Identification of Risk Factors for Delayed Time Schedule in

Summarecon Serpong Playfield Preschool Project

Deni Setiawan

1a

and Stefanny Abigail

2b

1

Department of Civil Engineering, Faculty of Engineering, Maranatha Christian University, Jl. Surya Sumantri 65,

Bandung, West Java, Indonesia

2

Bachelor Degree Student of Civil Engineering, Faculty of Engineering, Maranatha Christian University,

Jl. Surya, Sumantri 65, Bandung, West Java, Indonesia

Keywords: Delay, Risk Factors, Risk Identification, Project, Construction.

Abstract: Construction tasks are generally carried out beneath surroundings characterised with the aid of using various

diploma of hazard and uncertainties, which could end result from ‘acknowledged’, ‘acknowledged-

unknown’, and ‘unknown-unknown’ situations (Smith, 1999). Delays withinside the mission that may be as

a result of numerous elements, each inner and outside elements. However, it can't be denied that during

Indonesia stage of mission put off is pretty excessive and may be as a result of numerous elements, each

inner and outside elements. The motive of this take a look at is to investigate the elements of put off

withinside the implementation of the Playfield Preschool Summarecon Serpong mission. Final effects of the

take a look at there are variations of opinion concerning the elements inflicting mission delays among

mission people and teachers who're specialists withinside the area of production control. Based at the

descriptive take a look at effects of the 6 classes of put off, it changed into discovered that the thing

inflicting the best put off changed into the monetary class. More certain studies is wanted which may be

analyzed greater deeply into the elements inflicting mission delays aside from the monetary class.

a

https://orcid.org/0000-0002-0335-2111

b

https://orcid.org/0000-0003-3776-8657

1

INTRODUCTION

In Indonesia, the extent of mission delays is pretty

excessive, primarily based totally on studies carried

out with the aid of using 168 respondents who're

contractors, one hundred fifteen of whom stated that

delays in tasks frequently arise. The percent of put

off withinside the mission, it changed into

discovered that withinside the first role eighty two

respondents had a percent of delays beneathneath

1%, then withinside the 2nd role sixty one

respondents had a put off percent of 1-five% as

reported in Widhiawati (2012).

Delays withinside the mission that may be as a

result of numerous elements, each inner and outside

elements. Apart from inner and outside elements, in

general, a mission has a production control

representative in order that a mission can run in step

with the deliberate time, however in center to

decrease tasks that is frequently neglected. Playfield

Preschool is one in every of the faculties positioned

in a constructing that has been finished to be

particular withinside the Summarecon Digital Center

mall, Gading Serpong, Tangerang. This is because

of the growing want for the network withinside the

area of schooling which isn't matched with the aid of

using the provision of vacant land. To get round this,

many colleges were set up in purchasing

centers/mall or different transformed homes.

The Summarecon Serpong Playfield Preschool

improvement mission includes 2 mission elements,

specifically the development of a swimming pool and

the development of a faculty section. In the absence

of a production control representative at the mission,

maximum contractors aren't privy to the elements that

may reason delays withinside the mission. Where if a

production mission stories a put off, the time for the

finishing touch of the mission that has been said

withinside the agreement record wishes to be

increased. In addition to permitting extra prices and

190

Setiawan, D. and Abigail, S.

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project.

DOI: 10.5220/0010747900003113

In Proceedings of the 1st International Conference on Emerging Issues in Technology, Engineering and Science (ICE-TES 2021), pages 190-199

ISBN: 978-989-758-601-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

others to arise, it's far important to become aware of

and examine the hazard elements that reason the

mission put off. The motive of this take a look at is to

investigate the elements of put off withinside the

implementation of the Playfield Preschool.

2

LITERATURE REVIEW

2.1 Overview of Delay in Construction

Delay is partial unusable implementation time in

step with plan, consequently inflicting a number of

the sports that accompanied have become behind

schedule or cant be finished on time table deliberate

Ervianto (2005). In every other words, put off may

be appeared because the end result of now no longer

being fulfilled time table plans which have been

made, because of situations fact isn't the equal/in

step with the modern situations the time table is

made. Delay can as a result of the proprietor,

contractor or brought on herbal situations and

surroundings past the cap potential human or known

as pressure majeure.

The production commercial enterprise is a

commercial enterprise with excessive dangers,

dangers including monetary, political, safety and

hazard dangers at some stage in the implementation

itself ought to be controlled and treated well with the

aid of using the contractor. Meanwhile, at the part of

the mission proprietor, from the selection making

withinside the layout level to the level in which the

constructing is bodily operated, the mission

proprietor is confronted with unsure situations

concerning the very last final results of the mission.

On time, on price and as predicted are the 3 hazard

occasions that exist in every mission and of route

have an effect at the conduct of the mission

proprietor. Risk is taken into consideration an

occasion that isn't positive to arise, however if the

occasion takes place it's going to reason price

overruns Wang (2013).

2.2 Delay Risk Factors in Construction

Project delays may be as a result of numerous

elements, each herbal and human elements, in order

that the same old agreement files issued with the aid

of using the AIA (American Institute of Architects)

vary withinside the form of the mission into 3

classes, specifically: Compensable Delay,

Excusable/Non Compensable Delay, and Non-

Excusable Delay. Research carried out with the aid

of using Pinori et al. (2015) to decide the elements

that reason delays withinside the mission, there are

22 elements that reason delays withinside the class

of Reasonable Delay that merits Compensable Delay

(CD), 18 elements inflicting delays withinside the

class of Unreasonable Delay /Non Excusable Delay

(NED), and five elements that reason put off

withinside the Reasonable Delay class however do

now no longer get compensation / excusable put off

(ED). After the forty five elements are grouped into

three classes, then those elements are categorized

primarily based totally at the control components

reviewed as in Table 1. In a take a look at carried out

with the aid of using Pinori et al. (2015).

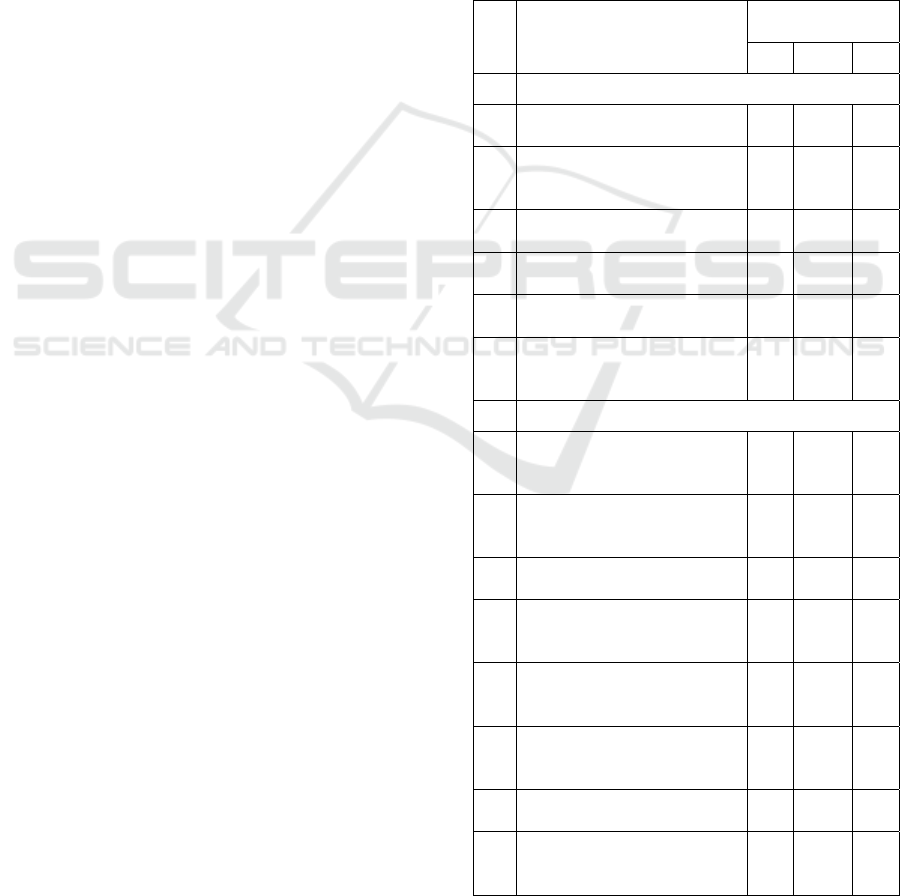

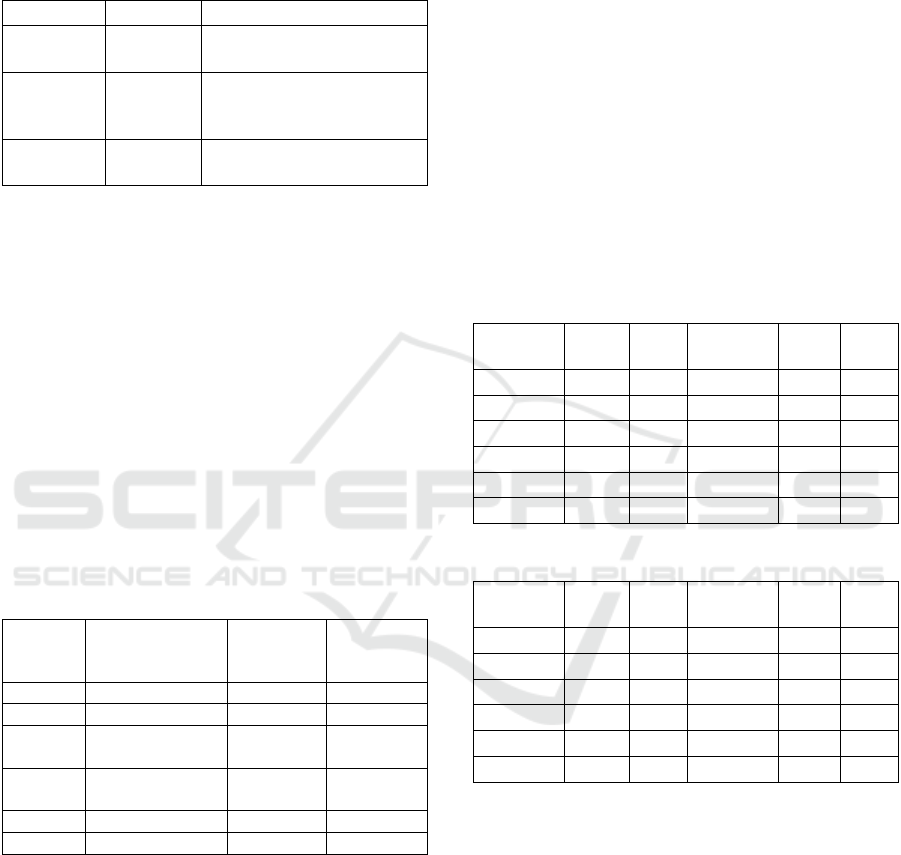

Table 1: Delay risk factors.

No Delay Risk Factors

Delay Type

Category

CD NED ED

A

Planning and Scheduling Aspects

1

Very strict project schedule

setting by owner

●

2

Incomplete identification of

the type of work that must

exist

●

3

Poorly structured / integrated

work sequence plan

●

4

Inaccurate determination of

time duration

●

5

The owner's work plan

changes frequently

●

6

The wrong method of

construction / work

execution

●

B

Scope Aspects and Work Documents (Contracts)

1

Planning (drawings /

specifications) is wrong /

incomplete

●

2

Changes in design / work

details at the time of

execution

●

3

Change in scope of work at

the time of implementation

●

4

The process of making a

working drawing by a

contractor

●

5

Process of requesting and

approving working drawings

by owners

●

6

Disagreement with the rules

for creating working

drawings

●

7

There is a lot (often) of extra

work

●

8

There is a request for

changes to work that has

been completed

●

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project

191

Table 1: Delay risk factors (cont.).

No Delay Risk Factors

Delay Type

Category

CD NED ED

C

Aspects of Organizational, Coordination and

Communication Systems

1

Limited authority of owner

personnel in decision

making

●

2

Qualifications of personnel /

owners who are not

professional in their fields

●

3

The owner's biocratic way

of inspection and control of

work

●

4

Failure of the owner to

coordinate the work of many

contractors / sub-tractors

●

5

The failure of the owner to

coordinate the transfer / use

of land

●

6

Delay in providing tools /

materials provided by the

owner

●

7

Poor technical and

managerial qualifications of

personnel in the contracting

work organization

●

8

Poor coordination and

communication between

parts of the contractor's

work organization

●

9

Occurrence of work

accidents

●

D Aspects of Readiness / Resource Preparation

1

low mobilization of resources

(materials, tools, labor)

●

2

Lack of skills and skills as

well as work motivation for

field workers

●

3

The number of workers who

are inadequate / in

accordance with existing

work activities

●

4

The unavailability of

sufficiently definite /

appropriate materials as

needed

●

5

Unavailability of work tools /

equipment which are

adequate or as needed

●

6

Negligence / tardiness by

work subcontractors

●

7

Funding of project activities

that are not well planned

(funding difficulties in

contractors)

●

8

Contractor is not paid

properly according to his

rights (funding difficulties

by the owner)

●

E

f

the Inspection, Control and Job Evaluation Syste

m

1

Unscheduled submission of

sample materials by

contractors

●

2

The process of requesting

and approving samples of

materials by the old owner

●

3

The process of testing and

evaluating the material test

of the owner is not relevant

●

4

The work permit approval

process is lengthy

●

5

Failure of the contractor to

carry out the work

●

6

Many work results have to

be repaired / redone because

of defects / incorrect

●

7

The process and procedures

for evaluating the progress

of the work took a long time

and through an agreed time

●

F

Other Aspects (Aspects beyond the capabilities of

the owner and contractor)

1

The physical condition of

the project work field turned

out to be not as expected

●

2

Transportation to project

sites is difficult

●

3

Unforeseen things happen

such as fire, flood,

earthquake, landslide

●

4

There was riot / damage,

war

●

5 There was a labor strike ●

6

The occurrence of damage /

damage due to negligence or

actions of third parties

●

7

Changes in the government's

political / economic

situation or policies

●

2.3 Analytical Hierarchy Process

(AHP)

Thomas L. Saaty stated: “Analytical Hierarchy

Process is a way that may produce a framework for

overcoming troubles in a selection without making

assumptions that are regarding independence among

better and weaker stages of factors”. The definition

of the hierarchy is a illustration of a complicated

hassle in a multi-stage shape in which the primary

stage is the aim with the stages of elements, criteria,

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

192

and sub- criteria. Hierarchy will remedy the

complicated hassle with interpreting it into a few

organizations that are organized right into a

hierarchical shape. Then, the ones troubles will seem

greater established and systematic. Risk thing fee is

then performed, which may be calculated with the

subsequent in equation 1.

= + − ( )

(1)

Where:

FR = Risk Factor, scale 0

-1 L = Risk Probability

I = Risk Impact

3 RESEARCH METHOD

3.1 Research Framework

This study uses a survey method in the form of a

questionnaire which is conducted by analyzing

research and final assignments that have been

carried out in the field of project management,

especially building construction projects. Then the

next step is to find factual information about the

conditions that occur in the Playfield Preschool

project with a survey method in the form of an

interview.

The purpose of this study is to identify risk

factors of delays that occur in the implementation of

the Summarecon Serpong Playfield Preschool

project. So that from this research, it is obtained the

order of the levels of delay factors that affect all

project performance.

The survey method in this study was conducted

to determine the dominant factors that occurred. The

survey was conducted with two types, in the first

type the distribution targets were people who

worked on the Playfield Preschool project

(contractors, consultants and site managers) and for

the second type were academics who had skills in

the field of project management. Furthermore, from

the results of the questionnaire will be compared and

found the factors that cause delays that most affect

project implementation. The questionnaire process

will explain the type of this research, the research

stages will be described as follows:

1.

Formulating problems based on previous

research studies. Then determine the concepts

and research hypotheses on which to base. The

questionnaires collected previously were

grouped into several main areas:

a.

Labor;

b.

Materials and equipment;

c.

Characteristics of the place;

d.

Managerial;

e.

Finance;

f.

Other factors.

2.

Distributing questionnaires to people who

have capabilities in the field of construction

management and Playfield Preschool project

workers (contractors, consultants and site

managers). Then compare the results of the

two questionnaires.

3.

The final stage is to determine priority risk

factors with descriptive analysis conducted by

interviewing Playfield Preschool project

workers (contractors and site managers).

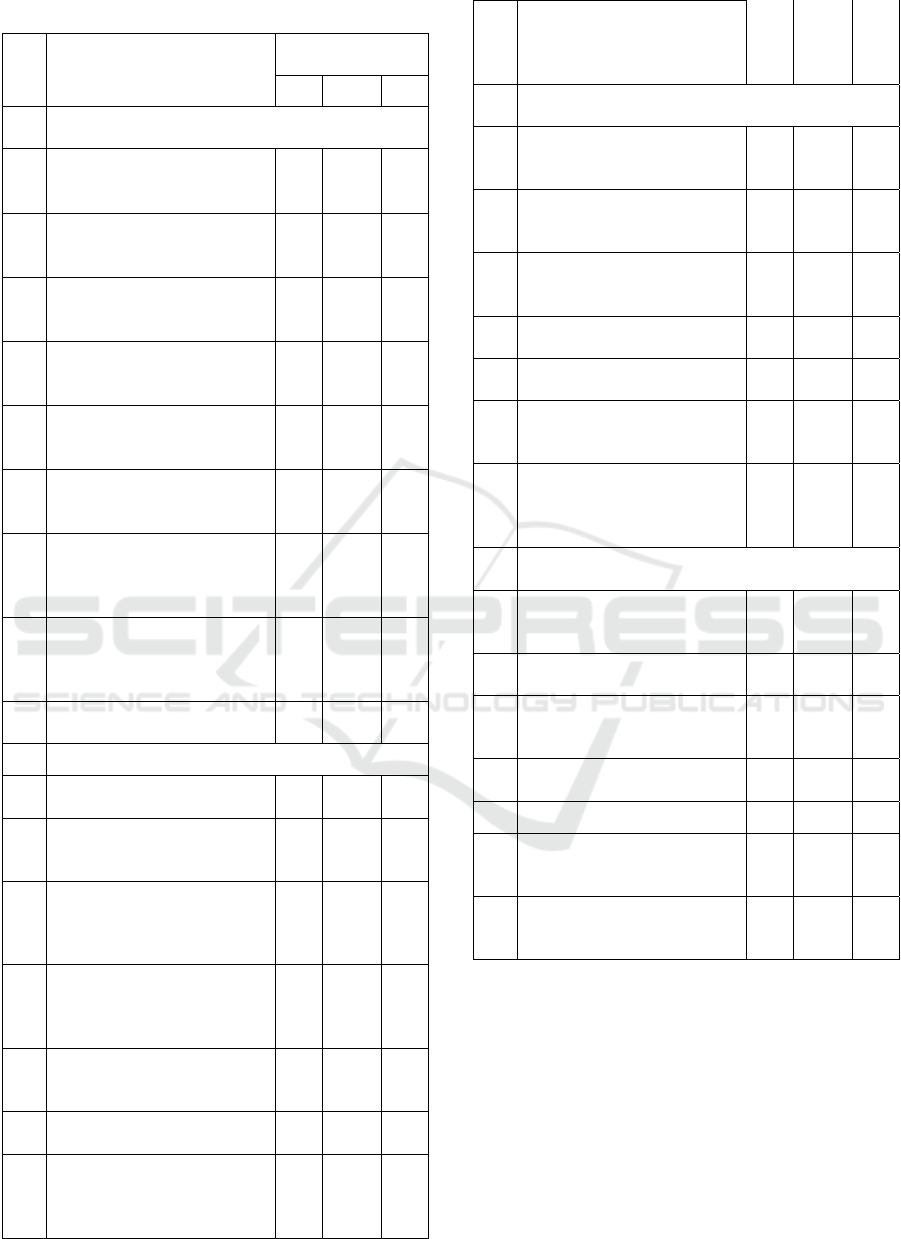

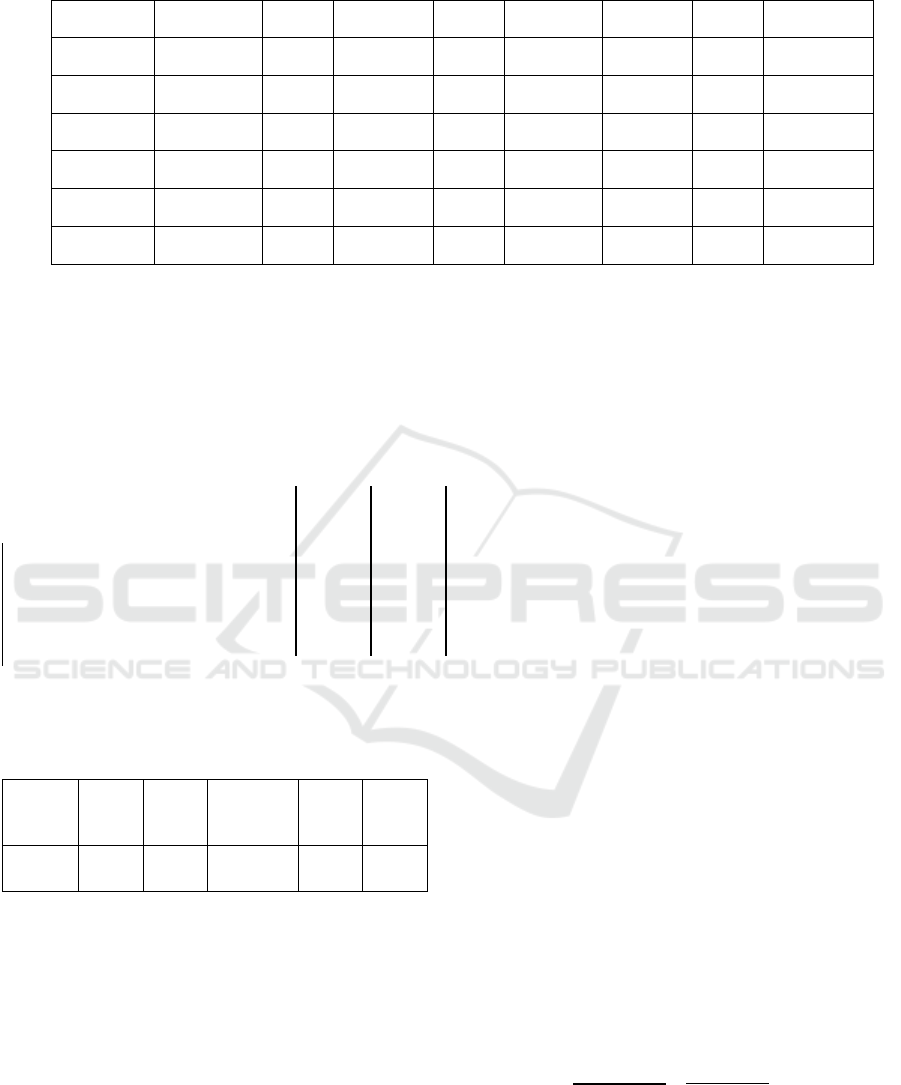

3.2 Research Variables

The dependent variable in this study is the time

delay that may occur in the project as shown at

Table 2.

Table 2: Delay risk factors variables.

Category Sub Variable

1. Labors

1.1 Workforce expertise

1.2 Labor discipline

1.3 Work motivation

1.4 Absence rate

1.5 Availability of labor

1.6 Replacement of a new

workforce

1.7 Communication between

workforce and advisory bodi

2. Materials and

equipment

2.1 Delivery of materials

2.2 Availability of materials

2.3 Quality of ingredients

2.4 Availability of equipment

2.5 Quality of equipment

3. Characteristics of

the site

3.1 Surface and below ground

conditions

3.2 Visions or responses to

the surrounding environment

3.3 Physical characteristics of

buildings around the project

site

3.4 Storage of materials /

materials

3.5 Access to the project site

3.6 Workspace requirements

3.7 Project location

4. Managerial

4.1 Project supervision

4.2 Quality of job control

4.3 Experience of field

managers

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project

193

Table 2: Delay risk factors variables (cont.).

Category Sub Variable

4. Managerial

4.4 Calculation of material

requirements

4.5 Design changes

4.6 Communication between

consultants and contractors

4.7 Communication between

contractor and owner

4.8 Schedule for delivery of

materials and equipment

4.9 Schedule of work to be

completed

4.10 Preparation /

determination of site design

5. Finance 5.1 Payments by owner

5.2 Material prices

6. Other factors 6.1 Rainfall intensity

6.2 Economic conditions

6.3 Work accidents

6.4 Pandemic

3.3 Research Instruments

The measurement instrument of this study is about

the level of respondents' perceptions of the

probability and impact of the delay factors given in

the questionnaire on the development process of the

Playfield Preschool Summarecon Serpong. The data

collection tools or instruments in this study used an

ordinal scale from 1 to 5 as shown in Table 3. Then

for the independent variables used on the probability

and impact of respondents can be seen in Table 4

and Table 5.

Table 4: Probability scale variable.

Scale Rating Information

1

Very small

It will be very unlikely to

happen

2

Small

It is unlikely that this will

happen

3 Moderate

It is equally likely that it

happened or did not happen

4 Big Most likely it could happen

5 Very large

It is certain that it will be

possible

Table 5: Variables of impact scale.

Scale Rating Information

1 Very small

Impossible so it doesn't affect time

(no delay)

2 Small

There was a delay of 2 days in a

period of 4 weeks

3 Moderate

There was a delay of 3-4 days in a

period of 4 weeks

4 Big

There was a delay of 4 - 5 days in a

period of 4 weeks

5 Very large

There was a delay of 6 - 7 days in a

period of 4 weeks

3.4 Analytical Hierarchy Process (AHP)

Analytical Hierarchy Process (AHP) will be

considered in this research. This method is used to

determine the quality or value of risk factors that may

affect the project from the most influential or domi-

nant to the small one. Quantitative data were obtained

from tabulations. This will be analyzed to determine

which factors have the most influence on project

delays depending on the respondent's experience in

working on the project. Table 6 shows the numerical

ratings that will be used in the AHP method.

Table 3: Instrument Scale.

Probability Impact

1 2 3 4 5 1 2 3 4 5

Table 4 displays a scale for the respondents to

provide an opinion on the probability that can occur if

the delay factor occurs in the project. In Table 5 a

scale is displayed for respondents who can give their

opinion on the impact of the time delay that occurs if

the delay factor occurs in the project. Linkert's five-

point scale is used because it can align conflicting

goals and offer sufficient choice because there are two

or three choices that measure the strength of an

opinion. In addition, some previous studies have

recommended the use of this scale. Dillman et al.

(2009).

Table 6: Numerical rating (Source: Saaty's Scale of

Relative Importance (2005)).

Scale Numerical Rating Reciprocal

Extremely Preferred 9 1/9

Very Strong Extremely 8 1/8

Very Strongly Preferred 7 1/7

Strongly to Very Strongly 6 1/6

Strongly Preferred 5 1/5

Moderately to Strongly 4 1/4

Moderately Preferred 3 1/3

Equally to Moderately 2 1/2

Equally Preferred 1 1

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

194

Risk Category is a method to determine risk into

groups based on the level of risk and to determine

the category of these variables by using Table 7.

Table 7: Risk category (Source: RSNI (2006)).

FR Value Category Handling Steps

>0.7 High Risk

Risk reduction must be

carried out to a lower level

0.4 – 0.7

Average

Risk

Improvement steps are

needed within a certain

period

<0.4 Low Risk

Corrective steps are taken

whenever possible

4 ANALYSIS

Based on the objectives of the descriptive analysis,

each category was separated into its own level. Then

each table from the tabulation results of the

questionnaire data will be corrected for some

differences. The comparison between type I and type

II questionnaires depends on the highest mean value

of each category for both types of questionnaires. In

Table 8 the results of tabulation of data from each

type of questionnaire which are sorted by the largest

mean value to the smallest mean value, so that the

ranking of each type of questionnaire is obtained.

Table 8: Results of type I dan type II questionnaire data

tabulation.

Ranking Category

Mean Value

Type 1

Mean Value

Type 2

1 Finance 9.8 12.514

2 Labor 8.286 11.4

3

Site

Characteristics

8.286 10.8

4

Materials and

Equipment

7.8 10

5 Other Factors 7.25 9.62

6 Managerial 6.54 8.971

As seen in Table 8, the project delay category

ranking on the two types of questionnaires is

different, where in the type I questionnaire the

financial category has the highest mean value while

in the type 2 questionnaire it is the labor category

that has the highest mean value. This difference is

due to the type II questionnaire obtained from

academics with various experiences in project

management, had an effect on the project was the

financial category and the labor category. After

interviewing Playfield Preschool project workers,

according to them the factor category that most often

became a factor for delays in project implementation

was the financial category.

Differences of opinions can arise due to

differences in place, equipment and workers due to

the timing of the project. Thus, from the results of

these comparisons, the focus of testing the

Analitycal Hierarchy Process (AHP) is the financial

category.

4.1 AHP Analysis Result

The paired matrix will analyze the probability and

impact, so that the paired comparison matrix is

obtained. Then, the form will get 5 (five) element

values to be compared. Table 9 and Table 10 show

the paired matrix

Table 9: Impact pairwise comparison matrix.

Very

High

High Moderate Low

Very

low

Very high 1 3 5 7 9

High 0.33 1 3 5 7

Moderate 0.2 0.33 1 3 5

Low 0.14 0.2 0.33 1 3

Very low 0.11 0.14 0.2 0.33 1

Amount 1.78 4.67 9.53 16.33 25

Table 10: Probability pairwise comparison matrix.

Very

High

High Moderate Low

Very

low

Very high 1 3 5 7 9

High 0.33 1 3 5 7

Moderate 0.2 0.33 1 3 5

Low 0.14 0.2 0.33 1 3

Very low 0.11 0.14 0.2 0.33 1

Amount 1.78 4.67 9.53 16.33 25

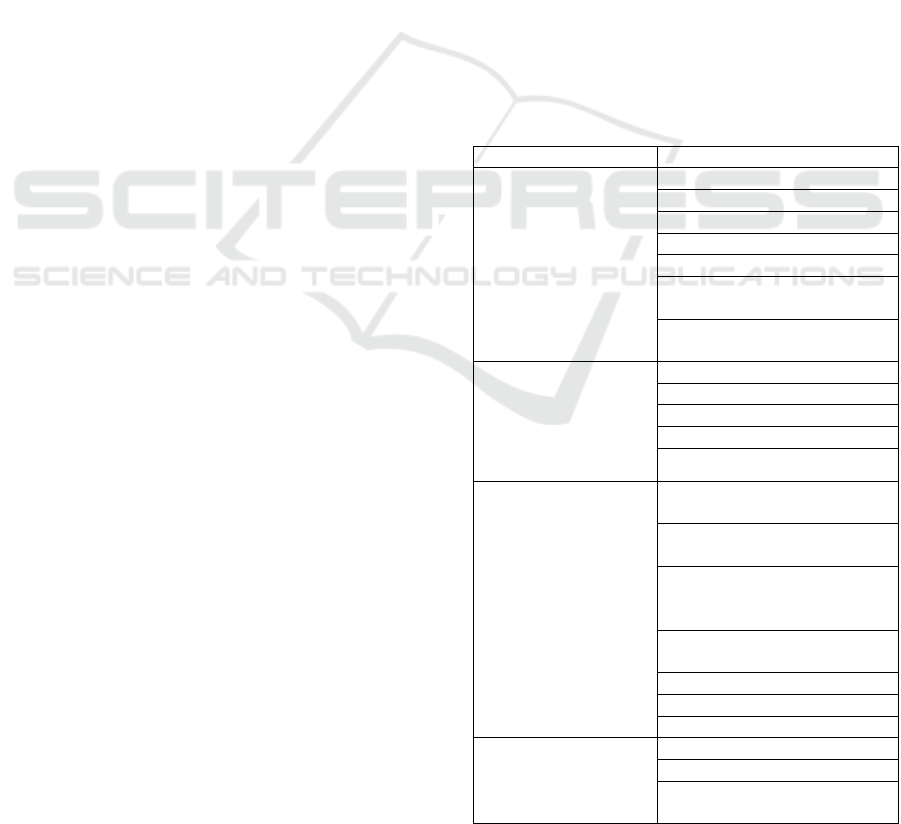

4.1.1 Element Quality

Calculation of the quality of the elements in each

element of the matrix, both the quality of the

elements on the impact and the quality of the

elements on the infrastructure and project field

conditions encountered.

The results obtained from questionnaire II data

for the category of the highest tardiness factor were

the labor category then the material and equipment

category, while the Playfield Preschool project

workers argued that the category of late factors that

probability. The results of the calculation of the

impact element quality are shown in Table 11.

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project

195

Table 11: Calculation quality element of impact and probability.

Very High High Moderate Low Very low Amount Mean Percentage

Very high 0.562 0.642 0.525 0.429 0.360 2.518 0.504 100.00

High 0.185 0.214 0.315 0.306 0.280 1.301 0.260 51.66

Moderate 0.112 0.071 0.105 0.184 0.200 0.672 0.134 26.68

Low 0.079 0.043 0.035 0.061 0.120 0.337 0.067 13.40

Very low 0.062 0.030 0.021 0.020 0.040 0.173 0.035 6.87

Amount 1.000 1.000 1.000 1.000 1.000 5.000 - -

0.562 0.642 0.525 0.429 0,360

0.185 0.214 0.315 0.306 0,280

0.112 0.071 0.105 0.184 0,200

0.079 0.043 0.035 0.061 0,120

0.062 0.030 0.021 0.020 0,040

1 3 5 7

0,504

2,739 0,504 = 5,440

0,33 1 3 5

0,260

1,409 0,260 = 5,416

0,2 0,33 1 3 x 0,134 = 0,696 : 0,134 = 5,183

0,14 0,2 0,33 1

0,067

0,338 0,067 = 5,011

0,11 0,14 0,2 0,33

0,035

0,176 0,035 = 5,074

Ammount 26,124

Figure 1: Matrix Consistency and Hierarchy Test.

Table 12: Quality elements of impact and probability.

Very

low

Low Moderate High Very

High

Quality 0.069 0.134 0.267 0.504 1.000

The calculation of element quality in the

probability element matrix is carried out in the same

way as the impact element matrix shown in Table 13

and Table 14.

4.1.2 Consistency and Hierarchy Test

The results in Table 12 must have the same diagonal

and consistent values. In finding a consistent value,

the maximum eigenvalues (λ

max

) must be close to

the

number of elements (n) and the eigenvalues

remain zero.

The figures for each row is 0.504; 0.260; 0.134;

0.067; and 0.035. The vector of the column will be

multiplied by the original matrix, giving the value of

each row. Then, each value will be divided by the

value of the vector concerned. Therefore, it is

necessary to calculate the consistency ratio based on

Table 13.

a.

Consistency Index (CI)

Based on Table 13 the value of n (Criteria total /

Order matrix) = 5,. Thus, the RI value for n = 5 is

1.12.

CI =

(λmaks – n)

=

(5,225 – 5)

= 0.056

(−1) (5−1)

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

196

Table 13: Consistency random index value (CRI).

Ordo Matrix RI Ordo Matrix RI Ordo Matrix RI

1 0 6 1.24 11 1.51

2 0 7 1.32 12 1.48

3 0.58 8 1.41 13 1.56

4 0.9 9 1.45 14 1.57

5 1.12 10 1.49 15 1.59

Table 14: Probability mean value.

Financial Category

Very High High Moderate Low Very low

Probability Mean Value

1.000 0.518 0.267 0.135 0.069

Payment by owner 0 2 2 1 0 0.431

Material prices 0 0 1 3 1 0.148

Table 15: Average value of impact.

Financial Category

Very High High Moderate Low Very low

Average Value of Impact

1.000 0.518 0.267 0.135 0.069

Payment by owner 3 1 0 1 0 0.731

Material prices 0 0 3 2 0 0.214

Probability

Impact

Very Low Low Moderate High Very High

Very

High

High

Moderate

F 5.1

Low F 5.2

Very Low

Figure 2: Qualitative risk analysis. Factor (F) Description: F 5.1 Payment by owner, F 5.2 Prices for materials.

4.2 Risk Factor Value Analysis

After obtaining the average value of the impact and

probability, the next step is to calculate the risk

factor by using equation 2.

= + − ( )

(2)

The result of the calculation of the consistency index

(CI) is 0.056 which indicates that the calculation is

consistent because <0.1 where 0.1 is the critical limit

of consistency.

b.

Consistency Ratio (CR)

The calculation of the consistency ratio is carried out

to ensure that (CR) is less than 10%. If the CR value

is greater than 10%, the comparison matrix needs to

be improved.

CR =

CI

=

0,056

= 0.05

RI 1,12

Table 16 shows the recapitulation of the value

results of the aggregate variables/risk events.

Table 16: Value of risk factors.

Financial Category

Probability

Mean Value

Average

Value of

Impact

Risk

Factor

(RF)

Payment by owner 0,431 0,731 0,847

Material prices 0,148 0,214 0,33

The result of the calculation of the consistency

ratio is 0.05 which when viewed in the form of a

presentation of 5%. This result is less than 10%, so

the hierarchy is consistent and the level of accuracy

is high.

c.

Average Value of Impact and Frequency

After passing the test of consistency, hierarchy and

accuracy, the next step is to determine the average

value of the impact and probability. The calculation

results are shown in Table 14 and Table 15.

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project

197

After calculating the risk factor value of each

probability and impact, the rating scale uses RAM.

Then an analysis of the probability of each factor

that occurs and its impact is carried out to determine

the level of risk. Qualitative risk assessment can also

help to determine whether these factors require

special attention, so that in the future this delay

factor can be minimized. Figure 2 gives the

qualitative risk analysis matrix.

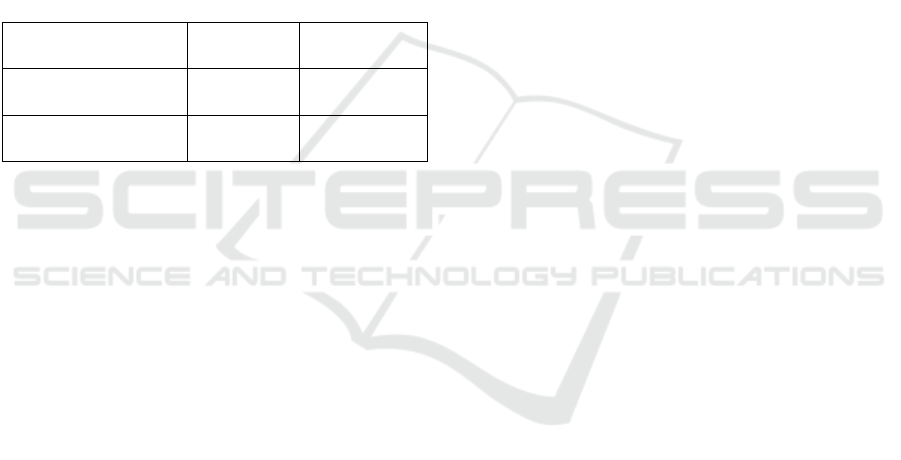

4.3 Risk Category Analysis

Risk category analysis is a way to determine risk

categories into groups based on the level of risk that

occurs. In determining it, the risk category table is

used which is shown in Table 17.

Table 17: Results of the risk category in the financial

category with AHP.

Financial Category Risk Factor Risk Level

5.1 Payments by Owner 0,847 High

5.2 Prices for Materials 0,33 Low

5 RESULTS AND DISCUSSION

Discussion of the AHP method, based on the results

of Table 17, it is known that the payment by the

owner of the financial category is a factor that

greatly influences the implementation of the

Playfield Preschool project, resulting in delays. This

is supported by interviews from Playfield Preschool

project workers where the owner is often late in

making payments so that project implementation is

hampered because as a result of the late payment the

goods / materials that are used up should be

immediately repurchased instead of being delayed

due to lack of funds to buy materials. So it is

necessary to review the applicable contract, so that it

can be seen that the delay was caused by the

contractor or from the owner.

Apart from the factor of payment by the owner,

the delay due to indiscipline of workers from the

labor category ranks the second factor that

influences the delay in this Playfield Preschool

project. According to the site manager and the field

contractor, the delay is also caused by the

indiscipline of the workers which makes the

implementation process slow down, because

workers are often found lying about the number of

attendances on one day at a project site, there are 15

workers and in the afternoon it is reduced to 12, the

following day workers reduced to 10 people. This

happens every day in this Playfield Preschool project

because the worker contract system is daily, not

wholesale. Where this hampers the implementation

of project work, because it is ineffective and

inefficient.

Then the third rank factor which affects the delay

in the Playfield Preschool project is the opinion /

response of the surrounding environment from the

place characteristics category. The location of the

Playfield Preschool project which is located in the

shopping center / mall area is one of the inhibiting

factors, because the process of transporting goods

needs to be carried out outside the operational hours

of the shopping center/mall. Opinions/responses

from the mall are very influential in the project

implementation process, where if there is damage to

the project area it is necessary to communicate

between the site manager /contractor and the mall.

Often the mall is slow in dealing with existing

project location problems, such as a leak at the

project site, it took a long time to finally be handled

by the mall.

6 CONCLUSIONS

From the analysis and discussion above, it can be

concluded that of the 6 categories of delay: Labor,

Materials and Equipment, Place Characteristics,

Managerial, Financial and Other Factors. The most

influential factor of the delay is the financial

category, especially an indicator of late payment by

owners.

There are difference of opinions on the category

of tardiness that is most influential according to the

Playfield Preschool project workers and academics.

This is because the academics are the stakeholders

on a wide range of construction projects with

varying field conditions, while the Playfield

Preschool project workers give their opinion on what

is happening on the project site.

REFERENCES

Dillman, D. A., Phelps, G., Tortora, R., Swift, K., Kohrell,

J., Berck, J., & Messer, B. L. (2009). Response Rate

and Measurement Differences in Mixed-Mode

Surveys Using Mail, Telephone. Interactive Voice

Response (IVR) and the Internet, Social Science

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

198

Research 38(1). Elsevier Inc.: 1–18,

doi:10.1016/j.ssresearch.2008.03.007.

Ervianto, W. (2005). Manajemen Proyek Konstruksi.

Yogyakarta: Salemba Empat.

Pinori, Mickson, et al. (2015). Analisis Faktor

Keterlambatan Penyelesaian Proyek Konstruksi

Gedung Terhadap Mutu, Biaya Dan Waktu Di Dinas

Pekerjaan Umum Kota Manado. Jurnal Ilmiah Media

Engineering 5(2).

Wang, F. (2013). The High-Speed Railway Construction

Project Quality Risk Management Theory and

Practice. Railway Engineering Construction

Management of Exploration and Practice. Tsinghua

University Press, Beijing.

Widhiawati, I. A. R. (2012). Analisis Faktor-Faktor

Penyebab Keterlambatan Pelaksanaan Proyek

Konstruksi, Majalah Ilmiah Teknik Elektro 8(2),

doi:10.24843/10.24843/MITE.

Smith et al. (1999). Small to Medium Contractor

Contingency and Assumtion of Risk, Journal of

Consruction Engineering and Management.

ASCE.125.

Identification of Risk Factors for Delayed Time Schedule in Summarecon Serpong Playfield Preschool Project

199