Diesel Engine Performance with Diesel and Biodiesel Fuel

from VCO on the High Load

Aris Palinggi

1

, Lukas Lantang

1

and Bernandus

2

1

State Politecnic of Kupang, Adi Sucipto, Kupang, Indonesia

2

Chemical Engineering Dept. Nusa Cendana University, Kupang, Indonesia

Keywords: Biodiesel, VCO, Performance, High Load.

Abstract: This study aims to test the performance of diesel engines at high loads and speeds using biodiesel from Virgin

Coconut Oil ( VCO ) to reduce exhaust emissions with high performance, because diesel engines are often

used in heavy duty. The method used is an experimental method using biodiesel from VCO mixed with pure

diesel fuel with a percentage of 30% and 40% VCO as fuel for a four-cylinder diesel engine equipped with a

fuel heater and tested at high load and speed of 35 kgf load and 3000 to 4000 rpm. The experimental data

were then analyzed using excel and made in the form of a graph. The results showed that at 30% the higher

the engine speed, the closer the performance to the use of pure diesel and exhaust emissions showed that a

mixture of VCO and pure diesel could reduce exhaust emissions of carbon monoxide (CO ) and hydrocarbons

( HC ), while in the 40% mixture there is a decrease in exhaust emissions but lower performance. So it can be

concluded that the use of VCO as biodiesel in a mixture of 30% and tested at high load and rotation produces

performance that is close to the use of pure diesel and can reduce exhaust emissions of diesel engines so it is

very good to use.

1 INTRODUCTION

As we know that the world is approaching a state of

energy crisis because fossil energy will soon run out,

therefore it is necessary to look for alternative fuel

substitutes to meet the increasing energy needs due to

industrial development and economic progress. In

addition, the fuel used must meet the exhaust

emission standards that have been set, namely fuel

that does not damage the environment. Indonesia is

rich in vegetable natural resources which are

alternative sources of renewable and environmentally

friendly energy so that when used as fuel it does not

produce exhaust gases that pollute the environment

and increase global warming. Biodiesel is an

alternative energy that is being developed because it

can be renewed and the raw materials are abundant,

but in its use it cannot be fully utilized directly

because it must meet diesel engine fuel standards.

Biodiesel currently available is sourced from palm oil

which in its use is called B 30 or a mixture of

biodiesel and fuel in the percentage of 30% biodiesel

and 70% fuel. In addition to palm oil, there are several

sources of biodiesel energy that can be an alternative

to be developed due to its abundant availability, one

of which is local coconut which is currently not

processed as biodiesel and is only used as food. There

are two kinds of local coconut processing, namely by

using heat and without heating which is called VCO.

Processing without heat causes VCO to have a clear

color and low viscosity so that it is close to the

requirements for diesel engine fuel.

Several studies that have been carried out using

VCO still have to be mixed with diesel or the like with

the highest percentage still having good performance,

namely 30% (Palinggi, 2020) and the efficiency is

still inferior to pure diesel because the viscosity of the

mixture of VCO and diesel is still higher than pure

diesel. Therefore, to overcome the problem of fuel

viscosity, it is necessary to heat the fuel before it is

injected into the combustion chamber (Madhava,

2016). To ensure the use of biodiesel from VCO has

high performance in every engine working condition,

the test must be carried out at high loads and high

rotations because in this condition the torque reaches

its maximum state (Supriyana, 2015).

The main problem that will be discussed in this

study is whether the use of biodiesel from VCO with

a mixed percentage of 30% VCO 70% pure diesel and

40% VCO 60% diesel meets the fuel requirements of

156

Palinggi, A., Lantang, L. and Bernandus, .

Diesel Engine Performance with Diesel and Biodiesel Fuel from VCO on the High Load.

DOI: 10.5220/0010941500003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 156-160

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

diesel engines and if supported by fuel heating before

injection, has good performance. good. good and

efficient at larger loads and high rotation. The goal to

be achieved is to utilize VCO as a diesel mixture and

then use it in engine conditions at varying loads and

high rotations, as well as to determine the comparison

between the use of a mixture of diesel with VCO and

pure diesel. The urgency of this research is to

emphasize the use of local coconut as a source of

biodiesel.

Diesel engine is an engine with a compression

ignition system, therefore the fuel characteristics for

a diesel engine must match the compression ignition

system. The characteristics of the fuel include:

calorific value, flash point, viscosity, specific gravity

and cetane number. In diesel engines, the important

fuel characteristics are the cetane number which must

be high so that it is not easy to knock and has good

lubricating properties (Palinggi, 2019).

The use of biodiesel is very appropriate to reduce

dependence on fossil fuels because the characteristics

of biodiesel from several materials known today are

close to the characteristics required for diesel engine

fuel. These characteristics such as lubricating

properties, calorific value, cetane number, viscosity

and specific gravity. One source of biodiesel that is

often used is used cooking oil or used cooking oil,

with chemical treatment the used cooking oil can be

cleaned so that it can be used as a diesel mixture that

can reduce diesel engine exhaust emissions without

reducing performance.( Elma, 2016) . One of the uses

of biodiesel is using mahua oil as biodiesel and mixed

with diesel and found that the mixture of mahua oil

can save fuel by up to 30% and reduce exhaust

emissions by 35% (Kumar, 2018 ). The use of VCO

as a diesel mixture found that a mixture of VCO in

diesel can increase engine power at medium speed,

but if the engine rotates at high RPM the power will

decrease. If the percentage of VCO is increased, the

torque and fuel consumption will decrease

(Bhikuning, 2013).

Virgin cocnut oil (VCO) is oil produced from

ordinary coconut (Cocos Nucifera) which is

processed naturally without chemicals so it is safe for

engine components and when used as a diesel mixture

it can improve engine performance at medium speed

(Bhikuning, 2013). The natural processing produces

durable, low-fat and clear VCO which can

significantly reduce exhaust emissions (Nazir, 2017).

The fuel heating instrument in the diesel engine

aims to reduce the viscosity of the fuel so that the

atomization is more perfect and fuel consumption is

more efficient and exhaust emissions decrease

(Indartomo, 2016). Heating spark plugs are an option

that is often used to heat diesel engine fuel before it is

injected, but there are also those that use incandescent

lamps mounted on the fuel line (Supriyana, 2016).

2 MATERIAL AND METHOD

The research method used is a direct experimental

method by observing the phenomena that occur in

diesel engines which are tested at high loads using a

mixture of VCO and pure diesel at a mixture of 30%

and 40%.

The VCO biodiesel used is taken directly from

small industries, while diesel is a product of

Pertamina. The characteristics of the fuel used are as

in table 1 and are the results of testing the

characteristics of pure diesel and VCO as well as a

mixture of VCO and pure diesel. The diesel engine

used for the experiment was a Nissan brand with 4

cylinders and 4 strokes equipped with a fuel heater.

The engine was tested at a maximum allowable load

of 35 kgf and engine speed at 3000, 3200, 3400, 3600,

3800 and 4000 rpm. The engine was tested first using

pure diesel fuel then a mixture of 30% VCO and

finally a mixture of 40% VCO. The experimental data

is then made in the form of tables and then graphed

using excel software. The engine performance that

will be analyzed is the effective power, fuel

consumption, thermal efficiency and exhaust

emissions of carbon dioxide and hydrocarbons.

Table 1: Physical Properties of Material fuel.

Fuel

Material

Heating

Value

( Calori/gram )

Viskosity

( cSt ) 40ºc

Density

( gram/ml )

100%

Diesel fuel

10755 3.6 0.83

100 % VCO 8979.5 24.3 0.917

30 % VCO 10222,3 9,8 0.85

40 % VCO 10044,8 11,88 0.86

3 RESULT AND DISCUSSION

3.1 Resuslt and Analysis

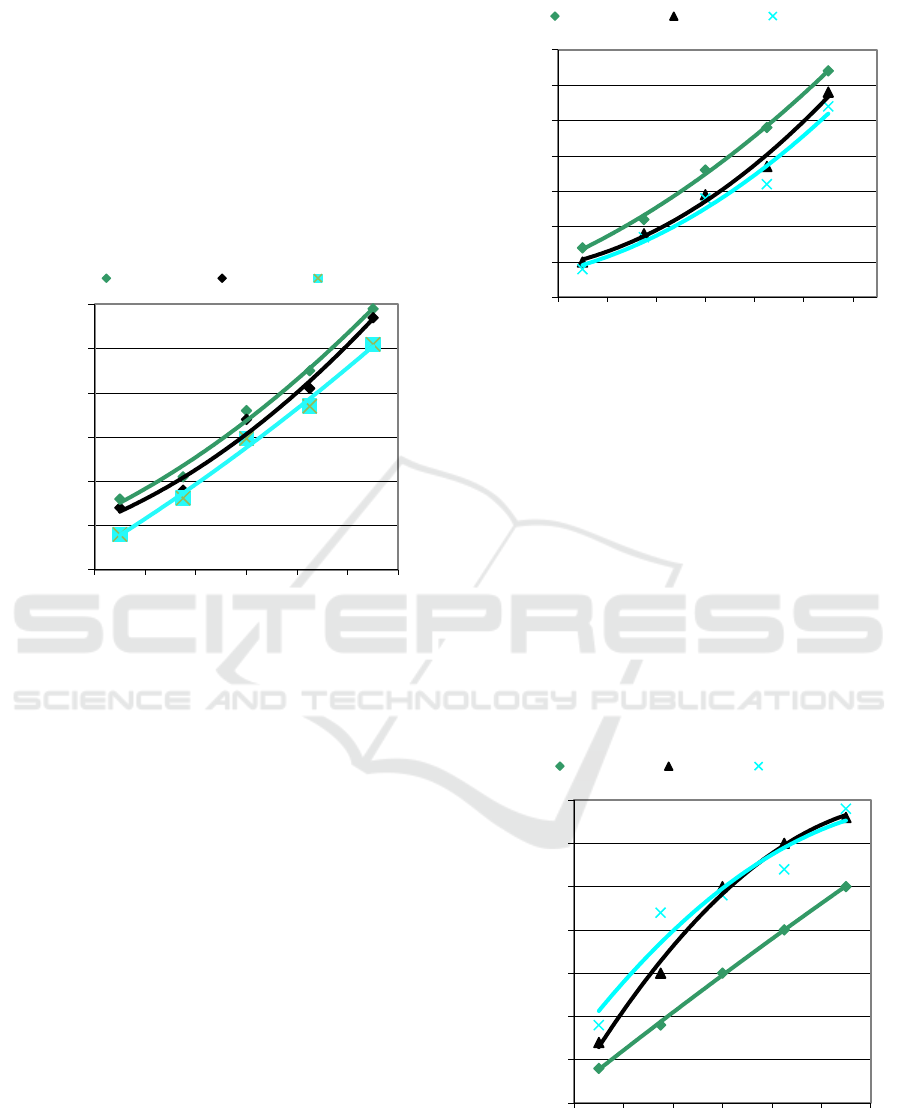

Effective Power: Effective power can be seen in Fig.

1. which shows that the use of pure diesel produces

greater power, but if the engine speed is increased, the

power produced in a mixture of 30% is closer to the

power produced by the use of pure diesel. at 3000 rpm

Diesel Engine Performance with Diesel and Biodiesel Fuel from VCO on the High Load

157

rotation pure diesel produces 31.7 HP of power and a

mixture of 30% 31.3 rpm, but at 4000 rpm rotation,

the power produced by pure diesel is 35.9 HP and a

mixture of 30% produces 35.8 HP of power, the

difference is getting smaller . This happens because

heating the fuel before it is injected into the

combustion chamber can reduce the viscosity so that

the combustion is easier. For a 40% mixture the

effective power produced is lower than the 30%

mixture, although if the engine speed is increased the

power produced also increases

Figure 1: Effective Power of blend diesel fuel VCO and

pure diesel fuel.

Thermal Efficiency: The thermal efficiency

generated by the use of a mixture of VCO and diesel

at a mixture of 30% is almost the same as the use of

pure diesel, in Fig. 2 it can be seen that with the

maximum load, the higher the engine speed, the

efficiency will increase. This happens because the

viscosity of the fuel has decreased to near the

viscosity of pure diesel due to heating so that it can

maximize fuel atomization and better combustion. at

a mixture of 40% it can be seen that the resulting

efficiency is lower.

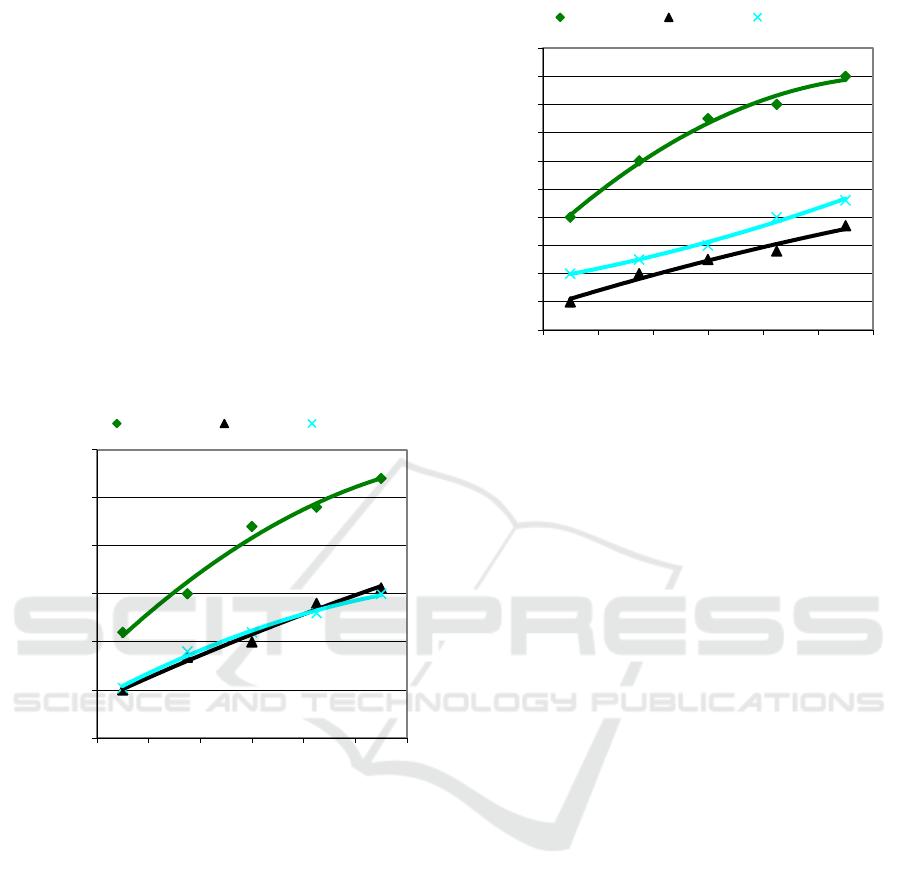

Fuel Consumption: Specific fuel consumption relates

to the mass flow rate of the fuel to the power generated

by the engine. In Fig. 3 it can be seen that with an

increase in the percentage of VCO by 30% in fuel, the

specific fuel consumption increases. This means that

the use of pure diesel is more efficient than the use of

biodiesel. This is caused by the calorific value of the

mixture of VCO and pure diesel which is lower than

the calorific value of pure diesel so that at high loads

and rotations the engine flows more fuel to run the

engine. in a mixture of 40% VCO it is more wasteful

than the use of pure diesel and a mixture of 30%.

Figure 2: Thermal Efficiency of a mixture of VCO with

diesel fuel and pure diesel fuel.

Fuel Consumption: Specific fuel consumption

relates to the mass flow rate of the fuel to the power

generated by the engine. In Fig. 3 it can be seen that

with an increase in the percentage of VCO by 30% in

fuel, the specific fuel consumption increases. This

means that the use of pure diesel is more efficient than

the use of biodiesel. This is caused by the calorific

value of the mixture of VCO and pure diesel which is

lower than the calorific value of pure diesel so that at

high loads and rotations the engine flows more fuel to

run the engine. in a mixture of 40% VCO it is more

wasteful than the use of pure diesel and a mixture of

30%.

Figure 3: Specific fuel consumption of mixture VCO with

pure diesel and pure diesel.

30

31

32

33

34

35

36

2900 3100 3300 3500 3700 3900 4100

Effective Power (HP)

Rotation (rpm)

Diesel Fuel 30% vco 40% vco

28

29

29

30

30

31

31

32

2900 3100 3300 3500 3700 3900 4100

Thermal Efficiency (%)

Rotation (rpm)

Diesel Fuel 30% vco 40% vco

0,245

0,25

0,255

0,26

0,265

0,27

0,275

0,28

2900 3100 3300 3500 3700 3900 4100

SFCe (kg/HP./h)

Rotation (rpm)

Diesel Fuel 30% vco 40% vco

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

158

CO Exhaust Emissions: at low speed Increasing

engine speed causes the amount of CO to be reduced

in all types of fuel used. but if the engine operates at

high speed and load, the opposite occurs, namely the

higher the engine speed, the CO will increase. in Fig.

4 it can be seen that by adding VCO to the fuel,

exhaust gas emissions will decrease when compared

to the use of pure diesel. This happens because VCO

does not contain materials that can form CO in the

exhaust gas. At a mixture of 40%, exhaust emissions

are almost the same as a mixture of 30% and if the

engine speed is increased the exhaust emissions will

also increase but the exhaust emissions of CO are less

than 30% if at maximum speed, the more VCO in

diesel fuel will significantly reduce exhaust

emissions, so the percentage of VCO in diesel fuel

needs to be increased

Figure 4: Percentage of CO exhaust gas of mixture VCO

with pure diesel and pure diesel.

Exhaust Gas Emissions of HC: HC are

hydrocarbons and are one of the dominant residual

fuel residues in the fuel so that the increase in engine

speed causes HC to also increase, in Fig. 5 when

viewed on each fuel, pure diesel fuel causes the

highest HC, while the lowest HC is in the 30% VCO

Mix. This is caused by the presence of a fuel heating

device installed in the engine which lowers the

viscosity of the fuel before use so that the atomization

becomes better which causes better fuel combustion.

in the 40% mixture there is still more HC because the

increase in VCO in the fuel causes the viscosity to

increase.

Figure 5: The amount of HC in exhaust gas from mixture of

VCO with pure diesel and pure diesel.

3.2 Discussion

The use of VCO as bio-diesel with a percentage of

30% and 40% is quite good judging from the results

of research conducted, although it is not the same as

the use of pure diesel. By adding VCO to pure diesel,

it is certain to increase the viscosity because the

viscosity of VCO is higher than pure diesel. Likewise

with the calorific value of the fuel mixture, because

the calorific value of diesel is higher than VCO, when

the two fuel materials are mixed, the calorific value

will be reduced. The fuel heater installed in the test

engine is quite helpful in reducing the viscosity

because heat can reduce the viscosity of the fuel. The

graph in Figure 1 shows that if the engine speed is

increased, the effective power increases for each fuel

consumption, the ratio between the use of pure diesel

and a mixture of 30% increases in balanced power

even though the use of pure diesel is still better but

the difference is small. In Figure 2 the efficiency

produced at a mixture of 30 and 40% is quite high and

close to the use of pure diesel, meaning that heating

the fuel before injection reduces the viscosity so that

the fuel bar atomization is better. Similarly, for

specific fuel consumption the use of pure diesel is

more efficient but the use of VCO biodiesel to

generate power but the use of 30% VCO is quite

economical and close to the use of pure diesel, this

can be seen in Figure 3. In Figures 4 and 5 the use of

VCO as biodiesel is quite profitable. because it can

reduce exhaust emissions, this is indeed the purpose

of using biodiesel, although if the engine speed is

increased the exhaust emissions also increase this is

0,2

0,225

0,25

0,275

0,3

0,325

0,35

2900 3100 3300 3500 3700 3900 4100

CO (%)

Rotation(rpm)

Diesel Fuel 30% vco 40% vco

43

44

45

46

47

48

49

50

51

52

53

2900 3100 3300 3500 3700 3900 4100

HC ( PPM)

Rotation(rpm)

Diesel Fuel 30% vco 40% vco

Diesel Engine Performance with Diesel and Biodiesel Fuel from VCO on the High Load

159

due to the amount of fuel used due to high rotation

and high load. In previous studies, due to low revs and

light loads, the emission reduction was only slightly,

but if the rotation and load were high, it significantly

reduced CO and HC exhaust emissions.

4 CONCLUSIONS

In this study, VCO biodiesel was used as a diesel

mixture without further processing, but the fuel heater

was installed on the test machine before spraying.

Then it can be concluded as follows:

- Biodiesel from VCO is very good as a mixture of

diesel fuel for diesel engines that work at high

loads, because if the rotation is increased, the

power and efficiency of the engine also increase.

- The addition of VCO to pure diesel can

significantly reduce CO and HC exhaust

emissions because with the presence of VCO

that does not contain hydrocarbons, the exhaust

gas will be cleaner.

- The use of VCO as biodiesel needs to be

supported and increased because the raw

materials are abundantly available, but the most

important thing is to find a way to increase the

percentage of VCO in diesel fuel without

reducing engine performance.

ACKNOWLEDGMENT

This research was funded by the State Polytechnic of

Kupang, therefore we are grateful its contribution.

REFERENCES

Palinggi, (2020). Optimizing The Performance Of Diesel

Engine With Dexlite and Biodiesel Fuel From Local

Virgin Coconut Oil. Proceeding Internatuional

Confrence ICAST, Padang 18-20.

Madhava, Sudhakar (2016) Peformance of DieselEngine By

Using Biodiesels. International Journal of Engineering

Trends and Advance Sciences.( IJETAS) 49-63.

Supriyana, (2015). Performance of Diesel Engine With

Fuel Heating System. SYMETRIC Journal Vol. 6.

No.2.

Palinggi, (2019). The Use Of Used Oil From Treatment

With Absorption and Pyrolysis As A Mixed of Diesel Oil

To Performance Diesel Engine. Proceding International

Confrence ICECS, Labuan Bajo: 18-19.

Elma, (2016). The Process of Making Biodiesel from a

Mixture of Coconut Oil and Used Cooking Oil. ULM

Energy Conversion Journal: 9-19.

Kumar, (2018). Experimental Investigation of Combustion

Characteristics of Mahua Oil Biodiesel-diesel Blend

Using a DI Diesel Engine Modified with EGR and

Nozzle Hole Orifice. Biofuel Research journal. 863-

871.

Bhikuning. (2013). Analysis of Engine Performance With

Biodiesel Made from Virgin Coconut Oil in Diesel

Engines. Journal of Energy and Manufacturing vol. 6

No. 2: 95-100.

Nazir, (2017). The Effect of Adding Bio-Solar from Virgin

Coconut Oil to Diesel on the Smoke Thickness of a Four

Stroke Diesel Engine. Journal of JIT UNP Vol. 1 No. 1:

1-5.

Indartono, (2016). The Effect of Use of Fuel Heating

Equipment on Fuel Use and Exhaust Gas Emissions for

Mitsubishi Diesel Motor 4D34-2A17. Journal of

Traction Vol. 16 No.2: 66-74.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

160