Analysis of Display Cabinet Temperature and Humidity Condition

for Fresh Fish Displayed

I Dewa Made Cipta Santosa

a

, I Nyoman Gede Suta Waisnawa, I Gusti Agung Bagus Wirajati,

I Gede Thio Cahya Dinata and I Komang Raditya Cahya Dinata

Politeknik Negeri Bali, Jalan Kampus Bukit Jimbaran, Kuta Selatan, Badung, Bali, 80364, Indonesia

Keywords: Fresh Fish, Display Cabinet, Temperature, Humidity.

Abstract: Fresh fish products are highly consumed and become very interesting local culinary to support tourism

development. In nowadays, restaurants, cafes, and others food centre do not provide a cooling system for

display cabinets. This condition causes an impact that the quality of fresh fish was not so good and hygienic

for international standard food. Thus, this study aims to investigate the quality of fish products in display

cabinets based on temperature and humidity during storage and compared with the investigation of the

Coefficient of Performance (COP) of the cooling system dan frost condition. This research was conducted by

experimental method. A display cabinet has been built with energy sourced from integration solar energy and

the national grid electricity (PLN). The results showed that optimization of storage conditions is temperature

of -0,6

o

C and humidity of 95% that can keep the product quality fresh and hygienic. However, this prototype

can reach the standard temperature very well but not to humidity which only reach in average 60%. In future

will develop a specific humidifier with low energy and integrated with de-frost control dan infiltration control

to get low energy display cabinet for storage fresh fish, so that operating costs can be reduced.

1 INTRODUCTION

The operation of the display cabinet still requires a lot

of electrical energy so that the operational costs are

relatively expensive. Because in general, display

cabinets have a high infiltration of open display

systems. Another condition is the electricity tariff

(PLN) which continues to be more expensive in line

with the depleting supply of fossil energy. So to

maintain sustainability, as a tropical country, solar

energy is a renewable energy in the future. At this

time cooling in the display cabinet is done by soaking

water and adding ice and certain preservatives, so that

the quality of fresh fish is very bad for health.

Efforts for operational efficiency of display

cabinets have been carried out in several studies in

previous related studies. Chaomuang et al. (2019) and

Manson et al. (2019) conducted an experimental

study on the effects of operating conditions, including

door opening frequency, ambient air temperature and

product occupied volume, on the distribution of air

and product temperatures in closed refrigerated

a

https://orcid.org/0000-0002-9912-629X

display cabinets. From the results of this study, it was

found that the position of the product in the cabinet is

a determining factor for its temperature: high

temperatures are observed at the front, especially at

the top of the cabinet, and low temperatures are

observed at the rear. Air infiltration due to door

opening causes an increase in product temperature at

the front and a decrease in temperature at the rear.

Meanwhile, Santosa et al. (2021) has developed a

dual humidifier system to maintain the humidity of

the cooling room for storing fresh fruits and

vegetables. Chaomuang et al. (2020a), Redo et al.

(2019) and Chaomuang et al. (2020b) carried out air

velocity measurements to study air flow patterns and

analyzed that installing doors on open-air refrigerated

display cabinets is a simple and effective way to

improve cabinet performance because it can reduce

air entry. warm and moist into the cupboard. Large

unstable eddies develop in the mixing layer, thereby

increasing the infiltration of larger external air. The

model is then used to predict the effect of air

infiltration through the door gap on the performance

of closed display cabinets in both thermal and energy

254

Santosa, I., Waisnawa, I., Wirajati, I., Dinata, I. and Dinata, I.

Analysis of Display Cabinet Temperature and Humidity Condition for Fresh Fish Displayed.

DOI: 10.5220/0010943300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 254-258

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

aspects. Applications in supermarkets were also

observed that door opening is the main energy loss in

display cabinets and in supermarkets a lot of waste is

needed because many display cabinets are open.

Gaspar et al. (2011) and Yu et al. (2009) stated that

the thermal entrainment factor was analysed and

compared with the total sensible and latent heat yields

for experimental testing. From an engineering point

of view, it is concluded that the thermal entrainment

factor cannot be used arbitrarily, although its use is

suitable for designing better cabinets under the same

climatic class conditions.

In terms of the frost phenomenon that can cause a

decrease in the performance of the cooling system,

previous research has been carried out related to the

control system of frost control on the evaporator.

Malik et al. (2020) stated that freezing is the most

detrimental phenomenon to the efficiency of the

refrigeration system. Frost accumulation blocks

airflow, worsening cooling capacity and performance

coefficient. Tan et al. (2020) researched that frost

dramatically worsens the operating performance of

air source heat pump units and causes additional

energy consumption. Zhang et al. (2017) conducted a

study related to frost-free refrigerated display

cabinets, in which freezing could be inhibited by

removing moisture from the air before entering the

display cabinet evaporator through a desiccant-coated

heat exchanger and was found to significantly

increase the COP by about 35%.

Thus, this study aims to investigate the quality of

fish products in display cabinets based on temperature

and humidity during storage and compared with the

investigation of the Coefficient of Performance

(COP) of the cooling system and frost condition.

2 METHODOLOGY

This research is an experimental research by making

a product/prototype of a display cabinet system for

storing fresh marine fish and designing an integrated

energy source from solar power and state grid

electricity (PLN). A prototype display cabinet with a

temperature that can be -5

o

C with a precise control

system and the storage volume is 118 litter (L). The

research was carried out at the Refrigeration Lab, Bali

State Polytechnic. Experimental tests have been

carried out on the refrigeration system from the

display cabinet and product quality tests (fresh marine

fish). The solar power system used is an integrated

system as shown in Figure 1.

Figure 1: Prototype display cabinet with integrated solar

energy and national grid (PLN) energy sources.

The data collection system was carried out with

type K thermocouple with an accuracy of up to 0.3

o

C

and humidity was measured with a hygrometer with

an accuracy of +-3% and pressure was measured with

a pressure gauge. as shown in Figure 1. System

performance data collection is carried out by

measuring temperature (T) and pressure (P) in each

condition (state) of the display cabinet refrigeration

cycle, Temperature (T) and Humidity (RH) in the

cabin and product. In terms of electricity, from solar

energy sources and components, the electric power,

current and input voltage are also measured carefully.

3 RESULTS AND DISCUSSIONS

In this results and discussions section, it consists of,

1) Review of display cabinet storage conditions, 2)

Analysis of storage conditions for prototype display

cabinet based on temperature and humidity, 3)

Analysis of average COP (theoretical), 4) Visual

analysis of frost and stored products. Where a detailed

explanation is as follows.

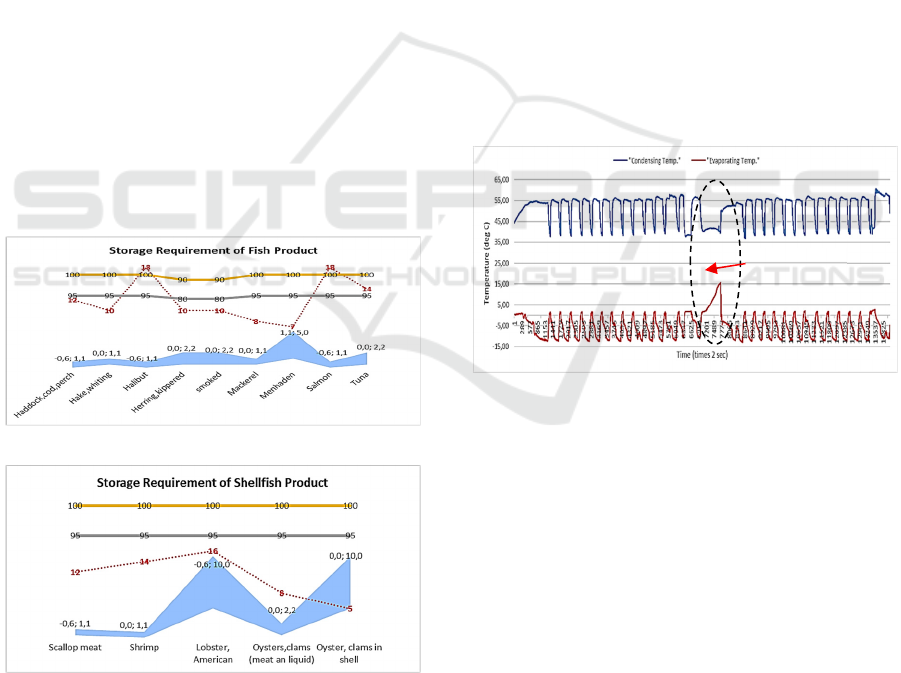

3.1 Review of Storage Condition of

Display Cabinet

The products stored in this display cabinet are fresh

seafood products. Storage conditions based on

ASHRAE (2014) that for fish products are shown in

Figure 2a and for shellfish and shrimp products are

shown in Figure 2b. Average storage temperature is -

0.6

o

C to 2.2

o

C , and relative humidity ranging from

80% to 90% and between 95% RH to 100% RH with

storage time in the display cabinet ranging from 7

Photovoltaic

Array

Controller

and

Batteries

Display Cabinet

Fish

Products

Analysis of Display Cabinet Temperature and Humidity Condition for Fresh Fish Displayed

255

days (for Menhaden products) to 18 days (for Halibut

and Salmon products) while other products ranging

from 8-14 days are still maintained freshness. Based

on these data, the capacity of the designed display

cabinet system is able to work up to a temperature of

-5

o

C. To achieve this temperature does not require

high energy because it is a medium temperature, but

to maintain high humidity, a special humidifier must

be added which is most suitable for the system to be

able to maintain hygiene. A suitable and energy

efficient humidifier system will be developed in

future research. The standard conditions for cold

storage of fish products are shown in Figure 2a.

While the storage conditions for shellfish

products (scallop meat, shrimp, lobster, oysters) are

more varied in terms of storage temperature

according to the type of product stored. The average

storage temperature is from -0.6

o

C to a maximum of

10

o

C. When compared to product fish, this product

requires a higher temperature especially for lobster

Oyster products (clams in shell). For humidity

requirements in display cabinet storage, humidity

(RH) is evenly distributed for all products between

95% to 100%, with a storage period of up to 16 days

(lobster) and only 5 days for Oyster and between 8-

14 days for products. other. Standard display cabinet

storage conditions for shellfish are shown in Figure

2b.

(a)

(b)

Figure 2: Standard storage conditions: (a). fish products and

(b). shellfish products.

3.2 Analysis of Storage Conditions of

Display Cabinet based on

Temperature and Humidity

From the results of testing on temperature (

o

C) and

humidity (%RH) on the results of the prototype

display cabinet design that was built, it was found that

the operational characteristics of the display cabinet

refrigeration system temperature were very good and

in accordance with the desired settings as shown in

Figure 3. Operational control temperature with on-off

condensing unit system has been running very well

which is controlled by a thermostat system. De-frost

occurs at the 4th hour and it can be seen that during

de-frost it can increase the maximum evaporating

temperature by about 12

o

C for a period of 12 minutes.

De-frost is done by turning off the condensing unit

(compressor and condenser fan), so that the ice melts

naturally. While the condensing temperature has no

effect, it is still the same as the de frost process. This

shows that the balance of high and low pressure

during de-frost is still maintained so that when the

system starts again it does not require high energy in

the compressor motor.

Figure 3: Condition of condensing temperature and

evaporating temperature.

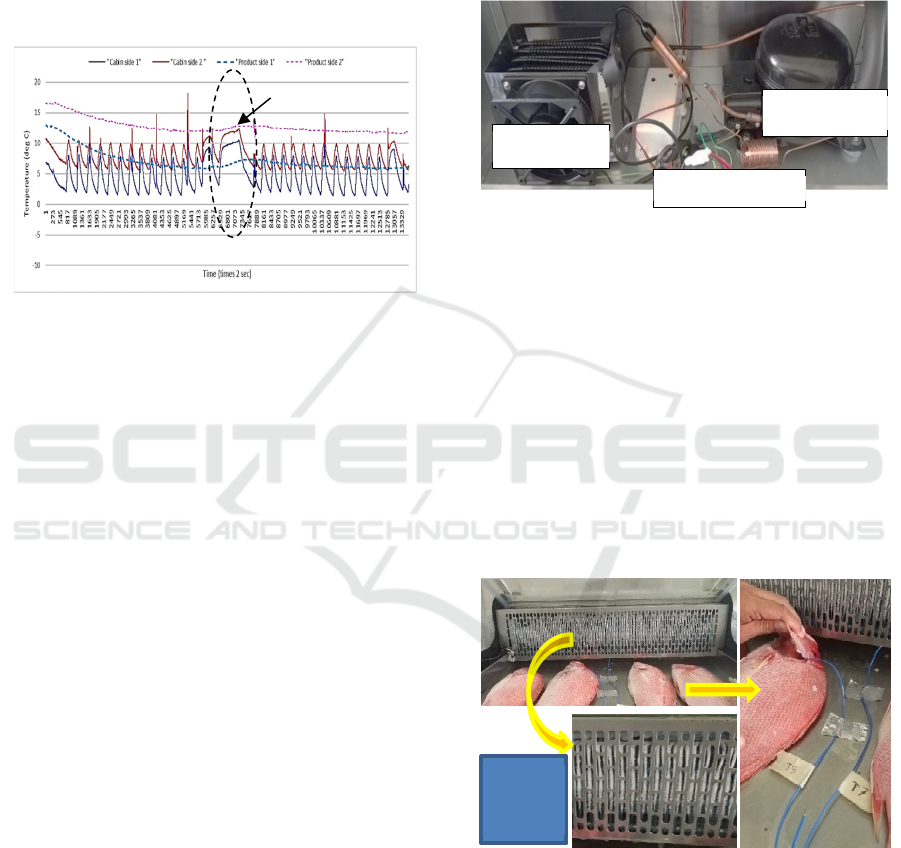

Figure 4 shows the characteristics of the cabin

temperature and the product according to its

placement, side 1 is a place near the evaporator and

side 2 is a place in front close to the cabin door. There

is a fairly high temperature difference at the different

positions in the cabin of approximately 3.2

o

C and the

difference in product temperature at the same time

there is an average difference of 5.5

o

C. This is

because the display cabinet is in a transparent

condition, resulting in high heat transfer from the

environment. When de-frost occurs, it is not

accompanied by a significant temperature increase in

cabin temperature and product temperature. This is

because the operating temperature is almost the same

as the frost temperature itself, which is around 0

o

C

and the prototype is still in a small capacity

de-frost

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

256

(compressor 1/2 Hp) so that the volume of the cabin

space is not too large which results in not too high

heat transfer from the environment. Besides that, the

material in the cabin is made with good stainless-steel

material to be able to store cold energy. Meanwhile,

the average humidity condition in the cabin is 60%

RH which of course is not enough to meet humidity

standards to get a good product in accordance with

ASHRAE (2014).

Figure 4: Cabin and product temperature characteristics.

The solar power system has also been able to work

well and is integrated using the ATS (automatic

Transfer Switch) system where energy will be

transferred to the national grid energy source – (PLN)

when battery charging drops below 30%. This

transfer occurs at night and returns to normal

conditions (connected to a solar energy source)

during the day, with the system and planning carried

out in this research the proportion of solar energy use

and the national grid (PLN) 70% : 30%, respectively.

Optimization analysis needs to be done to get the

most efficient optimal condition between the

proportion of solar energy and solar power between

the energy produced and the investment required. In

the next research, it will be developed to obtain the

most efficient solar and PLN capacity proportion

model for operating display cabinets.

3.3 Analysis of Theoretical Coefficient

of Performance (COP)

The COP calculation is based on the average

temperature conditions in the main state of the

refrigeration cycle which includes: temperature point

1 at the compressor entry position, point 2 at the

compressor exit position, point 3 at the condenser exit

position and point 4 at the exit position of the

capillary tube or entering the evaporator. From the

calculation with the @Coolpack, the coefficient of

performance (COP) is theoretically obtained at 4.8.

From a comparison with other refrigeration systems,

the theoretical COP is already very good. Thus, future

developments will focus on humidifier and control

systems to reduce the effects of infiltration and frost

effects. The main condensing unit components of the

prototype display cabinet covering, compressor,

capillary tube and condenser which are shown in

Figure 5 below.

Figure 5: Main condensing unit components of display

cabinet refrigeration system.

3.4 Frost and Product Visual Analysis

Figure 6. shows frost that occurs evenly on the entire

surface of the evaporator and at the 4

th

hour has begun

to be controlled the de-frost system works

periodically by turning off the compressor system for

12 minutes. This frost occurs because the average

temperature in the pipe and fin evaporator is around -

5.3

o

C with 60% humidity, so frost can easily occur.

Testing the temperature of the product (fresh fish) and

the stored space about 118 litter(L) is also shown in

Figure 6.

Figure 6: Visual frost condition and fish product quality.

From the analysis of fish products stored for 6

days in a display cabinet in general, it can be seen that

the fish is still fresh with good quality (from the color

of the gills, the smell and the condition of the

flexibility of the meat). However, the upper fish skin

is a little dry because of the lack of moisture in the

display cabinet cooling chamber. This will be the

de-frost

Condenser

Compressor

Capillary tube

Frost

visual

Analysis of Display Cabinet Temperature and Humidity Condition for Fresh Fish Displayed

257

focus of attention in further research, namely by

developing a humidifier system that is suitable for

display cabinets for storing fresh fish.

4 CONCLUSIONS

Based on the tests and analyses that have been carried

out, it can be concluded that this display cabinet

system has operated very well with a fairly high

performance with theoretical COP approximately 4.8.

However, it is still not able to produce sufficient

humidity for fresh fish storage standards. The

required humidity ranges from 80% to 90% and

between 95% RH to 100% RH. With a natural method

by manually opening regularly every 1 hour with an

opening duration of 10 seconds, it is only able to

produce 60% humidity. With evaporator setting

temperature of -5

o

C and humidity in average of 60%

naturally, at evaporator fin and tube surface already

occur a frost evenly. So that for future research

development, a humidifier system, de-frost control

and infiltration control from the display cabinet

system will be developed so that it can produce

product storage with excellent quality and energy

saving.

ACKNOWLEDGEMENTS

This research was supported by the Directorate of

Sumber Daya, DIKTI, Ministry of Education, Culture

and Research Technology, Indonesian Government,

Grant No: 249/E4.1/AK.04.PT/2021 and

41/PL8/PG/2021 for the in cash contribution. The

authors wish to acknowledge the contributions of The

Mechanical Engineering Department-Bali State

Polytechnic for the in-kind contributions. Also,

Centre for Research and Community Service (P3M-

PNB) for all administrative support.

REFERENCES

ASHRAE. (2014). ASHRAE Handbook of Refrigeration.

ASHRAE, Inc., Atlanta, 749 pgs.

Chaomuang, N, Denis, F, Denis, A, Laguerre, O. (2019).

Influence of operating conditions on the temperature

performance of a closed refrigerated display cabinet.

International Journal of Refrigeration, 103,32–41.

Chaomuang, N, Denis, F, Denis, A, Laguerre, O. (2020).

Experimental and numerical characterization of airflow

in a closed refrigerated display cabinet using PIV and

CFD techniques, International Journal of

Refrigeration, 111, 168-177.

Chaomuang, N, Laguerre, O, Flick, D. (2020). A simplified

heat transfer model of a closed refrigerated display

cabinet, Thermal Science and Engineering Progress,

17, 100494.

Gaspar,P,D, Gonçalves, L,C, Pitarma, R,A.(2011).

Experimental analysis of the thermal entrainment factor

of air curtains in vertical open display cabinets for

different ambient air conditions. Applied Thermal

Engineering, 31, 961-969.

Malik, A, N, Khan, S, A, Lazoglu, I. (2020). A novel hybrid

frost detection and defrosting system for domestic

refrigerators. International Journal of Refrigeration,

117, 256-268.

Månsson, T., Rukundo, A, Almgren, M, Tsigas, P, Marx, P,

Ostermeyer, Y. (2019). Analysis of door openings of

refrigerated display cabinets in an operational

supermarket. Journal of Building Engineering,

26,100899.

Redo, M, A, Ohno, K, Giannetti, N, Yamaguchi, S, Saito,

K. (2019). Seasonal performance evaluation of CO

2

open refrigerated display cabinets. Applied Thermal

Engineering, 163, 114354.

Santosa, I, D, M, C, Waisnawa, I, N, G, S Sunu, P, W,

Wirajati, I,G,A,B. (2021). Investigation of optimization

of solar energy refrigerator with natural humidifier.

International Journal of Thermofluid Science and

Technology, Vol. 8, Issue 2, Paper No. 080201.

Tan, H, Xu, T, Liu, Z, Tao, T, Xu, G. (2020). Investigation

of ultrasonic array defrosting method based on

synergism of standing wave intermittent phase-stagger

and multi-frequency for finne d-tub e evaporator.

Energy & Buildings, 218, 110054.

Yu, K, Ding, G, L, Chen, T, J. (2009). A correlation model

of thermal entrainment factor for air curtain in a vertical

open display cabinet. Applied Thermal Engineering, 29,

2904–2913.

Zhang, L, Fujinawa, T, Saikawa, M. (2017). Theoretical

study on a frost-free refrigerated display cabinet.

International Journal of Refrigeration, 74, 95-104.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

258