The Experimental Study of Optimum Thickness on Riprap Layer

Design

Dea Lidya

a

, Robby Yussac Tallar

b

and Alexander Yovan Suwono

c

Civil Engineering Department, Maranatha Christian University, Jl. Surya Sumantri 65 Bandung, Jawa Barat, Indonesia

Keywords: Riprap, Riprap Layer Thickness, Scouring.

Abstract: Flow velocity in rivers may have significant effects on flow pattern and velocity distribution, especially for

horizontal flow. In river engineering, hydraulics engineering, and river restoration project, it is essential to

consider in the analysis if there is a change or modification in the waterway such as the pier of the bridge.

The existence of a bridge pier causes a change in the pattern of river flow to vertical water flow, this can

cause local scouring. Riprap is one of the protection methods concerning local scouring. Therefore, the main

purpose of this study is to determine the optimum thickness of the riprap layer within a certain diameter in

the flow under clear water conditions and under sediment-based riprap layer. The experimental study was

used to inquire the resulted optimum thickness on the riprap layer design. This study used a cylindrical-

shaped of bridge pier to study the scouring pattern, failure mechanism, and riprap stability. This study

offered several scenarios. The result indicated that the thickness of the riprap layer affected the depth of

local scouring. Further study, it is essential to investigate the relationship among variables of riprap, pier,

hydraulics characteristics. The application of the riprap design method is very useful for the long-term

protection of river structures.

a

https://orcid.org/0000-0003-2023-7788

b

https://orcid.org/0000-0001-7307-3348

c

https://orcid.org/0000-0002-2577-8519

1

INTRODUCTION

A river has consisted of water flow and flow

velocity where moves from the upper area to the

lower area, flow velocity in rivers may have a

significant effect on flow patterns, especially for

horizontal flow. River engineering can be defined as

the design and implementation of river works and

river restoration (Tallar & Suen, 2017). The

existence of a bridge pier causes a change in the

pattern of river flow to vertical water flow, this can

cause local scouring. There are two types of local

scouring, specifically, live bed scour and clear water

scour. This study used clear water scour. Scouring is

usually interpreted as a local phenomenon, it

includes degradation that can cause erosion over a

considerable length of a river, scouring on the bridge

pier occurs when the base material is carried away

by water flow (Arneson, Zevenbergen, Lagasse, &

Clopper, 2012), if this happens continuously will

cause the failure of the bridge which can endanger

the construction of the bridge.

The engineering method used to solve the

scouring problem of the pier is to place the riprap

around the foundation. Riprap is defined as a layer

of facing rock that protects from erosion. Riprap has

consisted of a well-graded mixture of rock, broken

concrete, or other material, usually dump or hand-

placed, therefore the riprap should be hard, durable,

and dense. In addition, it should be resistant to

weathering, free from overburden, spoil, shale, and

organic material. The thickness of the riprap layer

affects the depth of the scour, it has criteria depends

on the diameter of the rock is used.

The problem of analysing scouring through the

pier appears deceptively easy, perhaps because it has

been oversimplified by assuming a horizontal

channel and flow at the normal depth parallel to the

bed (Guan, Chiew, Wei, & Hsieh, 2019). In reality

the bed level will vary considerably so that the depth

becomes almost meaningless, while the flow may

not be at the normal depth (Tallar & Suen, 2015).

180

Lidya, D., Tallar, R. and Suwono, A.

The Experimental Study of Optimum Thickness on Riprap Layer Design.

DOI: 10.5220/0010747700003113

In Proceedings of the 1st International Conference on Emerging Issues in Technology, Engineering and Science (ICE-TES 2021), pages 180-183

ISBN: 978-989-758-601-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

It is sometimes assumed that scour will be a

problem only when the bed material consists of fine

cohesionless material. This is not true: ultimately the

scour depth in cohesive or cemented soils can be just

as large, it merely takes longer for the scour hole to

develop. For example, under constant flow

conditions, scour will reach maximum depth in sand

and gravel in a matter of hours (perhaps during one

flood); in cohesive materials it will take days;

However, the biggest and most frequently

encountered scour-related problems usually concern

loose sediments that are easily eroded. Scouring is a

very serious problem. Floods that result in scour are

the principal cause of bridge failure.

2

EXPERIMENTAL SET UP AND

SCENARIO

An experimental study to specify the optimum

thickness of the riprap layer effected on the depth of

local scouring.

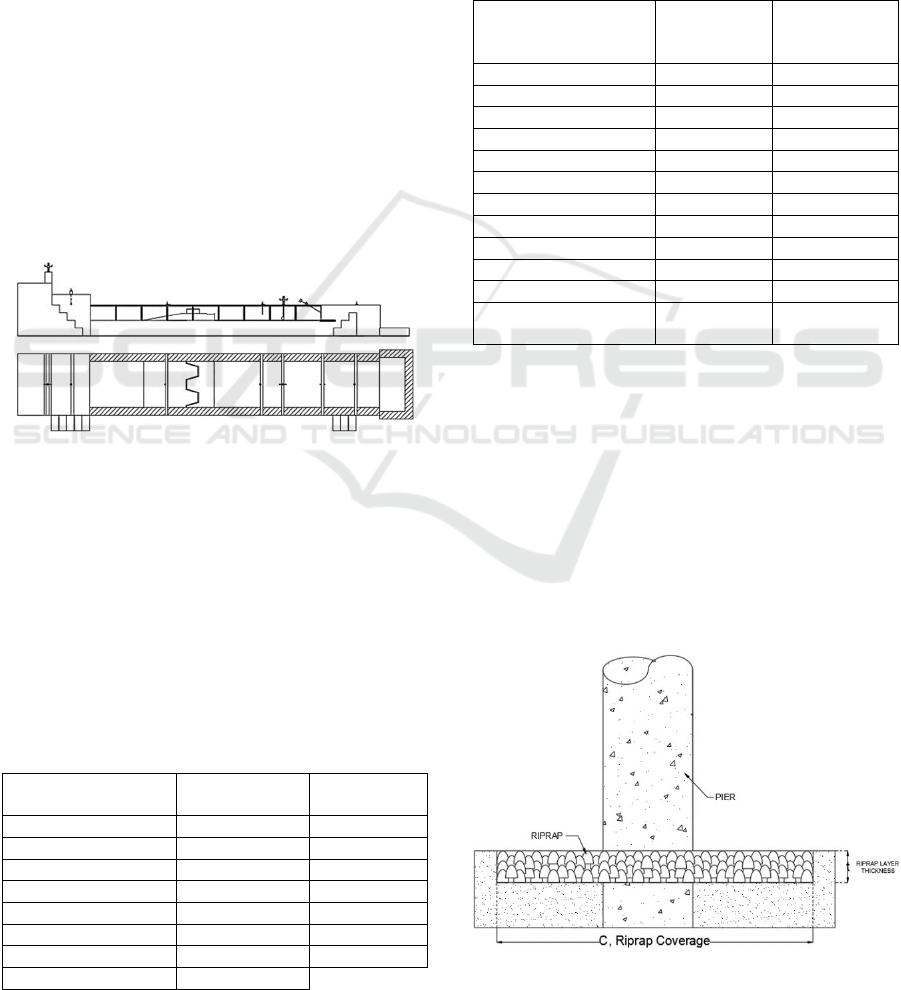

Figure 1: Experimental set up (top view and side view).

2.1 Sediment Sieve Analysis

The sediment factor at bridge piers includes particle

size distribution, basic sediment type, and the spatial

distribution of sediment size. The difference in basic

sediment affects scouring behavior. For example for

coarse-grain soil and fine grain soil, scouring behavior

will be different although the distribution particle. The

purpose of sediment sieve analysis is to specify the

distribution or gradation of the sediment used.

Table 1: Sediment sieve analysis result.

No. Sieve

Retained

Wei

g

ht

(g

ram

)

Soil Retained

(

%

)

No. 4 83 8.34

No. 8 144 14.47

No. 16 168 16.88

No. 50 349 35.08

No. 100 169 16.98

No. 200 37 3.72

Pan 45 4.52

∑ Restrained Weight 995

From data (Table 1) by using Soil Classification

Chart, it is classified that sediment is categorized in

Poorly Graded Sand.

2.2 Riprap Sieve Analysis

The riprap sieve analysis is to specify the dr

50

on

riprap. dr

50

is the middle value of riprap size from

the

aggregate grading curve.

Table 2: Riprap sieve analysis result.

No. Sieve

Retained

Weight (gram)

Soil Retained

(%)

19,11 mm 0 0.00%

12,7 mm 1635.2 81.87%

9,52 mm 288.5 96.32%

4,75mm

(

No. 4

)

55.2 99.08%

2,36mm

(

No. 8

)

0.2 99.09%

1,18mm(No. 16) 0.6 99.12%

0,6 mm (No.30) 2 99.22%

0,3 mm(No. 50) 1.1 99.27%

0,15mm

(

No. 100

)

4.1 99.48%

0,075mm(No. 200) 5.4 99.75%

Pan 5 100.00%

∑ Restrained Weight 1997,3

From data (Table 2) by using Aggregate

Distribution Curve, then we get dr

50

is 10,5 mm, dr

50

determines the riprap layer thickness (t), which t =

2dr

50

- 3dr

50

2.3 Riprap Layer Thickness

The riprap layer thickness depends on the size of the

aggregate, which has been calculated above dr

50

is

10,5 mm. According to Melville and Coleman

(2000), some recommendations in the placement of

riprap around bridge piers.

Figure 2: Detail sketch of the riprap layer.

The Experimental Study of Optimum Thickness on Riprap Layer Design

181

The riprap layer thickness (t) = 2dr

50

- 3dr

50

.

Riprap coverage (C) = 3 – 4 diameters of pier The

riprap layer thickness effects the depth of local

scouring.

In Figure 2 the diameter of pier is eight

centimeters (80 mm) and the riprap coverage (C) is twenty-

eight centimeters (280 mm) and scenario (Table 3).

Table 3: Scenarios of study.

Scenario Riprap Layer Thickness

Scenario 1 22 mm

Scenario 2 26 mm

Scenario 3 30 mm

3

RESULTS AND DISCUSSION

The result indicated that the thickness of the riprap

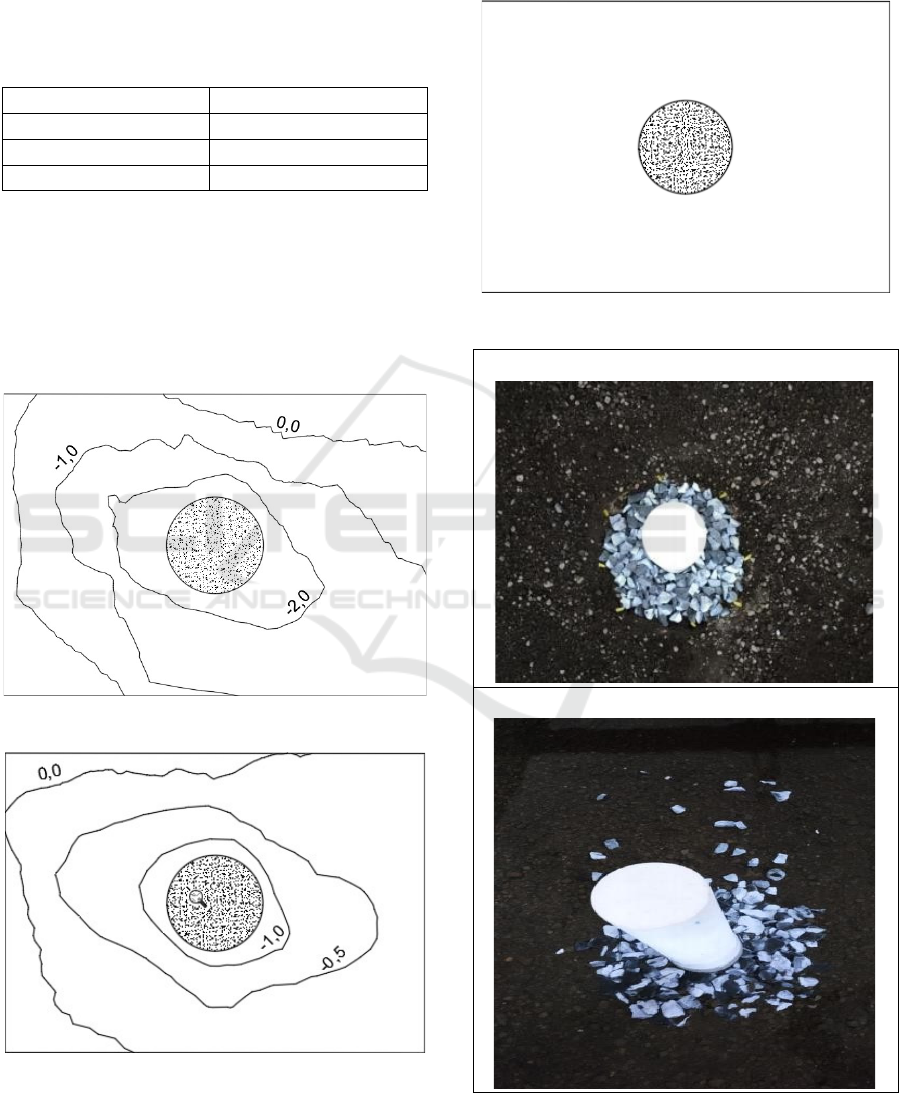

layer effected on the depth of local scouring. Figure

3 to 5 shows the contour pattern and Figure 6 shows

before and after the experiments.

Figure 3: Grind Contour Scenario 1.

Figure 4: Grind Contour Scenario 2.

In scenario 1 there is scouring around the piers

and has a deepest point of -2 cm. In scenario 2 there

is scouring on the side of the piers and has a deepest

point -1 cm. In scenario 3 there is no scouring

around, the sediment remains unchanged at -3,0 cm

according to the planned riprap layer depth.

Figure 5: Grind Contour Scenario 3.

Before (a)

After (b)

Figure 6: Modeling in the laboratory before and after the

experiment.

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

182

Table 4 gives the results of the riprap experiment

scenarios.

Table 4: Results of the riprap experiments.

Scenario d

s

Information

Scenario 1 -2

Partial failure, there is scour

around the piers and the area the

layer changes in thickness

Scenario 2 -1

There is scouring on the side of

the piers, riprap rock on the side

right and left of the pier carried

by the flow towards the

downstream of the pier

Scenario 3 0

No significant failures were seen,

the seams were thinned in some

areas but still provided full

protection to the piers

4

CONCLUSIONS

In this paper local scouring around a circular bridge

pier has been examined experimentally under clear

water scouring and under sediment-base riprap layer.

This research has looked at certain aspects of riprap

design like the size of stone, systematically

investigates flow, sediment, and pillar parameters

against scouring.

Each parameter involved in the riprap layer

performance of the pillar is identified visually.

Results of this study show that the optimum

thickness is at 30mm because there is no significant

failures were seen and increasing the riprap size has

a significant effect on depth scour.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the support for

this study provided by Civil Engineering

Department, Maranatha Christian University,

Indonesia, and with LPPM (Lembaga Penelitian dan

Pengabdian Masyarakat) Maranatha.

REFERENCES

Arneson, L. A., Zevenbergen, L. W., Lagasse, P. F., &

Clopper, P. E. (2012). Evaluating scour at bridges.

National Highway Institute (US).

Guan, D., Chiew, Y.-M., Wei, M., & Hsieh, S.-C. (2019).

Characterization of horseshoe vortex in a developing

scour hole at a cylindrical bridge pier. International

Journal of Sediment Research, 34(2), 118–124.

Tallar, R. Y., & Suen, J.-P. (2015). Identification of

waterbody status in Indonesia by using predictive

index assessment tool. International Soil and Water

Conservation Research, 3(3), 224–238.

Tallar, R. Y., & Suen, J.-P. (2017). Measuring the

aesthetic value of multifunctional lakes using an

enhanced visual quality method. Water, 9(4), 233.

The Experimental Study of Optimum Thickness on Riprap Layer Design

183