Analysis of Jig Supplier Selection with Analytical Hierarchy Process

Method: Case Study at Purchasing Department at PT Patlite

Indonesia

Roza Andila and Rahmat Hidayat

Business Administration Study Program, Politeknik Negeri Batam, Jl. Ahmad Yani, Batam Centre 29461, Indonesia

Keywords: AHP, Quality, Price, Delivery, Supplier Profile, Service, Jig Supplier.

Abstract: PT Patlite Indonesia is a manufacturing industry that produces Warning Signal Lamp. The increasing number

and types of products affect the raw materials and equipment used, due to limited production capacity, labor,

and other production facilities, causing PT Patlite Indonesia to rely heavily on suppliers. The most widely

used equipment in the production process at PT Patlite Indonesia is the Jig. This jig supports the entire

production process. The purpose of this study is to find the criteria that are considered important in the

selection of jig suppliers and the order of priority for the best jig suppliers at PT Patlite Indonesia. The research

method used is the Analytical Hierarchy Process (AHP) method with qualitative descriptive analysis tools

and data processing using Ms. Excel. The results of this study indicate several criteria that are considered

important, namely Quality, Price, Delivery, Supplier Profile, Service, and Supplier The best Jig with the

highest weight being the order of top priority is PT Media Sarana Sukses with a total weight of 0.681 or 68.1%,

the second priority is PT Ingram Indonesia Jaya with a total alternative weight of 0.226 or 22.6% and the last

priority with the lowest weight is PT Buana Batam Mandiri with a total alternative weight of 0.093 or 9.3%.

1 INTRODUCTION

Jigs are work tools commonly used in the production

process. Jigs come in different types depending on

their intended use. Jigs can also be defined as a

special tool that is useful for holding, holding, and

maintaining the position of the workpiece during the

production process so that the quality of the resulting

product is uniform. Apart from being a work tool,

several other types of jigs are also useful as function

test tools for finished goods. Jigs have many benefits

for manufacturing companies that produce large

quantities of products every day, including time

efficiency and maintaining the quality of the products

produced.

In the growing world of the manufacturing

industry in Batam, every industry is required to

compete with each other. To win the competition, the

company must be able to maximize every process that

is carried out, starting from the procurement process

and then producing to delivery of goods. In addition,

companies must also be able to meet increasing

market demand, to satisfy consumer needs,

companies must be able to produce products with the

best quality and increase production rates to meet

consumer needs. Good product quality is certainly the

result of a good and precise production process. The

production process is very dependent on the

procurement of raw materials.

The procurement of raw materials is the first step

before the production process. The procurement of

raw materials plays an important role in facilitating

the production process. The procurement of raw

materials also has several very important functions,

including being responsible for ensuring the

efficiency of all raw materials and services and

having to find and maintain good relationships with

suppliers. To meet the availability of quality raw

materials and as needed, companies must find and

find the right supplier. The right supplier will provide

many advantages, such as obtaining raw materials at

a more affordable price, the availability of products

with raw materials delivered on time, being able to

meet needs in certain circumstances with short lead

times, as well as good quality and according to

standards. To determine the supplier, you must go

through a selection or decision-making process

because, in addition to being a supplier of raw

408

Andila, R. and Hidayat, R.

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia.

DOI: 10.5220/0010935000003255

In Proceedings of the 3rd International Conference on Applied Economics and Social Science (ICAESS 2021), pages 408-417

ISBN: 978-989-758-605-7

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

materials, suppliers will also be partners who work

together for the progress of the company.

Supplier selection becomes very important

because it will affect the company's production. The

selection is made to get the expected supplier and by

the criteria desired by the company. Problems that

often occur so far regarding the selection of suppliers

are wrong in making decisions or alternative suppliers

that do not meet all the required criteria. Companies

must know what criteria they need and be a priority

so that they are right in making decisions to choose

the best supplier.

PT Patlite Indonesia is part of the Japanese Patlite

Corporation. PT Patlite Indonesia is a manufacturing

industry that produces Warning Signal Lamps and has

grown rapidly since its inception due to huge

consumer needs. The increasing number and types of

products will certainly affect the raw materials and

equipment used, due to limited internal capacity and

production equipment, it is impossible to produce all

the raw materials needed, this causes PT Patlite

Indonesia to rely heavily on suppliers. If you choose

the wrong supplier, it can have a bad impact on

production. The selection of suppliers for each raw

material at PT Patlite Indonesia is handled by the

purchasing department.

The Purchasing Department at PT Patlite

Indonesia handles purchases for two types of raw

material needs, namely main raw materials and

factory supply. Factory Supply is an internal need for

each section that supports the production process

which consists of several parts, namely tooling, parts,

repair, calibration, and other needs that are commonly

used every month such as safety tools and equipment,

labels for finished products, and also tools. . The need

for tooling is one that must be considered because

tooling is a requirement that includes work tools, one

of which is a jig and also tool repair. This jig supports

the entire production process. PT Patlite Indonesia

has three types of jigs used, namely function jigs

which are useful for viewing and ensuring the

accuracy of finished goods functions, jigs which are

useful as work aids such as holding and holding

objects during the production process so that they

remain stable, and Firmware which is a master code

or software used to create a jig work system according

to standards and needs.

Based on a preliminary interview conducted with

the Assistant Purchasing Manager of PT Patlite

Indonesia, there is an explanation of the criteria used

in the selection of jig suppliers consisting of price,

quality, and delivery (lead time). The price standard

only focuses on the lowest price offered by the

supplier and the lead time standard is evaluated

according to the timeliness of delivery with the

specified schedule and quality is evaluated according

to the drawings and specifications provided by the

Engineering department. The selection of jig

suppliers at PT Patlite Indonesia requires other

criteria that suppliers should have and not only based

on 3 criteria so that they can be taken into

consideration to make it even better and this criterion

also still follows the criteria for other products and

has not been standardized for factory supply products.

Therefore, this research was conducted to look at

other criteria that might be needed and be taken into

consideration for choosing the priority suppliers

needed. In general, by using the AHP method, the

resulting priorities will be theoretically consistent,

logical, transparent, and participatory. Based on this

background, it is hoped that "Analysis of Jig Supplier

Selection with the Analytic Hierarchy Process (AHP)

Case Study Method at the Purchasing Department at

PT Patlite Indonesia." This can help companies,

especially the purchasing department, in determining

the right supplier for jig products.

2 LITERATURE REVIEW

2.1 Supplier Selection

Supplier selection is a multi-criteria problem where

each criterion used has different interests and

information about it is not known precisely

(Noviandri et al., 2015). The selection of suppliers

must be adjusted to the criteria most needed by the

company. This supplier selection certainly has a

major impact on the company's sustainability, this is

evidenced by the company's financial condition. The

right supplier can reduce the cost of spending or

purchasing. However, the selection of this supplier

cannot only be assessed in terms of price but must

also pay attention to other criteria such as product

quality, accuracy in delivery, supplier response, and

others. The more criteria the company wants to

choose suppliers make the problem more

complicated, therefore a decision-making technique

is needed in supplier selection (Rimantho et al.,

2017).

2.2 AHP (Analytical Hierarchy Process)

The Analytic Hierarchy Process method or

commonly referred to as AHP was first developed by

Dr. Thomas L. Saaty in 1970. The AHP method is a

mathematical decision-making system. AHP uses

input centered on the perception of experts. Experts

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia

409

are people who understand the problem or have an

interest in the problem. According to Saaty and

Vargas (2012), AHP is a form of decision selection

that allows users to form opinions and provide

boundaries to problems through estimates or

conjectures and produce the desired problem

resolution. The AHP method can be used to solve

various problems, analyze benefit and cost decisions,

rank available alternatives, forecast, and set

development priorities for business units and other

complex problems.

2.3 AHP Method Principle

The AHP method is built on three main principles

(Saaty, 1980), including:

a. Principles of hierarchical structure

The Hierarchical arrangement is done to

obtain detailed knowledge.

b. The principle of setting priorities

Priorities are determined based on the opinion

of experts and related parties who are competent

in making decisions.

c. Principle of logical consistency

The application of the principle of logical

consistency covers both qualitative and

quantitative aspects of the human brain.

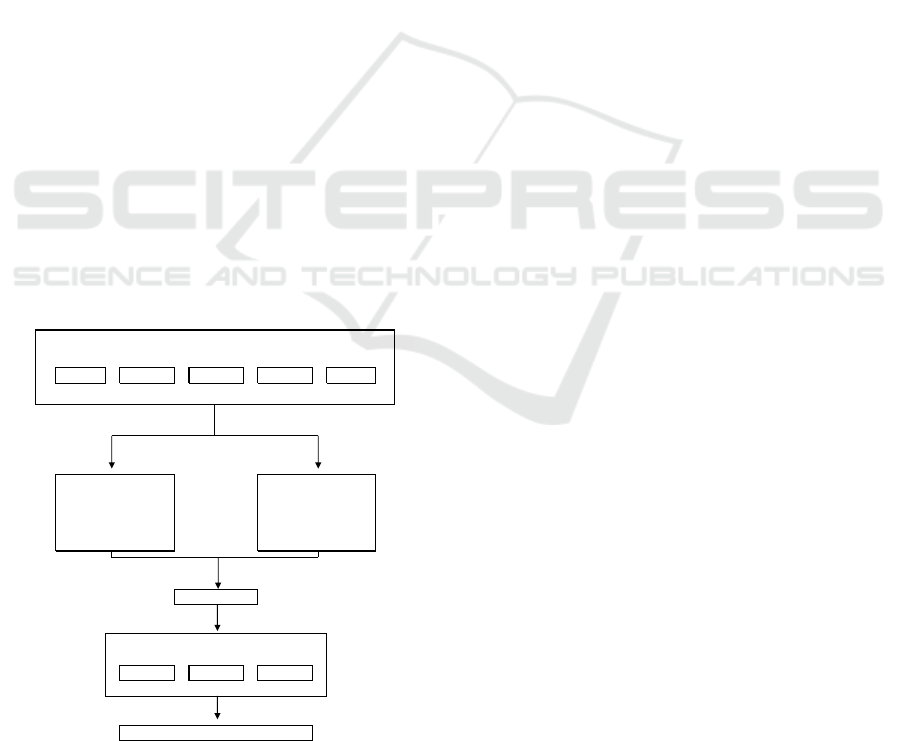

2.4 Framework

The framework of thought contained in this research

is as follows:

(source: data processing, 2021)

Figure 1: Framework.

3 RESEARCH METHOD

3.1 Design, Focus, and Subject

The research conducted is a type of qualitative

research with the focus of research is the

implementation of the policy of determining the most

important criteria and according to the needs of PT

Patlite Indonesia in choosing the best jig supplier

priority that meets these criteria. The research

subjects were 4 people, namely Assistant Manager for

Purchasing, Supervisor for Purchasing, Operator for

Purchasing, Assistant Supervisor for Equipment

Engineering.

3.2 Data Type

The primary data in this study are the results of in-

depth interviews with resource persons in the

purchasing and equipment engineering department

regarding the assessment of jig suppliers. Secondary

data in the form of company profiles, supplier data,

and documents related to jigs.

3.3 Data Collection Technique

Data collection techniques in this study using in-

depth interviews or can also be called in-depth

interviews are interactions/conversations that occur

between one interviewer and one informant

(Manzilati, 2017).

3.4 Stages of Data Processing

The stages of data processing in this study are as

follows:

Criteria 1 Criteria 2 Criteria 3 Criteria 4 Criteria 5

Supplier A Supplier B Supplier C

AHP Analysis

Alternative Jig Supplier Selection

Best Jig Supplier Priorit

y

Jig Supplier Selection Criteria

Respondents' perception

of the importance of

each criterion

Respondents'

perceptions of supplier

performance related to

each criterion

ICAESS 2021 - The International Conference on Applied Economics and Social Science

410

(source: data processing, 2021)

Figure 2: Stages of Data Processing.

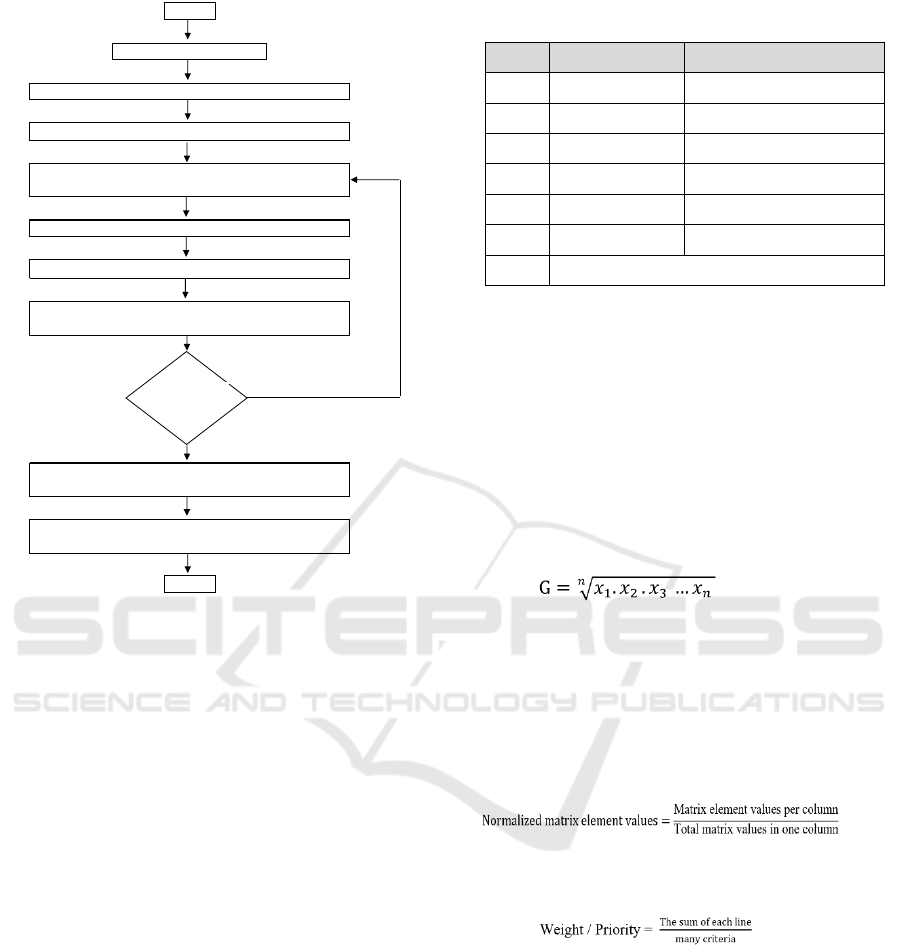

Based on Figure 2 above, the following is an

explanation of the stages of data processing in this

study:

1. Identify the problem

The purpose of this stage is to find out the cause of a

problem and what the right solution is to solve it

2. Setting Goals

Goal setting is useful for determining problem

boundaries so that research becomes clear and

directed

3. Develop a supplier selection hierarchy

4. Do pairwise comparisons

Pairwise comparisons are made based on

(judgment) by assessing the importance of one

element compared to other elements. The following

is the priority scale in the pairwise comparison

assessment:

Table 1: Pairwise Comparison Rating Scale.

(source: Saaty, 1994)

The assessment of criteria and alternatives is

carried out by several experts, while the use of the

AHP method only requires data obtained from the

assessment of one expert. According to research

conducted by Hati and Fitri (2017) that the

assessments made by respondents, then the results

will be averaged using the Geometric Mean average.

This is done because AHP only requires one answer

for the pairwise comparison matrix. The formula used

to find the geometric mean value is as follows:

(1)

Where: G : Geometric Mean

X1: Participant Assessment 1

X2: Participant Assessment 2

X3: Participant Assessment 3

n : Many Criteria

5. Melakukan perhitungan normalisasi dan

pembobotan

(2)

After calculating the value of the normalized matrix

elements, a calculation will be carried out to get the

weight or priority value

(3)

6. Calculating the Maximum Eigen Value

a. Multiply each value in the first column by the

priority of the first element and the value in the

second column by the second priority, and so on.

b. Adding each row of multiplication

results.

c. The result of the sum of each row is then

divided by the priority element concerned

d. Calculating the number of quotients

above then divided by the number of

elements, it will get λmax.

7. Calculating the value of consistency index and

consistency ratio

Start

NO

YES

Finished

Calculating Consistency Index (CI) and Consistency Ratio (CR)

Values

Calculating the Preference Value of Each Alternative and

Co mpiling Priority Ranking

The Best Jig Supplier with the Most Suitable C riteria fo r PT

Patlite Indonesia Needs

Identification of problems

Esta blishing a Sup plier Se lection Hierarchy

Determining Research Objectives / Goals

Perform Pairwise Comparison Calculations Based on Priority

Scale

Performing No rmaliza tio n and Weighting Ca lculations

Calculating Maximum Eigen Value (λmax)

CONSISTENCY

CR ≤ 0.1

3

1

KeteranganDefinisi

Intensity of

interest

Opposite

2, 4, 6, 8

9

7

5

If for activity i gets 1 point compared to activity j, then j has the opposite value

compared to i

Values between two adjacent considerations

One element is absolutely more important than

the other elements

One element is very important than the other

elements

One element is more important than the other

elements

One element is slightly more important than the

other

Both elements are equally important

Equally to moderate Importance

Extreme Importance

Very Strong Importance

Strong Importance

Moderate Importance

Equal Importance

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia

411

(4)

Where: CI: Consistency Index

n: Many Criteria

(5)

Where: CR: Consistency Ratio

RI: Random Consistency Index

Table 2: Random Consistency Index.

(source: Saaty, 1994)

8. Arrange Priority Ranking

Determining the priority weight value

obtained by adding the weight value of the

comparison between criteria multiplied by the

weight value of the comparison of alternative

answers (Hati and Nelmi, 2017).

9. Determine the best jig supplier

After finding the calculation results between

the criteria and alternatives, the best jig

supplier is determined which has the highest

weight as a priority and the order after that.

4 RESULTS AND DISCUSSION

4.1 Supplier Selection Criteria and

Alternative Supplier Jig

PT Patlite previously had 3 basic criteria that had

been used in supplier selection, namely price, quality,

and delivery (lead time), and through the interview

process that had been carried out previously, other

criteria that were considered important were obtained,

namely supplier and service profiles. These criteria

become a reference in choosing the right jig supplier.

The criteria for selecting a jig supplier are as follows:

a. Quality

The supplier can provide quality by the company's

wishes and produce jigs according to the agreed

drawings.

b. Price

Suppliers can offer the best and affordable prices.

c. Delivery

The supplier can deliver the jig on time according to

the agreed schedule.

d. Supplier Profile

A Supplier with a good reputation, history, capacity,

and adequate production facilities

e. Service

The supplier can respond to every complaint and

request properly and responsively

The alternatives contained in this study are several

suppliers who have collaborated with PT Patlite

Indonesia. The alternatives include PT Media Sarana

Sukses (MSS), PT Ingram Indonesia Jaya

(INGRAM), CV Buana Batam Mandiri (BBM).

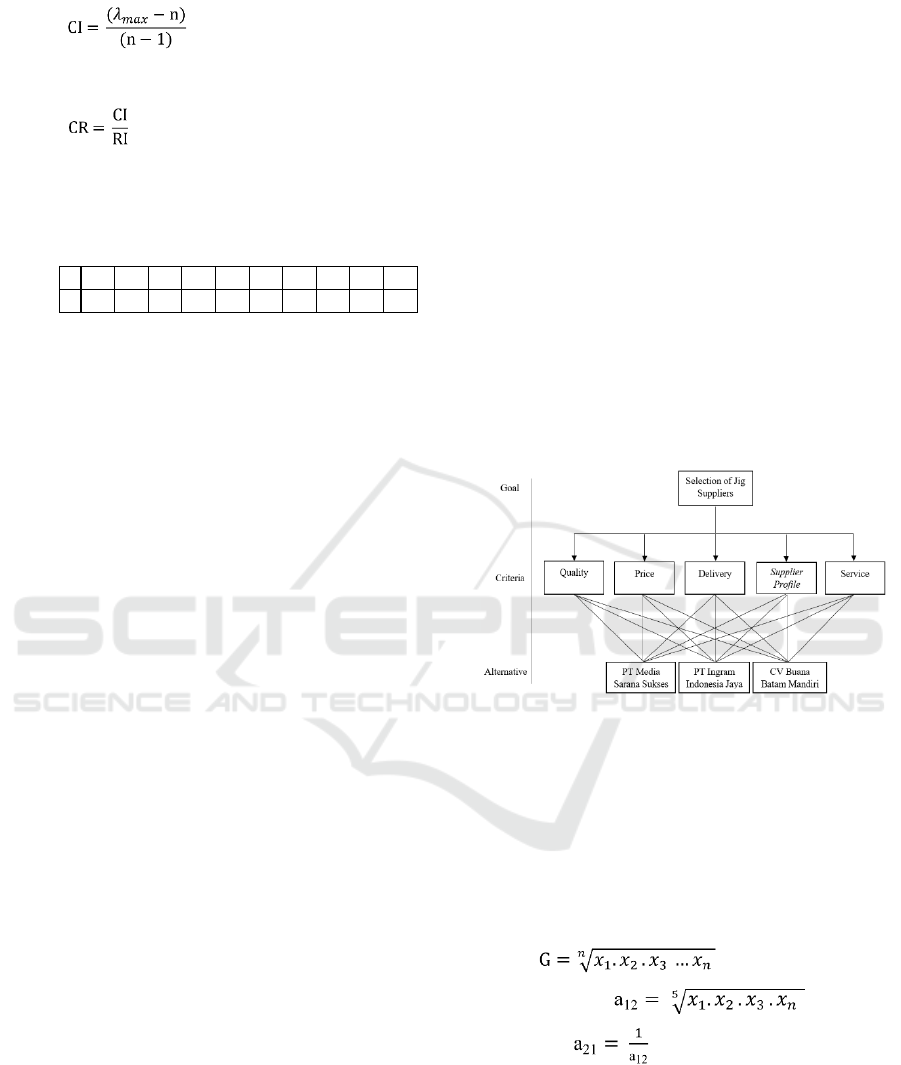

After the criteria and alternatives are obtained, the

first step in the data processing stage is compiling a

jig supplier selection hierarchy. The results of the

initial data processing before conducting the

consistency test in this study are as follows:

1. Preparation of the Jig Supplier Selection

Hierarchy

After the criteria and alternatives are obtained, the

next step is to develop a jig supplier selection

hierarchy. This jig supplier selection hierarchy is

structured to see in detail the objectives, criteria, and

alternatives to be evaluated

(Source: Data Processing, 2021)

Figure 3: Jig Supplier Selection Hierarchical Structure.

2. Pairwise Comparison Matrix

A pairwise comparison matrix is made based on

an assessment of the importance of one element

compared to other elements. As for several pairwise

comparison matrices between criteria and

alternatives, each geometric mean value has been

obtained as follows:

(6)

If element (7)

Then (8)

For

a

= a

= a

= a

= a

= 1

n12345678910

RI

0 0 0.58 0.9 1.121.241.321.411.451.49

ICAESS 2021 - The International Conference on Applied Economics and Social Science

412

Table 3: Geometric Mean Overall Criteria Paired

Comparison Matrix.

(source: data processing, 2021)

The Geometric Mean calculation process is also

carried out for pairwise comparison matrices between

alternative jig suppliers with the same steps.

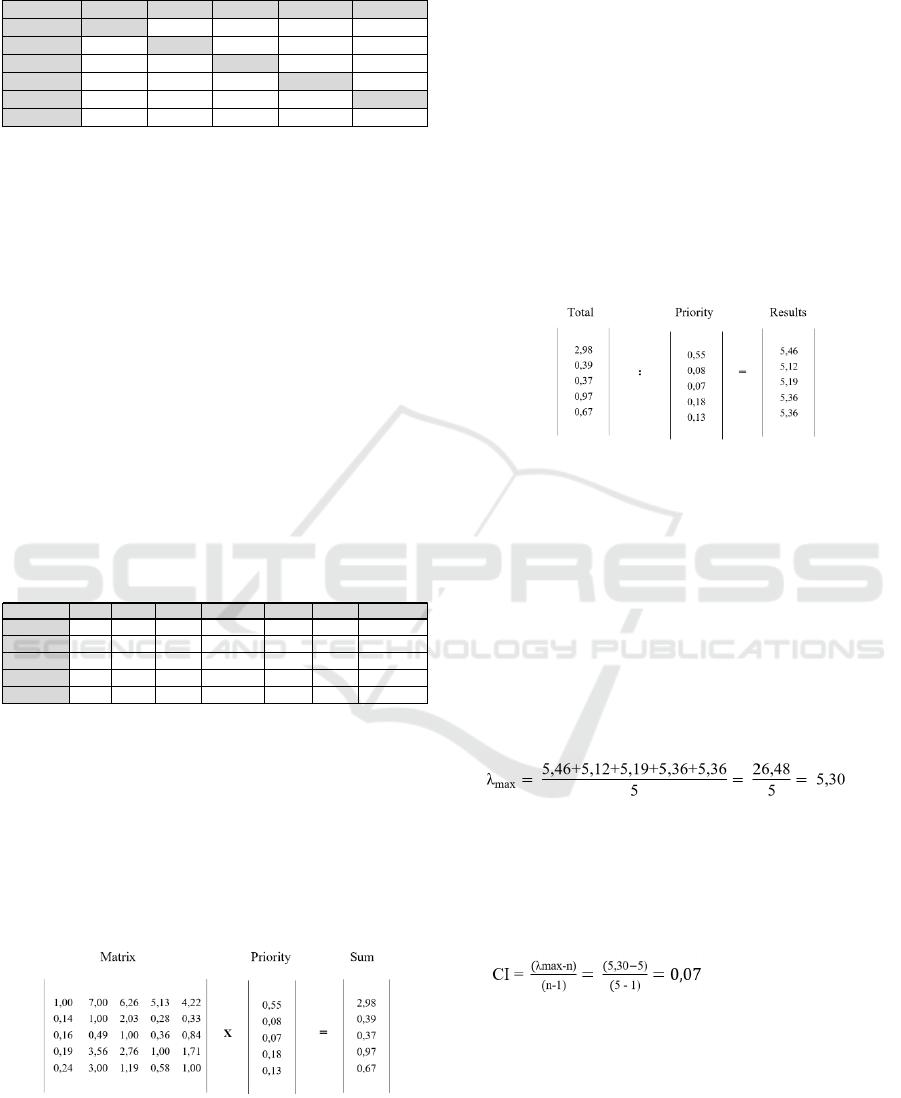

4.2 Weighting and Consistency Test

The consistency test is to calculate the consistency

ratio of the weights of each criterion and alternative.

This is done to determine whether the weighting is

consistent. Before performing the consistency test,

the results of pairwise comparisons will be

normalized first. The data normalization calculations

in Table 3 are as follows:

1. Calculation of Consistency Test for Jig

Supplier Selection Criteria

Table 4: Results of Normalization of Criteria Matrix.

(source: data processing, 2021)

The quality weight value in the first row with a

total of 2.73 is divided by many criteria, namely 5, it

becomes 0.546, and so on for each row, the

weight/priority is obtained as can be seen in Table 4.

The next step is to calculate the Maximum Eigen

Value (λmax) by multiplying the pairwise

comparison matrix in Table 3 with the weight/priority

concerned and then adding up each row as follows:

Based on the above calculation, the number is

obtained from the multiplication of the pairwise

comparison matrix with the weights/priorities. The

way to get the total value for quality is (1.00*0.55) +

(7.00*0.08) + (6.26*0.07) + (5.13*0.18) +

(4.22*0.13) = 2.98, the sum for the price is obtained

from the calculation (0.14*0.55) + (1.00*0.08) +

(2.03*0.07) + ( 0.28*0.18) + (0.33*0.13) = 0.39, the

amount for shipping is obtained from the calculation

(0.16*0.55) + (0.49*0.08) + ( 1.00*0.07) +

(0.36*0.18) + (0.84*0.13) = 0.37, the number for

supplier profile is obtained from the calculation

(0.19*0.55) + (3.56*0.08) + (2.76*0.07) +

(1.00*0.18) + (1.71*0.13) = 0.97, the number for

services is obtained from the calculation (0.24*0.55)

+ (3.00*0.08) + (1.19*0.07) + (0.58*0.18) +

(1.00*0.13) = 0.67. Then the sum of each row is

divided by the corresponding weight/priority as

follows:

Based on the above calculations, the results are

obtained from the calculation of the number divided

by the weight/priority. The total quality is 2.98

divided by the weight of 0.55, then the result is 5.46.

The total price of 0.39 is divided by a weight of 0.08,

so the result is 5.12. The number of shipments is 0.37

divided by a weight of 0.07, so the result is 5.19. The

number of supplier profiles is 0.97 divided by a

weight of 0.18, so the result is 5.36. The number of

services is 0.67 divided by a weight of 0.13, then the

result is 5.56. After that, calculate all the total results

and divide the number of elements, it will get max as

follows:

(9)

If you have obtained the maximum eigen value,

the next step is to calculate the consistency index (CI)

value. The CI value is calculated to ensure the

consistency level of decision makers when filling out

pairwise comparison values between criteria. The

way to calculate the CI value is as follows:

(10)

To get the consistency ratio (CR) value, the next

step is to divide the consistency index (CI) value with

the Random Index value. A pairwise comparison

matrix is declared consistent if the CR value is not

more than or equal to 0.1 or 10%. If not, then the

assessment that has been made may be done

randomly and needs to be corrected or data retrieval

is carried out. The value of n = 5 then the value of RI

Quality Price Delivery Supplier Profile Service

Quality

1,00 7,00 6,26 5,13 4,22

Price

0,14 1,00 2,03 0,28 0,33

Delivery

0,16 0,49 1,00 0,36 0,84

Supplier Profile

0,19 3,56 2,76 1,00 1,71

Service

0,24 3,00 1,19 0,58 1,00

Σ

1,73 15,05 13,23 7,36 8,10

Quality Price Delivery Supplier Profile Service Total Weight / Priority

Quality

0,58 0,47 0,47 0,70 0,52 2,73 0,546

Price

0,08 0,07 0,15 0,04 0,04 0,38 0,076

Delivery

0,09 0,03 0,08 0,05 0,10 0,35 0,071

Supplier Profile

0,11 0,24 0,21 0,14 0,21 0,90 0,181

Service

0,14 0,20 0,09 0,08 0,12 0,63 0,126

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia

413

is 1.12. The RI value was obtained from the random

consistency index table with the number of n as many

as 5. The calculation of the CR value was as follows:

(11)

If the consistency value of CR <0.1 then it is

declared consistent and the assessment given by the

participants is considered appropriate. Based on the

calculation of the consistency ratio above, it can be

seen that the results of the calculation of the criteria

are declared consistent because the CR value is <0.1

where the CR value of 0.07 is not greater than 0.1 and

the assessment given by the participants is considered

appropriate.

The process of calculating the consistency test

between these criteria is also carried out on the

consistency test between alternative jig suppliers

against each criterion with the same steps.

Table 5: Weight and Order of Ranking Criteria.

(source: data processing, 2021)

Based on Table 4 above, it is clear that the criteria

that are considered the most important and must be

owned by jig suppliers are quality with a weight of

0.546 or 54.6%, the second most important criterion

is the supplier profile with a weight of 0.181 or

18.1%, criteria with the next position is service with

a weight of 0.126 or 12.6%, then followed by price

criteria with a weight of 0.076 or 7.6% and in the last

position is delivery with a weight of 0.071 or 7.1%.

2. Calculation of the Consistency Test for

Alternative Jig Suppliers against the Criteria

Table 6: Consistency Test for Alternative Jig Suppliers

against Quality Criteria.

(source: data processing, 2021)

The value of CR consistency <0.1 is 0.06, then it

is declared consistent.

Table 7: Consistency Test for Alternative Jig Suppliers

against Price Criteria.

(source: data processing, 2021)

The value of CR consistency <0.1 is 0.04, then it

is declared consistent.

Table 8: Consistency Test for Alternative Jig Suppliers

against Delivery Criteria.

(source: data processing, 2021)

The value of CR consistency <0.1 is 0.01, then it

is declared consistent.

Table 9: Consistency Test for Alternative Supplier Jig

against Supplier Profile Criteria.

(source: data processing, 2021)

The value of CR consistency <0.1 is 0.04, then it

is declared consistent.

Table 10: Consistency Test for Alternative Jig Suppliers

against Service Criteria.

(source: data processing, 2021)

Criteria Weight/ Priority Ranking

Quality

0,546 1

Price

0,076 4

Delivery

0,071 5

Supplier Profile

0,181 2

Service

0,126 3

MSS INGRAM BBM Weight/Priority

Ranking

MS S

0,70 0,74 0,57 0,67 1

INGRAM

0,20 0,21 0,35 0,25 2

BBM

0,10 0,05 0,08 0,08 3

λmaks

CR

RI

CI

0,06

0,58

0,03

3,07

MSS INGRAM BBM Weight/Priority

Ranking

MS S

0,73 0,76 0,64 0,71 1

INGRAM

0,17 0,18 0,27 0,21 2

BBM

0,10 0,06 0,09 0,08 3

λmaks

CR

RI

CI

0,04

0,58

0,02

3,04

MSS INGRAM BBM Weight/Priority

Ranking

MS S

0,58 0,59 0,53 0,56 1

INGRAM

0,34 0,34 0,40 0,36 2

BBM

0,09 0,07 0,08 0,08 3

λmaks

CR

RI

CI

0,01

0,58

0,004

3,01

MSS INGRAM BBM Weight/Priority

Ranking

MS S

0,76 0,68 0,81 0,75 1

INGRAM

0,12 0,11 0,07 0,10 3

BBM

0,12 0,21 0,13 0,15 2

λmaks

CR

RI

CI

0,04

0,58

0,03

3,05

MSS INGRAM BBM Weight/Priority

Ranking

MS S

0,69 0,74 0,58 0,67 1

INGRAM

0,20 0,21 0,33 0,24 2

BBM

0,11 0,06 0,09 0,09 3

λmaks

CR

RI

CI

0,05

0,58

0,03

3,06

ICAESS 2021 - The International Conference on Applied Economics and Social Science

414

The value of CR consistency <0.1 is 0.05, then it

is declared consistent.

4.3 Rank Calculation and Determination

of the Best Jig Supplier

Table 11: Overall Weights/Priorities for each criterion and

alternative.

(source: data processing, 2021)

Based on Table 11 the calculation results for the

weights/priorities on the criteria and alternatives are

carried out by multiplying the weights of each

criterion with the weights of each alternative and then

calculating the number, then the total weight of the

alternatives is obtained. The highest total alternative

weight is the MSS supplier (PT Media Sarana Sukses)

with a total weight of 0.681 or 68.1%. This is

supported by the weight of each criterion that most

MSS can dominate with the highest weight of each

criterion and are in the first rank. In line with the

participant's opinion that the MSS Supplier provides

better quality jigs than other suppliers, not only

quality but other criteria such as relatively lower

prices, timely delivery, supplier profile as evidenced

by adequate production capacity, and facilities such

as complete equipment. compared to other suppliers

as well as good service in responding to jig work

problems and updates. Based on the results of this

weight/priority calculation, MSS becomes the most

priority in choosing a jig supplier.

The INGRAM supplier (PT Ingram Indonesia

Jaya) has a total alternative weight of 0.226 or 22.6%

and this means that the INGRAM supplier also meets

all the criteria quite well and is in the second priority

position after the MSS supplier, but the INGRAM

supplier still has to add experience in focus on jig

work because for the supplier profile criteria

INGRAM is ranked third after the fuel supplier with

a weight of 0.10 or 10% and only 5% difference with

the fuel supplier. In line with the participant's opinion

that the INGRAM supplier also provides quality jigs

that are by the requests or drawings provided and

have never caused problems while being a PT Patlite

Indonesia jig supplier, the prices offered are quite

affordable, deliveries that have never passed the due

date and adequate service. both in terms of

communication-related to jig work problems and

providing support if there is a request for a direct visit

by PT Patlite Indonesia.

The alternative Jig Supplier who is in the last

priority order is the BBM supplier (CV. Buana Batam

Mandiri) with a total alternative weight of 0.093 or

9.3%. The BBM supplier is a new supplier

collaborating with PT Patlite Indonesia for special jig

products, so for each criterion, the BBM supplier has

not been able to be superior to other suppliers.

However, BBM suppliers still meet every criterion

for selecting PT Patlite Indonesia suppliers and BBM

suppliers are also companies that focus on making

machines such as jigs and goods for other industrial

production so that BBM suppliers are superior to

INGRAM suppliers with a weight of 0.15 or 15%

against the Supplier Profile criteria.

Determination of the best jig supplier can be

determined based on the results of the calculation of

the ranking and weight/priority of each criterion and

alternative. The best supplier with the highest total

weight is PT Media Sarana Sukses and this shows that

in the selection of suppliers for jig products the main

priority is PT Media Sarana Sukses and the second

priority is PT Ingram Indonesia Jaya, the last priority

with the lowest weight is PT Buana Batam Mandiri.

5 CONCLUSIONS

Based on the results of research regarding the

selection of jig suppliers using the AHP (Analytical

Hierarchy Process) case study at the Purchasing

Department at PT Patlite Indonesia, the following

conclusions were obtained:

1. Important criteria in selecting a jig supplier at PT

Patlite Indonesia are quality criteria, supplier

profile, service, price, and delivery

2. The criterion that has the highest weight and is in

the first rank order based on the results of the

pairwise comparison matrix calculation is the

quality criterion with a weight of 0.546, followed

MS S INGRAM BBM

Quality 0,546 0,67 0,25 0,08

% 54,6% 67% 25% 8%

123

Price 0,076 0,71 0,21 0,08

% 7,6% 71% 21% 8%

123

Delivery 0,071 0,56 0,36 0,08

% 7,1% 56% 36% 8%

123

Supplier Profile 0,181 0,75 0,10 0,15

% 18,1% 75% 10% 15%

132

Service 0,126 0,67 0,24 0,09

% 12,6% 67% 24% 9%

123

0,681 0,226 0,093

IIIIII

Priority

Total Alternative Weight

Rankin g

Rankin g

Kriteria Weight/Priority

Alternative

Rankin g

Rankin g

Rankin g

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia

415

by the second rank, namely the supplier profile

criterion of 0.181, the third rank of the service

criterion of 0.126, the fourth rank of the price

criterion of 0.076, and the final ranking of the

delivery criteria with the lowest weight of 0.076.

3. The order of priority for the best jig supplier based

on the total alternative weights is PT Media

Sarana Sukses, followed by the second priority by

PT Ingram Indonesia Jaya, and the last priority by

PT Buana Batam Mandiri

ACKNOWLEDGEMENTS

Acknowledgments are addressed to the Politeknik

Negeri Batam, the academic ranks and staff of the

Business Management Major, as well as The Lecturer

of Applied Business Administration Study Program.

REFERENCES

Ahmadi, H. B., Petrudi, S. H., & Wang, X. (2016).

Integrating Sustainability into Supplier Selection with

Analytical Hierarchy Process and Improved Grey

Relational Analysis: A Case of Telecom Industry.

International Journal Adv Manuf Technol, 15 October

2016, 15.

Arikunto, S. (2010). Prosedur Penelitian Suatu Pendekatan

Prakter . Jakarta: Rineka Cipta.

Arsyad, M. (2019). Perancangan Sistem Pendukung

Keputusan Pemilihan Kepala Sekolah Terbaik Tingkat

Kabupaten Deli Serdang Menggunakan Metode

Analytical Hierarchy Process (AHP). Journal Of

Informatic Pelita Nusantara Volume.4 Nomor. 2, 8.

Arunkumar, N., Karunamoorthy , L., & Muthukumar, S.

(2011). Supplier Evaluation and Selection for A

Manufacturing Industry Using Analytical Hierarchy

Process - A Case Study. International Journal and

Systems Engineering Volume. 8, Nomor. 3 2011, 20.

Asamoah, D., Annan, J., & Nyarko, S. (2012). AHP

Approach for Supplier Evaluation and Selection in a

Pharmaceutical Manufacturing Firm in Ghana.

International Journal of Business and Management

Volume.7 Nomor 10 May 2012, 15.

Astanti, R. D., Mbolla, S. E., & Ai, T. J. (2020). Raw

Material Supplier Selection In A Glove Manufacturing:

Application of AHP and Fuzzy AHP. Decision Science

Letters, 22.

Bruno, G., Esposito, E., Genovese, A., & Passaro, R.

(2012). AHP-Based Approaches for Supplier

Evaluation: Problems and Perspectives. Journal of

Purchasing & Supply Management 18 (2012), 14.

Handayani, R. I., & Darmianti , Y. (2017). Sistem

Pendukung Keputusan Pemilihan Supplier Dengan

Metode Analytical Hierarchy Process pada PT.Cipta

Nuansa Prima Tangerang. Jurnal Techno Nusa Mandiri

Volume. 14, Nomor. 2 September 2017, 8.

Hanum, B., & Asmarani, C. (2015). Analisa Pemilihan

Supplier Sebagai Komponen Pendukung Produksi PT.

XYZ Menggunakan Metode Analytic Hierarchy

Process (AHP). Jurnal PASTI Volume. IX, Nomor.2

2015, 10.

Hati, S. W., & Fitri , N. S. (2017). Analisis Pemilihan

Supplier Pupuk Npk Dengan Metode Analytical

Hierarchy Process (AHP). Jurnal Inovasi Bisnis

Volume 5, Nomor 5, Desember 2017, 11.

Indriantoro, N., & Supono, B. (2013). Metodologi

Penelitian Bisnis untuk Akuntansi dan Manajemen .

Yogyakarta: BPFE Yogyakarta.

Kartawiguna, D., Prayudo, Y. A., Sutiono, M., & Roesly,

H. (2012). Analisis dan Perancangan Sistem

Pendukung Keputusan Pemilihan Pemasok Terbaik dari

Pemasok Tersedia dengan Metode Analytical

Hierarchy Process (AHP). ComTech Computer

Mathematics and Engineering Applications Volume.3

Nomor.2 Desember 2012, 14.

Koc, E., & Burhan, H. A. (2014). An Analytic Hierarchy

Process (AHP) Approach to a Real World Supplier

Selection Problem: A Case Study of Carglass Turkey.

Global Business and Management Research: An

International Journal Volume. 6 Nomor. 1 (2014), 14.

Malik, A. Y., & Haryanti, T. (2018). Penerapan Metode

Analytical Hierarchy Process (AHP) Untuk Sistem

Pendukung Keputusan Pemilihan Program Keahlian

Pada SMK Daarul Ulum Jakarta. Jurnal PILAR Nusa

Mandiri Volume. 14 Nomor. 1, 8.

Munir, M. (2016). Pemilihan Supplier Sodium Hiroxide

Liquid Integrasi dengan Metode AHP - Topsis. Jurnal

Teknik Industri Volume. 17, Nomor. 2 Agustus 2016,

10.

Noviandri , M. R., Tama, I. P., & Yuniarti, R. (2015).

Analysis Pemilihan Supplier Metallic Box

Menggunakan Fuzzy Analytic Hierarchy Process

(AHP). Jurnal Rekayasa dan Manajemen Sistem

Industri Volume.3 No.3 2015, 10.

Pratiwi, I., MZ , H., & Aprilyanti, S. (2018). Pemilihan

Supplier Terbaik Penyedia Barang Consumable

Menggunakan Metode Analytical Hierarchy Process

(Studi kasus di Departemen Pengadaan Barang

PT.PUSRI). Jurnal Manajemen Industri dan Logistik

Volume. 2 Nomor. 2 November 2018, 12.

Purnomo, E. N., Sihwi S.Kom., MTI, S. W., &

Anggrainingsih, R. (2013). Analisis Perbandingan

Menggunakan Metode AHP, TOPSIS, dan AHP-

TOPSIS dalam Studi Kasus Sistem Pendukung

Keputusan Penerimaan Siswa Program Akselerasi.

Jurnal ITSMART Volume. 2 Nomor. 1, 8.

Rakasiswi, L. S., & Badrul, M. (2020). Penerapan Metode

Analytical Hierarchy Process Untuk Pemilihan Siswa

Terbaik. Jurnal PROSISKO Volume. 7 Nomor. 1, 7.

Rimantho, D., Fathurohman, Cahyadi, B., & Sodikun.

(2017). Pemilihan Supplier Rubber Parts Dengan

Metode Analytical Hierarchy Process Di PT.XYZ.

Jurnal Rekayasa Sistem Industri Volume 6 Nomor 2

Oktober 2017, 12.

ICAESS 2021 - The International Conference on Applied Economics and Social Science

416

Rouyendegh, B. D., & Erkan, T. E. (2012). Selecting the

Best Supplier Using Analytic Hierarchy Process (AHP)

Method. African Journal of Business Management

Volume. 6 Nomor. 4, 1 February 2012, 8.

Saaty, T. (1994). How to Make a Decision: The Analytic

Hierarchy Process. Interfaces. University of Pittsburgh:

RWS publication.

Saaty, T., & Vargas, L. (2012). Models, Methods, Concept

& Applications of The Analytic Process. New York:

2nd edition. Springer.

Sugiyono. (2013). Metode Penelitian Pendidikan

Pendekatan Kuantitatif, Kualitatif, dan R&D. Bandung:

Alfabeta.

Sugiyono. (2015). Metode Penelitian Pendidikan (

Pendekatan Kuantitatif, Kualitatif, dan R&D ).

Bandung: Alfabeta.

V, M., Agrawal, R., & Sharma, V. (2014). Supplier

Selection Using Social Sustainability: AHP Based

Approach in India. International Strategic Management

Review 2 November 2014, 15.

Zaman, M. (2020). Supplier Selection Using AHP-VIKOR

and AHP-TOPSIS Method: A Case Study for

Bangladeshi Jute Mill of Khulna Region. International

Journal of Industrial Engineering Volume 7 Issue 1

January - April 2020, 11.

Analysis of Jig Supplier Selection with Analytical Hierarchy Process Method: Case Study at Purchasing Department at PT Patlite Indonesia

417