The Effect of Condenser Cooling to Coefficient of Performance

(COP) and Electrical Consumption on AC Split

Ida Bagus Gde Widiantara

a

and I Wayan Suastawa

b

Politeknik Negeri Bali Kampus Bukit Jimbaran, Kuta Selatan Badung, Indonesia

Keywords: Modified Condenser, Coefficient of Performance (COP), Electrical Consumption, Condensed Water.

Abstract: The refrigeration equipment currently available is a split AC with some capacity. One of the processes that

occur in cooling machine is condensation which produces water and hot refrigerant. Inside the condenser,

some of refrigerant heat must be removed with the help of a blower to avoid the damage of compressor. Seeing

this, the condensed water from the evaporator will be reused as a cooling fluid. The purpose of this research

is to determine the coefficient of performance (COP) and electrical consumption without and using an

additional condenser cooling system. The test was carried out by modified condenser split AC 1 Pk R-410a

by installing 9 nozzles, a DC pump where the 3 nozzles horizontal and 3 nozzles vertical. The independent

variables of this test are the 3 nozzles horizontal position and the spraying time is 1, 2 and 3 minutes. The

room used is a 6 x 6 x 3.5 m as cooling load. From the results, it was found that there was an increase in the

performance of the cooling machine with the addition of a cooling system of about 34%, while in the electrical

consumption, there was a slight decrease about 5%.

1 INTRODUCTION

Indonesia as a tropical country that gets sunlight

almost all year round. This condition has an impact

on the air temperature and humidity which is quite

high. Along with the human desire to more comfort,

the use of cooling systems, air conditioning (AC) for

comfort is increasing. In its application, this system is

used in various aspects of life, ranging from the food

industry, chemical industry, hotels, hospitals,

aviation, shipping and even in households.

One type of cooling system that we often find is a

split cooling system where the evaporator will be

placed inside of the room but the compressor,

condenser and the expansion valve are outside which

are widely used in households. Generally air

conditioning generally work on the principle of vapor

compression, where there are several main

components, such us compressor, condenser,

expansion valve and evaporator. These 4 components

form a system to condition the air of a room. In the

process, there are two main processes i.e. heat transfer

processes, the process of absorption of heat in the

evaporator and heat dissipation in the condenser

a

https://orcid.org/0000-0001-7349-9146

b

https://orcid.org/0000-0001-9290-3298

where the heat in the refrigerant is pushed into the

environment using air and assisted by blower, where

the condensed water from the evaporator will be

discharged through the exhaust pipe. This process

will not take place perfectly when the outside air

temperature is high enough (Patel and Sheth 2015) so

that an additional system is needed to cool the

condenser and reduce compressor work. In direct

evaporative system, water evaporates directly in the

air stream, producing an adiabatic process of heat

exchange in which the air-dry bulb temperature

decreases as its humidity increases. Thus, the amount

of heat transferred from the air to the water is the

same as the one employed in the evaporation of the

water. (Porumb, Bălan, and Porumb 2016) said that

the evaporative system allowed the reduction of

energy consumption for the fresh air cooling with

almost 80% and also (Patel and Sheth 2015) mention

that the evaporative system is ecofriendly and is not

associated with ozone layer depletion problem

because it does not need any refrigerant. Seeing this,

the researcher wants to make an innovation, reducing

the use of electric power, but the comfort can still be

fulfilled.

Widiantara, I. and Suastawa, I.

The Effect of Condenser Cooling to Coefficient of Performance (COP) and Electrical Consumption on AC Split.

DOI: 10.5220/0010939300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 23-26

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

23

Data on electricity usage, especially in its use for

air conditioning, has increased quite sharply. The

Executive Director of the IEA (International Energy

Agency) was said in Asia, respectively ASEAN, that

the use of air conditioners had triggered a higher

global demand for electricity. (Alhamdo, Theeb, and

Abdulhameed 2015) also mention that in air cooled

condensers, the power consumption is a major issue

in vapor compression cycle. The power consumption

concern increased much more if the air-cooled

condensers work in area with very high ambient

temperature (between 50-60 ⁰C). Seeing these

phenomena, the researchers tried to further examine

the use of evaporative cooling systems in Air

Conditioning. From a previous study (Ridhuan and

Juniawan 2014) said that the highest coefisient of

performance (COP) value of cooling with only

blower (before modified) was 6.44 while the highest

COP after being modified with evaporative cooling

systems was 15.43. So it can be said that cooling with

water is better than air conditioning. In the otherside

(Rif and Km 2016) also said that a decrease in

electricity consumption of 0.5 kW without a cooling

load and with a loading of 2000w reduced compressor

work by 0.4 kW. This proves that the potential for

using water as a cooling medium is quite large. In any

subsequent research by (Alhamdo et al. 2015)

(Silalahi, Ajiwiguna, and Kirom 2018), (Ardita and

Subagia 2018) that the use of condensate water can

reduce the temperature of the refrigerant entering the

condenser by 2.2

o

C and decrease the use of electric

power by 0.5 kW with 2000W cooling load. So, The

purpose of this research is to design a system that is

able to reduce the use of electricity consumed by a

compressor split AC

2 METHODOLOGY

The design of this research is to modify the AC split

condenser by adding an additional system consisting

of a water reservoir, condensate water, pump and

nozzle as shown in Figure 1 to see the effect of

additional cooling on AC split performance. The

placement of this additional cooling system is behind

the condenser / in front of the cooling blower in the

form of water spray through the nozzle. The water

used is the result of air condensation from the air

conditioner itself, collected, pumped and reused to

cool the condenser in the same way.

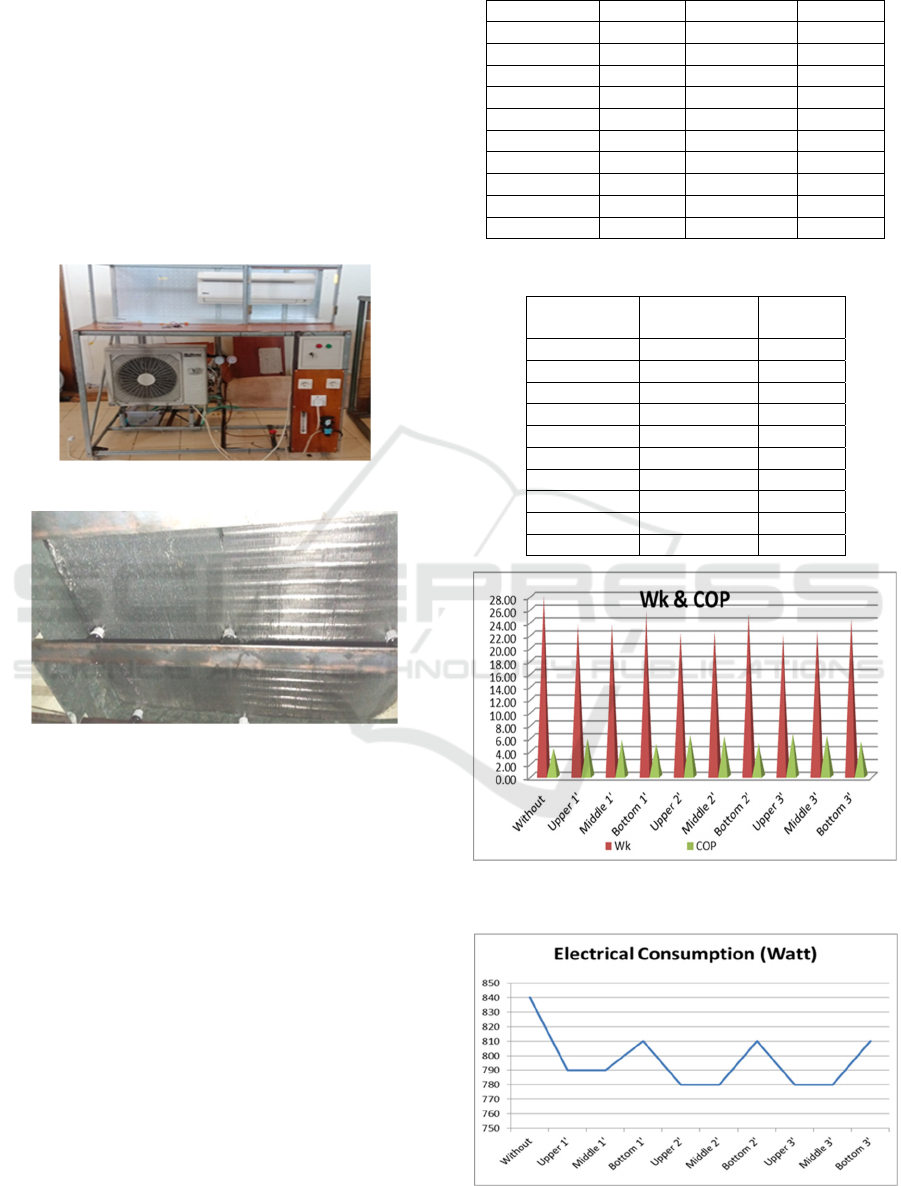

Figure 1: Design.

Figure 2: Measurement position design.

The test will be carried out based on variations in

horizontal position of the nozzle and the time of

spraying. The 3 nozzles horizontal position means;

top, middle, and bottom row. The spraying time

variation is the length of spraying time the condenser

is sprayed, consecutively 1, 2 and 3 minutes. For the

data collection will use several instruments, such us

thermocouple to take temperature data, voltmeter to

take current and voltage data and pressure gauge

which is directly added on the refrigeration machine

to determine the low and high pressures that’s occur.

The test conditions are:

1. Average room temperature 30

0

C

2. Room: Applied Refrigeration Laboratory,

Mechanical Engineering, Bali State

Polytechnic

3. Condition of room: 6 x 6 x 3.5, 2 doors glass,

8 glass windows, 1 x 2 m equipped with

curtain

4. Average voltage: 225 Volt

5. Stuffs: 3 bookcases with books inside and

several other tools

6. Cos Ø : 0.8

7. Data taken every 5 minutes for 1 hour

8. Layout of nozzle as figure 3

Figure 3: Layout of nozzle.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

24

3 RESULT AND DISCUSSION

The results that have been achieved are a set of test

equipment consisting of 1 set of split AC 1 Pk,

refrigerant R410a, 840 watts, low pressure 160-170

psi, 4.6 Ampere where these results are in accordance

with the specifications of this cooling machine. The

installation of the pressure gauge is to determine the

high pressure and low pressure that occurs in the

system and the thermocouple that has been installed

to determine the temperature at each position properly

on the test instrument as shown in Figures 4 and 5.

Figure 4: Test equipment.

Figure 5: Nozzel.

The next step is to collect data by measuring pressure,

temperature, voltage and current. To see the

differences that occur, several variations were tested.

The variations made for the position of the nozzle and

time of spraying where 3rd nozzles will be placed

horizontally. For the spraying time, 3rd variations

horizontal will be carried out, namely 1, 2 and 3

minutes. The test will take place with 9 variations,

when the 1st test without additional coolant to test the

initial ability of the cooling machine, 2

nd

, 5

th

and 8

th

for the top horizontal nozzle with a spraying time of

1 minute, 3

rd

, 6

th

and 9

th

for the top horizontal nozzle

with a spraying time of 2 minutes and 4

th

, 7

th

and 10

th

for the top horizontal nozzle with a spraying time 3

minutes.

From the results of the tests carried out, the results

are as shown in the table and figure below:

Table 1: Comparison ER, Wk and COP.

Condition ER Wk

(

k

j

/k

g)

COP

Without 122.99 28.13 4.37

U

pp

er 1 138.86 23.6 5.88

Middle 1 136.71 23.66 5.78

Bottom 1 130.33 25.74 5.06

Upper 2 144.39 22.40 6.44

Middle 2 141.39 22.68 6.23

Bottom 2 130.56 25.31 5.16

U

pp

er 3 145.77 22.02 6.62

Middle 3 143.61 22.62 6.35

Bottom 3 133.40 24.56 5.43

Table 2: Comparison Electrical Consumption & COP.

Condition Electrical

Consumption

COP

Without 840 4.37

U

pp

er 1 790 5.88

Middle 1 790 5.78

Bottom 1 810 5.06

Upper 2 780 6.44

Middle 2 780 6.23

Bottom 2 810 5.16

U

pp

er 3 780 6.62

Middle 3 780 6.35

Bottom 3 810 5.43

Figure 6: Comparison Work of Compression (Wk) &

Coefficient of Performance (COP).

Figure 7: Electrical Consumption.

The Effect of Condenser Cooling to Coefficient of Performance (COP) and Electrical Consumption on AC Split

25

Based on table 1 and Figure 6 above, it is known

that the COP value of the 1 Pk R410a split AC system

before the additional cooling system on the condenser

is turned on the COP result of 4.37. After the

additional cooling system is turned on, the horizontal

nozzle on top, middle and bottom rows for 1 minute

spray the COP results of 5.88, 5.78 and 5.06. In the

5th variation where the additional cooling system will

spray water for 2 minutes, the COP is 6.44, 6.23 and

5.16, respectively. In the 8th variation where the

additional cooling system will spray water for 3

minutes, the COP values are 6.62, 6.35, and 5.43. The

changes the values of COP with the addition of

cooling system in condenser are quite significant due

to the reduced compression work which affects the

COP value.

Based on Figure 7, it’s known that the power

consumption of the 1 PK R410a split system before

the additional condenser cooling system is turn on,

the power consumption is 0.84 watts and after the

condenser additional cooling system is turn on in the

top and middle horizontal nozzles for 1 minute, the

power consumption decrease to 0.79 watts but the

value of power consumption is 0.81 watts at the

bottom row horizontal of the nozzle. Similarly, for

spraying 2 minutes, the top row and the middle

horizontal nozzles are 0.78 watts but in the bottom

row it increases to 0.81 watts. In 3 minutes of

spraying, the power consumption is 0.78 watts on the

top and middle horizontal nozzles while the bottom

row is 0.81. So in general the value of power

consumption after the condenser auxiliary cooling

system is turned on is smaller than when the

condenser auxiliary cooling system is turned off.

These changes occur because the compressions work

(Wk) decreases where the compression work is the

work done by the compressor using electric power.

4 CONCLUSIONS

Within the limitations of materials and time to

experiment, the results obtained in this work, can be

summarized that there is an increase in AC

performance by 34% in the additional cooling system

working especially on the horizontal upper nozzle

which sprays water for 1, 2 and 3 minutes with a

decrease in electrical consumption of 3Watt hour in

average. From the results above, the test will be

continued by testing the spray with the nozzle in the

vertical direction and adding cooling fins to the

compressor.

REFERENCES

Alhamdo, Mohammed H., Maathe A. Theeb, and Jaafar J.

Abdulhameed. 2015. “Using Evaporative Cooling

Methods for Improving Performance of an Air-Cooled

Condenser.” Universal Journal of Mechanical

Engineering 3(3):94–106. doi:

10.13189/ujme.2015.030304.

Ardita, I. N., and I. W. A. Subagia. 2018. “The Application

of Condensate Water as an Additional Cooling Media

Intermittently in Condenser of a Split Air

Conditioning.” Journal of Physics: Conference Series

953:012059. doi: 10.1088/1742-6596/953/1/012059.

Patel, Rupal, and Beena Sheth. 2015. “Evaporative Cooling

of Water for Indirect Air Cooling.”

Porumb, Bogdan, Mugur Bălan, and Raluca Porumb. 2016.

“Potential of Indirect Evaporative Cooling to Reduce

the Energy Consumption in Fresh Air Conditioning

Applications.” Energy Procedia 85. doi:

10.1016/j.egypro.2015.12.224.

Ridhuan, Kemas, and I. Gede Angga Juniawan. 2014.

“PENGARUH MEDIA PENDINGIN AIR PADA

KONDENSOR TERHADAP KEMAMPUAN KERJA

MESIN PENDINGIN.” Turbo : Jurnal Program Studi

Teknik Mesin 3(2). doi: 10.24127/trb.v3i2.11.

Rif, Muhammad, and Kampus Bina Widya Km. 2016.

“Potensi Air Kondensat Sebagai Media Pendingin

Untuk Aplikasi Modul Evaporative Cooling Terhadap

Performansi AC Split 1 PK.” 3:5.

Silalahi, Benny Sarihot Tua, Tri Ayodha Ajiwiguna, and M.

Ramdlan Kirom. 2018. “Studi Pendingin Evaporatif

Untuk Pendinginan Air.” eProceedings of Engineering

5(3).

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

26