The Optimization of the Adsorption of the Tannic Acid on the

Fluorite Mineral Surface using a Response Surface Methodology

Mariam Tangarfa

1 a

, Naoual Semlali Aouragh Hassani

1,2 b

1

Engineering Mohammadia School, Mohamed V University in Rabat, Department of Industrial Process, B.P 765, 10090

Agdal Rabat, Morocco

2

Engineering Mohammadia School, Mohamed V University in Rabat, Department of Industrial Process and Civil

Engineering, B.P 765, 10090 Agdal Rabat, Morocco

Keywords: Response surface methodology, central composite design, optimization, fluorite, tannic acid, adsorption.

Abstract: The separation flotation of fluorite containing calcite by depression using the tannic acid is complex due to

similar surface properties of calcium minerals. The improvement of this process requires an essential

evaluation of the adsorption process. Therefore, the objective of this study is the optimization of the adsorption

of the tannic acid onto fluorite. We conducted this experimental study by Central Composite Design of

response surface methodology. We used experimental results obtained to develop a statistical model at a

confidence level of 95 % using Statgraphics centurium software 18. This model revealed that the initial tannic

acid concentration and the solution pH were the most significative parameters. Therefore, we exploited the

obtained model to reach optimal conditions, allowing to achieve a maximum adsorbed tannic acid amount.

1 INTRODUCTION

Fluorite is an essential industrial mineral used to

produce essentially hydrofluoric acid (Zhang and

Song 2003; Gao et al. 2018; Zhang et al. 2018b). It

usually coexists with other calcium-containing

minerals, including calcite (Chen et al. 2019; Gao et

al. 2019). Generally, physicochemical properties of

calcium minerals such as fluorite and calcite are

similar. Both interact similarly with anionic reagents

(Liu et al. 2016). Thus, the valorisation of fluorite

containing calcite as a gangue mineral is a very

industrial problem and remains a challenging to

overcome (Ren et al. 2017a; Gao et al. 2019).

In general, flotation is the physicochemical

technique that permits to separation between fluorite

and calcite minerals (Rutledge and Anderson 2015;

Liu et al. 2016; Chen et al. 2017; Zhang et al. 2018a).

The principle of this technique is the tannic acid

adsorption on the fluorite mineral surface (Zhang et

al. 2018c). To improve the separation process

between calcium minerals, it is so important to

evaluate this primary step before reaching flotation.

To our knowledge, there are few published studies

a

https://orcid.org/0000-0003-4303-4166

b

https://orcid.org/0000-0001-5969-9459

about the evaluation of the tannic acid adsorption

process on fluorite surface. Most of them showed a

strong interaction between phenolic tannin groups

and ion calcium onto fluorite using optimization

conventionnel method of adsorption (Ren et al.

2017b; Wei et al. 2017; Gao et al. 2018; Zhang et al.

2018a). Thus, the use of an efficient method to design

and optimize the adsorption process is necessary.

In this work, we optimized the tannic acid

adsorption process on the fluorite surface by a

response surface methodology using Statgraphics

centurium 18 software. This methodology permit to

obtain a statistical model at a confidence level of 95

%. This model has been then exploited to determine

the effect of reactional parameters (initial tannic acid

concentration, solution pH and temperature) on the

studied adsorption process. Finally, we used three-

dimensional response surface methodology to

determine optimal conditions of adsorption

investigated.

Tangarfa, M. and Semlali Aouragh Hassani, N.

The Optimization of the Adsorption of the Tannic Acid on the Fluorite Mineral Surface using a Response Surface Methodology.

DOI: 10.5220/0010732600003101

In Proceedings of the 2nd International Conference on Big Data, Modelling and Machine Lear ning (BML 2021), pages 285-288

ISBN: 978-989-758-559-3

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

285

Table 1: Experimental range of independent variables and

their real and coded values.

Variables

Levels and ranges

-1 0 1

C: Initial tannic acid

concentration (mg/L)

20 60 100

p

H: Solution

p

H 5 7,5 10

T: Tem

p

erature

(

K

)

303 318 333

2 SETTINGS: ADSORPTION

EXPERIMENTAL DESIGN

we conducted adsorption experiments by mixing 1 g

of fluorite and 100 mL of distilled water using a

thermostatic water bath equiped with an electric

shaker under different conditions of the initial tannic

acid concentration, the pH and the temperature. The

mixture was analysed after equilibrium by the

spectrophotometer Ultra Violet Visible to obtain the

adsorbed tannic acid amount using the following

expression:

Q

C

C

m

∗V

(1

)

Where Ci and Ce (mg/L) are the initial and the

equilibrium tannic acid concentration, respectively. V

(L) is the solution volume, and m (g) is the adsorbent

mass.

We selected operating parameters, including

initial the tannic acid concentration, the solution pH

and the temperature to evaluate their effect on the

adsorption capacity. We chose the experimental range

of each operating parameter based on preliminary

experiments. We coded real factor values as -1, 0 and

1. Table 1 presented the experimental range, real and

coded values of these parameters.

We conducted experimental tests under Central

Composite Design CCD. We calculated the number

of CDD experiments by the following formula:

N2

2∗

k

N

(2)

Where k is the variable number, and N0 is the

replicate number of the central value of the

experimental range. We replicated this value three

times (N

0

=3) to estimate the experimental error and

data reproducibility. Using thus the equation (2) and

knowing that the variable number is 3 (k=3), we

obtained 17 tests. Table 2 summarized CDD with its

experimental results. We performed this experimental

design using Statgraphics Centurium 18.

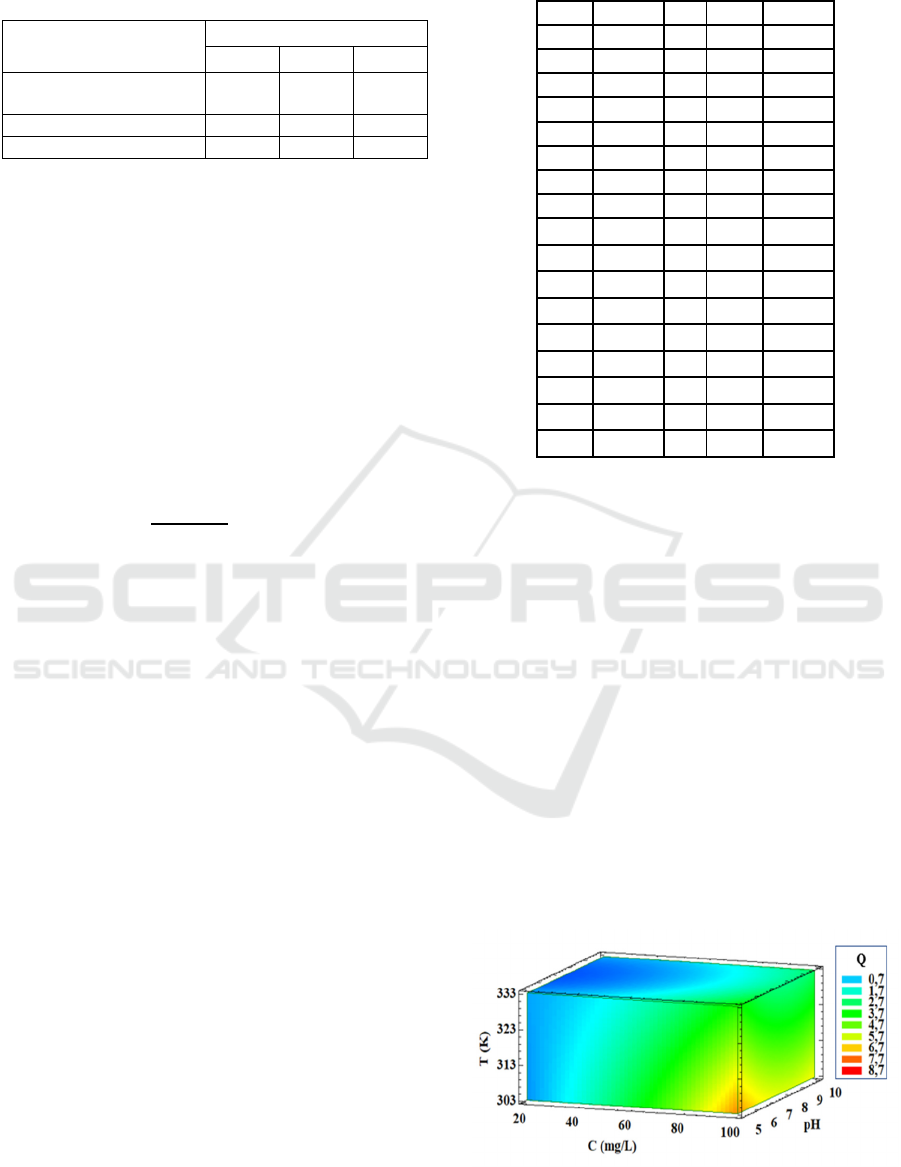

Table 2: CDD and experimental results.

Row C

(

m

g

/L

)

p

H T

(

K

)

Q

(

m

g

/

g)

1 20 5 303 0,035

2 100 5 303 7,56413

3 20 10 303 0,0337

4 100 10 303 6,2756

5 20 5 333 0,02865

6 100 5 333 3,9976

7 20 10 333 0,016203

8 100 10 333 2,6506

9 20 7,5 318 0,01024

10 100 7,5 318 3,62935

11 60 5 318 2,31678

12 60 10 318 1,94653

13 60 7,5 303 1,76912

14 60 7,5 333 0,85021

15 60 7,5 318 1,20021

16 60 7,5 318 1,1984

17 60 7,5 318 1,1996

3 RESULTS AND DISCUSSIONS

3.1 Statistical Modelling

In the present research, experimental results of Table

2 were exploited to obtain a statistical model using

Box-Cox procedure (Box P 1964). We studied this

model by analysis of variance ANOVA using

Statgraphics Centurium 18. Table 3 summarized

obtained results of this analysis.

Based on the high correlation coefficient (0,9994)

and the low mean absolute error (0,027), the Box-Cox

model provides a good description of tannic acid

adsorption onto fluorite. In addition, ANOVA results

indicate that all parameters are significantly based on

the low P-Value (less than 0,05) except the second

term of temperature.

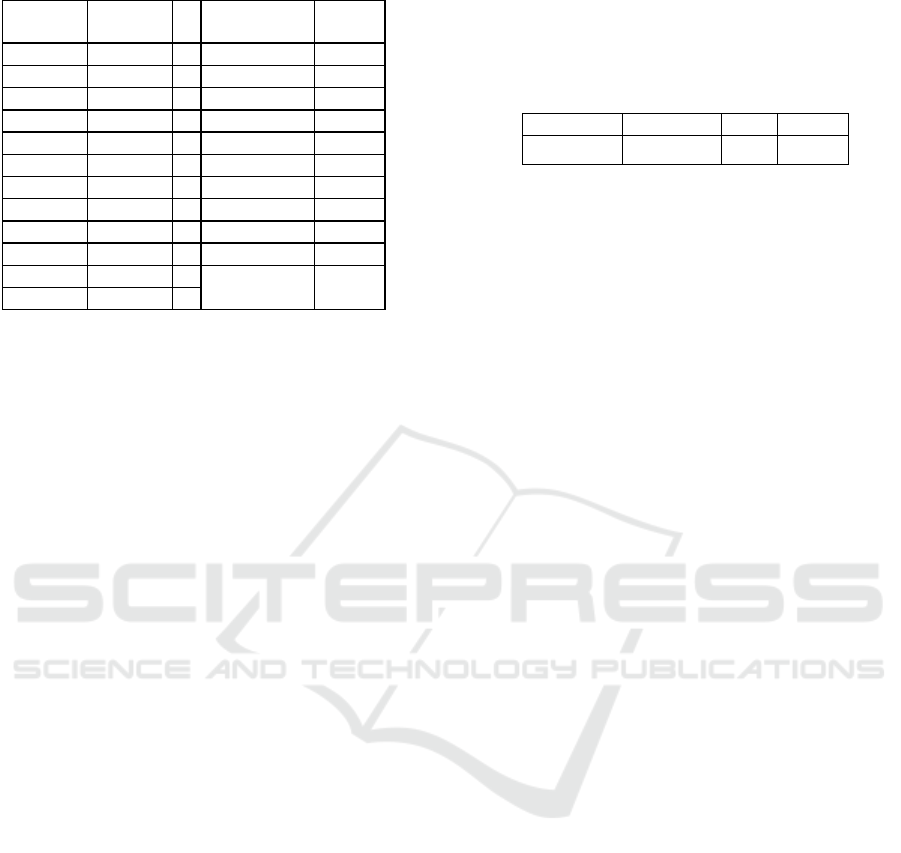

Figure 1:

Contours of the estimated response surface

.

BML 2021 - INTERNATIONAL CONFERENCE ON BIG DATA, MODELLING AND MACHINE LEARNING (BML’21)

286

Table 3: ANOVA analysis.

Source

Sum of

S

q

uares

Df Mean Square P-Value

C 28,9465 1 28,9465 0,0000

p

H 4,97127 1 4,97127 0,0000

T 1,09445 1 1,09445 0,0000

C*C 1,52303 1 1,52303 0,0000

C*

p

H 0,0307715 1 0,0307715 0,0071

C*T 0,192934 1 0,192934 0,0000

p

H*

p

H 0,33356 1 0,33356 0,0000

p

H*T 0,0150994 1 0,0150994 0,0361

T*T 0,0032496 1 0,0032496 0,2768

Model 37,1108 9 4,12343 0,0000

Residual 0,019088 8 0,002386

Total 37,1299 17

The obtained statistical model is expressed by:

Q = 0,16*C - 0,46*pH - 0,004*T -

0,0005*C*C - 0,0004*C*pH - 0,0002*C*T

+ 0,05*pH*pH - 0,001*pH*T +

0,00001*T*T

(3)

3.2 Optimization

To optimize the tannic acid adsorption process onto

fluorite, we used a three-dimensional (3D) response

surface methodology. Figure 1 illustrates the contours

of estimated response surface. Table 4 summarize

obtained optimal conditions of the studied process.

The optimization results show that we reach a

maximum tannic acid adsorption onto fluorite using

an initial tannic acid concentration of 100 mg/L, a pH

of 5 and a temperature of 30 °C. Thus, we can

compare these results with those obtained in our

previous work (Tangarfa et al. 2021) of the

optimization of the tannic acid adsorption onto

calcite. We obtained a maximum adsorbed tannic acid

amount onto calcite under an initial tannic acid

concentration of 175 mg/L and a pH of 8. This means

that the obtained optimal conditions of the adsorption

corresponding to fluorite and calcite minerals are so

different and selective. Therefore, we can use these

results in our next works to separate between fluorite

and calcite by flotation.

4 CONCLUSIONS

The experimental study of the tannic acid adsorption

onto fluorite as a function of initial tannic acid

concentration, pH and temperature was carried out

and optimized by CDD of response surface

methodology. We considered obtained results to get a

validated statistical model checked by ANOVA

analysis. Based on the high correlation coefficient

Table 4: Optimal conditions of the tannic acid adsorption

on the fluorite surface.

Q (mg/g) C (mg/L)

p

H T (K)

6,99 100 5 303

and the low mean absolute error, we indicated that the

Box-Cox model described well the tannic acid

adsorption onto fluorite. Furthermore, we revealed

based on the low P-Value (less than 5%) that the

initial tannic acid concentration and the solution pH

influenced the studied adsorption. Optimization

results using 3D response surface methodology

showed that we reached a maximum adsorbed tannic

acid amount of about 7 mg/g using an initial tannic

acid concentration of 100 mg/L, a pH of 5 and a

temperature of 30 °C. The all above finding provides

valuable results in mineral processing, allowing to

enhance the fluorite valorisation by flotation using the

tannic acid as a depressant.

REFERENCES

Box P CR (1964) An analysis of

transformation_boxcox_1964. Journal of the Royal

Statistical Society 26:211–252

Chen W, Chen Y, Bu X, Long T, Zhang G, Chen F, Liu R,

Jia K, Song Y (2019) Rheological investigations on the

hetero-coagulation between the fine fluorite and quartz

under fluorite flotation-related conditions. Powder

Technology 354:423–431 .

https://doi.org/10.1016/j.powtec.2019.06.019

Chen W, Feng Q, Zhang G, Yang Q, Zhang C (2017) The

effect of sodium alginate on the flotation separation of

scheelite from calcite and fluorite. Minerals

Engineering 113:1–7 .

https://doi.org/10.1016/j.mineng.2017.07.016

Gao J, Hu Y, Sun W, Liu R, Gao Z, Han H, Lyu F, Jiang W

(2019) Enhanced separation of fl uorite from calcite in

acidic condition. 133:103–105 .

https://doi.org/10.1016/j.mineng.2019.01.013

Gao J, Sun W, Hu Y, Wang L, Gao Z, Chen P, Tang H,

Jiang W, Lyu F (2018) Propyl gallate : A novel

collector for flotation separation of fluorite from

calcite. Chemical Engineering Science.

https://doi.org/10.1016/j.ces.2018.09.017

Liu C, Feng Q, Zhang G, Chen W, Chen Y (2016) Effect of

depressants in the selective flotation of scheelite and

calcite using oxidized paraffin soap as collector.

International Journal of Mineral Processing 157:210–

215 . https://doi.org/10.1016/j.minpro.2016.11.011

The Optimization of the Adsorption of the Tannic Acid on the Fluorite Mineral Surface using a Response Surface Methodology

287

Ren Z, Yu F, Gao H, Chen Z, Peng Y, Liu L (2017a)

Selective separation of fluorite, barite and calcite with

valonea extract and sodium fluosilicate as depressants.

Minerals 7: . https://doi.org/10.3390/min7020024

Ren Z, Yu F, Gao H, Chen Z, Peng Y, Liu L (2017b)

Selective separation of fluorite, barite and calcite with

valonea extract and sodium fluosilicate as depressants.

Minerals 7:24 . https://doi.org/10.3390/min7020024

Rutledge J, Anderson CG (2015) Tannins in mineral

processing and extractive metallurgy. Metals 5:1520–

1542 . https://doi.org/10.3390/met5031520

Tangarfa M, Semlali N, Hassani A, Alaoui A (2021)

Preparation and characterization of calcite for tannic

acid adsorption : Optimization by response surface

methodology coupled by Box-Cox transformation

procedure. 36–45 .

https://doi.org/10.37190/ppmp/134242

Wei S, Tang H, Yin Z, Zhang C, Guan Q, Hu Y, Gao J

(2017) Selective adsorption of tannic acid on calcite and

implications for separation of fluorite minerals. Journal

of Colloid and Interface Science 512:55–63 .

https://doi.org/10.1016/j.jcis.2017.10.043

Zhang C, Sun W, Hu Y, Tang H, Yin Z, Guan Q, Gao J

(2018a) Investigation of two-stage depressing by using

hydrophilic polymer to improve the process of fluorite

flotation. Journal of Cleaner Production 193:228–235 .

https://doi.org/10.1016/j.jclepro.2018.05.055

Zhang C, Wei S, Hu Y, Tang H, Gao J, Yin Z, Guan Q

(2018b) Selective adsorption of tannic acid on calcite

and implications for separation of fluorite minerals.

Journal of Colloid and Interface Science 512:55–63 .

https://doi.org/10.1016/j.jcis.2017.10.043

Zhang C, Wei S, Hu Y, Tang H, Gao J, Yin Z, Guan Q

(2018c) Selective adsorption of tannic acid on calcite

and implications for separation of fluorite minerals.

Journal of Colloid and Interface Science 512:55–63 .

https://doi.org/10.1016/j.jcis.2017.10.043

Zhang Y, Song S (2003) Beneficiation of fluorite by

flotation in a new chemical scheme. Minerals

Engineering 16:597–600 .

https://doi.org/10.1016/S0892-6875(03)00136-5

BML 2021 - INTERNATIONAL CONFERENCE ON BIG DATA, MODELLING AND MACHINE LEARNING (BML’21)

288