Design of Brackish Water Distillation using Cylindrical and Square

Types of Solar Radiation Absorbers Made of Galvanized Base

for Coastal Communities

Dedy Nataniel Ully, Agus Laka, Bernadus Wuwur and Lukas Lantang

Department of Mechanical Engineering, State Politeknk of Kupang, Adi Sucipto, Kupang, Indonesia

Keywords: Brackish Water, Distillation, Radiation, Absorber, Solar Energy.

Abstract: The availability of clean water for people living on the coast is an unsolved problem for various reasons. To

meet the need for clean water consumption, people on the coast only rely on water from shallow wells that

are contaminated with sea water, where it tastes brackish or salty and the quality is not guaranteed. Thus, it is

necessary to apply appropriate technology in the form of distillation of brackish water into fresh water by

utilizing solar energy. The specific purpose of this research is to apply appropriate technology in the form of

a brackish water distillation device into fresh water in order to overcome the clean water crisis for coastal

communities. This research was conducted using real experimental methods in the field and was carried out

at 08:00 am to 04:00 pm with a volume of water in the distillation basin as much as 120 liters. The results

showed that there was an increase in performance with the use of solar radiation absorbent plates. The square

type solar radiation absorber can produce the highest efficiency of 21.63%, while the cylindrical type solar

radiation absorber only produces an efficiency of 21.13%.

1 INTRODUCTION

The availability of clean water on the coast is an

unsolved problem for various reasons. Residents who

live on the coast are dominated by fishermen, so they

have to choose to dig groundwater wells or buy tank

water. To meet the needs of clean water consumption,

people on the coast only rely on water from shallow

wells that are contaminated with sea water, so that it

tastes brackish or salty and the quality is not

guaranteed. To overcome the problem of clean water,

especially in coastal areas, it is necessary to apply

appropriate technology in the form of brackish water

distillation by utilizing solar energy as an energy

source to assist the condensation process, so that this

process is natural and environmentally friendly.

The purpose of this brackish water distillation is

to separate the excess salt in brackish water with the

help of a simple technology, namely solar powered

brackish water distillation. To speed up the process of

absorbing solar heat, it is equipped with a heat-

absorbing plate made of galvanized material which is

square and cylindrical. This is done to speed up the

heating and condensation process and can test the

performance of the two designs of installed solar

radiation absorber plates.

Research on the development of brackish water

distillation into clean water has been carried out by

many previous researchers. In 2006 a research was

conducted on desalination of brackish water to meet

drinking water needs in coastal areas. This research

was conducted with the aim of obtaining important

technical data for design and for use at a factory scale.

The research was conducted using real experimental

methods in the field. From the research results, the

system performance can work well (Siregar and

Siegar, 2019).

Further research will be conducted on micro-scale

reverse osmosis techno-economy analysis for the

process of brackish water distillation. This research

was conducted to obtain an economical design result

for the distillation scale of 12 to 14%. From the results

of the study showed that the evaluation based on NPV

and IRR stated that it was feasible (Adami and

Pudjiastuti, 2017).

Further research was conducted on modeling,

optimization and simulation of various aspects of

brackish water distillation for clean water needs.

Distillation column modeling can help in predicting

Ully, D., Laka, A., Wuwur, B. and Lantang, L.

Design of Brackish Water Distillation using Cylindrical and Square Types of Solar Radiation Absorbers Made of Galvanized Base for Coastal Communities.

DOI: 10.5220/0010938600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 5-10

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

5

various parameters for the separation between salt

and water elements. The optimal reflux ratio is highly

dependent on the feed mole fraction, feed quality,

relative volatility, and the separation factor being

carried out (Kurkami,2017).

The next research is about the effect of

temperature and operating time on the distillation

process for aquades processing. This research was

conducted with the aim of knowing the temperature

and operating time of the volume of distilled water

produced and to determine the efficiency of the

performance of the distillation apparatus. This

research was conducted using real experimental

methods in the field. The results showed that the

highest efficiency was 51, 30% and obtained a

temperature of 145

O

C (Sivieri and Teixeira, 2019).

Further research on the identification model of

column distillation. This study aims to determine a

suitable model for brackish water distillation. The

results showed the feasibility of using a linear model

to identify the dynamic equation of the distillation

column (Widiasa and Yoshi, 2016).

The next research conducted is about the use of

modeling technology for the process of distillation of

brackish water to meet the needs of clean water. The

purpose of this study is to identify whether this

technology can be applied and developed for

optimization and design purposes. The results of the

study indicate that the model made is able to

successfully describe the concentration and

distribution during the distillation process (Widiasa

and Kusumayanti, 2009).

Furthermore, research was conducted on

experimental studies of the effect of tilt angle on

seawater distillation equipment utilizing solar energy.

The results showed that the greatest potential for solar

radiation at 12.00 am was 908.712 W/m2. This is

caused by the position of the sun perpendicular to the

distillation apparatus. After doing research, the slope

angle of 30

O

is the most effective angle where the

seawater temperature obtained is 73

O

C at 12.30 am,

the radiation heat transfer rate is 92.86 Watts per day

and the fresh water produced is 650 ml (Honarparvar

and Xhang, 2019).

The new contribution of this research is to

overcome the clean water crisis in coastal areas by

applying a simple technology, namely the distillation

of brackish water into fresh water with the addition of

square and cylindrical solar radiation absorber

designs. This is done to speed up the process of

distillation of brackish water, so that production

capacity has increased.

2 RESEARCH METHODOLOGY

Research on the design of brackish water distillation

using square and cylindrical solar radiation absorbers

made of galvanized for coastal communities was

carried out using real experimental methods, where

observations on research objects were carried out in

coastal areas that were young exposed to direct

sunlight. Research was also carried out with the

application of square and cylindrical solar radiation

absorber designs to determine the highest

performance of the two designs. Data collection was

carried out at the same time for both radiation

absorbent designs this sun. The data collection

process was carried out from 8:00 am to 4:00 pm.

Data collection is done every hour and is done

repeatedly for three days, then look for the average

value as valid data for analysis purposes.

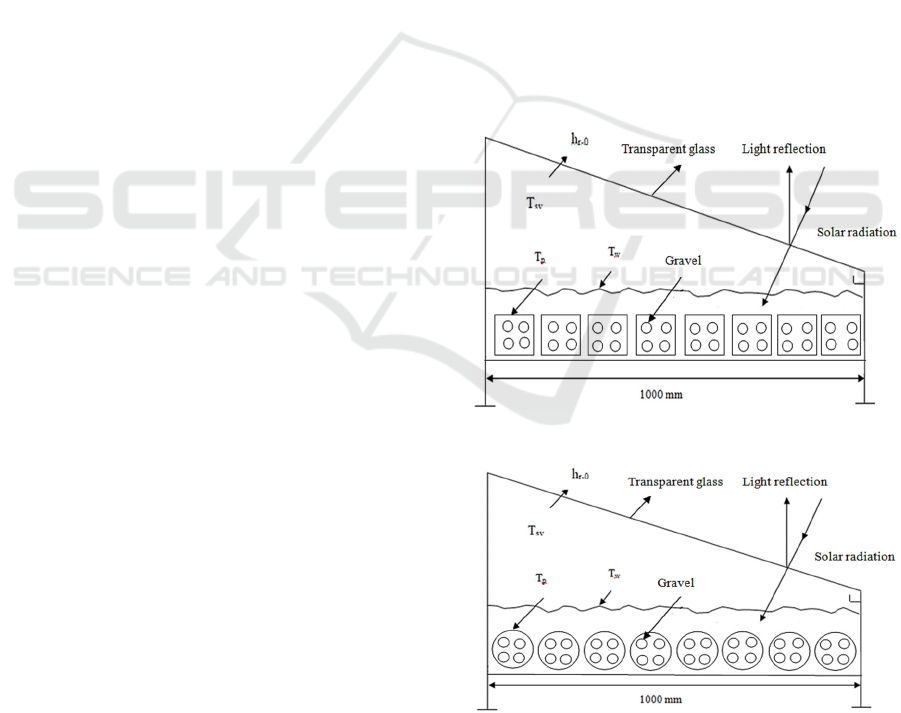

The research instruments or installations

regarding the use of square and cylindrical solar

radiation absorbers to support the process of

distillation of brackish water into clean water can be

seen in Figure 1 and 2 below :

Figure 1: Installation of square type solar radiation absorber.

Figure 2: Cylinder type solar radiation absorber installation.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

6

Caption :

IT = solar intensity (W / m

2

).

qr, 1 = The rate of radiation heat transfer from the

collector to the surface in the glass (Watt).

qc, 1 = Convection heat transfer rate from water vapor

to the surface in the glass (Watt).

qc, w = The rate of convection heat transfer from

water to water vapor (Watt).

Qk = Conduction heat transfer rate from the collector

to the outer wall (Watt).

qr, O = The rate of radiation heat transfer from the

glass to the environment (Watts).

qc, O = Convection heat transfer rate from the glass

surface to the environment (Watt).

Ta = Environmental temperature (

O

C).

Tw = water temperature (

O

C).

Tc = glass surface temperature (

O

C).

Tsv = Water vapor temperature (

O

C).

Tp = Temperature of absorbent plate (

O

C).

2.1 Distillation

Distillation is a method of separating liquids from

their mixtures according to differences in boiling

points or the ability of substances to evaporate.

Distillation has a working principle that is when a

substance in a solution does not evaporate equally, it

means that the vapor of the solution will have

different components from the original solution. If

one of the substances evaporates, it means that the

separation will occur completely. But if the two

substances evaporate, the separation process occurs

only partially but the distillate or product will have a

richer precipitate of components than the original

solution.

2.2 Heat Collector

Heat collector is a device that can accommodate heat

which aims to prevent heat drastically. Various types

of heat collectors have been widely used, including

flat plate collectors, tubular heat collectors, flat plate

collectors arranged with a certain slope, collectors

with glass covers and collectors filled with water

flow.

2.3 Radiation

Radiation can be defined as energy emitted in the

form of particles or waves. Solar radiation can

produce energy. The energy produced is used to boil

the brackish water that flows from the brackish water

tank. The power generated from solar radiation is

calculated based on the equation:

ATeP ...

4

τ

=

(Watt) (1)

Where :

P = Radiation power (Watt);

e = Emisivity coefficient;

τ

= Constant Stefan Boltzman;

T = Absolute temperature (

O

K);T

A = Cross-sectional area (m

2

)

2.4 Convection

Convection is the transfer of heat accompanied by the

movement of particles. Convection occurs in

substances in the form of gases and liquids. In the

distillation apparatus, heat transfer by convection

occurs in the air between the glass and the space

around the solar basin and in the evaporation of

brackish water. The equation to calculate the power

from convection is:

P = h . A .

T

Δ (Watt) (2)

Where :

P = Convection power (Watt);

h = Transfer rate;

A = Cross-sectional area (m

2

).

2.5 Conduction

Conduction is the transfer of heat through a substance

without the movement of its particles. In the

distillation apparatus, heat transfer by conduction

occurs in the glass and copper pipes. The equation for

calculating power from conduction is:

P = k . A .

d

TΔ

(3)

Where :

k = Thermal conductivity of heat conductor;

A = Cross-sectional area (m

2

);

T

Δ = Temperature change (

O

K);

d = Material thickness (m)

2.6 Heat Resistance

Heat resistance is the losses in the environment and

panels of the solar vapor evaporation system.

Win resistance :

The equation of the wind resistance coefficient is

shown in the equation:

h

c-0

= 5,7 + 3,8. v (4)

Where :

h

c-0

= Wind resistance coefficient;

v =Local wind speed

External radiation resistance :

Design of Brackish Water Distillation using Cylindrical and Square Types of Solar Radiation Absorbers Made of Galvanized Base for

Coastal Communities

7

External radiation resistance is an obstacle caused by

radiation reflected by the glass to the intensity of

heat received from the sun.

hr

-0

=

(

)

44

.

langitgc

TT −

τε

(5)

Where :

=

c

ε

Emisivity glass;

=

τ

Coefficient of Stefan Boltzman;

T

g

= Glass surface temperature;

T

sky

= Sky temperature 0,0552 (Ta

1,5

).

2.7 Efficiency

The efficiency of the distillation apparatus is obtained

from the equation:

%100x

T

T

desain

w

=

η

(6)

Where :

Tw = Brackish water temperature (

O

C);

T

desain

= Fresh water temperature (

O

C).

The performance of the brackish water distillation

design can be calculated using the following

equation:

Useful Energy Collektor

OutInU

QQQ −=

(7)

[

]

(. . .).( . ( . .( )

UcLcLcPA

QITAUAUATT

ατ

=−

Useful Energy Distillation

t

hmk

Q

fg

du

.

=

−

(8)

Efficiency of the Destillation

%100x

txIxA

hxmk

Tc

fg

d

=

η

(9)

3 RESULT AND DISCUSSION

3.1 Result

Based on the test data in the field, data processing is

carried out for further analysis based on its tendency,

as shown in tables 1 and 2 below:

Table 1: Test results and data processing (square type).

Time

T

sv

(

O

C)

m

k

( kg )

I

T

(W/m

2

)

Q

U-d

(kW)

d

η

(%)

08:00 am 26.10 0 533.42 0 0

09:00 am 35.43 0.129 688.84 0.086 13.91

10:00 am 38.16 0.175 785.02 0.117 16.61

11:00 am 42.66 0.217 853.32 0.144 18.84

12:00 am 43.10 0.259 887.67 0.172 21.63

01:00 p

m

42.96 0.255 893.46 0.169 21.13

02:00 p

m

39.16 0.209 878.08 0.139 17.69

03:00 p

m

38.76 0.159 783.37 0.106 15.09

04:00 p

m

37.33 0.138 723.46 0.092 14.20

Table 2: Test results and data processing (cylinder type).

Time

T

sv

(

O

C)

m

k

( kg )

I

T

(W/m

2

)

Q

U-d

(kW)

d

η

(%)

08:00 am 25.86 0 533.42 0 0

09:00 am 30.93 0.087 688.84 0.058 9.46

10:00 am 33.75 0.126 785.02 0.084 11.99

11:00 am 35.65 0.166 853.32 0.111 14.51

12:00 am 36.00 0.207 887.67 0.138 17.39

01:00 p

m

35.26 0.209 893.46 0.140 17.45

02:00 p

m

35.53 0.167 878.08 0.112 14.18

03:00 p

m

32.93 0.128 783.37 0.086 12.22

04:00 p

m

31.90 0.108 723.46 0.072 11.17

3.2 Discussion

After doing the calculations as shown in the table of

data processing results above, it is displayed in

graphical form, so that it can be discussed based on

existing trends. The discussion in question can be

seen in Figures 2, 3, 4 and 5 below, namely:

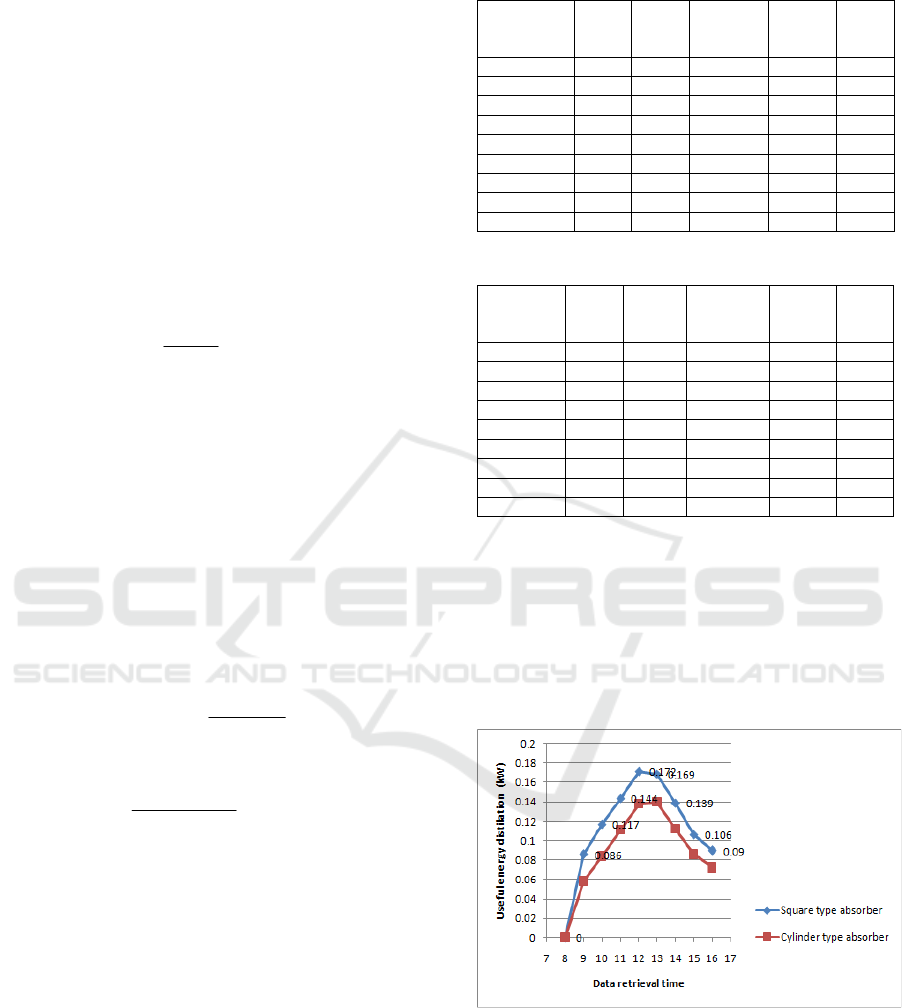

Figure 3: Graph of the correlation between time and

distillation useful energy.

From the graph above, it can be seen that the value

of useful energy has increased with increasing data

collection time. At 9.00 am to 12.00 am there was a

linear increase, this happened because the intensity of

solar radiation also increased from time to time until

the maximum occurred at 12.00 am. Furthermore, at

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

8

1.00 pm to 4.00 pm continued to decline. The value

of this useful energy is strongly influenced by the

amount of intensity of solar radiation that reflects its

light onto the glass surface, so that condensation

occurs and produces a certain amount of water vapor

with a certain condensate mass.

From the graph, it can be seen that the square

type solar radiation absorber can produce better

useful energy, when compared to the cylindrical type

solar radiation absorber. This happens because the

area of the square type of solar radiation absorber is

larger than the cylindrical type of solar radiation

absorber. The square-type solar radiation absorber

can produce the maximum useful energy of 0.1728

kW, while the cylinder-type solar radiation absorber

only produces 0.140 kW of useful energy, both of

which occur at 12.00 am.

Figure 4: Graph of the correlation between time and

distillation equipment efficiency.

Based on the graph above, it can be seen that the

efficiency value has increased along with the increase

in data collection time. The increase in efficiency

value linearly occurred at 9.00 am to 12.00 am.

Furthermore, the efficiency value decreased from

1.00 pm to 4.00 pm. The efficiency value is strongly

influenced by the mass value of the condensate, the

water vapor produced from the distillation process,

the size of the distillation surface area, the value of

the intensity of solar radiation and the time it takes.

From the graph, it can be seen that the square

type solar radiation absorber can produce the

maximum efficiency value when compared to the

cylindrical type solar radiation absorber. This

happens because the cross-sectional area of the

absorber, the mass of condensate and the resulting

condensation temperature are larger, when compared

to the results obtained from the cylindrical type of

solar radiation absorber.

The square type solar radiation absorber can

produce a maximum efficiency value of 21.63%,

while the cylindrical type solar radiation absorber

only produces a maximum efficiency of 17.45%.

Both the highest efficiency values occurred at 12.00

am, this happened because the highest intensity of

solar radiation occurred at 12.00 am when data

collection was carried out.

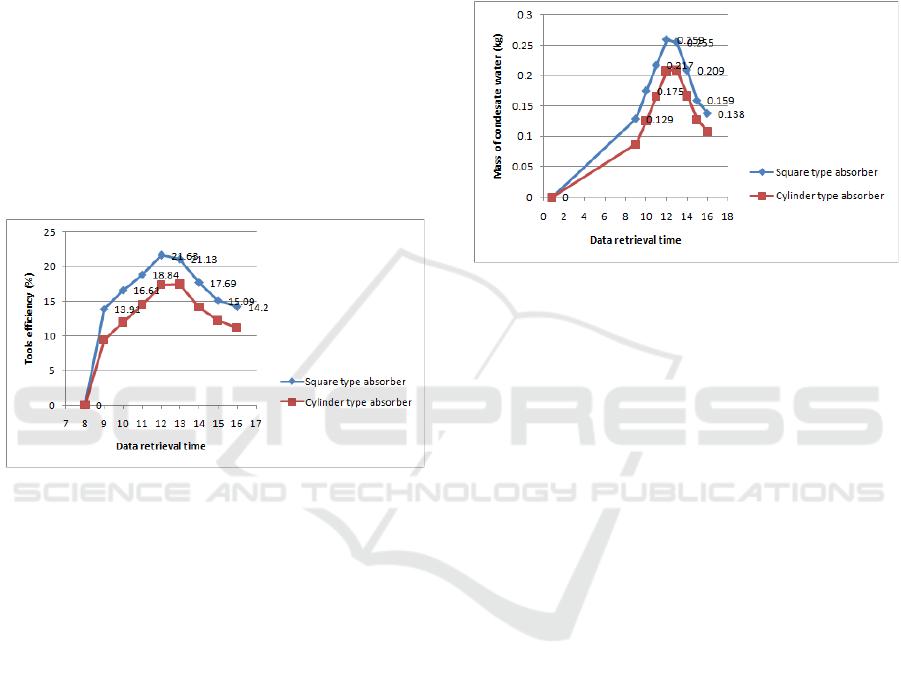

Figure 5: Graph of the correlation between time and

condensate.

Based on the graph above, it can be seen that the mass

of condensate produced from the distillation process

has increased with increasing data collection time.

The increase in condensate mass value linearly

occurred at 9.00 am and then decreased from 2.00 pm

to 4.00 pm. From the graph, it can be seen that the

square type solar radiation absorber can produce a

larger condensate mass when compared to the

cylindrical type solar radiation absorber. The

maximum condensate mass value produced by the

square type solar radiation absorber is 0.259 kg, while

the solar radiation absorber only produces a

condensate mass of 0.209 kg, both of which occurred

at 12.00 am.

4 CONCLUSIONS

Based on the results of the discussion above, several

conclusions can be drawn, including:

The square type solar radiation absorber can

produce useful energy, the efficiency and mass of the

condensate is greater, when compared to the

cylindrical type solar radiation absorber.

Design of Brackish Water Distillation using Cylindrical and Square Types of Solar Radiation Absorbers Made of Galvanized Base for

Coastal Communities

9

ACKNOWLEDGEMENTS

On this occasion the author would like to thank all

those who have helped, so that the writing of this

scientific article can be completed properly, namely:

Mrs. Nonce F. Tuati, SE., M.Si, as the director of

the Kupang State Polytechnic, who has provided

the opportunity to conduct research in an internal

scope.

Mr. Ramzy Sayonara, ST., MT, as assistant

director II of the Kupang State Polytechnic, who

has allocated research funds every year.

Mr. Prof. Dr. Adrianus Amheka, ST., M.Eng, as

the head of the research and community service

unit, who has provided direction in conducting

research every year.

ICAST 2021 colleagues and committee who have

provided guidance and direction in writing this

scientific article.

REFERENCES

Adami, I. S., Pudjiastuti, A. Y. (2017). The Effect of

Temperature and operation time on the process of

distilations for aquades processing in faculty of

engineering univercity mulawarman. Journal of

chemurgy, Vol. 01.

Honarparvar, S., Xhang, S., Chen, T., Chongzeng N.,

Reible, D. (2019). Modeling technologies for

desalination of brackish water-toward and sustainable

water supply. Current opinion in chemical engineering,

vol. 02, ISSN. 104-111.

Kurkami, J. S. (2017). Various aspects of distillation with

emphasis on modeling, optimation dan simulation.

International journal of science research in chemistry,

vol. 02, ISSN : 24568457.

Siregar, A. C., Sierigar, A. M. (2019). Study experimental

of the effect of angle tilt on seawater distillation

equipment utilizing solar energy. Journal of materials,

manufacturing and energy engineering, vol. 02, ISSN.

2622-7398.

Sivieri, M. F., Teixeira, P. E. (2019). Identification of the

dynamic model of a distillation column. International

journal o advanced engineering research and science,

vol. 06, ISSN. 2349-6495.

Widiasa, N. I., Paramita, Y., Kusumayanti, H. (2009).

BWRO Desalination for portable water supply

enhancement in coastal regions. Journal of coastal

development, vol. 12, ISSN : 1410-5217.

Widiasa, N. I., Yoshi, A. L. (2016). Techno-economy

analysis a small scale reverse osmosis system for

brackish water desalination. International journal of

science and enggineering, vol. 10, ISSN. 2086-5023.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

10