Decagon-shaped Water Bottle Design with Ergonomic Handle

Dwi Cahyadi

1

, Etwin Fibrianie Soeprapto

1

, Muhammad Kadafi

2

, Hertina Susandari

3

and Sukmawati

4

1

Design Department, Politeknik Negeri Samarinda, Jl. Ciptomangunkusumo, Samarinda, Indonesia

2

Accunting Department, Politeknik Negeri Samarinda, Jl. Ciptomangunkusumo, Samarinda, Indonesia

3

Design Department, Institut Teknologi Sepuluh Nopember Surabaya, Jl. Dispro, Surabaya, Indonesia

4

Lembaga Penjamin Mutu Pendidikan, Jl. Ciptomangunkusumo, Samarinda, Indonesia

Keywords: Ergonomic, Water Bottle, Decagon Shape, Handle, Amthropometry.

Abstract: Water bottle commonly found in Indonesia in the form of tubes that hold 19 liters of water. In the process of

moving, the water bottle is lifted and there is a risk of slipping so that the water bottle can falls and rolls

because water bottles are generally in the form of a tube and do not have a special handle. For this reason, it

is necessary to design a drinking water bottle shape with an ergonomic handle so that it is easy to move and

lift. The purpose of this study is to redesign a decagon-shaped drinking water bottle that has a handle according

to the anthropometry of the Indonesian hand. This study uses the application of hand anthropometric data for

95 percentiles of Indonesian men aged 18-25 years. The results of this study obtained a water bottle design in

the form of an ergonomic decagon and has a bottle handle with a length of 10 cm, with four finger grips each

measuring 2.5 cm. The contribution of this research proposes a drinking water bottle design that is different

from the previous one and has an ergonomic handle to reduce the risk of accidents when lifting it.

1 INTRODUCTION

Water as consumption such as drinking water is very

important for the human body because it functions to

transport minerals, vitamins, proteins, and other

nutrients throughout the body. Water is a lubricant for

body tissues as well as a cushion for joints, bones, and

muscles. About 80% of the human body consists of

water and of the organs of the body, blood, and brain

is the highest water content. Healthy drinking water

has the main and important characteristics, namely

odorless, tasteless, colorless and does not contain

harmful substances and microorganisms. (Sari,

2014);(Aryani, 2017).

By looking at the main needs of this water, many

companies are pushing to make new innovations in

the field of drinking water to make it easier for

consumers to meet the needs of healthy and fast

water. Bottled drinking water is one solution.

Packaging is an important element in a beverage

product. Bottled drinking water uses a lot of plastic

because of its ease of use and low production costs

(Aversa et al., 2021); (Prarudiyanto, Werdiningsih, &

Rokilah, 2018).

Packaging such as plastic bottles has become part

of daily activities, especially in activities related to

mineral water packaging. The use of plastic bottles

for mineral water packaging is a practical and concise

alternative (Wijayanto & Rusdi, 2017). Bottled water

in 19 liters in Indonesia is mostly used for daily needs

in households and offices because of the more water

capacity and practicality. Along with the increasing

need for bottled mineral water, the need in this case

the process of lifting and moving this 19 liter water

bottle from one place to another is a problem that is

often faced by consumers and producers. (Sasongko

& Purnomo, 2017); (Setiawan, Kirana, Cahyani, &

Suryoputro, 2019).

The current bottle has problems in lifting it to the

top of the dispenser because of the tubular shape of

the gallon and the heavy volume of 19 liters of water.

The tubular shape of the bottle has a risk of slipping

when lifted so that it can fall and roll on the ground.

In addition, the shape of the tube without a handle

adds to the difficulty in moving and lifting the bottle.

Thus the purpose of this research is to innovate the

design of changing the shape of the bottle

accompanied by an ergonomic handle to make it

easier to lift the bottle, which is needed to solve

Cahyadi, D., Fibrianie Soeprapto, E., Kadafi, M., Susandari, H. and Sukmawati, .

Decagon-shaped Water Bottle Design with Ergonomic Handle.

DOI: 10.5220/0010942800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 227-231

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

227

problems that often occur when lifting and moving it.

This research contributes positively to society by

innovating a different bottle shape than before and by

adding the added benefit of an ergonomic handle for

easy moving and lifting of water bottles.

2 LITERATURE REVIEW

2.1 Ergonomics in Product

Development

Definition of ergonomics according to the World

Health Organization -WHO (1972) Ergonomics is a

science-oriented field of work design technology

based on its users, namely humans, including the

fields of anatomy, physiology and psychology.

According to Wignjosoebroto (1995); (Nurmianto,

1998) Ergonomics can be referred to as human factor

engineering which is defined as a scientific discipline

that studies humans in relation to the work they do.

According Salvendy (2012); Lehto and Landry

(2013) Ergonomics is one of the disciplines that

discusses the understanding of the interaction of

humans and their environment of a system.

Ergonomics emphasizes the importance of applying

theories, principles, and methods in terms of

optimizing safety, comfort and human well-being and

overall system performance. One of the important

fields in ergonomics is anthropometry.

Anthropometry is used as a standard for determining

dimensions in product manufacturing and

development

.

2.2 Anthropometric Data as Product

Dimension Determination

Anthropometry is the measurement of the dimensions

of the human body as a basis for measuring

ergonomics for products and the workplace by

considering ethnicity, gender, body defects, body

position and posture during activities, as well as the

type of work performed. Anthropometric data is used

in ergonomics to determine the physical dimensions

of workspaces, equipment, and products used by

humans. Anthropometry is usually displayed in

tabular form by dividing its size into 5th percentile,

50th percentile and 95th percentile sizes. Where the

5th percentile is a measure of the data for the

population with a small body size, the 50th percentile

is for the average body size and the 95th percentile is

used for the larger body size. Several studies on

anthropometry for variations and redesign of products

such as furniture were carried out by changing the

dimensions of the consumer's body based on age and

ethnicity (Kahya, 2019); (Lee, Kim, Lee, & Yun,

2018); (Yanto, Lu, & Lu, 2017); (Taifa & Desai,

2017).

According Adnan and Dawal (2019) W. Lee et al.

(2018), Gonzalez, Barrios-Muriel, Romero-Sanchez,

Salgado, and Alonso (2020); Wang and Cai (2020)

designing tools, equipment, and furniture according

to the size of the human body, can provide maximum

benefits. Recent usage data from anthropometry can

synchronize users and products produced to suit the

user Anthropometry has been widely used to design

products and workplaces that are safe and sustainable

(Castellucci et al., 2020);(D Cahyadi, Fibrianie,

Irwan, Susandari, & Tantrika, 2019). In designing

product handles, paying attention to ergonomic

principles by using anthropometric tables can

improve hand posture, increase comfort, and reduce

discomfort when working with these products. (Veisi,

Choobineh, Ghaem, & Shafiee, 2019);(Ranger,

Vezeau, & Lortie, 2019);(Cahyadi, 2014)

3 METHOD

The design of the 19 liter mineral water bottle was

carried out in two stages, namely designing and

measuring the bottle handle according to

anthropometric data of the Indonesian human body

and the second was designing the shape of a mineral

water bottle with an ergonomic handle and the design

of a ten-shaped bottle using 3D software.

Anthropometric data used are hand width (HW)

dimension data, finger width (FW) and finger depth

(FD), male gender 95 percentile aged 18-25 years like

seen in table 1

(Purnomo, 2014).

Table 1: Anthropometric data hand width (HW), finger

width (FW) and finger depth (FD).

No Anthropometric

Data

Percentile

5%tile 50%tile 95%tile

1 Hand width (HW) 7,2 c

m

8,2 c

m

9,1 c

m

2 Fin

g

er width

(

FW

)

1,6 cm 1,8 cm 2,2 cm

3 Fin

g

er de

p

th

(

FD

)

1,3 c

m

1,7 cm 2,0 c

m

4 RESULT AND DISCUSSION

In this research, anthropometric data used were Asian

ethnic groups from Indonesia with male gender aged

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

228

18-25 years. For the initial stage, determine the length

of the bottle handle using anthropometric hand width

data. From the anthropometric data in the table 1, the

95th percentile value is 9,1 cm.

This value is the minimum value of the handle

length to be the lower limit of the ergonomic grip size.

Due to the dynamic movement of the fingers when

lifting the bottle, this product is designed to be 10 cm

for the length of the hand grip. In Figure 1, this size

is labeled with hand wide (HW).

To determine the size of the grip width on the

bottle handle, the Finger Wide (FW) size is used as

shown in Figure 1. Anthropometric data taken is

finger width data from the 95th percentile of male

gender. The value obtained in the anthropometric data

is 2,2 cm.

This value is a minimal value, so the value used in

the product is 2.5 cm to provide dynamic motion of

the finger. The number of handles designed is 4

indentations to strengthen the grip when lifting the

bottle using the index finger, middle finger, ring

finger and little finger.

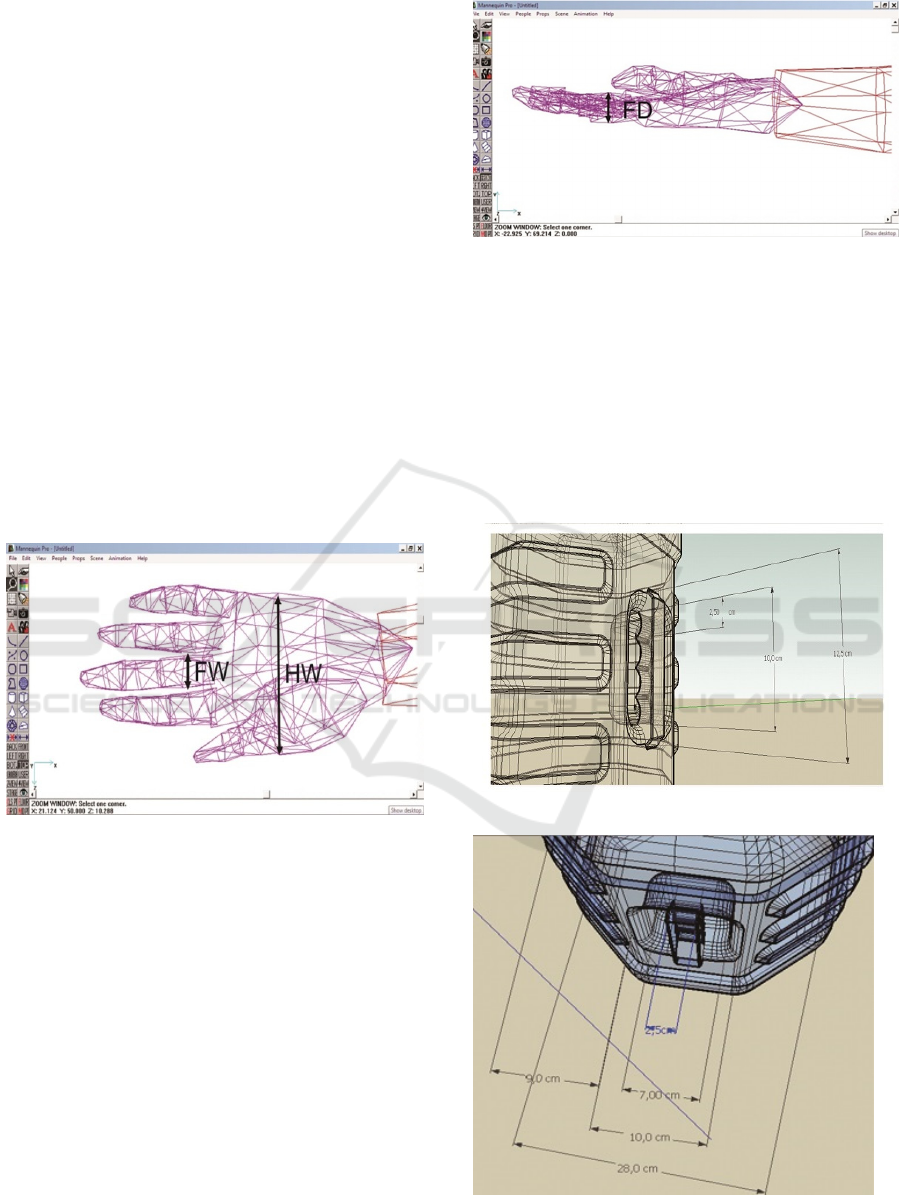

Figure 1: Anthropometric measurements of hand width

(HW) and finger width (FW) (mannequin pro software).

To determine the width of the grip, the finger depth

(FD) dimension is used as shown in figure 2. The

width of the grip space is designed so that there is

comfortable movement in the area between the bottle

body and the finger grip when lifting the bottle.

Finger depth is taken from anthropometric data of

the 95th percentile of men. The value obtained from

anthropometric data is 2 cm. This value is the

minimum value of the width of the hollow in the

bottle handle. In the design of this product, the

designed depth is 7 cm.

Figure 2: Anthropometric finger depth (FD) measure

(mannequin pro software).

The results of 3D modeling and rendering will look

like in Figure 3 and 4. Figure 3 and 4 are an image of

the shape and size of the bottle design. The shape of

the handle on the bottle is a box with a length of 10

cm and a width and height of 2.5 cm. The size of the

ergonomic handle that has been analyzed through the

use of anthropometric data is applied to the bottle

design.

Figure 3: The size of the bottle handle side view.

Figure 4: The size of the bottle handle top view.

Decagon-shaped Water Bottle Design with Ergonomic Handle

229

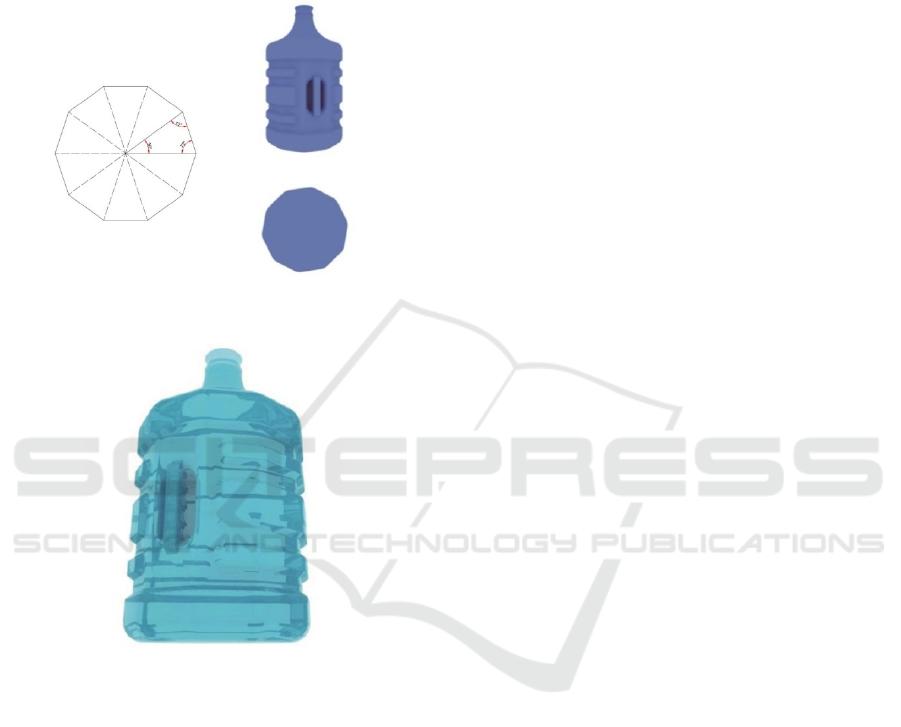

The next stage is the application of these

dimensions to bottle products using 3D software. The

software used in designing the decagon bottle is

google sketchup. Decagon is a ten-sided polygon that

has composed golden triangle (base angle 72

0

and

vertex 36

0

) as shown in figure 5. (Kimberly, 2011).

Figure 5: Application of the Golden section triangle to the

bottle design (decagon shape).

Figure 6: Modeling a decagon bottle with an ergonomic

handle.

Figure 6 is the final image of the bottle design

rendering process using 3D software. This rendering

aims to show the final result of the rectangular bottle

design and the position of the handle on the bottle.

5 CONCLUSIONS

Bottled mineral water that is commonly found in

Indonesia is in the form of a tube with a size of 19

liters of water. In the process of moving the water

bottle containing the water, the water bottle is lifted

and sometimes slips occur so that the water bottle

falls and rolls. The results of this study obtained a

decagon-shaped drinking water bottle design that is

ergonomic and has the shape of a handle on a box-

shaped bottle with a length of 10 cm and a width and

height of 2.5 cm. On the handle of the bottle there are

four grooves for the grip of the four fingers, namely

the index finger, middle finger, ring finger and little

finger.

This grip design has 7 cm of grip space to provide

comfort and safety when fingers enter and exit the

grip area. For further research, it can be developed

from the side of the geometric shape and material of

the handle on the bottle.

REFERENCES

Adnan, N., & Dawal, S. Z. M. (2019). Applied

anthropometric for wheelchair user in Malaysia.

Measurement, 136, 786-794. doi:10.1016/j.measure

ment.2018.11.002

Aryani, T. (2017). Analisis Kualitas Air Minum Dalam

Kemasan (AMDK) di Yogyakarta ditinjau dari

Parameter Fisika dan Kimia Air. Media Ilmu

Kesehatan, 6(1). doi:10.30989/mik.v6i1.172

Aversa, C., Barletta, M., Gisario, A., Pizzi, E., Prati, R., &

Vesco, S. (2021). Design, manufacturing and

preliminary assessment of the suitability of bioplastic

bottles for wine packaging. Polymer Testing, 100.

doi:10.1016/j.polymertesting.2021.107227

Cahyadi, D. (2014). Aplikasi Mannaquin Pro Untuk Desain

Industri: Leutikaprio.

Cahyadi, D., Fibrianie, E., Irwan, M., Susandari, H., &

Tantrika, C. F. M. (2019). Design of workstation in

the home industry of Amplang crackers production.

Paper presented at the iCAST-ES 2019.

Castellucci, H., Viviani, C., Arezes, P., Molenbroek, J. F.

M., Martínez, M., Aparici, V., & Dianat, I. (2020).

Applied anthropometry for common industrial

settings design: Working and ideal manual handling

heights. International Journal of Industrial

Ergonomics, 78. doi:10.1016/j.ergon.2020.102963

Gonzalez, A. G., Barrios-Muriel, J., Romero-Sanchez, F.,

Salgado, D. R., & Alonso, F. J. (2020). Ergonomic

assessment of a new hand tool design for laparoscopic

surgery based on surgeons' muscular activity. Appl

Ergon, 88, 103161. doi:10.1016/j.apergo.20

20.103161

Kahya, E. (2019). Mismatch between classroom furniture

and anthropometric measures of university students.

International Journal of Industrial Ergonomics, 74.

doi:10.1016/j.ergon.2019.102864

Kimberly Elam, 2011, Geometry of Design: Studies in

Proportion and Composition, 2

nd

Edition Revised and

Updated, Princeton Architectural Press, New York.

Lee, W., Yang, X., Jung, D., Park, S., Kim, H., & You, H.

(2018). Ergonomic evaluation of pilot oxygen mask

designs. Appl Ergon, 67, 133-141. doi:10.1016

/j.apergo.2017.10.003

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

230

Lee, Y., Kim, Y. M., Lee, J. H., & Yun, M. H. (2018).

Anthropometric mismatch between furniture height and

anthropometric measurement: A case study of Korean

primary schools. International Journal of Industrial

Ergonomics, 68, 260-269. doi:10.1016/j.ergon.2018.

08.010

Lehto, M., & Landry, S. J. (2013). Introduction to Human

Factors and Ergonomics For Engineering (Second

edition ed.): CRC Press

Nurmianto, E. (1998). Ergonomi Konsep Dasar dan

Aplikasinya (First Edition ed.): Guna Widya.

Prarudiyanto, A., Werdiningsih, W., & Rokilah, R. (2018).

Pengaruh Kombinasi Kemasan Dan Masa Simpan

Terhadap Beberapa Komponen Mutu Bumbu Plecingan

Instan (The Effect of Combination of Package and Self-

life on The Some Qualities of Instant Seasoning

Plecingan). Jurnal Ilmiah Rekayasa Pertanian dan

Biosistem, 6(1), 60-68. doi:10.29303/jrpb.v6i1.76

Purnomo, H. (2014). Pengukuran Antropometri tangan

Usia 18 Sampai 22 Tahun Kabupaten Sleman

Yogyakarta. Paper presented at the Seminar Nasional

IENACO.

Ranger, F., Vezeau, S., & Lortie, M. (2019). Tools and

methods used by industrial designers for product

dimensioning. International Journal of Industrial

Ergonomics, 74. doi:10.1016/j.ergon.2019.102844

Salvendy, G. (2012). Handbook of Human Factors and

Ergonomics (G. Salvendy Ed. Fourth Edition ed.): John

Wiley & Sons, Inc.

Sari, I. P. T. P. (2014). Tingkat Pengetahuan Tentang

Pentingnya Mengkonsumsi Air Mineral Pada Siswa

Kelas IV di SD Negeri Keptran A Yogyakarta. Jurnal

Pendidikan Jasmani Indonesia, 10(2).

Sasongko, D. A., & Purnomo, H. (2017). Perancangan

Ulang Rak Penyimpanan Galon dan Alat Bantu Angkat

dengan Metode Ergonomi Partisipatori. Paper

presented at the Seminar Nasional Teknik Industri

Universitas Gadjah Mada.

Setiawan, M. S., Kirana, I. W., Cahyani, A. D., &

Suryoputro, M. R. (2019). Penilaian Postur Pekerja

Pengangkatan Galon Dengan Metode REBA dan

Biomekanika. Paper presented at the Seminar dan

Konferensi Nasional IDEC.

Taifa, I. W., & Desai, D. A. (2017). Anthropometric

measurements for ergonomic design of students’

furniture in India. Engineering Science and Technology,

an International Journal, 20(1), 232-239.

doi:10.1016/j.jestch.2016.08.004

Veisi, H., Choobineh, A., Ghaem, H., & Shafiee, Z. (2019).

The effect of hand tools’ handle shape on upper

extremity comfort and postural discomfort among

hand-woven shoemaking workers. International

Journal of Industrial Ergonomics, 74. doi:10.1016/

j.ergon.2019.102833

Wang, C. Y., & Cai, D. C. (2020). Hand tool handle size

and shape determination based on hand measurements

using a contour gauge. Human Factors and Ergonomics

in Manufacturing & Service Industries, 30(5), 349-364.

doi:10.1002/hfm.20846

WHO. (1972). Introduction to Ergonomics (W. T.

Singleton ed.): WORLD HEALTH ORGANIZATION

Wignjosoebroto, S. (1995). Ergonomi, Studi Gerak dan

Waktu (First ed.): PT. Candimas Metropole.

Wijayanto, A., & Rusdi. (2017). Pendampingan Kelompok

Usaha Pencacahan Limbah Plastik di Kabupaten

Malang. Jurnal Pambudi, 1(1).

Yanto, Lu, C. W., & Lu, J. M. (2017). Evaluation of the

Indonesian National Standard for elementary school

furniture based on children's anthropometry. Appl

Ergon, 62, 168-181. doi:10.1016/j.apergo.2017.03.004

Decagon-shaped Water Bottle Design with Ergonomic Handle

231