Performance and Energy Consumption Analysis of Freezer Machines

for Mobile Ice Cream Sellers using Eco-friendly Refrigerant MC134

Dewa Made Susila

1a

,

Daud Simon Anakottapry

1b

, Wayan Adi Subagia

1c

, Putu Wijaya Sunu

2d

and Nengah Ardita

2e

1

Refrigeration and Air Conditioning Study Program, Bali State Polytechnic,

Kampus Bukit Jimbaran-Kuta Selatan-Badung, 80364, Indonesia

2

MEP Utility Engineering Technology Study Program, Bali State Polytechnic,

Kampus Bukit Jimbaran-Kuta Selatan-Badung, 80364, Indonesia

{wijayasunu, nengahardita}@pnb.ac.id

Keywords: Freezer, Performance, Energy Consumption, Refrigerant MC134.

Abstract: Ice cream is widely sold by mobile ice-cream sellers. This study aims to determine the performance and

energy consumption of a freezer machine for mobile ice-cream sellers using environmentally friendly

refrigerant MC134 with a compressor capacity of 1/10 HP. This research was conducted using an

experimental method. The size of the capillary tube using the Cap Tube 1.0.8.0 application program. The

evaporator used is a bare tube type that is formed by a coil and wrapped around an ice cream box. The test is

carried out by measuring the refrigerant temperature and pressure, the temperature in the ice cream box, and

the electric current and voltage in the system. The results of the analysis of performance and energy

consumption will also be compared if the system uses HFC134a refrigerant. From the test results, it was found

that the optimum mass loaded in the system for refrigerant MC134 was 155 grams and the optimum mass for

R-134a was 202 grams. The use of refrigerant MC134 is more efficient by 23.3%. The COP for MC134

refrigerant is 3.1 while the COP for R134a is 2.7. Energy consumption for MC134 is 83 kJ while for R134a

it is 67.8 kJ.

1 INTRODUCTION

Ice cream is a frozen form of ice that is made by

freezing a mixture of dairy products, sugar,

stabilizers, emulsifiers, and other ingredients. Ice

cream food is often used as a dessert. Ice cream is no

stranger to all ages because almost everyone likes ice

cream. To keep the ice cream cold and frozen, the

mobile ice cream seller uses shaved ice cubes which

are then placed around the ice cream container. But

now, blue ice or ice packs have started to be used to

keep the ice cream sold around cold and frozen.

However, the material used as a cooler over time will

certainly decrease in temperature so that the ice cream

a

https://orcid.org/0000-0002-2567-9932

b

https://orcid.org/0000-0001-7856-6512

c

https://orcid.org/0000-0001-9261-3549

d

https://orcid.org/0000-0002-6915-0475

e

https://orcid.org/0000-0003-3391-2404

temperature will also drop.

Therefore, it is necessary to use refrigeration

technology to keep the ice cream condition stable,

namely using a refrigeration machine such as a

freezer. Conventional refrigeration machines use a

vapor-compression refrigeration cycle. The use of

conventional refrigerants that have an impact on

ozone depletion and global warming should no longer

be produced.

The world today is looking for refrigerants that do

not contribute to global warming and ozone layer

depletion. Baharudin (2018) conducted a performan-

ce test on a fruit showcase machine using R134a and

MC134 working fluids. From the test results, it is

concluded that with R134a the actual COP = 2,528,

Susila, D., Anakottapry, D., Subagia, W., Sunu, P. and Ardita, N.

Performance and Energy Consumption Analysis of Freezer Machines for Mobile Ice Cream Sellers using Eco-friendly Refrigerant MC134.

DOI: 10.5220/0010939200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 17-22

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

17

and by using MC134, the actual COP = 2,710. (BC

Purnomo et al., 2019) conducted a study of double

expansion valves installed in parallel machines with

vapor compression refrigeration cycles using MC134

by varying the cooling load 0.23; 0.33; and 0.39 kg/s

and was observed while the system was operating to

steady conditions, giving a positive effect on the

refrigeration effect and COP. The highest

refrigeration effect produced was 257 KJ/kg and COP

was 5.84. In his previous research (BC Purnomo et al.

(2017) concluded that the use of MC134 has the best

refrigeration system performance -180

o

expansion

valve adjustment where in that position has a low

compression work value so that the compressor work

becomes light and does not require a large amount of

energy when operating.

Small-scale refrigeration machines such as

freezers and refrigerators currently still use R134a

refrigerant. This type of refrigerant belongs to the

HFC group with a high global warming potential

(GWP) of 1300 (DV Raghunatha Reddy et al, 2016).

The study was conducted to determine the effect of

evaporation temperature on the performance of air

conditioning machines using R134a and MC134

refrigerants at optimal refrigerant filling pressure.

The result showed that the optimal filling pressure for

R134a is 20 bar-g, and for MC134 is 25 bar-g. Based

on the parameters, the effect of refrigeration

increased by 106.43%, compressor work increased by

70.22%, compressor power decreased by 12.64%,

electrical energy consumption decreased by 14.69%,

and COP increased by 21.37% for MC134 when

compared to R134a (Hendri et al, 2014).

Heriyanto Rusmariyadi et al, 2019 in their

research on a comparative study of the performance

of the 1/5 PK freezer with R-134a and “Musicool”

(MC134) concluded that the retrofit from R-134a to

Musicool MC-134 is very feasible and feasible to use

without changing the supporting components of the

system. His research also resulted in a much faster

decrease in temperature than R-134a, which was 30%

faster for a setpoint temperature of -18

o

C.

Hydrocarbon refrigerant (HC) has better performance

than refrigerants from the HCFC and HFC groups. In

the European Union (EU), HFCs are currently being

discontinued due to their high GWP values (J.H. Koh

et al, 2017).

Hydrocarbon refrigerants have good potential to

completely replace HCFCs as refrigerants in the

future because their performance is in line with those

of HCFC refrigerants and the flammability problem

can be overcome by the use of effective designs and

improved safety. (Junghung Koh et al, 2017). The use

of natural refrigerants such as CO2, NH3, and

hydrocarbons such as R290, R600, R600a, and

hydrocarbon mixtures are possible solutions for

conventional refrigerants and are used efficiently in

many systems. (Madhu Sruthi Emani, et al, 2018).

Natural refrigerants such as hydrocarbons are a new

alternative to conventional CFC, HCFC, and HFC

refrigerants (Parashurama S.C. Et al, 2019).

One type of hydrocarbon refrigerant, produced by

Pertamina Processing Unit III in collaboration with

the Research & Laboratory Processing Division of the

Pertamina Downstream Directorate Head Office is

Musicool 134 (Puji Saksono, Gunawan, 2019).

Musicool 134 which is abbreviated as MC134 is a

refrigerant replacement for R134a. Hydrocarbon

refrigerant is an environmentally friendly refrigerant

because it does not harm global warming or the

depletion of the ozone layer. MC134 is a mixed

hydrocarbon refrigerant between Propane (R290) and

Iso Butane (R600).

The flammability of hydrocarbons requires a full

understanding of their safe use in refrigerators (Rene

Van Gerwen et al, 2008). The performance of

hydrocarbons is very similar to that of HCFCs and the

problem of flammability can be easily overcome by

the use of an effective design. Its use can be facilitated

by the adaptation of certain standards and properly

enforced laws.

(Tatang Hidayat, 2019) conducted a study on the

potential for obtaining electrical energy savings in

refrigerators by converting from R-134a to MC134

hydrocarbons to be allocated in simple type houses.

From the results of his research, it was concluded that

the refrigerant conversion in the refrigerator from R-

134a to MC134 could be obtained by saving 20% of

electrical energy.

2 STUDY OF LITERATURE

2.1 Vapor Compression Refrigeration

Cycle

This freezer machine for ice cream sellers uses a

vapor-compression refrigeration cycle. The main

components of the vapor-compression refrigeration

cycle are the compressor, condenser, expansion

device, and evaporator. The important performance

parameters of the vapor compression refrigeration

cycle are the coefficient of performance and energy

consumption.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

18

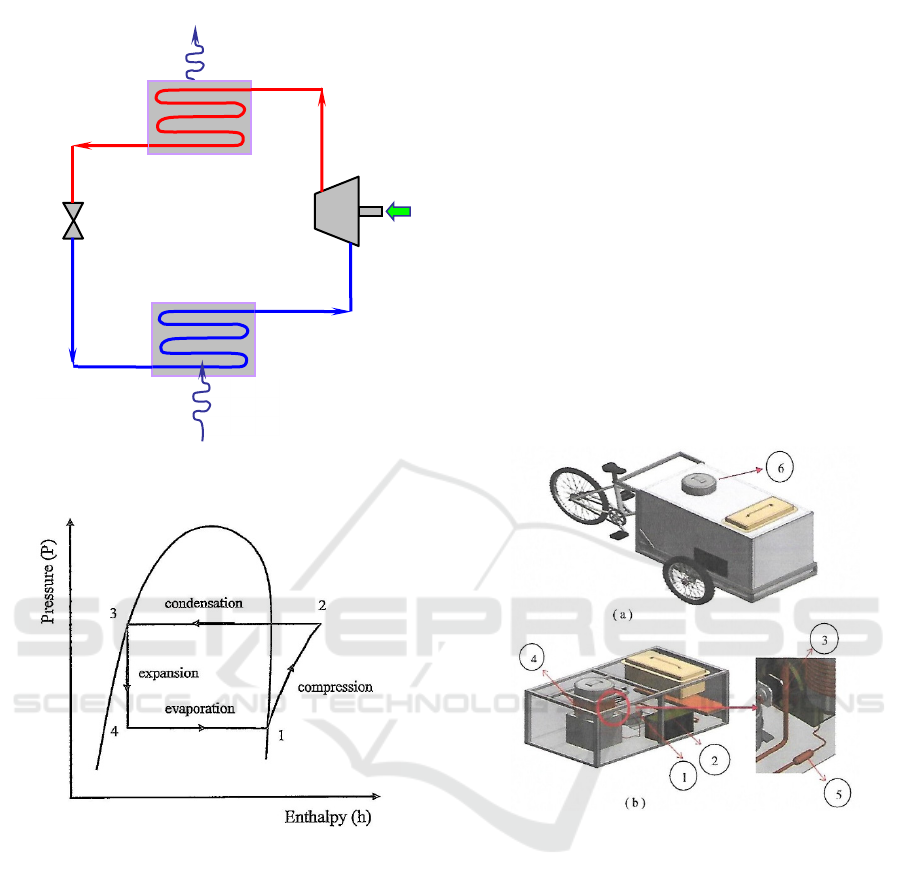

Figure 1: Work diagram of vapor compression refrigeration

cycle.

Figure 2: Pressure-enthalpy diagram of the vapor-

compression refrigeration cycle.

2.1.1 Coefficient of Performance (COP)

The coefficient of performance is the amount of

useful energy, namely the effect of refrigeration

divided by the work required by the system, namely

the work of compression. Mathematically, COP is

expressed by the formula:

COP = (h

1

– h

4

) / (h

2

– h

1

) (1)

2.1.2 Energy Consumption (E)

To calculate the energy consumption (E) is used the

formula:

E = [(V x I x Cos φ) x t ] / 1000 (kWh) (2)

3 RESEARCH METHODS

This research was carried out through an

experimental test on a prototype mobile ice cream

freezer designed with a compressor capacity of

1/10HP using R-134a, and MC134 refrigerant. The

size of the capillary tube is determined using the

Captube 1.0.8.0 application program where the

diameter and length of the capillary tube are found to

be 0.6096 mm in inside diameter, and 2,25 m long.

The evaporator used in this freezer has a heat

transfer area of 0.47 m

2

with an outer diameter of

9.525 mm copper pipe, and a pipe length of 15.8

meters. The evaporator pipe is formed into a coil and

wrapped around the outer wall of the ice cream box.

Pressure and temperature were measured at 4

measurement points that were already installed on the

prototype mobile ice cream freezer.

No Parts

1 Compresso

r

2 Condenso

r

3 Capillary tube

4 Evaporato

r

5 Filter/drye

r

6 Ice-cream box

Figure 3: Mobile ice cream freezer machine design.

For temperature, the measurements are added at 2

more points, namely in the middle of the evaporator,

and in the middle of the condenser. Pressure is

measured using an oil pressure gauge in Psi units.

While the temperature is measured with a type K

thermocouple which is connected to the temperature

display in Celcius units. To determine the COP of R-

134a, the Mollier Chart 1.2.0.3 application program

will be used, while to determine the COP of MC-134

using the P-h diagram of MC134.

Exp. device

q

c

evaporator

w

compressor

condensor

2

q

e

3

1

4

Performance and Energy Consumption Analysis of Freezer Machines for Mobile Ice Cream Sellers using Eco-friendly Refrigerant MC134

19

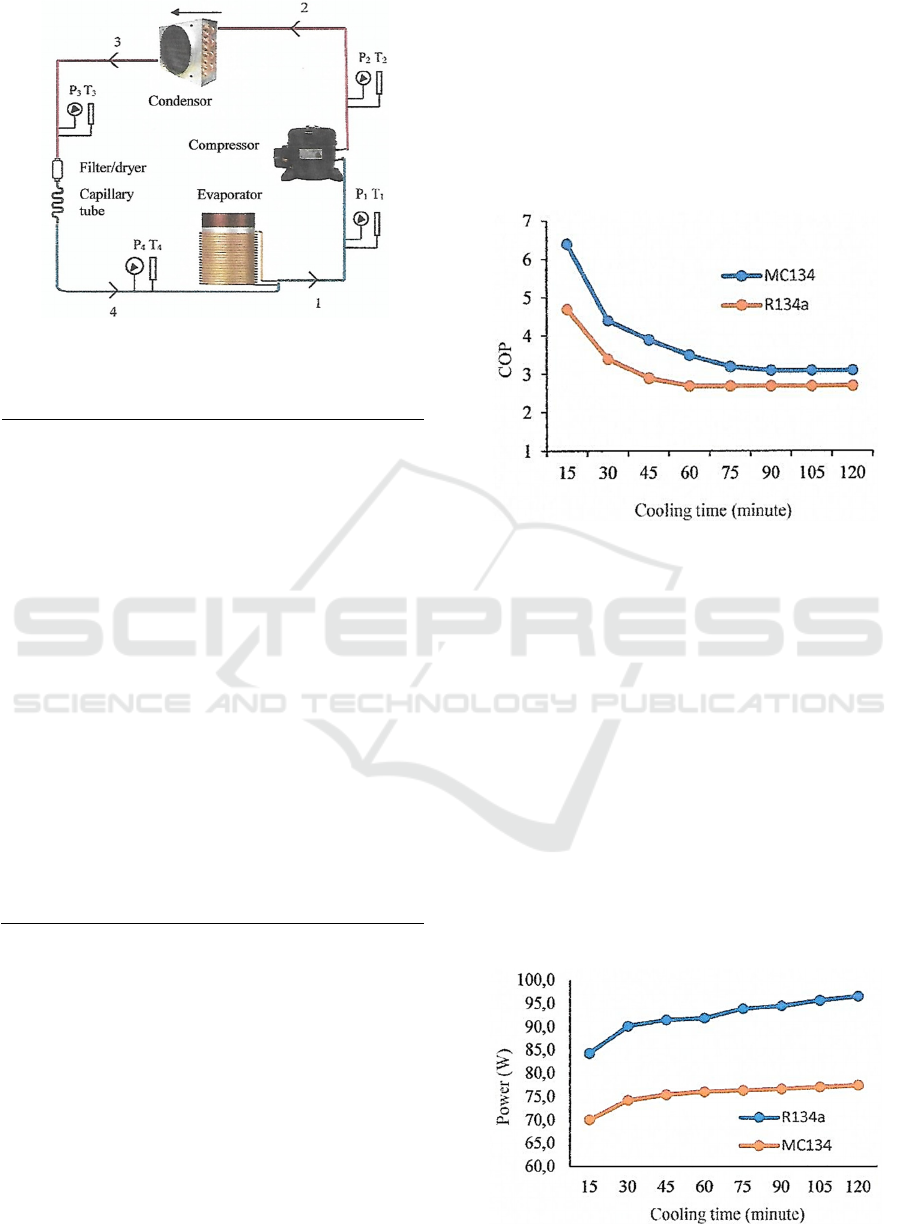

Figure 4: Piping diagram and measuring instrument set up.

Table 1: Technical specifications of mobile ice cream

freezer machine.

1

2

3

4

5

Total measurement

(LongxWidexHeight)

Condenser

Type

Outside diameter

Number of stages

Number of rows

Compressor

Type

Merk

Model

RLA

FLA

Refrigerant

Voltage (V)

Frequency (Hz)

Evaporator

Type

Material

Outside diameter

Length

Capillary Tube

Inside diameter

Length

(2250x100x112) mm

Finned-tube

9.525 mm

7

2

Hermetic

Tecumseh

TH830JH-092-A6

7.5

0.7

R134a

220

50

Coil

Copper

9.525 mm

15,8 m

0,6096 mm

2,25 meter

4 RESULTS AND DISCUSSION

Because this MC134 hydrocarbon refrigerant is used

as a substitute for R134a refrigerant, in addition to

testing the MC134 hydrocarbon refrigerant, testing is

also carried out on R-134a refrigerant. Both types of

refrigerants were tested at the optimum refrigerant

filling pressure.

From the testing of the two types of refrigerants

on the freezer machine for mobile ice-cream sellers,

the optimum mass of refrigerant HFC-134a filled into

the system is 202 grams while the optimum mass for

MC134 refrigerant is 155 grams. Judging from the

mass of the refrigerant, the optimum mass of MC134

is equal to 76.7% of the optimum mass of HFC-134a.

The test results in the form of system performance

and energy consumption will be explained in the

graph below.

4.1 Variation of COP and Cooling Time

Figure 5: Variation of COP and cooling time.

From Fig. 5 above, it can be seen that the curves for

R-134a and MC134 at the beginning of cooling the

COP curve are larger. However, the longer the

cooling time the COP curve decreases and tends to be

constant after 60 minutes. This is because the longer

the cooling time the evaporator temperature continues

to decrease until it reaches a temperature of -19

o

C.

The average COP for R134a was 2.7 and the COP for

MC134 was 3.1. The curves for R-134a and MC134

look identical, so it can be said that MC134 is very

suitable to be used as a substitute for R-134a. This is

also in line with research conducted by Heriyanto

Rusmariyadi et al, 2019.

4.2 Variation of Electric Power and

Cooling Time

Figure 6: Variation of electric power and cooling time.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

20

From Fig. 6 above, it can be seen that at the beginning

of cooling the required power using refrigerant R-

134a and MC134 is smaller. This is because the

compression ratio is still small, but over time, with

increasing cooling time, the power required tends to

increase. Up to 75 minutes the increase in power has

slowed down and tends to reach a constant value. The

average power required by the compressor for R-134a

is 92.2 W while for MC134 it is 75.3 W. So by using

MC134 refrigerant the use of electrical power is

18.8% more efficient. The results of this study are in

line with the results of research from various sources

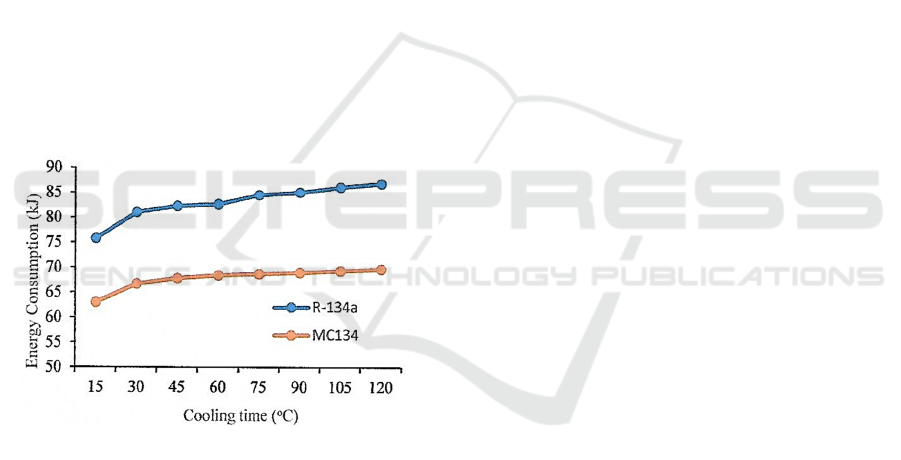

4.3 Variation of Energy Consumption

and Cooling Time

From Fig. 7 below, it can be seen that the curve of

energy consumption and cooling time is identical to

the curve of electric power with cooling time (fig. 6).

This is because the calculation of energy consumption

depends on the electrical power and the length of the

test time. So the average energy consumption using

refrigerant R-134a is 83 kJ while using refrigerant

MC134 is 67.8 kJ.

Figure 7: Variation of energy consumption and cooling time.

5 CONCLUSION

Hydrocarbon refrigerant is very appropriate to be

used as a substitute for synthetic refrigerants such as

HFC and HCFC because it has better performance

and has no impact on global warming. Refrigerant

MC134 which is filled into the system has a lower

mass compared to R134a which is 23.3% smaller so

that the compressor work is lower.

COP of refrigerant

MC134 is 3.1 while R134a is 2.7. Energy

consumption of refrigerant MC134 is lower than

R134a which is 28%.

So refrigerant MC134 is very

appropriate to be used as a replacement refrigerant

from R134a.

REFERENCES

Baharudin. 2018. Perbandingan Performansi Pada Mesin

Showcase Buah Menggunakan Fluida Kerja R134a dan

MC134. Jurnal Petra, Volume 5, No. 2, ISSN: 2460-

8408, Juli – Desember 2018.

BC Purnomo, Muji Setiyo, Budi waluyo, Saifudin, Noto

Widodo. (2019). Characteristics of Vapor Compression

Refrigeration System with Parallel Expansion Valves

using Refrigerant Musicool134. The 2nd International

Conference on Engineering and Applied

Technology/IOP Conf. Series: Materials Science and

Engineering 674 (2019) 012006.

BC Purnomo, Setiyo, M. (2017). Karakteristik Sistem

Refrigerasi Kompresi Uap Dengan Refrigeran

Campuran Musicool 134 - CO

2

. Jurnal Teknologi,

UNMUH. Jakarta.

DV Raghunatha Reddy, Bhramara Panitapu. 2016.

Hydrocarbon Refrigerant Mixtures as an Alternative to

R134a in Domestic Refrigeration System: The State-of-

the-Art Review.

https://www.researchgate.net/publication/302435899.

Hendri, Prayudi, Roswati Nurhasanah. (2014). Studi

Eksperimental Pengaruh Temperatur Evaporasi

Terhadap Unjuk Kerja Mesin Pendingin Dengan

Refrigeran R134a dan MC134. Proseding Seminar

Nasional Tahunan Teknik Mesin XIII (SNTTM XIII),

Depok 15-16 Oktober 2014.

Heriyanto Rusmaryadi, Iskandar Badil, Abdul Mu’in, Beno

Kharisma. (2019). Studi Perbandingan Kinerja Freezer

1/5 PK Dengan R134a dan Musicool (MC-134).

Turbulen: Jurnal teknik Mesin, Vol. 2, No. 2, hal. 68-74

J. H. Koh, Z. Zakaria, Veerasamy D,. (2017). Hydrocarbon

as Refrigerants – A Review. Asian Journal on Science

and Technology for Development.

Junghung Koh, Zaiinal Zakaria, Devaraj Veerasamy. 2017.

Overview of the Use of Hydrocarbon Refrigerant in Air

Conditioning Systems. Chemical Engineering

Transactions. A Publication of AIDIC.

Madhu Sruthi Emani, Bijan Kumar Mandal. 2018. The Use

of Natural Refrigerant in Refrigeration and Air

Conditioning Systems: A Review. International

Conference on Mechanical, Materials and Renewable

Energy, IOP Conf. Series: Material Science and

Engineering 377 (2018) 0102064 DOI: 10.1088/1757-

899X/377/1/012064.

Parashurama S, C., Ahamad Saleel, Govindegowda M.S, S.

A. Khan. 2019. Hydrocarbons as Alternative

Refrigerants in Domestic Refrigerators. International

Journal of Innovative Technology and Exploring

Engineering (IJITEE). ISSN: 2278-3075, Volume-8,

Issue-6S3, April 2019.

Puji Saksono, Gunawan. 2019. Penggunaan Refrigeran

Hidrokarbon Sebagai Refrigeran Alternatif yang

Ramah Lingkungan dan Hemat Energi. Seminar

Nasional Inovasi dan Aplikasi Teknologi di Industri,

Malang.

Rene Van Gerwen, Alan Gerrard, Fabio Roberti. (2008). Ice

Cream Cabinets Using a Hydrocarbon Refrigerant:

From Technology Concept to Global Rollout. 8

th

HR

Performance and Energy Consumption Analysis of Freezer Machines for Mobile Ice Cream Sellers using Eco-friendly Refrigerant MC134

21

Gustav Lorentzen Conference on Natural Working

Fluids. Copenhagen.

Tatang Hidayat, Ir, Msi. (2019). Potensi Perolehan

Penghematan Energi Listrik Pada Kulkas Dengan

Konversi Dari R-134a ke Hidrokarbon MC-134 Untuk

Dialokasikan di Rumah Tipe Sederhana.

https://musicoolpromo.com/article/18.

NOMENCLATURE

Cos φ power factor

E Energy consumption, kWh

h Enthalpy, kJ/kg

I Electrical current, Ampere

q Heat, kJ/kg

V Electrical voltage, Volt

w Work compression, kJ/kg

ABBREVIATION

C Degree Celcius

CFCs Chlorofluorocarbons

COP Coefficient of Performance

EU Europian Union

Exp Expansion

G Gauge

GWP Global Warming Potential

HCs Hydrocarbons

HCFCs Hydrochlorofluorocarbons

HFCs Hydrofluorocarbons

HP Horse Power

kJ Kilo-Joule

MC Musicool

P Pressure

Psi Pound per square inch

T Temperature

W Watt

SUBSCRIBES

c Condensor

e Evaporator

1,2 etc., State Point

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

22