Experimental Study of Shear Strength of

Purus Lobang Berkait (PLB): Masonry Wall

Marwahyudi

1,2 a

, Senot Sangadji

1b

, Halwan Alfisa Saifullah

1c

and Stefanus Adi Kristiawan

1d

1

Civil Engineering Department, Faculty of Engineering, Sebelas Maret University, Surakarta, Indonesia

2

Sahid University, Jl. Adi Sucipto, Surakarta Indonesia

Keywords: Brick, Bed Joint, Head Joint, Masonry, Shear Strength.

Abstract: The earthquake caused damage to buildings, especially simple houses that were not designed according to

engineering rules. Damage caused by earthquakes is often found in the form of cracks to the collapse of

masonry walls. Damage due to earthquake forces can be anticipated by increasing the strength of columns,

beams, and brick walls. Especially for brick walls, this can be done by increasing the strength of the brick

unit, mortar, and brick design that optimizes the function of the mortar. The regular brick stacking pattern

produces a square bed joint and head joint area, while the hook-hole purus brick stacking pattern produces a

square bed joint and an upright cylindrical head joint that connects from top to bottom. This study aims to

determine the effectiveness of the use of PLB masonry in increasing the shear strength of the wall through

laboratory tests using two groups of test objects. Laboratory test results were analysed to determine the shear

strength of masonry walls based on the SNI formula. Based on the results of laboratory tests, it can be

concluded that PLB bricks have a strength of 13.64% greater than ordinary bricks.

1

INTRODUCTION

Indonesia is an earthquake-prone area. Data from the

National Disaster Management Agency (BNPB)

March 22, 2021, shows 1830 natural disasters caused

by earthquakes, volcanic eruptions, forest and land

fires, droughts, floods, landslides, tidal waves. The

above incident resulted in 409 deaths, 3448 houses

were seriously damaged and 88 damaged health

facilities (BNPB, March 2021). The BNPB data

illustrates that most of the damage occurred in

residential houses where most of these buildings were

not designed according to engineering rules so they

were classified as Non-Engineering Building (NEB).

Residential construction practices that do not meet

engineering rules are often encountered in the

community in the form of using very low-quality

concrete due to the uncontrolled mixing of materials

(Figure 1).

The use of plain reinforcement and wide stirrups,

exceeding the design requirements (Figure 2).

a

https://orcid.org/0000-0002-9917-761X

b

https://orcid.org/0000-0001-5131-6273

c

https://orcid.org/0000-0001-5106-3544

d

https://orcid.org/0000-0002-0312-4960

Figure 1: Imperfect concrete manufacture.

Figure 2: Plain reinforcement and wide stirrups.

220

Marwahyudi, ., Sangadji, S., Saifullah, H. and Kristiawan, S.

Experimental Study of Shear Strength of Purus Lobang Berkait (PLB): Masonry Wall.

DOI: 10.5220/0010748300003113

In Proceedings of the 1st International Conference on Emerging Issues in Technology, Engineering and Science (ICE-TES 2021), pages 220-226

ISBN: 978-989-758-601-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

Figure 3: The details of the distribution reinforcement do not

meet the requirements.

Details of reinforcement at joints that do not meet the

distribution length (Figure 3) and others.

Figure 4: Damage caused by an earthquake.

The strength of the NEB needs to be increased so

that occupant safety is guaranteed. This increase can

be done by increasing the strength of the concrete

elements and their reinforcement and/or increasing

the strength of the walls. Columns and beams form a

frame structure system that supports the building and

walls as a filler for the frame structure can also play a

role in contributing to the strength of the building.

Increasing the strength of the concrete beam-column

can be through increasing the quality of the

compressive strength of concrete and installing

concrete reinforcement that meets the design

requirements. Increased wall strength through

increasing the strength of bricks, mortar in the bed

joint and head joint area. Several studies have shown

that portals with infill bricks have better strength than

portals without infilling bricks. It can be concluded

that bricks have a contribution in contributing to the

strength of the building(Cavaleri & Di Trapani, 2015;

Farooquddin, 2000; Nguyen & Meftah, 2014). This

means that an increase in the overall masonry strength

can increase the strength of the infill portal structure.

The strength of a masonry wall in resisting lateral

forces (earthquake) can be analyzed by modeling it as

a strut element in which the series of bricks is

simplified into a diagonal strut plane. Some of the

lateral forces acting on the joint are distributed to the

wall as an axial force received by the diagonal plane

of the strut. Approaches in strut modeling can be

grouped into two, namely wall modeling as a diagonal

plane of one strut and multi-strut. The struts method

is proven to be effective in analyzing the contribution

of masonry walls in bearing lateral forces (Bolea,

2016; Di Trapani et al., 2018; El-dakhakhni, 2017; El-

Dakhakhni et al., 2003).

The strength of the diagonal struts model is

influenced by several parameters related to

mechanical, geometrical, and empirical properties of

masonry infilled frame structure. One of the

mechanical properties that are taken into account in

determining the strength of the diagonal struts is the

shear strength. The shear strength of a series of bricks

is also influenced by the bed and head joint bonds.

The bed joint bond provides strength in the vertical

direction and the head joint bond provides strength in

the horizontal direction. Both strengths are required

in a masonry wall assembly. The stronger the bed and

head joint bonds, the more strength the masonry wall

will be.(Francisco J. Crisafulli, 1997b; Pallarés et al.,

2021; Smyrou et al., 2011).The arrangement of PLB

bricks will provide a different bed and head joint

pattern from ordinary bricks. The mortar that fills the

hollow of the brickwork produces a peg that acts to

resist the horizontal force. The effect of these pegs is

similar to that of interlocking masonry with holes

filled with sand mortar as in the study conducted by

Joyklad(Joyklad & Hussain, 2019).

PLB bricks have a simple and flat shape making

them easier to organize in storage. The basic materials

and methods of burning are the same as ordinary

bricks, no special furnace is required, so all brick

craftsmen can make them. The volume of material

used in the manufacture is less than ordinary bricks.

Similar studies with PLB bricks are still few so it is

necessary to conduct research that produces

applicable and conclusive designs for problems that

are also easily mass-produced.

This study aims to determine the effectiveness of

mortar post-filling PLB masonry in increasing the

shear strength of the wall. The shear strength of the

PLB masonry will be compared with the shear

strength of the ordinary masonry to determine the

contribution of the mortar post.

Experimental Study of Shear Strength of Purus Lobang Berkait (PLB): Masonry Wall

221

2

MATERIALS AND METHODS

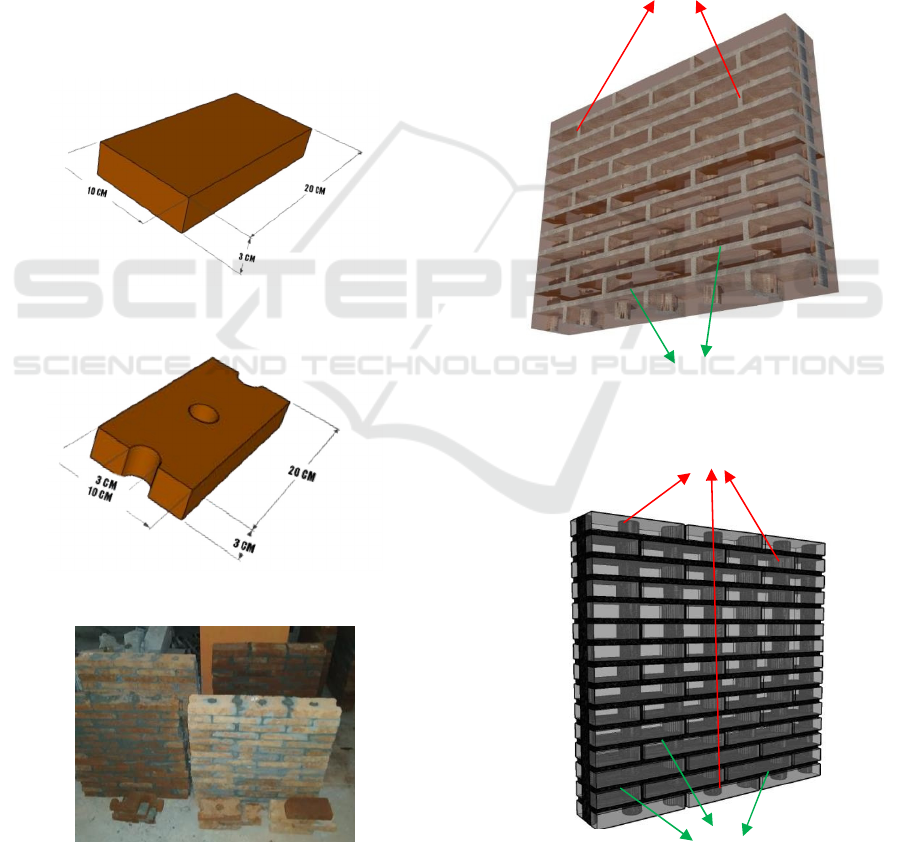

The test objects used were divided into two groups.

The first group is a PLB brick panel and the second

group is a regular model brick panel as a control.

2.1 Making Test Specimen

The normal brick panel (N) is made of ordinary

masonry measuring 10-centimeter wide, 20-

centimeter long, and 3-centimeter thick (see Figure

5). Meanwhile, PLB panels are made of hole bricks

of the same size as normal bricks but have a 3-

centimeter diameter hole (see Figure 6). The two

types of bricks are arranged to form a panel

measuring 60x60 cm (see Figure 7-8). The number of

test objects is shown in table 1.

Figure 5: Ordinary bricks.

Figure 6: Purus lobang berkait (PLB)Brick.

Figure 7: Manufacture of test specimens.

Figures 8 and 9: show the results of a series of

ordinary and PLB brick panels.

a) A series of panels made of ordinary bricks

produces the same bed joint and head joint

pattern, namely a rectangular area (see Figure 8).

b) The panel series of PLB bricks produces a

rectangular bed joint pattern and the head joint

has a cylindrical plane pattern that is connected

from the top to the bottom (see Figure 9).

c) The head joint pattern in the PLB is expected to

be able to withstand the lateral force

(earthquake) in the horizontal direction on the

brick series.

Head Joint

Bed Joint

Figure 8: Illustration of bed joint and head joint pattern.

Head Joint

Bed Joint

Figure 9: Illustration of bed joint and head joint pattern.

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

222

Table 1: Number of the test specimen.

Bric

k

T

y

pe Dia

g

onal Shea

r

Ordinar

y

(N) 3 specimen

Purus Loban

g

Berkai

t

(PLB) 3 specimen

2.2 Testing

Figure 10: Diagonal shear strength test.

The diagonal shear test procedure is as follows. First,

the test object is painted white to make it easier to

observe the cracks that occur. Then the test object is

placed in a diagonal position (see Figure 10) and the

end position of the test object must be in a vertical

line with the load cell or load jack. Followed by the

installation of the dial gauge on the right and left ends.

This tool serves as a strain gauge when receiving a

force. Loading is done by giving a force that increases

regularly. Loading starts from 0 and increases by 50

kgf until it is destroyed or the device is no longer able

to read. At every 50 kgf increase, the condition of the

specimen was observed and the strain was recorded.

Crack development is monitored from the beginning

of loading until failure. Then the results of the test are

analyzed.

2.3 Shear Stress

Shear Stress calculated according to the Indonesian

National Standard formula(SNI O3-4166-1996,

1996).

Diagonal shear strength formula:

Figure 11: Diagonal shear crack pattern(Borri et al., 2015).

f

vd

=

0,707𝑃𝑢+𝑊

𝑥(1 − µ) (1)

𝐴

𝐴

= ℎ 𝑥 𝑏 (1.2)

Where:

Pu = Maximum test load in N

W = Mass of internal aids N

b = Brick width in mm

h = The length of the shear plane of the

brick in mm

µ = Friction coefficient 0.3

A =Shear cross-sectional area (hxb) in mm2

The formula above shows that the diagonal shear

strength value is the ability of the magnitude of the

force in cutting across the diagonal area with the

length of the diagonal of the panel as h and the

thickness of the panel as b. This formula will be

effective if the crack of the test specimen has a

diagonal pattern so that the crack length is assumed to

be equal to the diagonal (as h). However, if the crack

pattern is not diagonal, then the proposed conversion

value (h) is derived from the length a of the crack or

the conversion of the magnitude of the force if the

crack pattern is in the diagonal direction.

3

RESULTS AND DISCUSSION

Masonry walls are made of bricks and mortar that

form a homogeneous whole. The bricks function as

filler and mortar as an adhesive for the bed joint and

head joint. Some researchers state that the wall is a

homogeneous series of marble and bricks in resisting

forces (Chopra, 2012; Francisco J. Crisafulli, 1997a;

Gambarotta & Lagomarsino, 1997; Miha Timocevic,

2006; Pauly, 2010).

Experimental Study of Shear Strength of Purus Lobang Berkait (PLB): Masonry Wall

223

The pattern of cracks/collapse that occurs between

ordinary panels and PLB panels has its

characteristics. The crack pattern starts from the area

that resists the force to the weak area. Weak areas are

found in the joints between mortar and bricks

(Cavaleri & Di Trapani, 2015; Lucchesi M, 2008;

Tomaževič, 2009). Pola ini sangat menarik untuk

diobservasi dan analisis.

The brick panels that receive a diagonal force

have a diagonal crack pattern that passes through the

head joint and bed joint (see Figure 11).

There are crack patterns that are produced in the

laboratory, starting from the top and some starting

from the bottom of the test object (as shown in

Figures 12 and 13).

Figure 12: Ordinary brick crack pattern.

Figure 13: Ordinary brick crack pattern.

The pattern of cracks/failure of normal bricks tends to

be lateral which is not following theoretical estimates.

The pattern of cracks that occurs predominantly in the

horizontal direction may be caused by the placement

of the corners of the test specimens not being perfect

at the ends of the brick panels so that during the

loading process the panels move slightly (see Figure

14). This movement causes the position of the panel to

shift slightly which results in the force not being in a

perfect diagonal direction and causing some of the

crack patterns to be horizontal.

Figure 14: The placement of the corners is not perfect.

The crack pattern of diagonal compression test

results on purus lobang berkaitbrick specimens.

Figure 15: PLB brick crack pattern.

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

224

Figure 16: PLB brick crack pattern.

The PLB crack/failure pattern is dominant in the

vertical direction with the crack pattern crossing the

bed joint and brick area. The cracks produced by PLB

bricks have a diagonal tendency. Figure 15

destruction of the panel above the second branch

because at the time of failure, the end of the panel

received a collision from the auxiliary tool so that the

crack direction pattern was in the same direction as

the bed joint. Figure 16 shows the failure of the top

plane not right at the end because the placement is not

perfect at an angle.

The results of the diagonal panel shear test in this

study showed a pattern of cracks through the bed

joint, head joint, and bricks. This pattern occurs in

both types of bricks. This test is very precise to

determine the diagonal shear strength of wall panels

from homogeneous mortar and brick bonds.

Meanwhile, to determine the shear strength of the bed

joint and head joint, a horizontal shear test is carried

out.

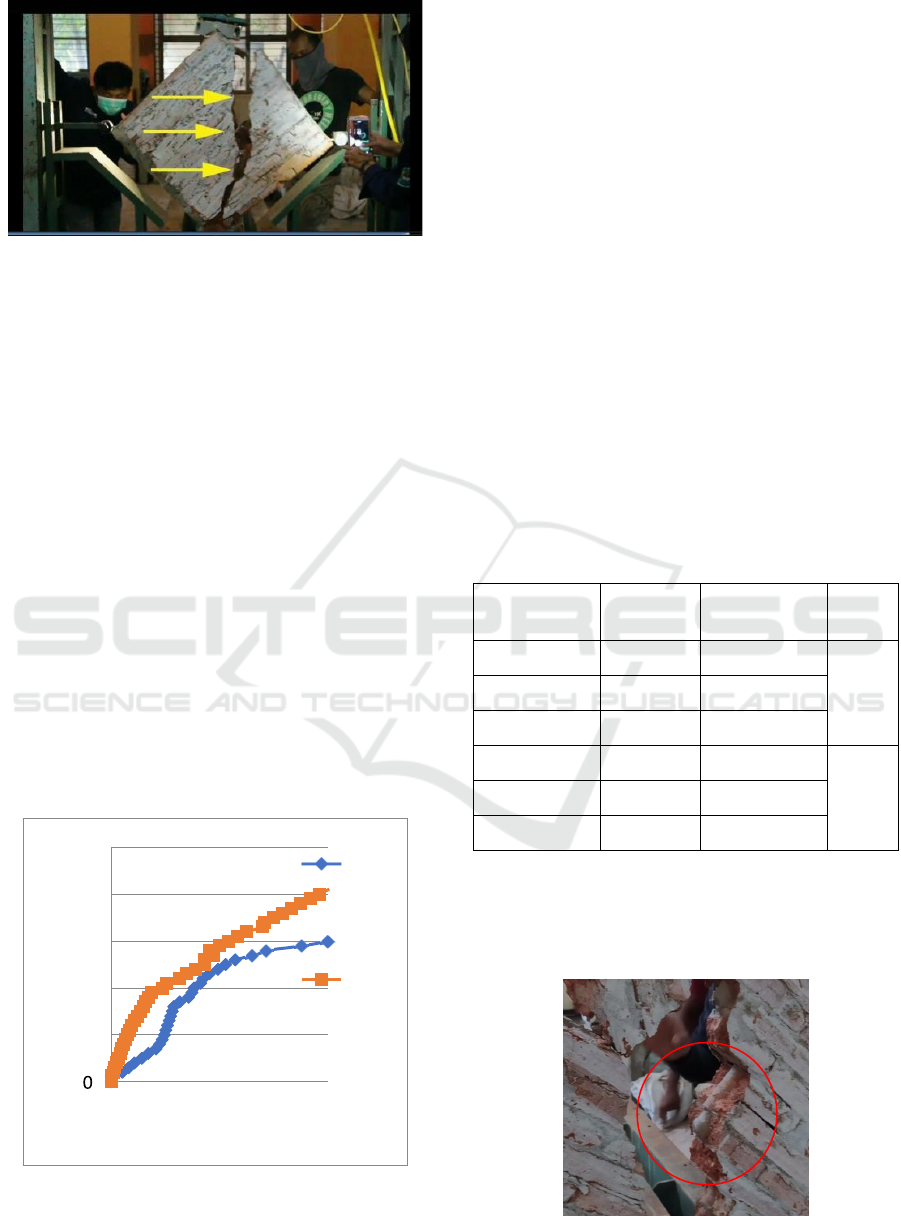

A lateral load-deformation diagram resulting from

laboratory tests.

Figure 17:

Load-

deformation

diagram.

This diagram shows that at the beginning of loading

shows a linear strength increases in proportion to the

deformation up to a certain point. After that, the

increase is not consistent with the deformation and

makes the non-linear direction until the total collapse.

Figure 17 shows that ordinary bricks (N) after

linear conditions increase in stiffness. This condition

is possible because the position of the elbow at the

end is still loose and unstable. At the time of loading

from the beginning to the end, the linear elbow at the

end experiences a movement that affects the stiffness

value. Then after that, the condition is stable which

increases the stiffness of the panel.

Normal bricks are in linear condition at a force of

0-450 kgf with deformation of 0.00 – 0.59 mm. Non-

linear conditions at 450-1550 kgf with deformation

0.59 – 2.73 mm, failure at 1300-1550 kgf. PLB bricks

are in linear condition at a force of 0-1000 kgf with

deformation of 0.00 – 0.64 mm. Non-linear

conditions at 1000-2150 kgf with deformation 0.64 –

2.79 mm, failure at 2000 -2200 kgf.

The results of the calculation of the diagonal shear

strength are summarized as follows:

Table 2: The results of the calculation of the shear strength

of the diagonal panel.

T

ypes of bricks

Early crack

(MPa)

Maximum shear

strength (MPa)

Average

(MPa)

Ordinary N 1

0,028 0,088

0,110

Ordinary N 2

0,040 0,138

Ordinary N 3

0,034 0,105

Lobang PLB 1

0,062 0,130

0,125

Lobang PLB 2

0,056 0,118

Lobang PLB 3

0,059 0,128

The results of the calculation of this study are

following the calculations carried out by Joyklad,

with the results of 0.096 - 2.183 MPa (Joyklad &

Hussain, 2019).

Figure 18: PLB brick-shaped mortar pegs.

2500

2000

Batu

bata

(N)

1500

1000

500

Batu

bata

(PLB)

Deformasi (mm)

Beban (kgf)

0,00

0,20

0,40

0,60

0,80

1,00

1,20

1,40

1,60

1,80

2,00

2,20

2,40

Experimental Study of Shear Strength of Purus Lobang Berkait (PLB): Masonry Wall

225

One of the reasons for increasing the strength of

PLB bricks is the formation of a cylindrical mortar

post in a vertical direction as shown in Figure 18. As

a validation, it is necessary to ensure the horizontal

shear test.

4

CONCLUSIONS

This research opens new insight that the strength of

masonry wall panels is influenced by the design of the

bricks that increase the function of the mortar. PLB

brick peg mortar increased the diagonal shear strength

of

the panel by 13.64% compared to ordinary bricks (N).

Tests in the laboratory showed that not all of the

crack patterns were following the theory. In future

research, more attention is paid to the setup of the test

object according to the standard to get results that are

closer to events in the field. In addition, numerical

studies are also needed as controls.

ACKNOWLEDGEMENTS

We would like to thank the laboratories of Universitas

Sebelas Maret Surakarta and Universitas Veteran

Bangun Nusantara for lending tools and places to

carry out the research. Also to the NEB research team

who provided input in the implementation of tests and

shared photos of earthquake damage documents.

REFERENCES

BNPB (2021). National Disaster Management Agency.

Jurnal Dialog Penanggulangan Bencana. 2087-636X.

Bolea, O. (2016). The Seismic Behaviour of Reinforced

Concrete Frame Structures with Infill Masonry in the

Bucharest Area. Energy Procedia, 85(November 2015),

60–76. https://doi.org/10.1016/j.egypro.2015.12.275

Borri, A., Castori, G., & Corradi, M. (2015). Determination

of Shear Strength of Masonry Panels Through Different

Tests. International Journal of Architectural Heritage, 9

(8), 913–927. https://doi.org/10.1080/15583058.2013.

804607

Cavaleri, L., & Di Trapani, F. (2015). Prediction of the

additional shear action on frame members due to infills.

Bulletin of Earthquake Engineering, 13(5), 1425–1454.

https://doi.org/10.1007/s10518-014-9668-z

Chopra, A. K. (2012). Dynamics Of Structures.

Di Trapani, F., Shing, P. B., & Cavaleri, L. (2018).

Macroelement Model for In-Plane and Out-of-Plane

Responses of Masonry Infills in Frame Structures.

Journal of Structural Engineering (United States),

144(2). https://doi.org/10.1061/(ASCE)ST.1943-

541X.0001926

El-dakhakhni, W. (2017). Three-Strut Model for Concrete

Masonry-Infilled Steel Frames. 9445(February 2003).

https://doi.org/10.1061/(ASCE)0733-9445(2003)129

El-Dakhakhni, W. W., Elgaaly, M., & Hamid, A. A. (2003).

Three-Strut Model for Concrete Masonry-Infilled Steel

Frames. Journal of Structural Engineering, 129(2),

177– 185. https://doi.org/10.1061/(ASCE)0733-

9445(2003)129:2(177)

Farooquddin, S. (2000). Lateral Stiffness of Infilled frame

with Door & Window Openings for varying Modulus of.

7–9.

Francisco J. Crisafulli. (1997a). Seismic behaviour of

reinforced concrete structures with masonry infills. In

Civil Engineering.

Francisco J. Crisafulli. (1997b). Thesis

fulltext_masonry.pdf. University of Canterbury.

Gambarotta, L., & Lagomarsino, S. (1997). Damage

models for the seismic response of brick masonry

shear walls . Part ii : the continuum model and its

applications.26(March 1996), 441–462.

Joyklad, P., & Hussain, Q. (2019). Axial compressive

response of grouted cement–clay interlocking hollow

brick walls. Asian Journal of Civil Engineering, 20(5),

733–744. https://doi.org/10.1007/s42107-019-00140-2

Lucchesi M. (2008). Masonry Constructions:

Mechanical Models and Numerical Applications. In

Masonry Constructions: Mechanical Models and

Numerical Applications. https://doi.org/10.1007/978-3-

540-79111-9 Miha Timocevic. (2006). Earthquake

Resistant Design of Masonry Building. Emparial

Collage Press.

Nguyen, T. D., & Meftah, F. (2014). Behavior of hollow

clay brick masonry walls during fire. Part 2: 3D finite

element modeling and spalling assessment. Fire Safety

Journal, 66, 35–45. https://doi.org/10.1016/j.firesaf.

2013.08.017

Pallarés, F. J., Davia, A., Hassan, W. M., & Pallarés, L.

(2021). Experimental and analytical assessment of the

influence of masonry façade infills on seismic behavior

of RC frame buildings. Engineering Structures, 235(Fe

bruary).https://doi.org/10.1016/j.engstruct.2021.112031

Pauly, T. (2010). Seismic Design of Reinforced Concrate

And Masonry Buildings. John Wiley & Sons.

Smyrou, E., Blandon, C., Antoniou, S., Pinho, R., &

Crisafulli, F. (2011). Implementation and verification

of a masonry panel model for nonlinear dynamic

analysis of infilled RC frames. Bulletin of Earthquake

Engineering, 9(5), 1519–1534. https://doi.org/1

0.1007/s10518-011-9262-6

SNI O3-4166-1996. (1996). Geser Dinding Pasangan Bata

Merah Dl Laboratorium. 2, 4166.

Tomaževič, M. (2009). Shear resistance of masonry walls

and Eurocode 6: Shear versus tensile strength of

masonry. Materials and Structures/Materiaux et

Constructions, 42(7), 889–907. https://doi.org/10.

1617/s11527-008-9430-6

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

226