Biochemical Characteristics of Ground Robusta Coffee under

Various Postharvest Technologies and Processing Parameters

Sri Wulandari, Makhmudun Ainuri

*

and Anggoro Cahyo Sukartiko

Department of Agro-Industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada

Jl. Flora 1 Bulaksumur, Yogyakarta 55281 Indonesia

Keywords: Caffeine, Chlorogenic Acid, Sucrose, Lipid, Roasting, Milling, Full Wash, Honey, Natural, Robusta Coffee.

Abstract: The purpose of this study was to analyze the biochemical characteristics of ground Robusta coffee under

various postharvest technologies and processing parameters and to find out the best treatment combination.

The orthogonal array notation of Taguchi method used was L

9

(3

4

) with four factors and three levels from

postharvest (full wash, honey, and natural), temperature (150 ºC, 175 ºC, 200 ºC), roasting time (10 minutes,

12.5 minutes, and 15 minutes) and milling (80 mesh, 100 mesh, and 120 mesh). The tested biochemical

characteristics were moisture, caffeine, chlorogenic acid, sucrose, and lipid contents. ANOVA for the mean

and SNR values were performed to determine significant differences between treatments. The best conditions

were carried out by Grey Relational Analysis, which furthermore tested with a confirmation test. The analysis

results showed that the effectiveness of the treatment had significant differences from each treatment from

parameters: moisture content, caffeine, chlorogenic acid, and lipid. The best conditions were the combination

of postharvest technologies (full wash), temperature and roasting time (175℃ and 12.5 minutes), and milling

(100 mesh) with moisture content (3.21%), caffeine (0.81%), chlorogenic acid (8.1%), sucrose (2.58%), lipids

(8.5%) and these results have been confirmed.

1 INTRODUCTION

Coffee is one of the mainstay plantation commodities

for Indonesia's national income and foreign

exchange. According to data from the International

Coffee Organization (ICO) in 2019, Indonesia ranks

fourth with a total production of 12 million bags of

coffee weighing 60 kg. In Indonesia, the Sumatra

Island is the largest coffee plantation area,

specifically in Bengkulu province which ranks 6

th

as

the largest coffee barn in Indonesia. Bengkulu coffee

plantation produced 184,168 tons of coffee in 2018

(Directorate General of Estate Crops, 2018)

There are three postharvest technologies for red-

picked Robusta coffee beans in Bandung Jaya,

Kepahiang, Bengkulu: In the full wash, honey, and

natural process. In the full wash process, the cherry

coffee must be soaked in a soaking tub, and then only

submerged cherry coffee is peeled off with a peeling

machine. Afterward, it is soaked for twenty-four

hours before dried in the drying house pulped coffee

beans washed. The honey process is simpler. After

the coffee cherries are peeled with a peeling machine,

the coffee beans from the pulper machine are

fermented in a sack for twenty-four hours, and then

dried in the drying house. In the natural process,

cherry coffee is not peeled in the peeling machine.

After soaking in the tub, it is immediately carried out

in the drying house.

Harvesting methods such as selective harvesting

are better than strip harvesting. Postharvest

processing affects all physical and roast quality

attributes so that variations in the physical properties

of roasting results due to different harvesting and

postharvest processing methods affect the quality of

ground coffee (Ameyu, 2016). Interaction of varieties

and postharvest processing methods affect the

biochemical yield of coffee beans (Kassaye et al.,

2019), such as different processing for wet pulper,

hand pulper, and eco pulper showing varying results

in fatty acid concentrations (Richard et al., 2020). The

wet method caused an increase in chlorogenic acid

and trigonelline content and a slight loss of sucrose

content compared to the dry method (Duarte et al.,

2010)

Roasting and milling operations are important

operations in ground coffee processing. Roasting is

the key to the quality of ground coffee, when roasting

Wulandari, S., Ainuri, M. and Sukartiko, A.

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters.

DOI: 10.5220/0010753900003113

In Proceedings of the 1st International Conference on Emerging Issues in Technology, Engineering and Science (ICE-TES 2021), pages 333-343

ISBN: 978-989-758-601-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

333

occurs the process of forming the taste and aroma of

the coffee beans. The aroma of coffee is intrinsically

related to chemical compounds in the beans, which

occur during the roasting process (Toledo et al.,

2016). While the factors that influence the roasting

process are the type and physio-organoleptic

properties of the coffee beans, the ratio of temperature

and roasting time, the degree of roasting, and the

roasting method (Mulato, 2019). The roasting process

causes changes in the chemical composition and

biological activity of coffee: while natural phenolic

compounds may be lost, other antioxidant

compounds are formed such as the products of the

Maillard reaction (Wang et al., 2011). Roasting

involves high-temperature treatment which triggers

non-enzymatic browning reactions, breakdown of

polymers (proteins, lipid, carbohydrates), breakdown

of polyphenols, and other chemical changes (Wei &

Tanokura, 2015).

The milling process in coffee aims to reduce the

particle size of coffee beans, this operation can also

affect the quality of ground coffee (Yüksel et al.,

2020). Like the fine texture of ground coffee, it also

determines the taste and aroma of ground coffee

(Bladyka, 2016).

Statistical methods have been developed and used

in various fields, one of which is optimization. The

statistical method commonly applied for optimization

is Taguchi. The Taguchi method is off-line quality

control which means preventive quality control that

ensures the product design or process before it

reaches production at the shop floor level. The

Taguchi method is expected to improve the quality of

products and processes while minimizing costs and

resources. The method is aimed to make the product

robust against noise (Sidi & Wahyudi, 2013). Taguchi

method is used to analyze the experimental finding to

achieve one or more of the following three objectives:

(1) to determine trends in the influence of factors and

interactions being studied, (2) to identify important

factors and their relative influence on outcome

variability, (3) to determine the best or optimum

conditions for a product or process (Roy, 2010).

Based on these considerations, it is necessary to

study the relationship between postharvest

technologies and processing parameters towards the

biochemical characteristics in premium, red-picked

Robusta coffee. This study aimed to analyze

differences in biochemical characteristics consisting

of moisture, caffeine, chlorogenic acid, sucrose, and

lipid content of premium red pick Robusta coffee

based on postharvest technologies (full wash, honey,

and natural) and processing parameters (roasting and

milling) of coffee in Bandung Jaya, Kepahiang,

Bengkulu. The Taguchi experiment was used in this

research and to find out the best conditions from

ground Robusta coffee used Grey Relational

Analysis.

2 METHODS (AND MATERIALS)

The method used in this research was the

experimental method which began with a literature

study, established problem formulations and

boundaries, determined parameters, performed the

tests, analyzed data, discussed test results, and drawn

the conclusions.

2.1 Taguchi Experimental Design

Experimental design involves evaluating the ability

of two or more factors (parameters) to influence the

average or variability of the combined results for a

specific product or process characteristics. Several

steps proposed by Taguchi to conduct experiments

systematically include the following: problem

formulation, experimental objectives, identification

of independent and dependent factors, determination

of each factor level, identification of interactions

between control factors, selection of orthogonal

arrays, experimental preparation, experiments

execution, analysis of data results with ANOVA,

interpretation of results, and confirmation (Sidi and

Wahyudi, 2013).

2.1.1 Determination of Each Factor’s Level

(Roy, 2010)

Determination of factors and levels is carried out

based on the results of literature studies, discussions

with coffee experts, and academics. In this study,

four-factor variables were selected at three levels

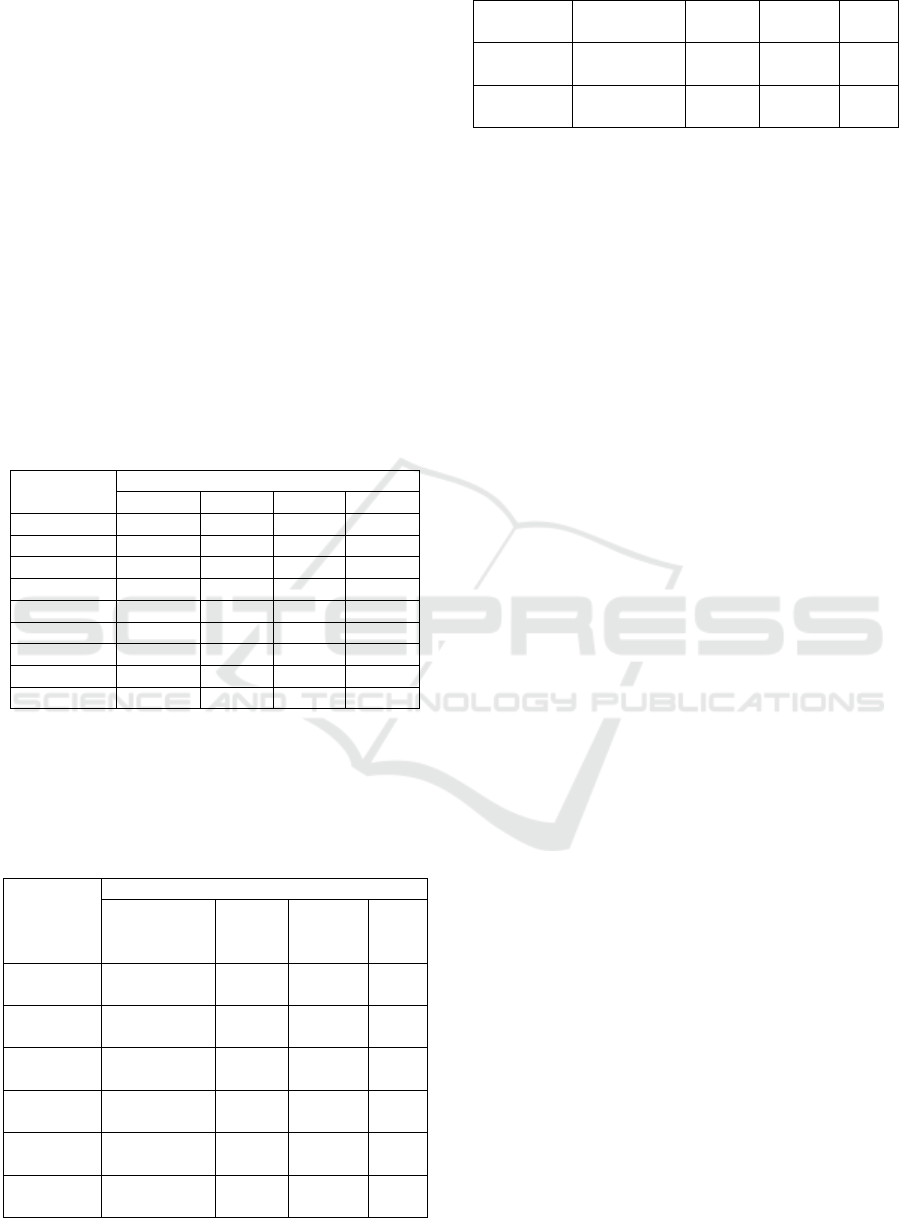

presented in Table 1.

Table 1: Factors and level treatment selected in processing

ground Robusta coffee.

No Facto

r

Level 1 Level 2 Level 3

1

Postharvest

technolo

g

ies

Full

wash

Honey Natural

2

Temperature

of roasting

150ºC 175 ºC 200 ºC

3

Time of

roastin

g

10.0

minutes

12.5

minutes

15.0

minutes

4 Milling 80 mesh

100

mesh

120

mesh

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

334

2.1.2 Selection of Orthogonal Matrix

(Roy, 2010)

An orthogonal matrix is a matrix of rows and

columns. Columns reflect the factors that can be

altered during an experiment. The row is a

combination of experiment levels and influence (Sidi

& Wahyudi, 2013). The orthogonal matrix used was

a standard matrix for experiments with a number of 3

levels: L

9

(3

4

), L

27

(3

13

) and L

81

(3

40

). The chosen

orthogonal matrix is one with a degree of freedom

equal to or greater than the experimental degree, as in

this study with a matrix L

9

(3

4

) where L denotes: Latin

square design, 9 denotes the number of rows or

experiments, 3 denotes the number of levels, and 4

denotes the number of columns or factors. Table 2

showed the orthogonal matrix L

9

(3

4

) which had 4

factors and 3 levels.

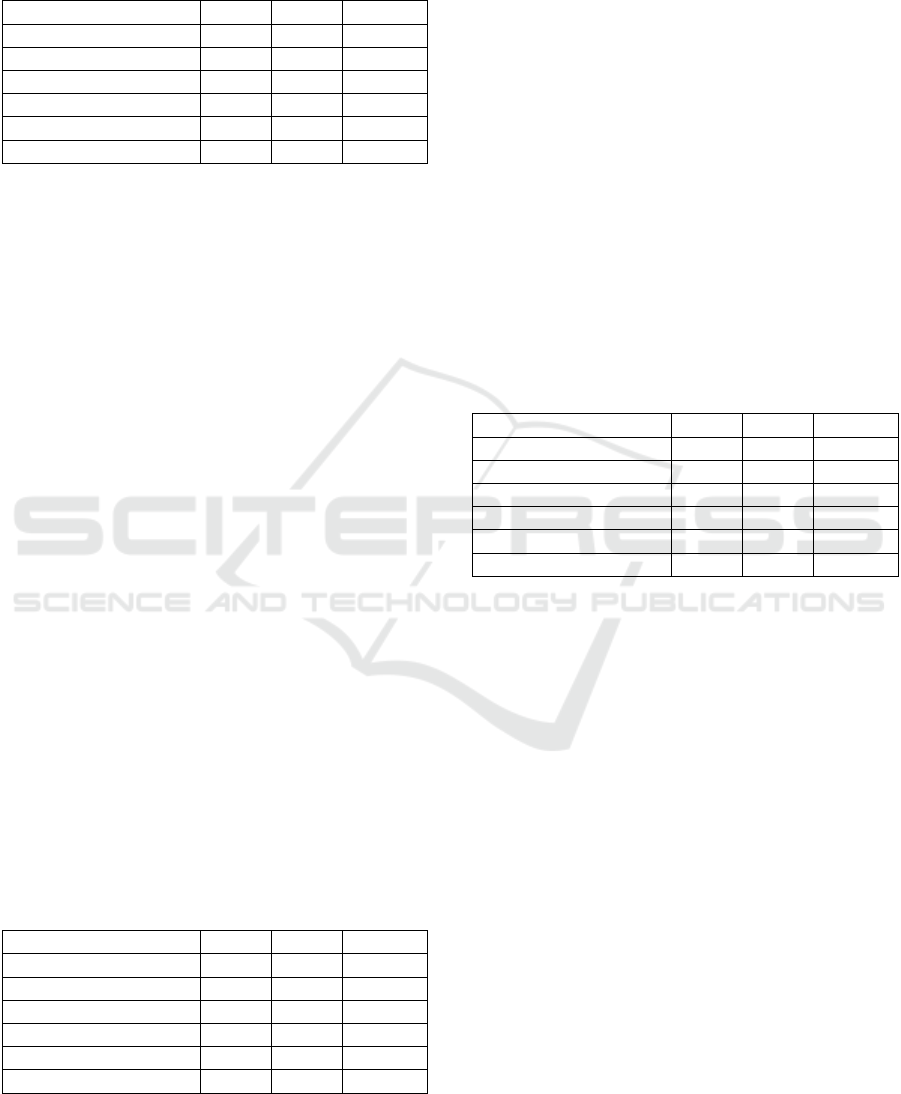

Table 2: Orthogonal Matrix L

9

(3

4

).

Experiment

number

Experimental factors

A B C D

1 1 1 1 1

2 1 2 2 2

3 1 3 3 3

4 2 1 2 3

5 2 2 3 1

6 2 3 1 2

7 3 1 3 2

8 3 2 1 3

9 3 3 2 1

The factors and levels that have been compiled

when combined follow the orthogonal array matrix

used, they can be presented in Table 3.

Table 3: The full interpretation of Taguchi’s orthogonal

array.

Experiment

number

Ex

p

erimental factors

Postharvest

technologies

Tempe-

rature of

roastin

g

Time of

roasting

Millin

g

1 Full wash 150ºC

10.0

minutes

80

mesh

2 Full wash 175ºC

12.5

minutes

100

mesh

3 Full wash 200ºC

15.0

minutes

120

mesh

4 Honey 150ºC

12.5

minutes

120

mesh

5 Honey 175ºC

15.0

minutes

80

mesh

6 Honey 200ºC

10.0

minutes

100

mesh

7 Natural 150ºC

15.0

minutes

100

mesh

8 Natural 175ºC

10.0

minutes

120

mesh

9 Natural 200ºC

12.5

minutes

80

mesh

2.1.3 The Stage of Carrying Out the

Taguchi Experiment

The processing treatment was carried out based on a

combination of factors and levels in the Taguchi

method with the experimental design shown in Table

3. The green coffee bean samples was prepared for

each treatment so that the total ingredients used were

27 kg (9 kg green bean full wash, 9 kg green bean

honey, and 9 kg natural green bean). Before the

roasting process, 1 kg of the bean sample was

weighed in triplicate one treatment. The sample was

roasted with the temperature and roasting time

according to the combination of factors and levels.

After the roasting process was complete, the coffee

was cooled and put into a labeled plastic. After

cooling (8-24 hours), the sample was grounded using

a grinder machine in the coffee processing plant.

Milling was carried out with a variety of mesh,

namely: 80, 100 and 120 mesh (Table 1).

The quality of ground coffee resulted from the

experiments was evaluated its biochemical

characteristics. The characters included moisture,

caffeine, chlorogenic acid, sucrose, and lipid content.

Determination of moisture content used the oven

method. The sample was dried in an oven set to 100

℃ - 102 ℃ until the sample has a constant weight.

Caffeine content was determined using the Balley-

Andrew method. The chlorogenic acid concentration

was measured using an HPLC instrument. The

sucrose content was calculated as the difference

between reducing sugar and the total sugar. The sugar

reduction was determined based on the Nelson

Somogyi method. Meanwhile, the lipid content was

measured using the Soxhlet method, the principle of

Soxhlet method was the separation of the components

contain in the substance by filtering for carried out

several times using a certain solvent so that the

desired component was obtained.

2.2 Data Analysis

2.2.1 Determine Effectiveness Treatments

with S/N (Signal to Noise) and ANOVA

The Taguchi method is used to design experiments

based on the orthogonal arrays to obtain the

maximum amount of information with minimum

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters

335

experiments. Moreover, it can also analyze the

experimental data based on the signal-noise ratio. The

signal-noise ratio (S/N) is the ratio of the mean

standard deviation which serves as an objective

function for the optimization process The

biochemical quality characteristics discussed in this

study are moisture content, caffeine, chlorogenic

acid, sucrose, and lipid in ground coffee. The quality

characteristics of the ratios used for each parameter

are described as follows:

1. Moisture content (smaller the better) which

means the smaller in moisture content value on

the test results, the better the nature of the ground

coffee produced, this determination refers to

where the maximum moisture content in coffee is

7% (The National Standardization Agency of

Indonesia, 2004), the moisture content is related

to the shelf life to prevent discoloration, mold and

the appearance of other microorganisms, so that

if the content is high, the product is easily

contaminated by microorganisms (Novita et al.,

2010).

2. Caffeine is determined (large the better), based

on states that caffeine in coffee it also as an index

of organoleptic quality and used as a

consideration to determine the mixing formula

for a recipe of ground coffee mixture (Marsilani

et al., 2020). The main role of caffeine in the

body is to increase psychomotor work so that the

body remains awake and provides a

psychological effect in the form of increased

energy (Thomas et al., 2016).

3. Chlorogenic acid is determined (larger the better)

with the consideration that chlorogenic acid is

beneficial for human health, namely as an

antioxidant, antiviral, hepatoprotective, and plays

a role in antispasmodic activities, high

chlorogenic acid in coffee can be used as a source

of therapy or drug manufacture (Farhaty &

Muchtaridi, 2014)

4. Sucrose is determined (larger the better) because

sucrose plays a role in influencing the test and

aroma of coffee so it is expected that its presence

is always high in coffee (Borem et al., 2016)

5. Lipids is determined (smaller the better) because

lipids in coffee affect the taste of coffee grounds,

an increase in free fatty acids during storage will

cause rancidity in coffee grounds so that it affect

to the taste, causing a decrease in the quality of

ground coffee (Hayati et al., 2012).

A mathematical model for the signal to noise ratio

(S/N) (Jeffrey et al., 2011):

For Smaller the better

SNR = -10 log (

∑

− 𝑦𝑖

) (1)

For Larger the better

SNR = 10 log (

∑

) (2)

where y

i

is a quality measurement; and n is the total

of the measurements.

ANOVA in Taguchi to detect differences in the

mean performance of the test groups of parts.

ANOVA can analyze the total variance into factor

variance so that it can be seen the effect of each factor

on the total variance. The use of ANOVA in the

Taguchi method is used as a statistical method to

interpret experimental data in the calculation of the

process as follows (Jeffrey et al., 2011):

1. Calculating the total sum of squares (Sstotal),

with the following formula :

Ss total=

∑

𝑦

2

(3)

Where y is the data for every replication.

2. Calculating the Sum of squares due to mean

(Ssmean)

Ssmean=𝑛.𝑦

2 (4)

Where n is total all replication.

3. Calculating the sum of square due to factors

SS

A

, SS

B,

etc), example factor A:

SSA=[ (𝐴1

)

2

𝑥𝑛1] +[(𝐴1 )

2

𝑥𝑛2]+…+

=[ (𝐴𝑖

)

2

𝑥𝑛1]-𝑠𝑠𝑚𝑒𝑎𝑛 (5)

4. Calculating the sum of square total (SST

SST= (𝑆𝑠𝑡𝑜𝑡𝑎𝑙− 𝑆𝑠𝑚𝑒𝑎𝑛) (6)

5. Calculating the sum of squares due to error

(SSe)

𝑆𝑆𝑒 = 𝑆𝑆𝑡𝑜𝑡𝑎𝑙 − 𝑆𝑆𝑚𝑒𝑎𝑛− 𝑆𝑆

A

-𝑆𝑆

B

-𝑆𝑆n (7)

6. The degrees of freedom factor (DF)

𝐷𝐹 =

(

𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑙𝑒𝑣𝑒𝑙𝑠 − 1

)

(8)

7. The degrees of freedom factor total (DF total)

𝐷𝐹 𝑡𝑜𝑡𝑎𝑙 =(𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑒𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡 − 1) (9)

8. Calculating mean sum of squares (MS)

𝑀𝑆 =

(10)

Where MS is mean Square, DF is degrees of freedom

9. Calculating of (F-Ratio)

𝐹 𝑟𝑎𝑡𝑖𝑜 =

(11)

10. Calculating the pure sum of square (SS’) for

each factor

SS’=(𝑆𝑆 𝑓𝑎𝑐𝑡𝑜𝑟− (𝑣 𝑓𝑎𝑐𝑡𝑜𝑟 𝑥𝑀𝑆 𝑒𝑟𝑟𝑜𝑟 (12)

11. Calculating % Ratio of each factor, example

factor A:

% 𝑅𝑎𝑡𝑖𝑜 𝐴 =

(13)

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

336

2.2.2 Determination of The Best Treatment

To overcome the multi-response problem in the

Taguchi method, Grey Relational Analysis (GRA)

was performed to obtain the best treatment with

several analysis steps below (Jeffrey et al., 2011):

1. Calculating the normalization of SNR value for

each response to reduce the effect of using

different units and reduce variability, the

equation is as follows:

X

i

*

(j)

=

(

)

()

(

)

()

(14)

(for signal to noise larger the better)

X

i

*

(j)

=

(

)

()

(

)

()

(15)

(For signal to noise small the better)

where xi(j) is the measurement of the quality

characteristics

2. Calculating the delta and gamma values (grey

relational coefficient) for each response. After

the deviation sequence value was obtained, put

into the formula to calculate the Grey Relational

Coefficient value. Distance measure Δ

oi

(j) was

performed which was the absolute value of the

difference between 𝑥

∗

and 𝑥

∗

on j point.

Δ

oi

(j) = ׀𝑥

∗

(

𝑗

)

− 𝑥

∗

(

𝑗

)

׀ (16)

Note:

𝑥

∗

(

𝑗

)

= 1 (highest value of SNR was inversed as

(1)

calculating grey relational coefficient γ

0i

(j), with

following equation:

γ

0i

(j) =

(

)

(17)

Note:

𝛥

= minimum value of 𝛥

(𝑗)

𝛥

= maximum value of 𝛥

(𝑗)

𝜆 = coefficient range between 0 and 1 (value

𝜆 determined by the decision-maker as he

expected, generally 𝜆 = 0,5)

3. Calculating grey relational grade which resulted

from the average of the grey relational coefficient

from the whole response

γ

i

=

∑

𝜉(𝑘) (18)

4. After obtaining the Grey Relational Grade value

for each experiment, the highest value was

determined from the response of each factor at

each level.

2.2.3 Confirm Test

The confirmatory experiment is designed to ensure

that the variables and levels chosen provide the

expected results. The confirmation test results are

declared valid or accepted if the confirmation test’s

confidence interval falls within the optimal value

interval and rejected if the confidence interval is not

within the optimal value interval. The confidence

interval was calculated using equations (Jeffrey et al.,

2011).

Optimal Condition (Taguchi Experiment)

a. Optimal Condition

𝜇𝑝𝑟𝑒𝑑𝑖ction= 𝑦̅ 𝑖𝑗𝑘𝑜𝑝𝑡𝑖𝑚𝑎𝑙− 𝑦̅ (19)

Note:

𝑦𝑖𝑗𝑘

optimal = The sum of the average value of

the optimal level

b. Calculation of Confidence Interval

𝐶𝑙𝑚𝑒𝑎𝑛 = ±

𝐹 ∝;𝑣1;𝑣2𝑥𝑀𝑆𝑒1 𝑥

(20)

𝑛𝑒𝑓𝑓=

Note:

Cl = confidence interval

𝐹∝;𝑣1;𝑣2 = F-ratio value from table

∝ = Risk, confidence level = 1 – risk

𝑣1 = Degree of freedom for the numerator

𝑣2 = Degree of freedom for the denominator

𝑀𝑆𝑒= Mean polled error sum of squares

Confirmatory Experiment

a. Calculation of Mean Value

µ=

∑

(21)

b. Calculation of confident interval

𝐶𝑙𝑚𝑒𝑎𝑛=±

𝐹 ∝;𝑣1;𝑣2𝑥𝑀𝑆𝑒1 𝑥

+

(22)

Note: r = The number of observations used to

calculate the mean

3 RESULT AND DISCUSSION

3.1 Effectiveness of Treatment on

Biochemical Characteristics

3.1.1 Moisture Content

ANOVA calculations use equations 3 to 13. In

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters

337

moisture content result presented in Table 4:

Table 4: ANOVA calculation of moisture content mean

from ground coffee.

Source F Ratio % ratio F -Table

Postharvest technolo

g

ies 2619.28 49.12 4.256

Temperature of roasting 881.0 16.51 4.256

Time of roastin

g

199.51 3.72 4.256

Millin

g

1626.19 30.49 4.256

Residual Erro

r

1 0.16 4.256

Total 100

According to ANOVA in Table 4, calculation

average of moisture content, all factors have an F-

ratio value ≥ F-Table which means that they have a

significant influence on the characteristics of the

moisture content. Postharvest technology factor is the

most influential factor on moisture content with the

largest contribution of 49.12%. Post-harvest handling

is an activity that includes all treatments from

harvesting to the production of green coffee beans

(Mayrowani, 2013). One of the causes to decrease in

moisture content is post-harvest handling and drying

of coffee beans (Novita et al., 2010). Full wash, honey

and natural processes which have different processing

stages affect the moisture content of the coffee beans,

this also affects the moisture content of the ground

coffee produced because the moisture content of the

initial coffee beans used is different. In addition, the

mill size factor also contributes greatly to the

moisture content of ground coffee, the size of the

mesh affects the resulting texture, the larger the mesh

size, the smoother the resulting material (Yulia et al.,

2018). The larger of the mesh size (the smaller the

particle size of the ground coffee), the higher the

absorbance intensity.

3.1.2 Caffeine

Table 4 shown the result of ANOVA calculations in

caffeine content.

Table 5: ANOVA calculation of caffeine mean from ground

coffee.

Source F Ratio % Ratio F-Table

Postharvest technolo

g

ies 75.50 22.04 4.256

Temperature of roasting 219.07 64.52 4.256

Time of roasting 26.00 7.40 4.256

Millin

g

12.93 3.53 4.256

Residual Erro

r

1 2.51 4.256

Total 100

According to ANOVA calculation in Table 5,

calculation average of caffeine, all factors have an F-

ratio value ≥ F-Table which means that they have a

significant influence on the characteristics of the

caffeine. Roasting temperature factor is the most

influential factor on caffeine content with the largest

contribution of 64.52%. Roasting time and higher

roasting temperature increased caffeine content due

to the breakdown of liquids and acids (Agustina et al.,

2019). Higher roasting temperature intensified the

caffeine content in the ingredients, as the amount of

liquid and acidic substances decreased, the amount of

non-liquid content such as caffeine, minerals, and

lipids increased (Wijayanti & Anggia, 2020).

3.1.3 Chlorogenic Acid

The results of the ANOVA calculations in

chlorogenic acid are presented in Table 6:

Table 6: ANOVA calculation of chlorogenic acid mean

from ground coffee.

Source F Ratio % Ratio F-Table

Postharvest technologies 370.23 60.17 4.256

Tem

p

erature of roastin

g

105.69 17.06 4.256

Time of roastin

g

15.73 2.40 4.256

Milling 117.51 18.99 4.256

Residual Erro

r

1 1.39 4.256

Total 100

In Table 6, it is known that all factors have an F-

ratio value ≥ F-Table, it means that the factors have a

significant effect on the characteristics of chlorogenic

acid. Postharvest technologies factor is the most

influential factor on the levels of chlorogenic acid

with the largest contribution of 60.17%. The

differences in the stages of processing coffee in full

wash, honey and natural processes in this study have

an effect on the content of chlorogenic acid. This is

appropriate where the biochemistry of coffee is

significantly influenced by the processing process,

such as the wet processing method causing an

increase in the content of chlorogenic acid (Duarte et

al., 2010).

3.1.4 Sucrose

The results of the ANOVA calculations of sucrose are

presented in Table 7.

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

338

Table 7: ANOVA calculation of sucrose mean from ground

coffee.

Source F Ratio % Ratio F-Table

Postharvest technologies 1.62 5.71 4.256

Tem

p

erature of roastin

g

2.08 9.93 4.256

Time of roastin

g

2.28 11.73 4.256

Milling 0.41 -5.44 4.256

Residual Erro

r

1 78.07 4.256

Total 100

F-ratio value ≤ F-Table which means that it does

not have a significant effect on the characteristics of

sucrose. Roasting time factor donating a percentage

ratio of 11.73% and a roasting temperature of 9.93%.

Roasting time and roasting temperature cause a

decrease in the content of sucrose, amino acids,

proteins, and polysaccharides (Williamso &

Hatzakis, 2019), because roasting causes the

evaporation of some substances in the coffee beans.

3.1.5 Lipid

The results of the ANOVA calculations of lipid are

presented in Table 8.

Table 8: ANOVA calculation of lipid mean from ground

coffee.

Source F Ratio % Ratio F Table

Postharvest technologies 4580.48 37.34 4.256

Temperature of roasting 2435.06 19.85 4.256

Time of roasting 4642.02 37.85 4.256

Milling 600.66 4.89 4.256

Residual Error 1 0.07 4.256

Total 100

Table 8 shows the F ratio value ≥ F-Table, this

means that all factors have a significant effect on the

lipid of ground coffee. The roasting time factor is the

most influential factor on lipid content with the

largest contribution of 37.85%. Differences in the

coffee process result in distinct tastes, owing

primarily to differences in the chemical composition

it contains. Wet-processed coffee beans contain

higher levels of amino acids, fats, and ash, and

contain less protein and caffeine than dry-processed

coffee. Conducted a study and demonstrated that

roasting had a significant impact on coffee and on the

lipid composition of coffee beans (Williamson &

Hatzakis, 2019).

3.2 Determination of the Best

Treatment

There were 5 types of response variables in this study,

each with a different set of quality characteristics

(moisture content “small the better, caffeine “large

the better”, chlorogenic acid “large the better”,

sucrose “large the better”, and lipid “small the better).

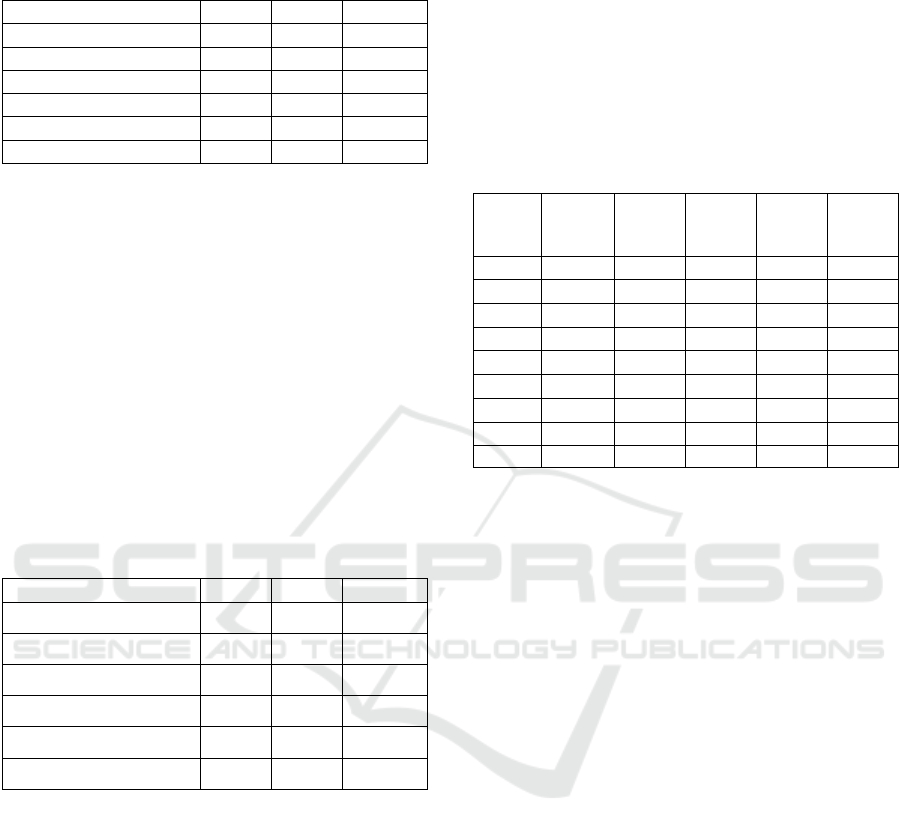

Table 9: SNR value for each response.

Experi

ment

Moisture

content

Caffeine

Chloro-

genic

aci

d

Sucrose Lipid

I -12.95 -3.54 15.32 -6.07 -20.76

II -13.06 -2.21 17.45 -3.69 -21.59

III -12.72 -1.67 13.84 -14.89 -21.06

IV -11.93 -2.62 9.11 -10.62 -20.83

V -10.38 -1.83 8.95 -20.00 -20.96

VI -11.85 -1.57 7.77 -13.55 -18.85

VII -13.94 -3.04 16.93 -13.36 -21.30

VIII -13.14 -2.73 12.79 -20.00 -21.03

IX -11.54 -2.33 9.98 -20.00 -21.27

The calculation of the SNR value for the five

responses was calculated with equation (1) and

equation (2). The result presented in Table 9: After

calculating the SNR, then the normalization of the

SNR was performed under equations (14) and (15).

The normality data of SNR is presented in Table 10.

Before performing the analysis using Grey

Relational Grade, first calculate the delta value and

gamma value of each response according to equation

(16), equation (17), and equation (18). Deviation

sequence (Delta) is presented in Table 11, meanwhile

the Grey Relational Coefficient and Grey Relational

Grade are presented in Table 12.

After obtaining the Grey Relational Grade value

for each experiment, the best treatment was

calculated as the response of each factor at each level

that produced the highest value (Table 13).

In table 13, the best treatment was obtained from

combination of the factors of A1B2C2D2 levels (full

wash postharvest technologies, roasting temperature

175 ºC, roasting time 12.5 minutes, and milling 100

mesh).

After obtaining the Grey Relational Grade value

for each experiment, the best treatment was

calculated as the response of each factor at each level

that produced the highest value (Table 13).

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters

339

Table 10: Normality of data.

Experiment

Normality of data

Factor

Moisture

content

Caffeine

Chlorogenic

acid

Sucrose Lipid

A B C D

I 1 1 1 1 0.720 0.000 0.779 0.854 0.698

II 1 2 2 2 0.753 0.672 1.000 1.000 1.000

III 1 3 3 3 0.656 0.947 0.627 0.313 0.805

IV 2 1 2 3 0.435 0.470 0.138 0.575 0.723

V 2 2 3 1 0.000 0.867 0.122 0.000 0.771

VI 2 3 1 2 0.413 1.000 0.000 0.395 0.000

VII 3 1 3 2 1.000 0.257 0.946 0.407 0.894

VIII 3 2 1 3 0.774 0.410 0.519 0.000 0.795

IX 3 3 2 1 0.324 0.613 0.229 0.000 0.884

Table 11: Deviation sequence (Delta).

Experiment

Deviation sequence (Delta)

Factor

Moisture

content

caffeine

Chlorogenic

acid

Sucrose Lipid

A B C D

I 1 1 1 1 0.280 1.000 0.221 0.146 0.302

II 1 2 2 2 0.247 0.328 0.000 0.000 0.000

III 1 3 3 3 0.344 0.053 0.373 0.687 0.195

IV 2 1 2 3 0.565 0.530 0.862 0.425 0.277

V 2 2 3 1 1.000 0.133 0.878 1.000 0.229

VI 2 3 1 2 0.587 0.000 1.000 0.605 1.000

VII 3 1 3 2 0.000 0.743 0.054 0.593 0.106

VIII 3 2 1 3 0.226 0.590 0.481 1.000 0.205

IX 3 3 2 1 0.676 0.387 0.771 1.000 0.116

Table 12: Grey Relational Coefficient and Grey Relational Grade.

Experimen

t

Grey Relational Coefficient

Grey

Relational

Grade

Factor

Moisture

content

Caffeine

Chlorogenic

acid

Sucrose Lipid

A B C D

I 1 1 1 1 0.641 0.333 0.694 0.775 0.623 0.613

II 1 2 2 2 0.669 0.604 1.000 1.000 1.000 0.855

III 1 3 3 3 0.592 0.904 0.572 0.421 0.720 0.642

IV 2 1 2 3 0.469 0.485 0.367 0.541 0.643 0.501

V 2 2 3 1 0.333 0.790 0.363 0.333 0.686 0.501

VI 2 3 1 2 0.460 1.000 0.333 0.453 0.333 0.516

VII 3 1 3 2 1.000 0.402 0.903 0.458 0.825 0.717

VIII 3 2 1 3 0.689 0.459 0.510 0.333 0.709 0.540

IX 3 3 2 1 0.425 0.564 0.393 0.333 0.812 0.506

Table 13: The response of each factor at each level.

Level

Facto

r

A B C D

1 0.703 0.611 0.556 0.540

2 0.506 0.632 0.621 0.696

3 0.588 0.554 0.620 0.561

Delta 0.197 0.077 0.064 0.156

Ran

k

1 3 4 2

In table 13, the best treatment was obtained from

combination of the factors of A1B2C2D2 levels (full

wash postharvest technologies, roasting temperature

175 ºC, roasting time 12.5 minutes, and milling 100

mesh).

3.3 Confirm Test

Confirmation is done by comparing the actual value

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

340

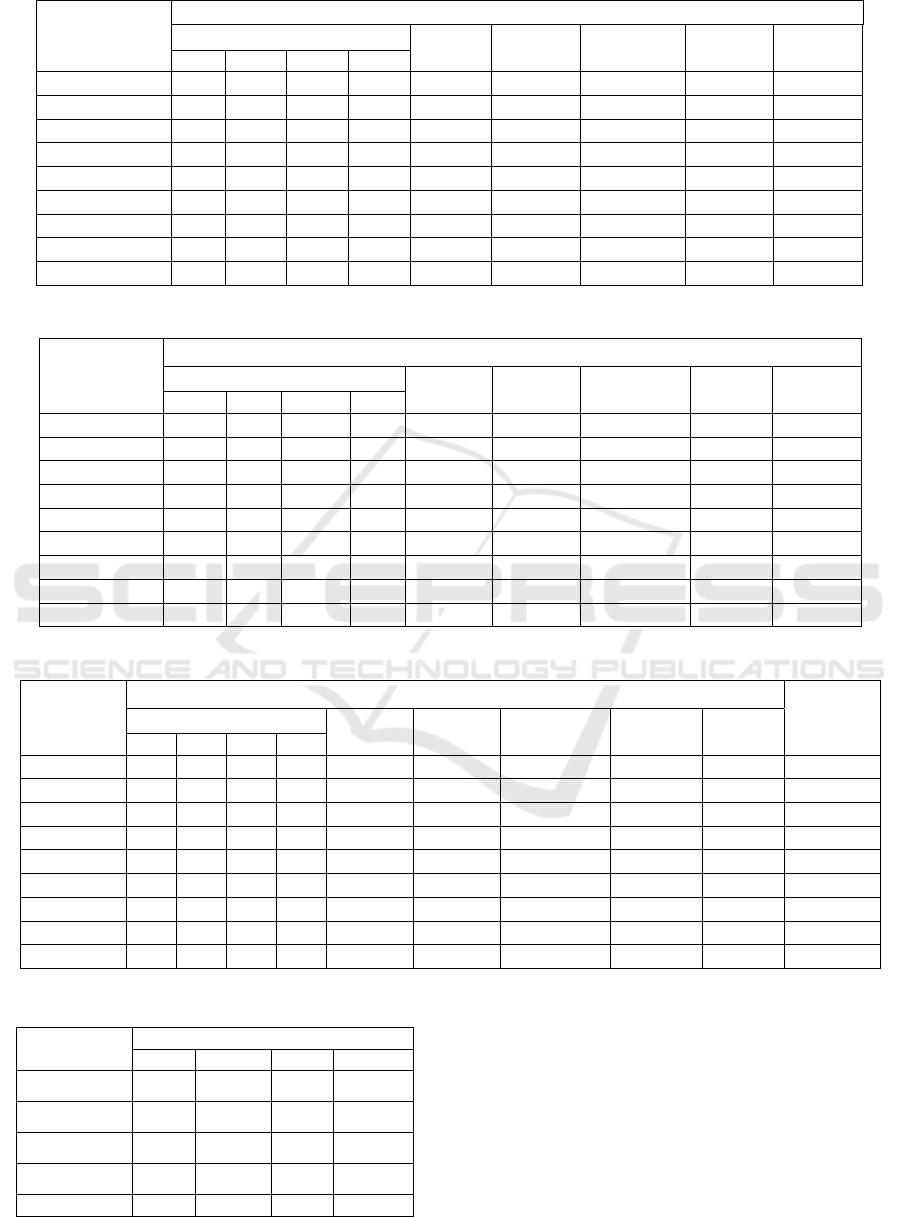

Table 14: Comparison experiment result confident intervals.

Response

Taguchi experiment Confirmatory experiment

Note

Prediction Optimization Prediction Optimization

Moisture content 3.37 3.37±0.2745 3.21 3.21±0.3783 Confirmed

Caffeine 0.84 0.84±0.0249 0.81 0.81±0.0343 Confirmed

Chlorogenic acid 7.19 7.19±1.0444 8.1 8.1±1.4395 Confirmed

Sucrose 0.75 0.75±0.3494 2.58 2.58±0.4815 Confirmed

Lipid 9.56 9.56±0.5599 8.5 8.5±0.7717 Confirmed

with the prediction interval so that the upper and

lower limits can be known. The treatment is said to

be confirmed if the actual value is in the predicted

value interval. The confidence interval was calculated

using equations (19) to (22). Table 14 comparison

experiment result in confidents intervals. The

decision on whether the optimal condition can be

accepted or not is to compare the mean value of the

prediction on Taguchi and the results of the

confirmation experiment with each level of

confidence. If the confidence interval of the

confirmation experiment is within the confidence

interval of the Taguchi experiment, then the decision

is accepted and confirmed even though not all are

vulnerable. In Table 14, biochemical characteristic in

confirmatory experiment is confirmed because the

result better than Taguchi experiments.

The best combination of factors and levels in this

study was the treatment with full wash postharvest

technology, temperature 175ºC, roasting time 12.5

minutes and milling 100 mesh, with moisture content

values (3.21%), caffeine (0.81%), chlorogenic acid

(8.1%), sucrose (2.58%), and lipid (8.5%). Research

related to the effect of postharvest handling on

chlorogenic acid and caffeine content shows that in

wet processing is greater than that of semi-wet and

dry processing (Kassaye et al., 2019). Similarly with

this study, to get a good chlorogenic acid and

caffeine, proper postharvest technology was the full

wash method.

The interaction between temperature and roasting

time has a significant effect on parameters, such as

moisture content, ash content, caffeine content,

antioxidant activity, yield (Saloko et al., 2019). At

different temperatures, the moisture content tends to

fluctuate, the longer the roasting time, the higher the

evaporated water. A roasting temperature of 190ºC

and a time of 10 minutes is the best combination of

treatments, if the temperature and roasting time

exceed it will cause a decrease in the quality of the

ash and caffeine content (Thomas et al., 2016).

Similarly with this study the combination of

postharvest technology full wash, temperature 175ºC,

time 12.5 minutes, and milling 100 mesh, interact

with each other to produce the best moisture and

caffeine content.

Chlorogenic acid will be degraded higher with a

long time and high temperature. The temperature of

225ºC for 19 minutes chlorogenic acid degraded up

to 85% (Diviš et al., 2019). The roasting process

produces melanoidin and aroma compounds while

reducing other important ingredients such as sucrose,

protein, amino acids, fatty acids, chlorogenic acids,

and polysaccharides. Only caffeine is relatively stable

during roasting because it is stable to heat (Wang &

Lim, 2015). Controlling the temperature and roasting

time at 175ºC and 12.5 minutes in this study caused

biochemical parameters such as caffeine, chlorogenic

acid, sucrose, and lipid to be in the best position.

Roasting conditions such as roasting degree affect

the antioxidants in coffee. During roasting, low water

activity and high temperature support the

development of the Maillard reaction, so that

phenolic compounds also participate in this reaction

which become part of melanoidin, can maintain or

increase antioxidant compounds, but with increasing

roasting activity will cause greater damage than

phenolic compounds. So that coffee that comes from

light roasting shows a greater antioxidant capacity

(Vignoli et al., 2014). The combination of treatment

with full wash postharvest technology, roasting

temperature of 175C, time of 12.5 minutes, and

milling 100 mesh, this find out light roasting product

so caused the best in biochemical characteristic.

4 CONCLUSIONS

The effectiveness of treatment has a significant

difference from each treatment for the parameters of

moisture, caffeine, chlorogenic acid, and lipid content

because value F-Ratio ≥ F-Table, but not significantly

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters

341

different for the mean on the sucrose parameter.

The best treatment was the combination of full

wash postharvest technologies, roasting temperature

175 ºC, roasting time 12.5 minutes, and milling mesh

100 which resulted in moisture content (3.21%),

caffeine (0.81%), chlorogenic acid (8.1%), sucrose

(2.58%), and lipid (8.5%). All these results were

confirmed through a confirmatory experiment.

ACKNOWLEDGMENTS

This research project is supported by the Final Project

Recognition (RTA) 2020, the Directorate of research,

Universitas Gadjah Mada.

REFERENCES

Agustina, R., Nurba, D., Antono, W., & Septiana, R.

(2019). Effect of Temperature and Roasting Time on

Physical-Chemical Properties of Arabica Coffee and

Robusta Coffee. Proceedings of the National Seminar,

53(9), 1689–1699.

Ameyu, M. A. (2016). ‘Physical Quality Analysis of

Roasted Arabica Coffee Beans Subjected to Different

Harvesting and Postharvest Processing Methods in

Eastern Ethiopia’.Journal of Food Science and Quality

Management. 57(1), 2224–6088.

The National Standardization Agency of Indonesia. (2004).

Ground coffee SNI 01-3542-2004. Jakarta, Indonesia.

Bladyka, E. (2016). ‘Coffee Brewing -Wetting, Hydrolysis

& Extraction’. Specialty Coffee Association of America,

1–6

Borém, F.M., Figueiredo, L.P., Ribeiro, F.C, Taveira ,J. H.

S., Giomo, G. S., & Salva, T. J. G. (2016). ‘The

Relationship between Organic Acids, Sucrose and the

Quality of Specialty Coffees’. African J. Agric. 11,

709–17.

Directorate General of Estate Crops. (2018). Tree Crop

Estate Statistics Of Indonesia 2017-2019 Coffee.

Directorate General of Estate Crops, 96.

Diviš, P., Pořízka, J., & Kříkala, J. (2019). ‘The effect of

coffee beans roasting on its chemical composition’.

Potravinarstvo Slovak J. of Food Sci. 13(1), 344–350

Duarte, G. S., Pereira, A. A., & Farah, A. (2010).

‘Chlorogenic acids and other relevant compounds in

Brazilian coffees processed by semi-dry and wet post-

harvesting methods’. Elsevier ltd J. Food Chemistry.

118(3), 851–855

Farah, A. (2012). Coffee: Emerging Health Effects and

Disease Prevention. First Edition. Inc and Institute of

Food Technologists (USA): Wiley Blackwell

Publishing Ltd;

Farhaty, N., & Muchtaridi. (2014).’Overview of Chemical

and Pharmacological Aspects of Chlorogenic Acid

Compounds in Coffee Beans’. Reviews. Supplement

Pharmacy, 14(1), 214–227.

Fisdiana, U., & Fitriyadi, E. M. (2018). ‘Effect of Roasting

Time on Moisture Content, Yield and Color of Robusta

Coffee Beans (Coffea canephora var. robusta ex

Frochner’. Agropross. 80(10), 22–24.

Hayati, R., Marliah, A., & Rosita, F. (2012). ‘Chemical

Characteristics and Sensory Evaluation of Arabica

Coffee Powder’. J Floratek. 7, 66–75.

ICO. (2019) Total Production by all exporting countries.

Retrieved from http:www.ico.org/prices/po-producti

on.pdf

Jeffrey Kuo, C. F., Su, T. L., Jhang, P. R., Huang, C. Y., &

Chiu, C. H. (2011). ‘Using the Taguchi method and

grey relational analysis to optimize the flat-plate

collector process with multiple quality characteristics in

solar energy collector manufacturing’. Elsevier Ltd J.

Energy, 36(5), 3554–3562.

Kassaye, T., Desalegn, A., Derbew, B., & Pascal, B. (2019).

‘Biochemical composition of Ethiopian coffees (Coffea

arabica L.) as influenced by variety and postharvest

processing methods’. African Journal of Food Science,

13(2), 48–56.

Marsilani, O. N., Wagiman, & Sukartiko, A. C. (2020).

‘Chemical profiling of western Indonesian single origin

robusta coffee’. IOP Conference Series: Earth and

Environmental Science. 425(1).

Mayrowani, H. (2013). Policies on Coffee Post-Harvest

Technology Development and Its Development Issues.

Forum Penelitian Agro Ekonomi, 31(1), 31–50.

Mulato, S. (2019). Physical and Chemical Changes of

Coffee Beans During Roasting.https://www.cctcid.

com/2019/07/22/.

Novita, E., Syarief, R., Noor, E., & Mulato, S. (2010).

‘Smallholder Coffee Bean Quality Improvement with

Semi Wet Processing based on Clean Production’.

Agrotek, 4(1), 76–90.

Richard, K. K., Beatrice, M., & Patrick, M. (2020). ‘Effects

of processing methods on fatty acid profiles and

biochemical compounds of Arabica coffee cultivars’.

African Journal of Food Science, 14(4), 92–97.

Roy, R. K. (2010). A Primer on the Taguchi Method.

Second Edition. Dearborn, Michigan.

Saloko, S., Sulastri, Y., Murad, & Rinjani, M. A. (2019).

‘The effects of temperature and roasting time on the

quality of ground Robusta coffee (Coffea robusta) using

Gene Café roaster’. AIP Conference Proceedings, 2199

(April 2020).

Sidi, P., & Wahyudi, M. (2013).’Taguchi Method

Application to Find Out Roundness Optimization In

Lathe Process’. Mechanical Engineering. 4(2), 101-108.

Tawali, A. B., Abdullah, N., & Wiranata, B. S. (2018). The

‘Influence of Fermentation Using Bacteria Lactic Acid

Yoghurt to the Flavor of Coffe Robusta (Coffea

robusta)’. Canrea J. Food Technology, Nutrition, and

Culinary, 90–97.

Thomas Edvan, B., Edison, R., Made Same, D., S. (2016).

‘The Effect of Temperature and Roasting Time on the

Quality of Robusta Coffee [Coffea robusta]’. Journal of

Plantation Agro Industry.. 4(1), 31–40.

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

342

Toledo, P. R. A. B., Pezza, L., Pezza, H. R., & Toci, A. T.

(2016). ‘Relationship Between the Different Aspects

Related to Coffee Quality and Their Volatile

Compounds’. Comprehensive Reviews in Food Science

and Food Safety. 15(4), 705–719.

Vignoli, J. A., Viegas, M. C., Bassoli, D. G., & Benassi, M.

de T. (2014). ‘Roasting process affects differently the

bioactive compounds and the antioxidant activity of

arabica and robusta coffees’. Food Research

International. 61, 279–285.

Wang, H. Y., Qian, H., & Yao, W. R. (2011). ‘Melanoidins

produced by the Maillard reaction: Structure and

biological activity’. Elsevier Ltd. Food Chemistry,

128(3), 573–584.

Wang, X., & Lim, L. T. (2015). ‘Physicochemical

Characteristics of Roasted Coffee’. Coffee in Health

and Disease Prevention, 247–254.

Wei, F., & Tanokura, M. (2015). Chapter 10 - Chemical

Changes in the Components of Coffee Beans during

Roasting. In V. R. Preedy (Ed.), Coffee in Health and

Disease Prevention (pp. 83–91). Academic Press.

https://doi.org/https://doi.org/10.1016/B978-0-12-

409517-5.00010-3

Wijayanti, R., & Anggia, M. (2020). ‘Analysis of Cafein,

Antioxidant and Quality level of Coffee Powder of

Some Small and Medium Industries (SMI) in The

Tanah Datar Regency’. Journal of Agricultural

Technology & Industry. 25(1). 1–6.

Williamson, K., & Hatzakis, E. (2019).’Evaluating the

effect of roasting on coffee lipids using a hybrid

targeted-untargeted NMR approach in combination

with MRI’. Elsevier Ltd Food Chemistry. 299(7),

125039.

Yüksel, A. N., Özkara Barut, K. T., & Bayram, M. (2020).

‘The effects of roasting, milling, brewing and storage

processes on the physicochemical properties of Turkish

coffee’. LWT-Food science and Technology.131(6), 1–8.

Yulia, M., Asnaning, A. R., & Suhandy, D. (2018). ‘The

Influence of Particle Size of Ground Roasted Coffee in

Discrimination of Decaffeinated Coffee Using

Ultraviolet-Visible Spectroscopy and PLS-DA

Method’. Journal of Applied Agricultural Research.

18(1), 46–51.

Biochemical Characteristics of Ground Robusta Coffee under Various Postharvest Technologies and Processing Parameters

343