box Traffic.

Figure 2: The points reviewed on the box traffic.

2.3 Mini Pile Foundation Construction

Design

The mini pile foundation is designed with a direct

foundation plate like a pile cap from the pile head

(foundation with a box traffic monolith structure) (Yu

& Wang, 2019). Thus, the head of the foundation is

in a clamped condition. It means that it can withstand

the moment or overturn in the structure or the moment

on the structure=0. Manual calculations carry out this

foundation design for the axial bearing capacity of the

pile foundation and the bearing capacity of the group

pile foundation. At the same time, the lateral bearing

capacity of pile foundations and pile foundation

settlement is modeled using structure analysis

software.

The calculations of three factors can determine the

number of piles, i.e. (1) the distance between the piles

(s) following the box traffic structure; (2) the

implementation of pile driving in the field; (3) the

efficiency of the pile group (de Sanctis et al.,

2021),(Feicheng & Jianjing, 2017). Based on these

factors, the distance between the piles is 1 m with the

pile group efficiency is 0.75 for cohesive soils based

on the group pile efficiency factor in cohesive soils

While for non-cohesive soils is 1. Thus, the number

of piles (n) that will be used is 279 piles and the cross-

section as shown in Fig.3.

Mini Pile Foundation Construction Design on Soft Soil Due to Box Traffic Loads based on Standard Penetration Test

359

Figure 3: Mini pile foundation design based on the distance

between the piles (s) is 1.

2.3.1 Loads on Foundation

Total loads on pile group (P

total

), is calculated

by the Eq 1.

𝑃

𝑅

𝑅

While,

R

A

= Reaction at point A (kN)

R

D

= Reaction at point D (kN)

The loads on each pile (P

single

), is calculated

from the P

total

divided by the number of pile

(n), as shown in Eq.2.

𝑃

These calculations give P

total

= 15037.01 kN, and

P

single

= 53.89kN.

2.3.2 Axial Bearing Capacity of Pile

Foundation

The axial bearing capacity of the pile foundation is

calculated based on the strength of the material and

soil conditions around the foundation (Liliwarti,

2019). The calculations is done at a depth of 10 m, 12

m, and 14 m. This aims to determine whether the pile

is able to withstand the loads both internally and

externally

Axial bearing capacity of pile foundation based on

SPT

The axial bearing capacity of the pile foundation

from the SPT data is calculated using an equation

based on the Meyerhof 1956 method (Hardiyatmo,

2011).

a. End Bearing Pile

- End Bearing Pile in cohesive soil

𝑄

𝑝

9 𝑥 𝑐

𝑢

𝑥 𝐴

𝑝

(3)

- End Bearing Pile in cohesive soil

Q

40 x N

x

x A

400 x A

x N

(4)

b. Friction pile

- cohesive soil

Q

α x c

x p x L

(5)

- Non cohesive soil

Q

s

2 x N

SPT

x p x L

i

(6)

- Total Bearing Capacity

Q

u

QpQs (7)

Where

Q

p

: friction pile (kN)

𝑁

𝑆𝑃𝑇

: N- SPT

c

u

: undrained cohesion (kN/m

2

)

L : dept of pile (m)

d : diameter of pile (m)

A

p

: area of pile (m

2

)

Q

s

: tahanan gesek tiang (kN)

α : coeficient adhesi soil and pile

p : perimeter of pile (m)

L

i

: dept of soil layer (m)

2.3.3 Lateral Bearing Capacity of Pile

Foundation

Pile foundation in the box traffic is designed with the

condition of the pile head pinched (Hardiyatmo,

2011). Thus, it can withstand the moment that will

occur (moment = 0). Lateral load on the foundation

based on structural mechanics is analyzed by using

analyzing software. It gives the result of 3.02 kN (H

= 3.02 kN). Furthermore, the lateral bearing capacity

of the pile foundation against the load is calculated

based on variations in the depth of pile penetration,

i.e., 10 m, 12 m, and 14 m.

The type of soil at the tip of the pile in each

variation of penetration depth in BH-01 and BH-02

includes silt and/or sandy soil. Therefore, based on

Broms's (1964) method in calculating the lateral

bearing capacity of the pile, the formula used is a

formula that is suitable for the type of soil at the end

of the pile, i.e., silt and or sand. The lateral bearing

capacity of the pile is calculated based on the pile

deflection and the ultimate lateral load-bearing

capacity that the pile can withstand (Hardiyatmo,

2011).

The ultimate lateral load of the pile is calculated

based on Broms method (1964) (Hardiyatmo, 2011).

Calculation of the pile type obtained from the previous

calculation pile vertical deflection and the type of soil

at the tip of the pile in BH-01 and BH-02. The

calculations result are shown in Table 4.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

360

Table 4: The ultimate lateral load-bearing capacity of the

pile on BH-01 and BH-02.

No. Depth Soil type

My

(kN-m)

Hu

(kN)

BH-01

1 10 m Silt 25.34 22.52

2 12 m Sandy silt -173.39 -127.26

3 14 m Sandy silt -250.17 -158.84

BH-02

1 10 m Silt sand 1492.05 799.32

2 12 m Sandy silt -278.62 -201.54

3 14 m Sandy silt -311.37 -196.14

Hardiyatmo (2011),(Hardiyatmo, 2011) states

that the maximum deflection for buildings, bridges,

and similar structures is 6 mm to 18 mm. Vertical pile

deflection from the analysis is shown in Table 5.

Table 5: Vertical pile deflection on BH-01 and BH-02.

No.

Penetrati

on depth

Soil

types

yo (m)

Cohesive

Gran

ular

BH-01

1 10 m Silt 0.00169 -

2 12 m

Sandy

silt

0.00143 -

3 14 m

Sandy

silt

0.00125 -

BH-02

1 10 m

Silt

san

d

- 8E-05

2 12 m

Sandy

silt

0.00111 -

3 14 m

Sandy

silt

0.00101 -

2.3.4 Pile Settlement

The total settlement that occurs in the pile foundation

is calculated based on the elasticity of the pile

material itself and the axial bearing capacity of the

pile (Wang et al., 2019), (Hardiyatmo, 2011). The

axial bearing capacity of the pile under review is the

carrying capacity based on SPT data on BH-01 and

BH-02. So that the pile settlement will be calculated

based on these two indicators, in addition, pile

settlement will also be calculated for each variation

of pile penetration depth on BH-01 and BH-02. The

settlement on the pile was calculated based on the

Vesic method (1977) according to the magnitude of

the axial bearing capacity of the pile based on SPT

data. The calculations result are shown in Table 6.

Table 6. The Total Pile Group Settlement on BH-01 and

BH-02.

Dept

h

Soil type

S

1

(cm

)

S

2

(cm

)

S

3

(cm

)

s

(cm

)

S

g(e)

(cm

)

BH-01

10 m

Silt 0.01 0.00 0.00 0.01 0.04

12 m

Sandy

sil

t

0.01 0.00 0.00 0.01 0.04

14 m

Sandy

sil

t

0.01 0.00 0.00 0.01 0.05

BH-02

10 m

Silt sand 0.01 0.00 0.00 0.01 0.05

12 m

Sandy

sil

t

0.01 0.00 0.00 0.01 0.05

14 m

Sandy

sil

t

0.01 0.00 0.00 0.01 0.05

3 RESULT AND DISCUSSION

Based on the previous calculation, the result of the

0.25 x 0.25 m mini pile foundation construction

design is obtained, as shown in Fig. 2 to Fig. 9.

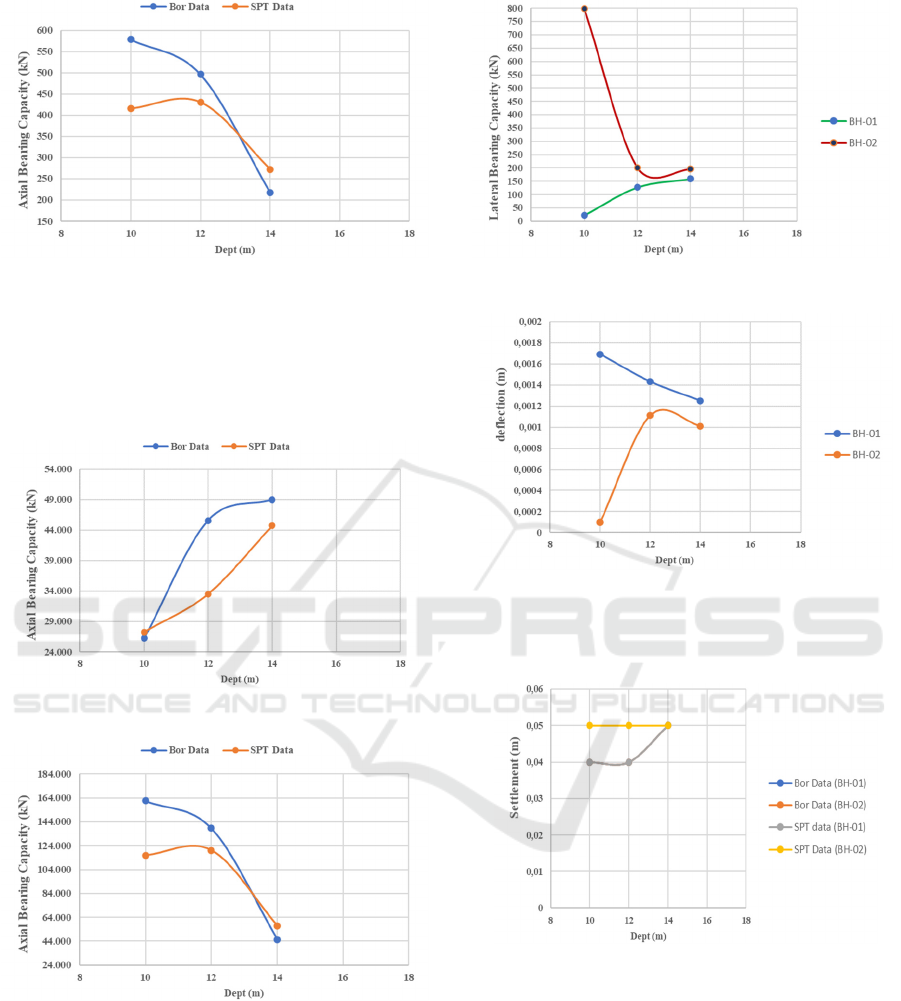

Figure 4: Axial bearing capacity single pile on BH-01.

Bearing capacity on BH-01 increases with the

dept of the pile, showing the deeper the pile driving,

the greater the bearing capacity of the soil.

Mini Pile Foundation Construction Design on Soft Soil Due to Box Traffic Loads based on Standard Penetration Test

361

Figure 5: Axial bearing capacity single pile on BH-02.

Bearing capacity on BH-02 decreases with the

dept of the pile, showing the deeper the pile driving

the lower bearing capacity of the soil. This is because

of the condition of the soil layer at a depth of 12 and

14 m in soft soil.

Figure 6: Bearing capacity of the pile group on BH-01.

Figure 7: Bearing capacity of the pile group on BH-02.

Bearing capacity for single piles and group piles

shows the same behavior in BH01 and BH 02.

Figure 8: Lateral load capacity on BH-01 and BH-02.

Figure 9: Maximum pile deflection on BH-01 and BH-02.

At BH01, the pile deflection decreases with

increasing depth of the pile, but otherwise for BH 02.

Figure 10: Pile settlement on BH-01 & BH-02.

Pile settlement BH 01 and BH02 showed the same

results in analysis with bor data. If analyzed with SPT

data, there was an increase in the value of pile

settlement, but still below the allowable settlement.

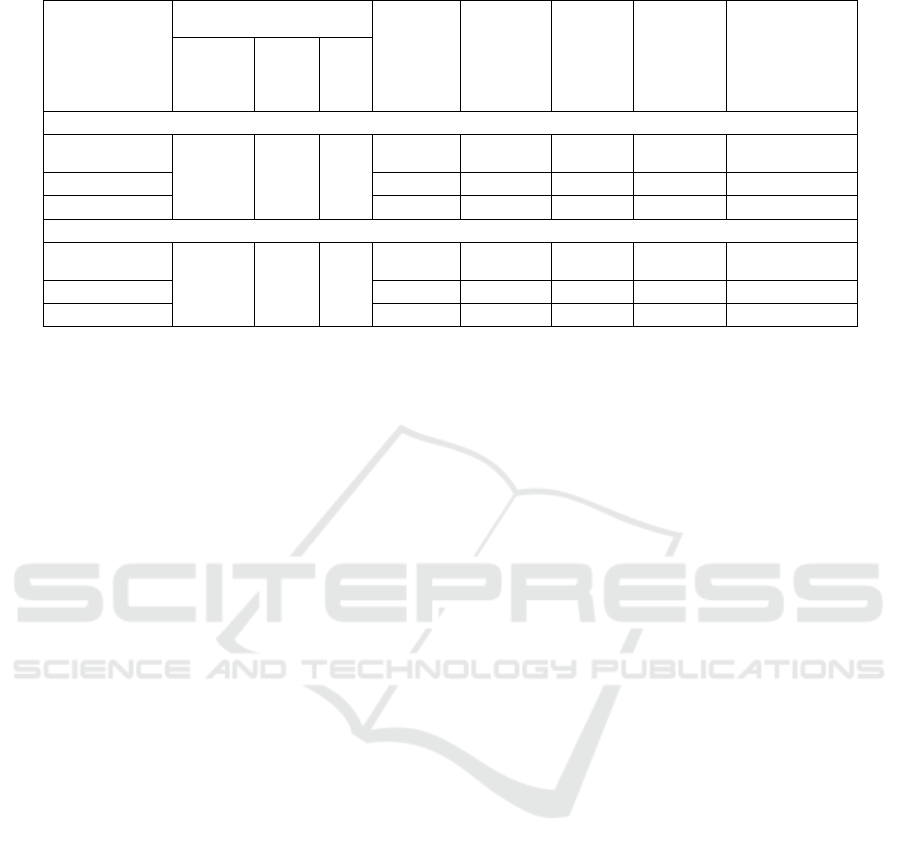

Based on the design calculations that have been

carried out, the mini pile foundation is planned with a

pile penetration depth (L) of 10 m, the distance

between piles (s) of 1 m, and the number of pile

foundation points (n) as many as 279 piles. It is

obtained based on the calculation output of the

permitted axial bearing capacity, group bearing

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

362

Table 7: The final result design of the mini pile foundation varies in-depth on BH-01 and BH-02.

Loads Acting on the

Foundation

Pile Axial

allowable

Bearing

Capacity

(Q

all

)

(kN)

Pile

Group

allowable

Bearing

Capacity

(Q

ag

) (kN)

Ultimate

Lateral

Load

(Hu)

(kN)

Pile

Deflection

(yo)

(m)

Settlement of

Pile

(S

g(e)

) (cm)

P

total

(kN)

P

tunggal

(kN)

H

(kN)

BH-01

Depth of Pile

10 m

15037.01 53.89 3.02

130.27 27258.6

22.52 0.002 0.04

Safety Factor

2.5 2.5

2.5 0.025

6.5

Safe Safe Safe Safe Safe

BH-02

Depth of Pile

10 m

15037.01 53.89 3.02

415.64 115963.6

799.32 0.0001

0.05

Safety Factor

2.5 2.5

2.5 0.025

4.0

Safe Safe Safe Safe Safe

capacity, lateral bearing capacity, and pile settlement

at a depth of 10 m based on SPT data that can

withstand the load that will work. The final result in

a mini pile foundation design for the traffic box is

shown in Table 7.

4 CONCLUSION

Based on the calculations that have been carried out,

the mini pile foundation is planned with a pile

penetration depth (L) of 10 m, a distance between

piles (s) of 1 m, and the number of pile foundation

points (n) as many as 279 piles. It is obtained based

on the calculation results of the permit axial bearing

capacity, group bearing capacity, lateral bearing

capacity, and pile settlement at a depth of 10 m based

on SPT data. It has been able to withstand the load,

and the load on the single pile (P

single

) and the pile

group (P

total

) is 53.89 kN and 15037.01 kN. The

magnitude of the decrease in the pile group that

occurs is 0.02 – 0.05 cm. It shows that the settlement

is safe for the structure because it does not exceed the

maximum pile settlement limit, which is 6.5 cm for

piles in clay and 4.0 cm for piles in the sand (SNI

8460:2017).

In further research, the calculation of the load on

the subgrade originating from the box traffic structure

load is expected to be closer to the original conditions

in the field so that the subgrade settlement due to the

working structure load can be calculated more

accurately. complete again so that the calculation of

settlement and foundation design can run smoothly

and have more accurate results.

ACKNOWLEDGMENTS

This research was fully funded by DIPA of

Politeknik Negeri Padang.

REFERENCES

de Sanctis, L., Di Laora, R., Maiorano, R. M. S., Favata, G.,

& Aversa, S. (2021). Failure envelopes of pile groups

under combined axial-moment loading: Theoretical

background and experimental evidence. Soils and

Foundations, xxxx.

https://doi.org/10.1016/j.sandf.2021.08.002

Desai, S., & Desai, A. (2017). International Journal of

Technical Innovation in Modern Engineering &

Science ( IJTIMES ). 3(5), 43–48.

Feicheng, L., & Jianjing, Z. (2017). A Simplified Method

for Pile- Supported Embankment Reinforced With

Geosynthetic over Soft Soil and the Influence of Design

Parameters. Electrical Journal of Geotechnical

Engineering, 22(07), 2545–2578.

Hardiyatmo, H. C. (2011). Analisa dan Perancangan

Fondasi II. Gadjah Mada University Press.

Liliwarti, L.-. (2019). Peningkatan Nilai CBR Tanah Dasar

(Sub Grade) dengan Penambahan Kapur dan Abu

Sekam Padi. Jurnal Ilmiah Poli Rekayasa, 14(2), 24.

https://doi.org/10.30630/jipr.14.2.124

Purwanto, E. (2019). Technology of mini piles for high

embankment stability on soft soils to prevent a

settlement. International Journal of Advanced

Research in Engineering and Technology, 10(6), 224–

233. https://doi.org/10.34218/IJARET.10.6.2019.026

Wang, Z., Hu, Z., Lai, J., Wang, H., Wang, K., & Zan, W.

(2019). Settlement Characteristics of Jacked Box

Tunneling underneath a Highway Embankment.

Journal of Performance of Constructed Facilities,

Mini Pile Foundation Construction Design on Soft Soil Due to Box Traffic Loads based on Standard Penetration Test

363

33(2), 04019005. https://doi.org/10.1061/

(ASCE)cf.1943-5509.0001269

Wrana, B. (2015). Pile Load Capacity – Calculation

Methods. Studia Geotechnica et Mechanica, 37(4), 83–

93. https://doi.org/10.1515/sgem-2015-0048

Yu, X., & Wang, X. (2019). Research on the Design of

Miniature Pile Foundation for Transmission Line. E3S

Web of Conferences, 136, 2–5.

https://doi.org/10.1051/e3sconf/201913602022

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

364