The Energy Saving through Live Line Pedestal Insulator Washing

with Snow Shampoo

I Wayan Jondra, I Nengah Sunaya, I Ketut Suryawan, Djoko Suhantono, I Made Sajayasa

and I Nyoman Sukarma

Electrical Departmen, Politeknik Negeri Bali, Bukit Jimbaran, Badung, Indonesia

madesajayasa@pnb.ac.id, sukarma@pnb.ac.id.

Keywords: Energy, Saving, Insulator, Washing, Un-touch.

Abstract: The electricity is the important energy to human activity affect to economic development. The electricity

efficiency affect to the efficiency of a country's development and climate change. Various efforts have be

done to reduce the loss energy. One of which is washing the pedestal insulator from pollutants sticks on the

surface of the insulator. This descriptive quantitative research proves that the un-touch insulator washing

treatment has succeeded to increasing the performance of the pedestal insulator. So that the insulation

resistance can be meet to the standard. The media used to wash the pedestal insulator in this study was a

solution of snow shampoo and clean distilled water. The implementation this method was increases the

performance of the pedestal insulator. The insulation resistance increases from 73.08 Mega-Ohms to 166.49

Mega-Ohms and energy saving up to 66.60%. This washing method is safe and easy to do in live line and

increase energy saving.

1 INTRODUCTION

1.1 Problems Background

The electricity have positive affect to economic

development of the country (Yılmaz and

Hasan.2014). The efficiency of electrical energy

consumption will support the efficiency of a country's

development and to decrease the climate change.

There are two basic ways to significantly reduce

harmful emissions: to radically increase the share of

renewable energy resources and to use the electrical

power more efficiently (Cepoi et al. 2017).

So many effort to increasing the efficiency of

processes utilizing these resources (Rosen. 1996).

Maintenance is an important action in the operation

of using electrical energy. One of the maintenance

actions to the pedestal insulator is to keep it clean

from pollutants. The insulator with full pollution had

a lower value of flashover voltage gradient compared

to other contamination profiles (Salem et al. 2021). A

leakage current is then established through the

superficial layer causing subsequent drying of the

pollution layer and electrical arcs may arise

(Alphonse and Haroun.2017). The low flashover

voltage gradient in the insulator will increase the flow

of electric current from the conductor of overhead

line to the earth which results in loss electrical energy

to the earth.

Overhead lines systems are exposed to many

problem including surface pollution on insulators

which is a factor of energy loss on bad weather

(Alphonse and Haroun.2017). Tropical climate

conditions affect to the severity of the surface

pollution of outdoor insulators and can reduce the

level of reliability of the electric power system

(Carlos.2020). To increase the efficiency of

distribution of electrical energy, it can be done with

regular maintenance of the insulator so as to avoid

pollutant (Abouelsaad. 2013).

The higher the value of equivalent salt deposit

density (SDD) to stick of the surface of the insulator

affect to the conductivity of the pollution layer will be

increase (Salem et al. 2021) (Carlos.2020). High

humidity will also affect the low performance of

polluting insulators. The high humidity of the air will

worsen the performance of polluting insulators

(Ahmet and Suleiman. 1990). The accumulation of

equivalent salt deposit density to stick on the surface

of insulators in the presence of wind, ambient

Jondra, I., Sunaya, I., Suryawan, I., Suhantono, D., Sajayasa, I. and Sukarma, I.

The Energy Saving through Live Line Pedestal Insulator Washing with Snow Shampoo.

DOI: 10.5220/0010943500003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 259-267

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

259

temperature, humidity, fog and moisture, conducting

layers of pollutant was performed (Majid et al. 2015).

Many studies have stated that pollutants in the

form of salt deposit density (SDD) result in low

insulator performance as evidenced by the low partial

discharge voltage and high leakage current, but few

have written about the solution to this problem. To

improve the performance of the insulator in the

seafront area, it can be done by giving a layer of

silicone rubber (Dini et al, 2017). Room Temperature

Vulcanisation (RTV) coating application increase the

performance of insulator under salty or polluted

conditions (Farah et al, 2017). This process is carried

out by coating the surface of the insulator in an offline

condition, this process will result in unsold electrical

energy during the silicone rubber coating process.

In this paper, presents the performance test to the

insulator under conditions polluted with NaCl, under

washing process, and dry condition, insulator washed

by using snow shampoo and distilled water. This

polluting insulator washing process is carried out

during the live line.

1.2 Problem

How is the performance of the pedestal insulator in a

polluted state, the phenomena that occur in the

touchless washing process and live line condition,

and the performance of the pedestal insulator after the

washing process is complete and completely dry?

2 RESEARCH METHOD

2.1 Research Approach and Concept

This research was designed as a quantitative approach

study to find insulator performance was washing from

pollutant in live line medium-voltage over head. The

washing tool assembled and simulation of washing

pollutant insulators were carried out at the Bali State

Polytechnic workshop.

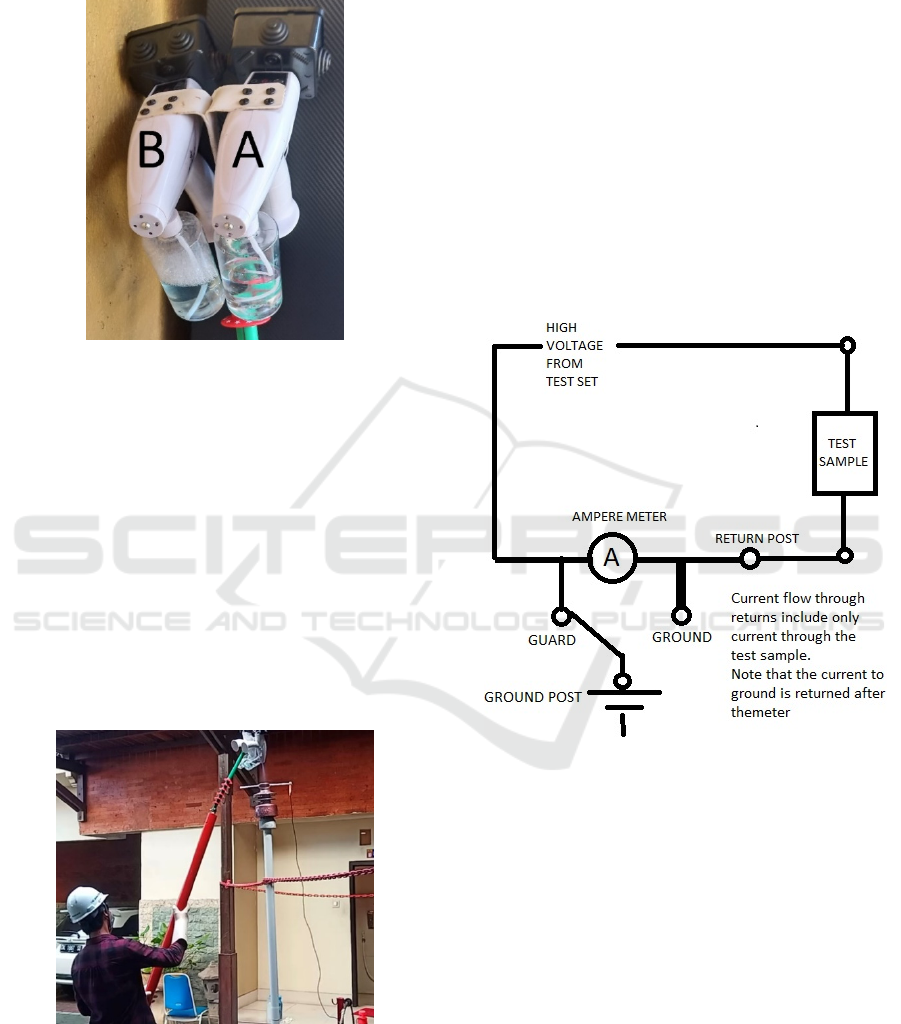

The washing tool/washing gun which is designed

to be operated on online/ live line electric distribution,

consists of two water guns, each connected to a water

bottle, which is operated using a remote. This online

insulator washing tool is an innovation by the Bali

State Polytechnic Research Team in Department of

Electrical Engineering.

The online condition test is done at the Executor

of Adjuster Unit (UP2D) of The Indonesian State

Electrical Company (PLN) Bali Distribution. The

data from the test results consist of: (a) sample

number, (b) voltage, (c) leakage current, (d) condition

and process of polluted insulator (sample) on going

washing process, the data from this test is processed

mathematically and statistically, which is presented in

the form of tables, figures and graphs. Analyst results

will be confirmed with the standards, and the progress

of improving the performance of washed insulators.

2.2 Total Sample

This research was conducted by six samples “polluted

pedestal insulator on going cleaning progress by

washing gun” that was taken from new insulator with

dummy pollution. The dummy pollution was done by

spraying salt dissolved in distilled water.

2.3 Variable Operational Definition

The focus of this study on observing the magnitude of

the leakage current and voltage test on insulator

washing. The test voltage is the amount of electrical

potential in kilo volt applied to the sample through the

medium voltage tester. Leakage current is the amount

of current flowing in the volume and at the surface of

the sample, due to a given test voltage and washing

process.

2.4 Tested

There are three step tests in this research. The first one

is the testing with the initial condition of the insulator

where the insulator is in polluted conditions. The

second one is the testing during washing. The third

one is the testing in dry condition.

Initial testing is carried out when the insulator is

exposed to artificial pollutants, the artificial pollutant

is prepared from a solution of NaCl with distilled

water. This solution is sprayed onto the surface of the

pedestal insulator. After the pollutants are dry and

evenly distributed on the surface of the insulator, this

test is carried out. The test is carried out by installing

an all-aluminum conductor electrode on top of the

insulator, this electrode is connected to the phase

terminal of the high-voltage test instrument, while the

insulator holder is connected to the grounding

terminal of the high-voltage test instrument. The

voltage of the AC high-voltage test equipment is

increased step by step from 5, 10, 15, 20, 25 kV. The

leakage current value can be read in the ampere meter

for each step of the test voltage.

The second test was carried out an AC voltage of

11,600 volts to the samples during the washing

process through all aluminum alloy conductor

electrode (IEC 60507, 1991). The washing process is

carried out by washing with shampoo, rinsing with

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

260

distilled water, the process is carried out three times

so that it becomes 6 washing stages, the seventh step

is rinsed again with distilled water. Each step is

observed and recorded the leakage current flowing to

the test object as displayed on ampere meter. The

third step test is carried out by testing after the

washing process is complete and the pedestal

insulator has dried perfectly.

2.5 Data Analysis

Data obtained from the test results are processed

quantitatively through mathematic and static

calculation. Data is processed mathematically and

statistically by finding the data variation on the step

by step washing progress. The data are processed

mathematically to obtain the insulation resistance of

the insulator at the initial of the test, during the

washing process, and finally when the insulator has

dried completely. The output mathematically data is

processed statistically to obtain the average data, data

sequence, which is also displayed graphically.

3 RESULT AND DISCUSSION

The results of this study are exposed in the figure and

characteristic of initial condition of pedestal insulator

tested, figure and characteristic of pedestal insulator

on going washing process, and final figure and

characteristic of dry pedestal insulator. The analysis

of this characteristic exposed graphically.

3.1 Result

There are seven aspects that must be considered in

using a pedestal insulator (Nzenwa and Adebayo,

2013), that are : that cannot conduct electricity,

economical, without compromising their ability, solid

materials, have high mechanical strength, high

resistivity, high mechanical strength, do not change

by working area, electrical polarity, will not leave a

trace.

In this study, observed the fulfilment of three of

the seven aspects of a pedestal insulator. The first one

is materials that cannot conduct electric current more

than standards. The second one is resistivity

(insulation resistance) is not lower than standards at

working temperature, water spray (washing),

humidity, sunlight (drying), electrical polarity

(voltage), Third, if it experiences an electric jump

(flash over) it will not leave a trace (disabled).

Most of the medium-voltage over head

distribution construction is carried out in places

where there are a lot of human activities, so that

pollutants are unavoidable. Salting on the seafront is

one of example for pollutant. Such as in Bali, have a

high chance of salt pollution contaminated and

decrease of pedestal insulator resistance will increase

the leakage current at the same voltage due the

insulator which can cause flashover, it can be

explained by Ohm's law and can be shown as an

equation below (Salman and Muhammad, 2011).

V=IxR

(1

)

R=V/I

(2

)

where:

R = Insulating Resistance (Giga-ohm)

V = Voltage charge due the sample (Kilo Volt)

I = Leakage Current (micro-ampere )

Based on formula (2) it can be described that,

when the pollutants increase which is characterized

by an increase in the value of Equivalent Salt Deposit

Density (ESDD) it can cause problems increasing the

leakage current through the surface of the pedestal

insulator, even with a large ESDD value it can cause

flashover from wire/conductor to ground. One way to

solve this problem is to reduce the ESDD value by

washing the pedestal insulator from pollutants.

There are 3 aspects to be noticed in conducting all

of the tests in this research such as resistivity and the

insulation resistance value, the leakage current and

without leave a trace (done by using the High Voltage

VLF Hi-pot Instruments Type: VLF4022). The

minimum resistance of pedestal insulator for medium

voltage is 100 Mega-ohms (Sanjay et la, 2018). The

maximum leakage current flow from line to ground

and should not over than 1 milliampere (Saba, 2014).

Disturbance of flashover that occurs on the surface of

the pedestal insulator must not leave a trace (Nzenwa

and Adebayo, 2019).

The pollutant in this experiment is an artificial

pollutant with NaCl dissolved in distilled water. NaCl

was chosen because NaCl is the pollutant with the

biggest affect on the poor in insulation quality

(Abouelsaad, 2013). The composition of the solution

used was 550 grams of NaCl was dissolved in 1500ml

distilled water to obtain the value of ESDD = 0.1485

mg/cm2. That is heavy pollution severity class,

because the value of ESDD more than 0.1 mg/cm2

(Salman and Muhammad, 2011).

Before calculating ESDD, it is necessary to first

calculate the surface area of the pedestal insulator

exposed to pollution. The calculation of the surface

area of the insulator is carried out in parts which are

divided into 5 parts as shown in Figure 1 at below.

The Energy Saving through Live Line Pedestal Insulator Washing with Snow Shampoo

261

Figure 1: Pedestal Insulator surface area.

The total surface area of the pedestal insulator

exposed to pollution is 881.56 cm2.

Based on the measurement results, the

conductivity value of 550 grams of NaCl dissolved in

1.5 litters of distilled water, at a temperature of 27

degrees Celsius is 356 µS/m. To determine the

conductivity at temperature of 20 degrees Celsius and

solution salinity can be calculated as below (Salem et

al, 2011).

σ(20

C) = σx(1 − b(t − 20)

(3)

Sa = 5.7 × (σ20)

.

(4)

SDD = Sa xV/A

(5)

where:

σ(20

0

C) = conductivity temperature of 20

0

C

(µS/m)

b = temperature coefficient=0.020166 (µS/m/

0

C)

t = temperature measured (

0

C)

Sa = solution salinity (mg/cm

3

)

SDD = salt deposit density (mg/cm

2

)

V = Volume of Solution (cm

3

)

A = Surface area are pollution (cm

2

)

Based on formula (3) the conductivity of the

solution can be calculated as below.

σ(20

C) = σx(1 − b(t − 20)

= 356X(1 − 0.020166(27 − 20) = 0.0306S/m

Based on formula (4) the solution salinity can be

calculated as below.

Sa = 5.7 × (σ20)

.

Sa = 5.7 × (0.0306)

.

= 0.1571mg/cm

After 5,000 cm3 of solution is used up for 6

samples, each sample will get 833.33 cm3 of solution.

The solution is sprayed from the top of the sample at

an angle of 30 degrees. Spraying is carried out

rotating on all sides of the sample evenly pollutants

are stick to surface. After each spraying, wait for it to

dry and the salts stick on the surface of the sample

with white color. After the pollutant is dry, the new

one of pollutant is added again with the next spray, so

that each sample is sprayed five times.

Figure 2: Dummy pollution spraying process.

By using formula (5) the equivalent salt deposit

density (SDD) will be calculated as shown in the

calculation at below.

SDD = SaxV/A

= 0.1571x833.33/881.56 = 0.1485mg/

Like that calculated at the front, the equivalent

salt deposit density on this paper is 0.1485 mg/cm

2

.

The condition of the insulator can be seen visually a

lot of salt stick on the surface of the pedestal insulator

which is the sample of this study, as shown in Figure

3 at below.

Figure 3: Dry dummy pollution on the surface of pedestal

insulator.

To wash the pollutants sticks to the surface of the

pedestal insulator as shown in Figure 3, an-touch

washing was carried out, using two water guns. The

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

262

water gun (A) contains distilled water, while the

water gun (B) contains snow shampoo dissolved in

distilled water, as shown in figure 4 below.

Figure 4: Water gun washer.

This water gun is modified from the handhold

nano spray gun. Hand hold nano spray gun during this

pandemic is used to sterilize a room by spraying

disinfectant. This tool inspired researchers to use it to

un-touch washing the polluted insulator pedestal. The

work of water gun washer is not explained in this

paper.

The washing to the pedestal insulator in this study

was carried out using two media, namely snow

shampoo and clean distilled water, the washing

process is did on the insulator has a AC voltage 11.6

kV from phase to ground, the operating voltage from

phase to ground only 11.6 KV. This job is done in a

live line condition, as shown in figure 5 below.

Figure 5: Online pedestal insulator washing.

The first test was carried out by testing the

leakage current of the sample in polluted condition.

This test is carried out to determine the amount of

leakage current and insulation resistance of the

sample. This first test was carried out with four

voltage steps of 5, 10, 15, 20 kV, at each voltage step

the leakage current was recorded.

The leakage current is measured using a high

voltage VLF hi-pot instruments that are shown in

Figure 5 it is done at PLN UP2D Bali Laboratory.

High voltage VLF hi-pot instruments are the

equipment of low frequency high voltage test. This

High voltage VLF hi-pot instruments converted the

voltage of 220 Volts 50 Hz into a DC voltage, then

converted back by decreased frequency 50 Hz into 0.2

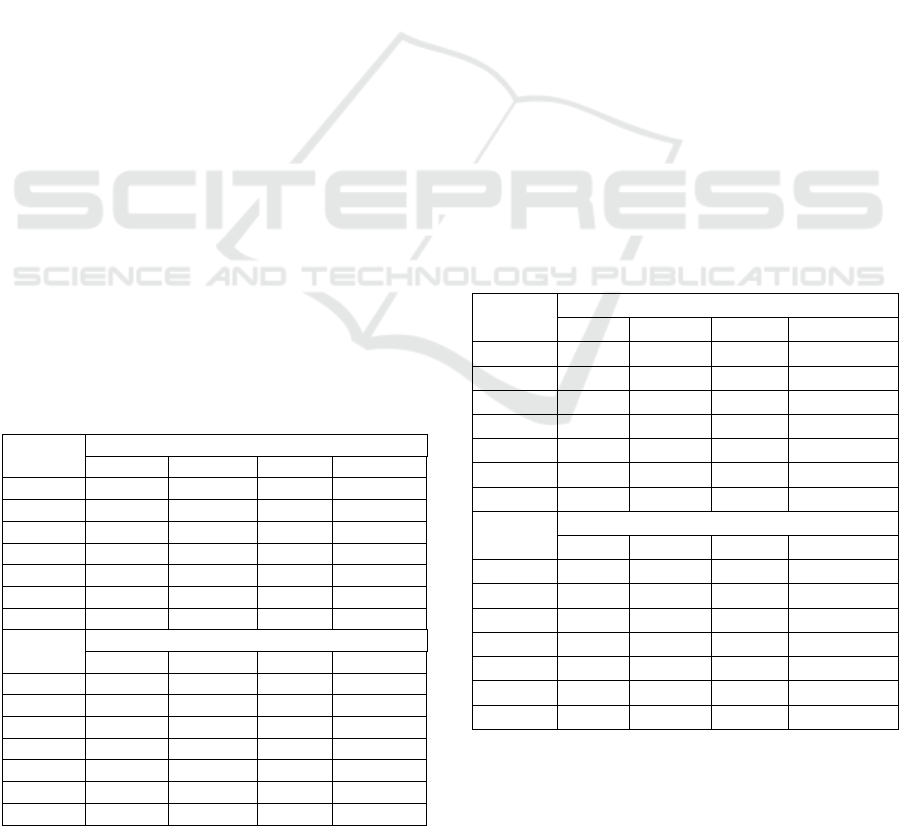

Hz and increased voltage from 220 Volt into AC high

voltage up to 40 kV. High voltage VLF hi-pot

instruments is solidly grounded for safety during the

observation process. Change the return switch (the

red one) to guard position as shown in Figure 6 to

measured the leakage current from ampere meter.

Figure 6: One line test diagram.

Leakage current test was conducted for the

polluted and dry test. After four voltage steps polluted

test is finished. High voltage VLF hi-pot instruments

is turned off for safety, followed by washing process.

The leakage current data on polluted condition

then is analyzed using the ohm formula. The

Insulation resistance of pedestal insulator on polluted

condition is equal to the tested given voltage divided

by the leakage current flow from electrode to the

earth. The calculation of insulation resistance of

pedestal insulator on polluted condition to sample

number one on first step tested is like describe below.

Test result:

Given voltage: 5,000 Volts AC

Leakage current: 0.053 milli amperes

The Energy Saving through Live Line Pedestal Insulator Washing with Snow Shampoo

263

The calculation of insulation resistance of

pedestal insulator on polluted condition by formula

(2) is like describe below.

Riso = V/I

= 5,000/(0.053x10

)

= 94,339.623Ohm

= 94.34Mega − ohms

Based on the results of the tests carried out on the

test samples numbered 2, 3, 4, 5, and 6, the leakage

currents were obtained respectively 0.056; 0.064;

0.05; 0.066; 0.061. with the same calculation method

as above, the insulation resistance of each sample

number 2, 3,4, 5, 6 is obtained sequentially as follows

89.29; 78.13; 100.00; 75.76; 81.97. From the test

results and calculations are summed and then divided

by 6, then the average leakage current and average

insulation resistance are obtained through the

calculations below.

()

=(

+

…

)/6

= (0.053 + 0.056 + 0.064 + 0.05 + 0.066

+ 0.061)/6

= 0.058m. A.

()

=

+

…+

)/6

= (94.34 + 89.29 + 78.13 + 100.00 + 75.76

+ 81.97)/6

= 86.58Mega − Ohms

Conducting the same calculation process, the

insulation resistance for all measured step is as

displayed in the table 1.

Table 1: Pedestal insulator insulation resistance analysis

with high voltage VLF hi-pot instrument on polluted

condition.

SAMPLE

LEAKAGE CURRENT (mA)

5 KV 10 KV 15 KV 20 KV

1 0.053 0.112 0.188 0.269

2 0.056 0.111 0.186 0.271

3 0.064 0.124 0.195 0.282

4 0.050 0.11 0.184 0.258

5 0.066 0.125 0.198 0.285

6 0.061 0.123 0.196 0.279

AVG 0.058 0.118 0.191 0.274

SAMPLE

INSULATION RESISTANCE (M-Ohm)

5 KV 10 KV 15 KV 20 KV

1 94.34 89.29 79.79 74.35

2 89.29 90.09 80.65 73.80

3 78.13 80.65 76.92 70.92

4 100.00 90.91 81.52 77.52

5 75.76 80.00 75.76 70.18

6 81.97 81.30 76.53 71.68

AVG 86.58 85.37 78.53 73.08

In table 1, data has been presented, that the higher

the test voltage, the leakage current also increases, but

on the other hand the insulation resistance decreases.

When the test voltage is the small one is 5 kV, there

is the smallest leakage current in sample number 4

with a value of 0.050 milli amperes, so that the largest

insulation resistance occurs with a value of 100 Mega

Ohms. When the high one test voltage is 20kV there

is the largest leakage current that are 0.285 milli

amperes in sample number 5, so that the lowest

resistance occurs with a value of 70.18 Mega Ohm.

Based on the average value, it can be explained that

the higher the test voltage also the higher the leakage

current and this was followed by the lower insulation

resistance of the test sample in a polluted condition.

The second test is a test carried out during the

pollutant washing process, which consists of three

stages, spraying shampoo, rinsing with clean distilled

water and drying, this washing process is repeated

three times, dried, then rinsed again with clean

distilled water, and dried by relying on the flow of the

surrounding wind and the heat of the sun. This

washing process is carried out when the sample is

given a test voltage of 20 kV, and in each process the

leakage current is observed and recorded. Finally at

completely washing and dry, the performance of

insulator as shown in table 2.

Table 2: Pedestal insulator insulation resistance analysis

with high voltage vlf hi-pot instrument on completely clean

and dry.

SAMPLE

LEAKAGE CURRENT (mA)

5 KV 10 KV 15 KV 20 KV

1

0.168 0.253 0.213 0.107

2

0.288 0.271 0.239 0.143

3

0.288 0.251 0.219 0.144

4 0.282 0.251 0.221 0.112

5 0.294 0.25 0.218 0.108

6 0.299 0.25 0.21 0.118

AVG 0.270 0.254 0.220 0.122

SAMPLE

INSULATION RESISTANCE (M-Ohm)

5 KV 10 KV 15 KV 20 KV

1

119.05 79.05 93.90 186.92

2

69.44 73.80 83.68 139.86

3

69.44 79.68 91.32 138.89

4

70.92 79.68 90.50 178.57

5

68.03 80.00 91.74 185.19

6

66.89 80.00 95.24 169.49

AVG

74.12 78.70 91.06 166.49

The average value of each testing process, the

average leakage current value is taken at the end of

the measurement. Base on leakage current multiple

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

264

by Voltage 11.6 kV, multiple by time operation, the

loss energy can be calculated as describe at below.

WL = IL x Vxt

(6)

where:

W

L

= Loss Energy (KWH)

I

L

= Leakage Current (Ampere)

V = Voltage (kV)

t = times (hour)

The leakage current on the polluted is 0.274 milli

amperes at a operated voltage of 11.6 kV, in one year

consisting of 365 days, the energy loss can be

calculated as below, while after the washing and

drying process is complete, the leakage current value

data is 0.092 milli amperes at a voltage of 20kV. The

energy loss will be reduced according to the

calculation by formula (6) as describe atbelow.

=

= 0.27411.624365

= 27,843WH = 27.84KWH/Year/Insulator

W

=I

xVxt = 0.092x11.6x24x365

= 9,349WH = 9.35KWH/Year/Insulator

W

=W

−W

= 27.48 − 9.35 = 18.13KWH/Year/Insulator

Based on the calculation results above, it is found

that the energy loss if the insulator pedestal

experiences pollutants with SDD = 0.1485 mg/cm2,

it can cause losses of up to 27.84

KWH/Year/Insulator. After washing with shampoo

and distilled water, the pollutants are clean, the

insulator is reduced to 9.35 KWH/Year/Insulator. The

full results of this calculation can be shown in table 3

below.

Table 3: Pedestal insulator insulation saving energy

analysis with high voltage vlf hi-pot instrument on

completely clean and dry.

Insulator

Condition

Leakage

current

(m A)

R

iso

(M-ohm)

Loss Energy

(KWH/Year/

Insulator)

Saving

Energy

(KWH/Year/

Insulator)

Polluted 0.274 72.99

27.84 0

1

st

washing 0.157 127.25

15.97 11.87

2

nd

washing 0.122 163.93

12.40 15.45

3

rd

washing 0.107 187.21

10.86 16.99

4

th

washing 0.103 195.12

10.42 17.43

Dry 0.092 218.58

9.35 18.13

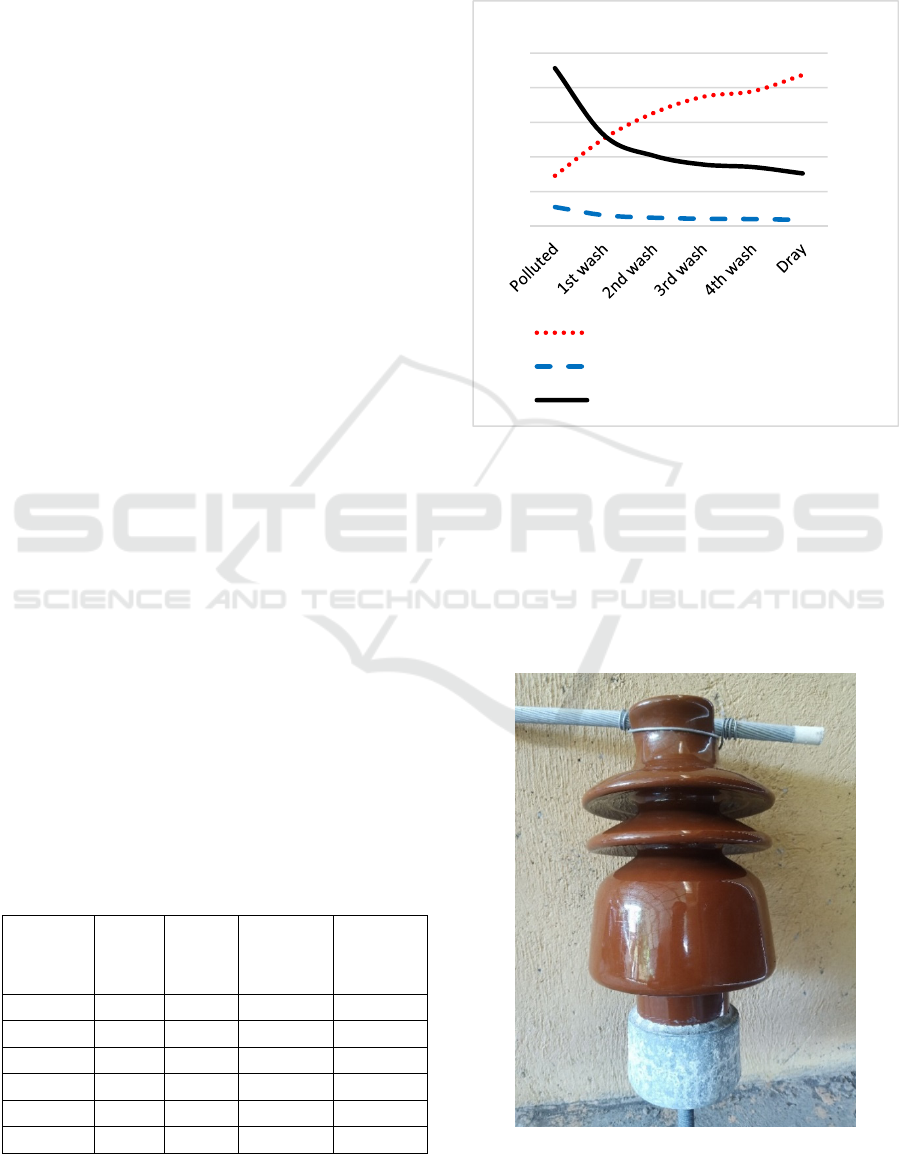

Based on Table 3 can be illustrated in graphical

form. This graphic form is presented to make it easier

to understand the phenomena that occur in the sample

of this study, as shown on figure 7 below.

Figure 7: Graphic leakage current, insulation resistance and

loss energy of pedestal insulator on clean and dry.

After the washing process is complete and the

electrical test is complete, it is followed by visual

observation. This visual observation was carried out

to determine the traces of partial discharge left during

the washing process. after the washing process the

insulator pedestal looks clean as shown in the figure

8 below.

Figure 8: Pedestal insulator on clean and dry.

0,000

0,050

0,100

0,150

0,200

0,250

0,300

0

50

100

150

200

250

Test Voltage 20 kV AC

Insulation Resistance (Mega Ohm)

Loss Energy (KWH/Y/Insulator)

Leakage Curent (mA)

The Energy Saving through Live Line Pedestal Insulator Washing with Snow Shampoo

265

Figure 8 presented visual observation of the

cleaned pedestal insulator, the washing result is clean,

and there were no traces of partial discharge. Even

though during the washing process there was a partial

discharge, it didn't leave any traces. Thus, washing

the pedestal insulator with the un-touch washing

method can be carried out safely without damaging

the surface of the insulator.

3.2 Discussion

SDD is influenced by NaCl in the solution is sprayed

to the surface of the pedestal insulator and the area of

the surface. The results of this study indicate that the

SDD value of 0.1485 mg/cm2 is classified as heavy

pollution (Salman and Muhammad 2011). Pollutants

with this classification are the heaviest pollution

classified, even visually it can be seen that there is

evenly white layer sticks on the surface of the

pedestal insulator that was sampled in this study as

shown in figure3.

Based on Table 1 the insulation resistance on

heavy pollution is 73.08 Mega ohms, that is lower

than the minimum standard for medium voltage

overhead lines, the minimum insulation resistance is

100 Mega Ohm(Sanjay et al, 2018). After washing as

shown in figure5, continued to four stages and drying,

the leakage current gradually decreased from 0.274

Milli Amperes to 0.122 Milli Amperes the insulation

resistance gradually increased from 72.99 Mega

Ohms to 166.49 Mega Ohms. The visually

observation the electric jump (flash over) during

washing did not leave a trace.

Based on the data as shown in table 3, insulator

washing in this study is the alternative method to gets

very good results to reduce the energy loss. The data

shown in the heavy pollution condition of the pedestal

insulator, energy loss is 27.84 KWH/Year/Insulator,

after washed and dry the decreases to 16.03

KWH/Year/Insulator, go down 66.60%.

4 CONCLUSIONS AND

SUGGESTIONS

4.1 Conclusions

The results and discussion have explained the process

and results of this research, which can be concluded

as follows. The equivalent salt deposit density SDD

(SDD) value is directly proportional to the

concentration of NaCl in the solution, the amount of

solution sprayed onto the surface of the test sample

and inversely proportional to the surface area of the

insulator. Polluted pedestal insulators with heavy

pollution levels have the opportunity to reduce the

performance of the insulator until it does not meet to

the standard because the insulation resistance drops to

less than 100 Mega Ohms for medium voltage

systems. The washing treatment to the live line

pedestal insulator using shampoo and distilled water

with the non-touch method was proven to be able to

restore the performance of the pedestal insulator to

meet the standard of at least 100 Mega Ohms, in this

study the insulation resistance increased from 73.08

Mega Ohms to 166.49 Mega Ohms. The electric jump

(flash over) during washing did not leave a trace as a

complements the success of this research. Increasing

the insulation resistance of the pedestal insulator after

washing treatment can decrease the energy loss

reaching 31.97 KWH/Year/Insulator and saving the

energy about 66.60% compared to when the

conditions the pedestal insulator were polluted with

heavy pollution levels.

4.2 Suggestions

Based on the results of this study, the suggestions can

be submitted to PLN and the researchers. It can be

suggested to PLN to do the un-touch washing

treatment the pedestal insulator to reduce energy loss

and saving the energy up to 66.60%, because this

method is safe to do and has been proven to

significantly improve the performance of polluting

insulators even for insulators with heavy pollution

levels. The next researcher can develop this research

by using other washing media such as distilled water

only, or by using a bleach solution.

ACKNOWLEDGEMENTS

This research was funded by DIPA Politeknik Negeri

Bali Year 2021. We thank Director of Politeknik

Negeri Bali for his support to this research.

REFERENCES

Abouelsaad, M.A., M.A. Abouelatta, B.Arafa, and

M.E.Ibrahim. (2013). Environmental pollution effects

on insulators of northern egypt hv transmission lines,

environmental pollution effects on insulators of

northern egypt hv transmission lines, Annual report

conference on electrical insulation and dielectric

phenomena.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

266

Ahmet Rumeli and Suleiman M, El-Debeiky. (1990).

Pollution flashover performance of high voltage

insulators around jeddah region, Medical Journal of

Islamic Academy of Sciences, 3:1. 1−5.

Alphonse Omboua1 and Haroun Abba Labane. (2017).

High voltage lines: energy losses in insulators. The

international journal of engineering and science

(IJES), Volume 6, Issue 10, Pages 58-62.

Carlos Sitompul, Zainuddin Nawawi, and Irfan Jambak.

(2020). Detection of polymer insulator surface based on

the effects of tropical climate using partial discharge

signals measurement, Journal of physics: conference

series.

Cepoi Radu Daniel, JAȘCĂU Flavia Florina and SZABÓ

Loránd. (2017) Current trends in energy efficient

electrical machines, Journal of electrical and

electronics engineering, Volume 10, Number 2,

October.

Dini Fauziah, Heldi Alfiadi, Rachmawati and Suwarno.

(2017). The effect of coating on leakage current

characteristic of coast field aged ceramic insulator,

Proc. EECSI 2017, p:371-376.

Farah Adilah Jamaludin, Mohd Zainal Abidin Ab-Kadir,

Mahdi Izadi, Norhafiz Azis, Jasronita Jasni and

Muhammad Syahmi Abd-Rahman. (2017). Effects of

RTV coating on the electrical performance of polymer

insulator under lightning impulse voltage condition,

PLOS ONE, November 14.

IEC 60507. (1991). Artificial pollution tests on high voltage

insulators to be used on AC systems.

Majid, M., Hussain, S Farokhi, S G McMeekin and M

Farzaneh. (2015). The effects of salt contamination

deposition on HV insulators under environmental

stresses, IEEE 11th international conference on the

properties and applications of dielectric materials

(ICPADM).

Nzenwa, E. C. and Adebayo. A. D.(2019). Analysis of

insulators for distribution and transmision networks,

American journal of engineering research (AJER),

Volume-8, Issue-12, pp-138-145.

Rosen, M. A. (1996). Energy efficiency and sustainable

development, IEEE Technology and society magazine,

vol. 15, no. 4, pp. 21-26, Winter.

Saba, T. M.. Tsado.J., 1Raymond. E., Adamu. M. J.. (2014)

The level of awareness on electrical hazards and safety

measures among residential electricity user’s in Minna

Metropolis of Niger State, Nigeria, OSR Journal of

Electrical and Electronics Engineering (IOSR-JEEE)

Vol. 9, Issue 5 Ver, I (Sep – Oct. 2014). PP 01-06

www.iosrjournals.org www.iosrjournals.org.

Salem, A. A. et al. (2021). Pollution flashover under

different contamination profiles on high voltage

insulator: numerical and experiment investigation,

IEEE Access, vol. 9, pp. 37800-37812, 2021.

Salman Amin and Muhammad Amin. (2011).

Thermoplastic elastomeric (tpe) materials and their use

in outdoor electrical insulation, Semanticscholar,

Edition 29 (2011), 15-30.

Sanjay Gothwal, Kaustubh Dwivedi and Priyanka

Maheshwari. (2018). Partial discharge characteristics

and insulation life with voltage waveform,

International Research Journal of Engineering and

Technology (IRJET), Volume: 05 Issue: 07 July.

Yılmaz Bayar and Hasan Alp Özel. (2014).

Electricity consumption and economic growth in

emerging economies, Scientific papers

(www.scientificpapers.org), Journal of knowledge

management. economics and information technology,

Vol. IV. Issue 2.

The Energy Saving through Live Line Pedestal Insulator Washing with Snow Shampoo

267