Smart Lifts: An Ontological Perspective

D. Slee, S. Cain, P. Vichare and J. I. Olszewska

School of Computing and Engineering, University of the West of Scotland, U.K.

Keywords:

Industry 4.0, Smart Lift Services, Digital Twin, Human-Machine Systems, Cyber-Physical Systems,

Knowledge Engineering, Knowledge Representation, Interoperability, Ontology Engineering, Enterprise

Ontology, Ontological Domain Analysis and Modeling.

Abstract:

Nowadays, there is a growth of smart factories and Industry 4.0 technologies, involving Artificial Intelligence

(AI) systems. These ones require interoperable solutions. In particular, ontologies have been widely used

for capturing, sharing, and representing knowledge in an interoperable way, that both humans and machines

can understand. Indeed, ontologies allow humans to communicate with machines in a semantic way, while

machines are able to make automated reasoning about the concepts and relationships which are encoded in

the ontology. For this purpose, this paper proposes the first-ever domain ontology for smart lifts. Its domain

covers smart lift design, operation, and maintenance, while its scope is to aid in automating such lift services.

This smart lift ontology (SLO), which contains 144 classes and 749 axioms, has been successfully developed

in collaboration with the elevator industry.

1 INTRODUCTION

The use of Artificial Intelligence (AI) in our Soci-

ety (Cockburn et al., 2018) is currently increasing

in applications, ranging from human-centered sys-

tems (Wilding et al., 2020) to intelligent manufactur-

ing (Lewandowski and Olszewska, 2020), expanding

from Smart Cities (Costanzo et al., 2016) to Smart

Factories (Xu and Hua, 2017), and contributing to

the current fourth industrial revolution, or ‘Industry

4.0’ (I4.0) (Marr, B., 2018). This trend leads to ad-

vances in digitalization and communication as well as

new manufacturing processes and innovative products

(Koh et al., 2019).

AI-driven technologies used throughout I4.0 in-

clude cyber-physical systems (CPS) (Derler et al.,

2011), internet of things (IoT) (Feki et al., 2013),

intelligent agents (IA) (Kannengiesser and Muller,

2013), human-machine interactions (HMI) and aug-

mented reality (AR) (Gorecky et al., 2014), au-

tonomous robotics (Bonci et al., 2017), 3D print-

ing, simulation and digital twin modeling (Zhong

et al., 2017), cloud computing, cybersecurity, ma-

chine learning and big data (Alcacer and Cruz-

Machado, 2019).

That results in smart products, smart machines,

and/or augmented operators, but also in challenges

such as interoperability, virtualization, decentraliza-

tion, real-time capability, service-orientation, and

modularity (Koh et al., 2019). Besides, I4.0 pro-

motes features such as interoperability, agility, flex-

Figure 1: Overview of the lift services.

ibility, decision-making, connectivity, quality, safety,

efficiency and cost reductions (Dopico et al., 2016).

In particular, interoperability refers to the ability of

two systems to communicate with and understand

each other (Koh et al., 2019). Moreover, there are

four levels of interoperability in I4.0, namely, oper-

ational, systematic, technical and semantic interop-

erability (Ide and Pustejovsky, 2010). Within smart

manufacturing, semantic interoperability of heteroge-

neous machines and/or agents, in order to be able

to communicate with one another in or across smart

factories, is one of the major features of I4.0 (Nils-

son and Sandin, 2018). Indeed, interoperability con-

structs a trusted environment in a manufacturing sys-

tem, in which information is accurately and swiftly

shared among machines and humans, resulting in a

cost-saving operation with higher productivity (Koh

et al., 2019).

210

Slee, D., Cain, S., Vichare, P. and Olszewska, J.

Smart Lifts: An Ontological Perspective.

DOI: 10.5220/0010690700003064

In Proceedings of the 13th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2021) - Volume 2: KEOD, pages 210-219

ISBN: 978-989-758-533-3; ISSN: 2184-3228

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In the case of the elevator industry, on one hand,

lift manufacturing starts to embrace I4.0 technologies

(Nott, 2018) and challenges (Berger, 2020) and, on

the other hand, lift services enter in the age of smart

buildings (Onag, G., 2019) and smart cities (Hoyes

and Mair, 2020), all requiring interoperable solutions.

Hence, Knowledge Engineering (KE) techniques

such as ontologies (Lee, 2019) are useful for Indus-

try 4.0. (Sampath Kumar et al., 2019). Indeed, an

ontology is a concept, which was defined by (Gruber,

1995) as an explicit specification of a conceptualiza-

tion, which allows semantic interoperability (Kalyaz-

ina and Kashevnik, 2018), leading to information be-

ing easily read and interpreted by both machines and

humans alike.

Therefore, ontologies have been used in Indus-

try 4.0 for intelligent manufacturing (Xu and Hua,

2017), agent-based manufacturing (Tang et al., 2018),

or cognitive manufacturing (Ferrer et al., 2019). More

specific ontologies have been applied to production

line (Cheng et al., 2016), micro-device assembly (Ce-

cil et al., 2018), sensor data analysis (Gyrard et al.,

2016), radio-frequency identification (RFID) system

configuration (Tsalapati et al., 2021), or AI-system

testing (Olszewska, 2020).

Some ontologies have been designed for cyber-

physical systems (CPS) (Engel et al., 2018; Al Sunny

et al., 2017; Wan et al., 2018; Brings et al., 2018;

Torsleff et al., 2018; Hildebrandt et al., 2020; Voinov

and Senokosov, 2021), Internet of Things (IoT) (Ma

et al., 2014), Digital Twin modeling (Steinmetz et al.,

2018), system of systems (SoS) modeling (Zhu et al.,

2017), Web of Things (WoT) (Sujith et al., 2011),

robotics (Fiorini et al., 2017), cloud robotic systems

(CRS) (Pignaton de Freitas et al., 2020), human-

machine interactions (HMI) (Jost et al., 2017), and

Human-Robot Interactions (HRI) (Smirnov et al.,

2016).

On the other hand, ontologies have been devel-

oped for critical infrastructures (Canito et al., 2020),

Smart Buildings (Kunold et al., 2019), and Smart

Cities (Burns et al., 2018). However, there is no exist-

ing ontology for the smart lift domain at the moment.

Thus, in this work, we endeavoured to develop

such smart lift domain ontology (SLO).

The core knowledge of our smart lift ontology in-

cludes elevator manufacturing as well as lift services,

as depicted in Fig. 1.

This domain ontology for smart lifts has been de-

veloped using Enterprise Ontology (EO) methodol-

ogy (Dietz and Mulder, 2020), since EO is a ma-

ture ontology development methodology for industry-

based domain ontologies (Fox and Gruninger, 1998;

Albani and Dietz, 2007; Syamili and Rekha, 2017).

SLO ontology has been coded in Web Ontology

Language Descriptive Logic (OWL DL) (Olszewska,

2021), which is considered as the international stan-

dard for expressing ontologies and data on the Se-

mantic Web (Guo et al., 2007), and using Protege tool

(Rubin et al., 2007) in conjunction with the HermiT

reasoner (Glimm et al., 2014).

Thence, the resulting SLO-based intelligent sys-

tem provides an interoperable solution for lift design,

operation, and maintenance.

The paper is structured as follows. Section 2

presents the purpose and the building of our ontol-

ogy for smart lift services (SLO), while its evaluation

and documentation are described in Section 3. Con-

clusions are drawn up in Section 4.

2 DEVELOPED SLO ONTOLOGY

To develop the SLO ontology, we followed an on-

tological development life cycle (Fernandez et al.,

1997; Jones et al., 1998; Bertolazzi et al., 2001;

Fernandez-Lopez and Gomez-Perez, 2002; Gomez-

Perez et al., 2004) based on the Enterprise Ontology

(EO) Methodology (Dietz and Mulder, 2020).

The adopted ontological development methodol-

ogy consists of four main phases (Olszewska and Al-

lison, 2018), which cover the whole development cy-

cle, as follows:

1. identifications of the purpose of the ontology

(Section 2.1);

2. ontology building which consists of three parts:

the capture to identify the domain concepts and

their relations; the coding to represent the ontol-

ogy in a formal language; and the integration to

share ontology knowledge (Section 2.2);

3. evaluation of the ontology to check that the de-

veloped ontology meets the scope of the project

(Section 3.1);

4. documentation of the ontology (Section 3.2).

2.1 Ontology Purpose

The scope of this smart lift domain ontology is (i) to

provide the elevator industry with a new technologi-

cal solution that copes with smart manufacturing chal-

lenges such as interoperability and (ii) to assist the rel-

evant stakeholders with smart lift services in context

of smart cities and smart buildings.

A way to refine the scope of the ontology is to

sketch a list of questions called competency questions,

Smart Lifts: An Ontological Perspective

211

that an intelligent agent based on the proposed on-

tology should be able to answer (Gruninger and Fox,

1995).

In the smart lift domain, the list of competency

questions includes but is not limited to:

• What are the modules of the lift controller?

• Where is the electrical compartment located?

• What does the door node handle?

• What is the lift display used for?

• How the call button is connected to the key

switch?

• Is the fingerprint reader optional?

• What is the TagReader RFID’s part number?

• Who is the supplier of the CiVoice part?

• How to lock the lift?

• What is the rated load of the platform lift Cibes

model A4000 type A5?

• How to adjust the overload switch?

• Where is the emergency stop located?

• How to emergency lower a lift?

• Which maintenance actions need to be performed

in the machine area?

• How often the brakes need to be tested?

Therefore, the SLO ontology aims to contribute

to the elicitation of the elevator industry knowledge

and the formalization of concepts for lift services

which comprise lift design, operation, and mainte-

nance. Furthermore, the smart lift domain encom-

passes different types of lifts such as platform lifts,

goods lifts, and passenger lifts.

2.2 Ontology Building

The ontology building consists of three parts: cap-

ture to identify the domain concepts and their rela-

tions (Section 2.2.1); coding to represent the ontology

in a formal language (Section 2.2.2); and integration

to share ontology knowledge (Section 2.2.3).

2.2.1 Concept Capture

The knowledge capture consists in the identification

of concepts and their relations within the elevator in-

dustry and smart lift service domains.

Hence, the SLO domain contains technical data

about elevators’ components and parameters that are

used for manufacturing and configuration and that

can be extracted, e.g., from lift documentation such

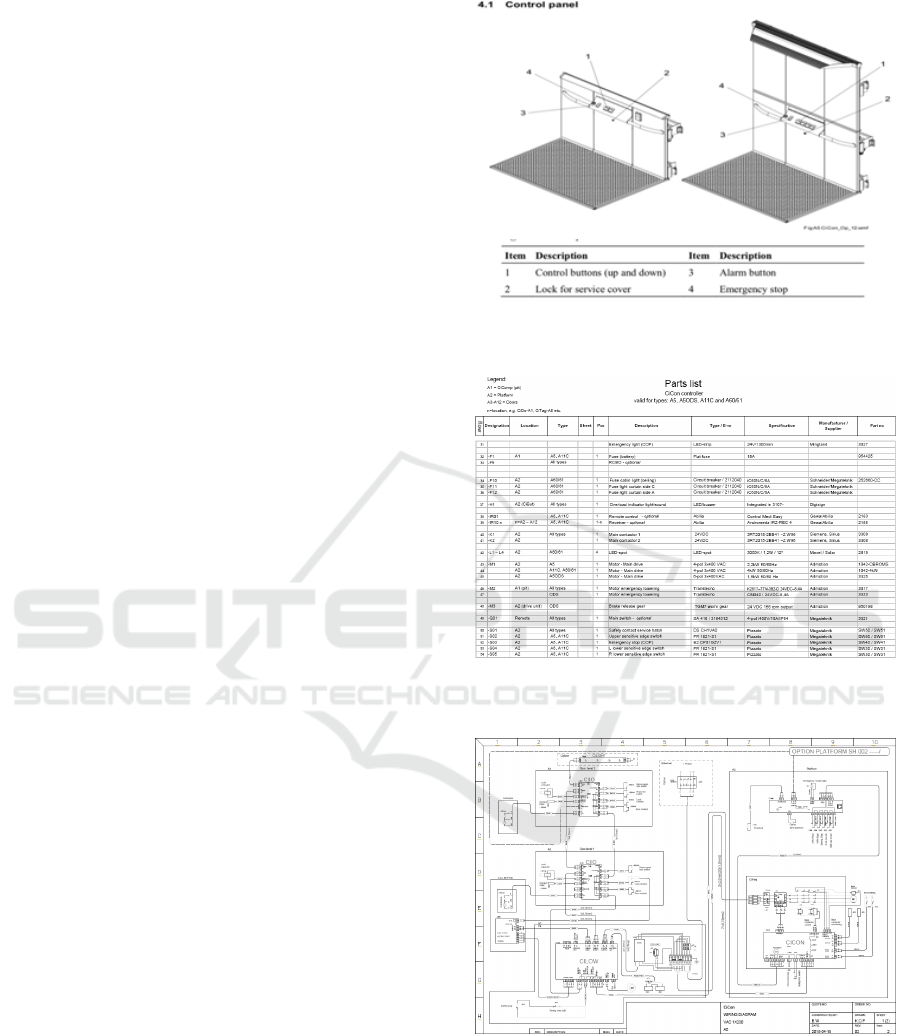

Figure 2: Diagram of the control panel of the system

(A5000 OM Manual).

Figure 3: Parts list for the CiCon controller system (A5-

1X230 Part List).

Figure 4: Parts list connection diagram (A5-1X230 Part

List).

as product documents, assembly instruction manu-

als, and installation guides (Siikonen, 1997; Hoon,

2006; Thyssen Krupp, 2014) as well as information

on lift services, which consist of lift design, lift opera-

tion, and lift maintenance, from user guides, operation

manuals, and maintenance instructions (Cibes Lift,

KEOD 2021 - 13th International Conference on Knowledge Engineering and Ontology Development

212

2017; Sheridan Lifts, 2018; Kone, 2020).

Lift documents cover design and function instruc-

tions; operating instructions, including normal and

emergency situations; maintenance instructions as

well as safety instructions; standards and directives;

parts’ lists and descriptions, and a number of dia-

grams.

As an example of a platform-lift operating in-

struction, Fig. 2 is a diagram of the control panel

within a lift car as well as a description table taken

from the documentation (Cibes Lift, 2017). Concepts

for the domain can be acquired from this diagram,

since the control panel itself would become the class

Control Panel of the SLO ontology.

This type of diagrams is helpful to map out con-

cepts of the domain, but within these documents,

these diagrams are only presented for larger parts of

the system and are not available for the smaller com-

ponents. So, other information are required for a

deeper capture of concepts. Thus, along with dia-

grams such as shown in Fig. 2, these documents also

include lists of parts, as displayed in Fig. 3. An ex-

ample of this could be that contents of the ‘Descrip-

tion’ column of the table shown in Fig. 3 can be

mapped into SLO classes, while the contents of ‘Man-

ufacturer/Supplier’ and ‘Part no’ columns can be used

when gauging individuals for the SLO concepts.

While Fig. 2 and 3 are useful for laying the foun-

dations of the SLO ontology domain and can help in

capturing initial main concepts, diagrams such as Fig.

4 help to establish relationships between these con-

cepts.

Other examples of how concepts can be extracted

from documents are provided in Figs. 5-6.

Figure 5 is a diagram of the machine area behind

the lift car’s service cover from the Cibes A5000 oper-

ation manual (OM) (Cibes Lift, 2017). This diagram

allowed to set concepts for the machine area of the

platform-lift system.

Figure 6 is a diagram showcasing the components

behind the service cover of the platform-lift system

(Cibes Lift, 2017). This diagram helped in captur-

ing some concepts of the lift maintenance service,

which are of great importance due to the safety conse-

quences if any classes or relationships are missed out

or mapped out incorrectly.

Hence, SLO domain has been built following a

middle-out approach. Indeed, documents, such as the

ones illustrated in Figs. 2-6, have been an aid in ap-

prehending the SLO ontology domain. Once a set

of concepts and relationships has been extracted from

these documents, it opened the way for capturing fur-

ther the domain by adding data and object properties

as well as establishing relationships with every con-

Figure 5: Diagram of the machine area of the platform-lift

system (A5000 OM Manual).

.

Figure 6: Diagram of the components behind the service

cover of the platform-lift system (A5000 OM Manual).

cept within the domain. After the initial ontology

domain was established, it was about repeatedly go-

ing through the process again and discussing with the

stakeholders such as domain experts, mechanical en-

gineers, electrical engineers, product designers, com-

puter scientists, ontologists, industrial partners, man-

ufacturers, vendors, service providers, users, etc. to

gather any additional concepts that should be added

or removed, whether that be through discussions or

further documents.

2.2.2 Concept Coding

The knowledge coding has been done in Descriptive

Logic (DL) (Black et al., 2021) and uses temporal-

interval logic relations as introduced in (Olszewska,

2016).

Smart Lifts: An Ontological Perspective

213

As an example of concept formalization for the

platform-lift design of the lift car’s control panel con-

cept, which has been described in Section 2.1, the

class of Control Panel is defined in DL, as follows:

Control Panel v Li f t Car

u ∃hasPart

=Alarm Button

u ∃hasPart

=Control Button

u ∃hasPart

=Emergency Stop

u ∃hasPart

=Service Cover Lock

.

(1)

As another example of concept formalization, the

platform-lift service consisting in the machine area’s

maintenance, which has been mentioned in Section

2.1, can be formulated in temporal DL, as follows:

Machine Area Maintenance v Li f t Maintenance

u (t

1

)(t

2

)

(MA

1

< MA

2

)

· (MA

1

@t

1

u MA

2

@t

2

),

(2)

with MA

1

, the maintenance activity defined as ‘Oil

Container Refill’, MA

2

, the maintenance activity con-

sisting in ‘Lifting Nut Visual Check’, and be f ore, the

temporal-interval relations as defined respectively in

temporal DL:

P

i

< P

j

≡ be f ore(P

i

@t

i

, P

j

@t

j

) v Temporal Relation

u (t

i

)(t

j

)

(t

i

+

< t

j

−

)

· (P

i

@t

i

u P

j

@t

j

),

(3)

where the temporal DL symbol represents the

temporal existential qualifier, and where a time in-

terval is an ordered set of points T = {t} defined by

end-points t

−

and t

+

, such as (t

−

,t

+

) : (∀t ∈ T )(t >

t

−

) ∧ (t < t

+

).

2.2.3 Concept Integration

The integration of the SLO ontology was done us-

ing the Web Ontology Language (OWL) and carried

out within the Protege software environment v.5.5.0

running HermiT v1.4.3.456 reasoner (Glimm et al.,

2014), in order to share the SLO ontology knowl-

edge among stakeholders as well as intelligent agents.

Indeed, Protege is a widely-used, open-source on-

tological environment which has a vast and operat-

ing community, exceeding 70,000 users (Rubin et al.,

2007), and which is adopted for most of the recent

engineering-based ontologies for I4.0 (Sampath Ku-

mar et al., 2019; Tsalapati et al., 2021).

Figure 7: Excerpt of the ‘Control Panel’ concept integration

within the SLO ontology.

Figure 7 shows a view of Protege integration of

some of the smart lift ontology main classes, along

with a related OWL/XML code excerpt. Indeed, Pro-

tege can generate OWL files that can be accessed

from different programming language platforms such

as XML. Producing these OWL files that are readable

with XML are the final part of the integration process.

Transferring the OWL files to XML format allows for

a broad range of systems the do;qin ontology could

then fully operate on.

It is worth noting that SLO version v2.0.0 contains

749 axioms and 144 classes. Moreover, SLO v2.0.0

includes 16 object properties and 21 data properties.

As an example, the SLO ontology defines the class

Control Panel, its relationships such as hasPart

and individuals (e.g., CibesA5ControlPanel). In

particular, hasPart is an object property which do-

main is ‘System’ concept and the range is ‘Compo-

nent’ concept. The object property hasPart is transi-

tive and has an inverse property called isPartOf. On

the other hand, properties involving lift’s key param-

eters, such as rated speed and rated load, or numeral

properties such as the part number have been set as

data properties. Further evaluation of these classes,

object properties, and data properties is provided in

Section 3.1.

3 VALIDATION AND

DISCUSSION

The developed SLO ontology has been evaluated both

quantitatively and qualitatively in a series of exper-

iments as described in Sections 3.1, while its docu-

mentation is mentioned in 3.2.

3.1 Ontology Evaluation

Ontology evaluation is concerned mostly with two

chief factors, namely, quality and correctness (Hlo-

mani and Stacey, 2014).

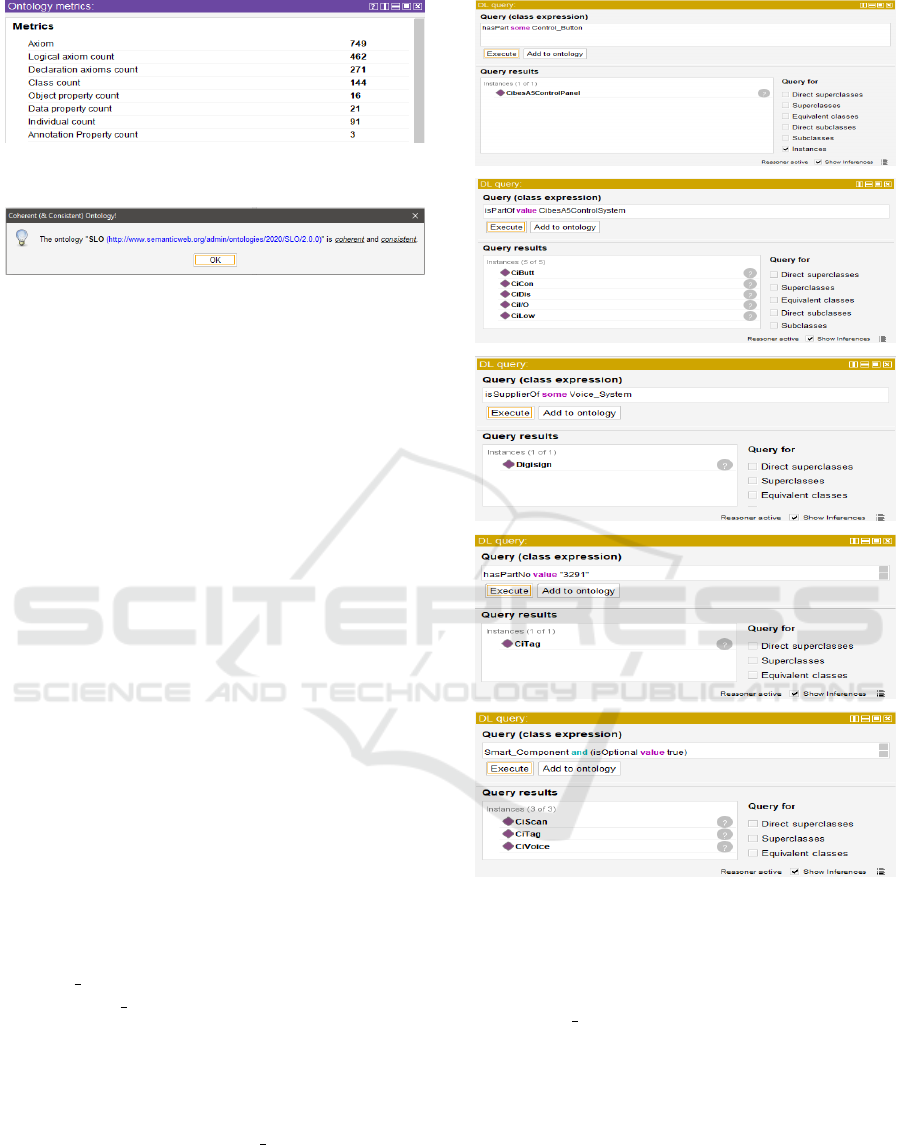

SLO quality evaluation used metrics such as pre-

sented in (Tartir et al., 2018). The computed values

by Protege are presented in Fig. 8.

KEOD 2021 - 13th International Conference on Knowledge Engineering and Ontology Development

214

Figure 8: Main metric values of the SLO ontology.

Figure 9: Result of the OntoDebugger when run on SLO

ontology.

It is worth noting that, in practice, a trade-off

should be achieved between computational efficiency

and completeness. Actually, SLO contains so far 749

axioms and 144 classes, while it is processed by Her-

miT in 2766ms and then performs DL queries in real

time.

Moreover, SLO cohesion could be assessed using

the number of root classes which is equal to 1, the

number of leaf classes which is equal to 112, and the

average depth which is equal to 3. All these metrics

indicate SLO shows promising performance for real-

world deployment.

Besides, the Protege OntoDebugger v0.2.2 allows

to automatically check the ontology consistency and

coherence. The result of this check for our SLO on-

tology is successful, as illustrated in Fig. 9.

On the other hand, in Protege, DL Query v4.0.1

allows for an evaluation to be carried out where the

two factors of quality and correctness are closely

evaluated and achieved. In particular, the ontology

correctness could be assessed through experiments

running DL queries based on competency questions

(Gruninger, 1995).

A first test scenario addresses the competency

questions of the type: ‘What components are part of

the platform-lift control panel?’. For this purpose, we

test the object property hasPart called on the class

Control Button through the DL query: hasPart

some Control Button, as in Eq. (1), and the correct

answer is provided by our SLO system in Fig. 10(a).

A second test scenario tries to answer the com-

petency question: ‘What are the components of the

platform-lift Cibes A5 control system?’. A query in-

volving the object property isPartOf can be called

an instance of the class Control System. The related

instances of the 5 modules of the control system are

correct, as illustrated in Fig. 10(b).

A third test scenario covers competency questions

such as ‘Who is the supplier of the Voice System

Figure 10: Some samples of query results in relation to the

competency questions.

part?’. Hence, the object property isSupplierOf is

used in the DL Query, as follows: isSupplierOf

some Voice System. The corresponding supplier is

successfully found in Fig. 10(c).

On the other hand, few experiments have tested

data properties such as hasPartNo to respond to the

competency question: ‘What component corresponds

to the part number 3291?’. So, we run the DL

query: hasPartNo value ‘‘3291’’, and the com-

ponent name is correctly displayed on Fig. 10(d).

A further experiment focused on competency

questions such as ‘Is the fingerprint reader optional?’,

Smart Lifts: An Ontological Perspective

215

and thus involved the data property isOptional.

An example of DL query is: Smart Component and

(isOptional value true), and the results success-

fully provided by SLO are shown in Fig. 10(e).

In all these experiments targeting classes, individ-

uals, object properties, and data properties, SLO on-

tology provided 100% correct answers, and no incon-

sistency has been observed.

3.2 Ontology Documentation

The SLO ontology has been documented and evalu-

ated, as reported in Section 2 and 3.1, respectively. To

recap, SLO is a middle-out, domain ontology which

has been collaboratively built using Enterprise On-

tology methodology. Hence, SLO domain knowl-

edge is based on non-ontological resources such as

primary sources, e.g. lift documentation, operational

manuals, safety standards, etc., and has been elicited

through collaboration with lift domain experts, in-

cluding lift designers, mechanical and electrical engi-

neers, as well as elevator industry partners. Moreover,

SLO ontology has been iteratively developed, with its

first version defining 476 axioms and its current, sec-

ond version containing 749 axioms.

The SLO ontology has not reused any existing on-

tology, since it is the first ontology in its kind for the

smart lift domain. Indeed, some attempts have been

made in the past to develop expert systems (Marcus

et al., 1987) and knowledge-based systems (Corsar

and Sleeman, 2007) for rudimentary elevators, but, on

one hand, these works had a limited scope, being fo-

cused on the sole design aspect and not embracing all

the lift’s modern services and, on the other hand, they

contained only very few components and parameters,

not representing the current, complex smart lift do-

main.

It is worth noting that SLO domain ontology cov-

ers all the smart lift services, addresses the cutting-

edge, smart lift domain, and also lays down the foun-

dation for smart lift’s digital-twin modeling. More-

over, SLO domain ontology could be used in conjunc-

tion with other I4.0 ontologies such as ontologies for

IoT (Ma et al., 2014) or other robotics and automation

ontologies (Fiorini et al., 2017) for further integration

in smart environments.

4 CONCLUSIONS

Since I4.0 has the ability to create new business capa-

bilities and service opportunities, while requiring in-

teroperable technologies, this work is focused on the

development of an ontology for the smart lift applica-

tion, in collaboration with the elevator industry. Our

ontology aims to formalize smart lift services, such

as smart lift design, operation, and maintenance, e.g.,

leading to lift automated design for mass customiza-

tion as well as multimodal operation and AI-enhanced

maintenance. Hence, the proposed smart lift ontology

(SLO) has the potential to provide the elevator indus-

try with I4.0 benefits, contributing toward innovative

smart products, smart machines, and augmented op-

erators, suitable for real-world deployment in context

of smart cities and smart factories.

ACKNOWLEDGMENT

The authors would like to thank Innovate UK and

Consult Lift Services Ltd for the support of this work.

REFERENCES

Al Sunny, S. M. N., Liu, X. F., and Shahriar, M. R. (2017).

MtComm: A semantic ontology based internet scale

communication method of manufacturing services in

a cyber-physical manufacturing cloud. In Proceed-

ings of the IEEE International Congress on Internet

of Things, pages 121–128.

Albani, A. and Dietz, J. (2007). Benefits of enterprise on-

tology for the development of ICT-based value net-

works. In Software and Data Technologies, pages 3–

22. Springer.

Alcacer, V. and Cruz-Machado, V. (2019). Scanning the

Industry 4.0: A literature review on technologies for

manufacturing systems. Engineering Science and

Technology, 22(3):899–919.

Berger, R. (2020). Emerging technologies could lift elevator

market.

Bertolazzi, P., Krusich, C., Missikoff, M., and Manzoni, V.

(2001). An approach to the definition of a core enter-

prise ontology: CEO. In Proceedings of the Interna-

tional Workshop on Open Enterprise Solutions: Sys-

tems, Experiences, and Organizations, pages 14–15.

Black, R., Davenport, J. H., Olszewska, J. I., Roessler, J.,

Smith, A. L., and Wright, J. (2021). Artificial Intel-

ligence and Software Testing: A Practical Guide to

Quality. BCS Press.

Bonci, A., Pirani, M., and Longhi, S. (2017). Robotics 4.0:

Performance improvement made easy. In Proceedings

of the IEEE International Conference on Emerging

Technologies and Factory Automation (ETFA), pages

1–8.

Brings, J., Daun, M., Hildebrandt, C., and Torsleff, S.

(2018). An ontological context modeling frame-

work for coping with the dynamic contexts of cyber-

physical systems. In Proceedings of the Interna-

tional Conference on Model-Driven Engineering and

KEOD 2021 - 13th International Conference on Knowledge Engineering and Ontology Development

216

Software Development (MODELSWARD), pages 396–

403.

Burns, M., Griffor, E., Balduccini, M., Vishik, C., Huth, M.,

and Wollman, D. (2018). Reasoning about smart city.

In Proceedings of the IEEE International Conference

on Smart Computing, pages 381–386.

Canito, A., Aleid, K., Praca, I., Corchado, J., and Mar-

reiros, G. (2020). An ontology to promote interop-

erability between cyber-physical security systems in

critical infrastructures. In Proceedings of the IEEE

International Conference on Computer and Commu-

nications (ICCC), pages 553–560.

Cecil, J., Albuhamood, S., and Cecil-Xavier, A. (2018). An

Industry 4.0 cyber-physical framework for micro de-

vices assembly. In Proceedings of the IEEE Interna-

tional Conference on Automation Science and Engi-

neering (CASE), pages 427–432.

Cheng, H., Zeng, P., Xue, L., Shi, Z., Wang, P., and Yu, H.

(2016). Manufacturing ontology development based

on Industry 4.0 demonstration production line. In

Proceedings of the IEEE International Conference on

Trustworthy Systems and their Applications, pages

42–47.

Cibes Lift (2017). Operating and Maintenance Instructions.

J45017.

Cockburn, I. M., Henderson, R., and Stern, S. (2018). The

impact of artificial intelligence on innovation. No.

w24449.

Corsar, D. and Sleeman, D. (2007). KBS development

through ontology mapping and ontology driven acqui-

sition. In Proceedings of the ACM International Con-

ference of Knowledge Capture (K-CAP), pages 23–30.

Costanzo, A., Faro, A., Giordano, D., and Spampinato, C.

(2016). Implementing cyber physical social systems

for smart cities: A semantic web perspective. In Pro-

ceedings of the IEEE Annual Consumer Communica-

tions and Networking Conference, pages 1–2.

Derler, P., Lee, E. A., and Sangiovanni Vincentelli, A.

(2011). Modeling cyber-physical systems. Proceed-

ings of the IEEE, 100(1):13–28.

Dietz, J. and Mulder, H. (2020). Enterprise Ontology.

Springer.

Dopico, M., Gomez, A., De La Fuente, D., Garcia, N.,

Rosillo, R., and Puche, J. (2016). A vision of Indus-

try 4.0 from an artificial intelligence point of view. In

Proceedings of the IEEE International Conference on

SArtificial Intelligence, pages 407–413.

Engel, G., Greiner, T., and Seifert, S. (2018). Ontology-

assisted engineering of cyber-physical production sys-

tems in the field of process technology. IEEE Trans-

actions on Industrial Informatics, 14(6):2792–2802.

Feki, M. A., Kawsar, F., Boussard, M., and Trappeniers, L.

(2013). The Internet of Things: The next technologi-

cal revolution. IEEE Computer, 46(2):24–25.

Fernandez, M., Gomez-Perez, A., and Juristo, N. (1997).

Methontology: From ontological art towards ontolog-

ical engineering. In Proceedings of the AAAI Spring

Symposium Series on Ontological Engineering, pages

33–40.

Fernandez-Lopez, M. and Gomez-Perez, A. (2002).

Overview and analysis of methodologies for build-

ing ontologies. Knowledge Engineering Review,

17(2):129–156.

Ferrer, B. R., Mohammed, W. M., Martinez Lastra, J. L.,

and Strzelczak, S. (2019). A semantic workbench for

editing, querying, navigating and distributing ontolo-

gies for cognitive manufacturing. In Proceedings of

the IEEE Annual Conference of the IEEE Industrial

Electronics Society (IECON), pages 2767–2772.

Fiorini, S. R., Bermejo-Alonso, J., Goncalves, P., Pigna-

ton de Freitas, E., Olivares Alarcos, A., Olszewska,

J. I., Prestes, E., Schlenoff, C., Ragavan, S. V., Red-

field, S., Spencer, B., and Li, H. (2017). A suite of on-

tologies for robotics and automation. IEEE Robotics

and Automation Magazine, 24(1):8–11.

Fox, M. S. and Gruninger, M. (1998). Enterprise modeling.

AI Magazine, 19(3):109–122.

Glimm, B., Horrocks, I., Motik, B., Stoilos, G., and Wang,

Z. (2014). HermiT: An OWL 2 reasoner. Journal of

Automated Reasoning, 53(3):245–269.

Gomez-Perez, A., Fernandez-Lopez, M., and Corcho, O.

(2004). Ontological Engineering. Springer-Verlag.

Gorecky, D., Schmitt, M., Loskyll, M., and Zuhlke, D.

(2014). Human-machine-interaction in the Industry

4.0 era. In Proceedings of the IEEE International

Conference on Industrial Informatics (INDIN), pages

289–294.

Gruber, T. R. (1995). Toward principles for the design of

ontologies used for knowledge sharing. International

Journal Human-Computer Studies, 43(5-6):907–928.

Gruninger, M. and Fox, M. S. (1995). The Role of

Competency Questions in Enterprise Engineering. In

Benchmarking - Theory and Practice, pages 22–31.

Springer.

Gruninger, M.and Fox, M. (1995). Methodologies for the

design and evaluation of ontologies. In Proceedings

of the IJCAI Workshop on Basic Ontological Issues in

Knowledge Sharing, pages 6.1–6.10.

Guo, Y., Qasem, A., Pan, Z., and Heflin, J. (2007).

A requirement driven framework for benchmark-

ing semantic web knowledge base systems. IEEE

Transactions on Knowledge and Data Engineering,

19(2):297–309.

Gyrard, A., Patel, P., Sheth, A., and Serrano, M. (2016).

Building the web of knowledge with smart IoT appli-

cations. IEEE Intelligent Systems, 31(5):83–88.

Hildebrandt, C., Kocher, A., Kustner, C., Lopez-Enriquez,

C.-M., Muller, A. W., Caesar, B., Gundlach, C. S., and

Fay, A. (2020). Ontology building for cyber-physical

systems: Application in the manufacturing domain.

IEEE Transactions on Automation Science and Engi-

neering, 17(3):1266–1282.

Hlomani, H. and Stacey, D. (2014). Approaches, methods,

metrics, measures, and subjectivity in ontology evalu-

ation: A survey. Semantic Web Journal, 1(5):1–11.

Hoon, C. S. (2006). Microcontroller based lift control sys-

tem. PhD thesis.

Hoyes, C. and Mair, R. (2020). Game changers in the ele-

vator market.

Smart Lifts: An Ontological Perspective

217

Ide, N. and Pustejovsky, J. (2010). What does interoperabil-

ity mean, anyway? Toward an operational definition

of interoperability for language technology. In Pro-

ceedings of the International Conference on Global

Interoperability for Language Resources, pages 12–8.

Jones, D., Bench-Capon, T., and Visser, P. (1998). Method-

ologies for ontology development. In Proceedings of

the IFIP World Computer Congress, pages 62–75.

Jost, J., Kirks, T., and Mattig, B. (2017). Multi-agent sys-

tems for decentralized control and adaptive interaction

between humans and machines for industrial environ-

ments. In Proceedings of the IEEE International Con-

ference on System Engineering and Technology, pages

95–100.

Kalyazina, D. and Kashevnik, A. (2018). Socio-

cyberphysical system resource semantic interoperabil-

ity: General scenarios and ontology. In Proceedings

of the Conference of Open Innovations Association,

pages 320–326.

Kannengiesser, U. and Muller, H. (2013). Towards agent-

based smart factories: A subject-oriented modeling

approach. In Proceedings of the IEEE/WIC/ACM

International Joint Conferences on Web Intelligence

(WI) and Intelligent Agent Technologies (IAT), pages

83–86.

Koh, L., Orzes, G., and Jia, F. J. (2019). The fourth in-

dustrial revolution (Industry 4.0): Technologies dis-

ruption on operations and supply chain management.

International Journal of Operations and Production

Management, 39(6-8):817–828.

Kone (2020). Lifting the elevator industry to a new era.

Kunold, I., Wohrle, H., Kuller, M., Karaoglan, N.,

Kohlmorgen, F., and Bauer, J. (2019). Semantic inter-

operability in cyber-physical systems. In Proceedings

of the IEEE International Conference on Intelligent

Data Acquisition and Advanced Computing Systems:

Technology and Applications, pages 797–801.

Lee, E. (2019). A fundamental look at models and intelli-

gence. In Proceedings of the IEEE/ACM International

Workshop on Software Engineering for Smart Cyber-

Physical Systems, page 1.

Lewandowski, R. and Olszewska, J. I. (2020). Automated

task scheduling for automotive industry. In Proceed-

ings of the IEEE International Conference on Intelli-

gent Engineering Systems, pages 159–164.

Ma, M., Wang, P., and Chu, C.-H. (2014). Ontology-

based semantic modeling and evaluation for Internet

of Things applications. In Proceedings of the IEEE

International Conference on Green Computing and

Communications, pages 24–30.

Marcus, S., Stout, J., and McDermott, J. (1987). VT: An

expert elevator designer that uses knpwledge-based

backtracking. AI Magazine, 8(4):41–58.

Marr, B. (2018). What is Industry 4.0? Here’s a super easy

explanation for anyone.

Nilsson, J. and Sandin, F. (2018). Semantic interoperability

in Industry 4.0: Survey of recent developments and

outlook. In Proceedings of the IEEE International

Conference on Industrial Informatics (INDIN), pages

127–132.

Nott, G. (2018). IoT, cloud and machine learning giving

elevator giants a lift.

Olszewska, J. I. (2016). Temporal interval modeling for

UML activity diagrams. In Proceedings of the Inter-

national Conference on Knowledge Engineering and

Ontology Development (KEOD), pages 199–203.

Olszewska, J. I. (2020). AI-T: Software testing ontology

for AI-based systems. In Proceedings of the Inter-

national Joint Conference on Knowledge Discovery,

Knowledge Engineering and Knowledge Management

(KEOD), pages 291–298.

Olszewska, J. I. (2021). Ontologies for Software Testing. In

Artificial Intelligence and Software Testing: A Practi-

cal Guide to Quality, pages 68–77. BCS Press.

Olszewska, J. I. and Allison, I. K. (2018). ODYSSEY: Soft-

ware development life cycle ontology. In Proceed-

ings of the International Joint Conference on Knowl-

edge Discovery, Knowledge Engineering and Knowl-

edge Management (KEOD), pages 303–311.

Onag, G. (2019). AI and IoT are the keys to smarter lifts

and escalators.

Pignaton de Freitas, E., Olszewska, J. I., Carbonera, J. L.,

Fiorini, S., Khamis, A., Sampath Kumar, V. R., Bar-

reto, M., Prestes, E., Habib, M., Redfield, S., Chibani,

A., Goncalves, P., Bermejo-Alonso, J., Sanz, R.,

Tosello, E., Olivares Alarcos, A., Konzen, A. A.,

Quintas, J., and Li, H. (2020). Ontological concepts

for information sharing in cloud robotics. Journal

of Ambient Intelligence and Humanized Computing,

pages 1–14.

Rubin, D. L., Noy, N. F., and Musen, M. A. (2007). Pro-

tege: A tool for managing and using terminology in

radiology applications. Journal of Digital Imaging,

20(1):34–46.

Sampath Kumar, V. R., Khamis, A., Fiorini, S. R., Carbon-

era, J. L., Olivares-Alarcos, A., Habib, M., Goncalves,

P., Li, H., and Olszewska, J. I. (2019). Ontologies for

Industry 4.0. Knowledge Engineering Review, 34:1–

14.

Sheridan Lifts (2018). The most common lift faults. Sheri-

dan Lifts.

Siikonen, M.-L. (1997). Elevator group control with artifi-

cial intelligence. PhD thesis.

Smirnov, A., Kashevnik, A., Mikhailov, S., Mironov, M.,

and Petrov, M. (2016). Ontology-based collaboration

in multi-robot system: Approach and case study. In

Proceedings of the IEEE System of Systems Engineer-

ing Conference, pages 1–6.

Steinmetz, C., Rettberg, A., Ribeiro, F. G. C., Schroeder, G.,

and Pereira, C. E. (2018). Internet of Things ontology

for digital twin in cyber physical systems. In Proceed-

ings of the IEEE Brazilian Symposium on Computing

Systems Engineering, pages 154–159.

Sujith, S., Atif, Y., Sheng, Q. Z., and Maamar, Z. (2011).

Web of Things: Description, discovery and integra-

tion. In Proceedings of the IEEE International Con-

ference on Internet of Things, pages 9–15.

Syamili, C. and Rekha, R. V. (2017). Ontology engineering

methodologies: An analytical study.

KEOD 2021 - 13th International Conference on Knowledge Engineering and Ontology Development

218

Tang, H., Li, D., Wang, S., and Dong, Z. (2018). CASOA:

An architecture for agent-based manufacturing system

in the context of Industry 4.0. IEEE Access, 6:12746–

12754.

Tartir, S., Arpinar, I. B., Moore, M., Sheth, A. P., and

Aleman-Meza, B. (2018). OntoQA: Metric-based on-

tology quality analysis. In IEEE International Con-

ference on Data Mining Workshop, pages 559–564.

Thyssen Krupp (2014). Orion - Gulliver Vertical Platform

Lift. Installation Manual. INS-OR04-EN-05.

Torsleff, S., Hildebrandt, C., Daun, M., Brings, J., and Fay,

A. (2018). Developing ontologies for the collabora-

tion of cyber-physical systems: Requirements and so-

lution approach. In Proceedings of the IEEE Interna-

tional Workshop on Emerging Ideas and Trends in the

Engineering of Cyber-Physical Systems, pages 25–32.

Tsalapati, E., Tribe, J., Goodall, P., Young, R. I. M., Jack-

son, T., and West, A. (2021). Enhancing RFID system

configuration through semantic modelling. Knowl-

edge Engineering Review, pages 1–30.

Voinov, A. and Senokosov, I. (2021). Ontological models

of cyber physical systems. Journal of Physics: Con-

ference Series, 1889(2):1–10.

Wan, J., Yin, B., Li, D., Celesti, A., Tao, F., and Hua,

Q. (2018). An ontology-based resource reconfigu-

ration method for manufacturing cyber-physical sys-

tems. IEEE/ASME Transactions on Mechatronics,

23(6):2537–2546.

Wilding, S., Walker, P., Clinton, S., Williams, D., and Ol-

szewska, J. I. (2020). Safe human-computer interface

based on an efficient image processing algorithm. In

Proceedings of the IEEE International Symposium on

Computational Intelligence and Informatics (CINTI),

pages 65–70.

Xu, X. and Hua, Q. (2017). Industrial big data analysis in

smart factory: Current status and research strategies.

IEEE Access, 5:17543–17551.

Zhong, R. Y., Xu, X., Klotz, E., and Newman, S. T. (2017).

Intelligent manufacturing in the context of Industry

4.0: A review. Engineering, 3(5):616–630.

Zhu, W., He, H., and Wang, Z. (2017). Ontology-based

mission modeling and analysis for system of systems.

In Proceedings of the IEEE International Conference

on Smart Data (SmartData), pages 538–544.

Smart Lifts: An Ontological Perspective

219