Application of Tools of the Technical Diagnostics System to Increase

the Efficiency of Mobile Equipment in the Agro-industrial Complex

in the Conditions of Sustainable Development

Oleg Mamaev

a

and Sergei Panov

b

K.G. Razumovsky Moscow State University of Technologies and Management

(the First Cossak University), Omsk, Russia

Keywords: Technical Diagnostics, Technical Condition of the Object, Built-in Diagnostics, Remote Diagnostics,

Technical Diagnostic Tools.

Abstract: the trouble-free performance of planned works by agricultural machinery both during the periods of sowing

and harvesting companies, and the performance of daily work. The problems considered in the work are

related to the fact that at the regional level there is a significant variation in the agricultural equipment used,

both by brands, types and production times of this equipment. In such conditions, it is rather difficult to use a

unified approach to conducting technical diagnostics, and the range of natural, climatic, and soil conditions

only complicates the task of developing the optimal option. The paper analyzes the survey of self-propelled

machines in the Omsk region farms located in different natural zones, assesses the system of technical

diagnostics in farms, formulates proposals for a strategy for developing technical diagnostics at the regional

level.

1 INTRODUCTION

A global trend is the saturation of the agricultural

industry with sophisticated energy-efficient mobile

equipment with a simultaneous decrease in the

number of workers employed in the industry

(MacDonald, 2015). Under these conditions, the

overall efficiency of the economy, which includes

both economic efficiency and the organization of

work, depends on the readiness of the technical

support complex.

In (Silva, 2019), it is noted that maintenance is

becoming one of the main functions of agribusiness

enterprises and is included in strategic assets that

increase their competitiveness.

Taking into account the widespread introduction

of digital and intelligent technologies in agriculture,

it is necessary to formalize the process of assessing

the readiness of a complex of machines. It is possible

to describe the readiness of a complex of machines of

a particular farm by the readiness factor, which can

be set by a number of parameters:

a

https://orcid.org/0000-0003-0835-4797

b

https://orcid.org/0000-0003-0834-0272

K

g

=

T

o

, P, Z, D

t

(1

)

where T

o

is the vector of the technical condition

of machines, P is the assessment of personnel

readiness, Z is the vector of the availability of spare

parts and operating materials, and D

t

is the system of

technical diagnostics.

The technical state of an object (machine),

including a mobile one, is a state that is characterized

at a certain point in time, under certain environmental

conditions, by the values of the parameters

established by the technical documentation for the

object (GOST 20911, 1989).

The types of technical condition according to

(GOST 25044-81, 1983) are: serviceable, efficient,

defective, inoperative, depending on the values of the

parameters set in the technical documentation for the

machine, at a given time.

Thus, the vector of the technical state of a

complex of farm machinery can be specified at a

certain time by the vector

T

o

=

s

1

, s

2

, s

3

,..s

n

(2)

374

Mamaev, O. and Panov, S.

Application of Tools of the Technical Diagnostics System to Increase the Efficiency of Mobile Equipment og the Agro-industrial Complex in the Conditions of Sustainable Development.

DOI: 10.5220/0010668900003223

In Proceedings of the 1st International Scientific Forum on Sustainable Development of Socio-economic Systems (WFSDS 2021), pages 374-379

ISBN: 978-989-758-597-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

where

si

, takes one of the values "faulty, faulty,

operable, inoperative", i = 1, n, n is the number of

agricultural machines on the farm.

The task of analyzing the influence of the

parameter "readiness assessment

personnel ", on the readiness of the complex of

machines, however, it is obvious that the rest of the

indicators depend on it, both directly and indirectly.

The parameter of availability of spare parts and

operating materials can be set at a certain moment in

the form:

Z=

z

1

, z

2

, z

3

,..z

n

(3

)

where z

i

, is determined as a percentage of the

required value, i = 1,n, n is the number of agricultural

machines on the farm.

According to (GOST 20911, 1989), a system of

technical diagnostics (monitoring of technical

condition) is a set of tools, an object and performers

necessary to carry out diagnostics (control) according

to the rules established in technical documentation.

The D

t

farm technical diagnostics system should

solve the problems defined in (GOST 25044-81,

1983):

determine, with a given probability, the

technical condition of the i-th machine;

to identify critical defects that change the

technical condition of the i-th machine;

to predict the time interval of changes in the

technical state of the i-th machine.

The assessment of the system of technical

diagnostics of a certain economy can be based on the

possibility of solving the above problems.

We define the type of technical diagnostics

system as C

1

, if the farm has created conditions for

solving problem 1, C

2

, if conditions are created for

solving problems 1 and 2 and C

3

, if conditions are

created for solving problems 1-3, C

0

-in the absence of

conditions for solving tasks 1-3.

Let us determine how the systems of technical

diagnostics C

0

-C

3

are implemented, it is obvious that

this implementation depends on the type of

equipment used.

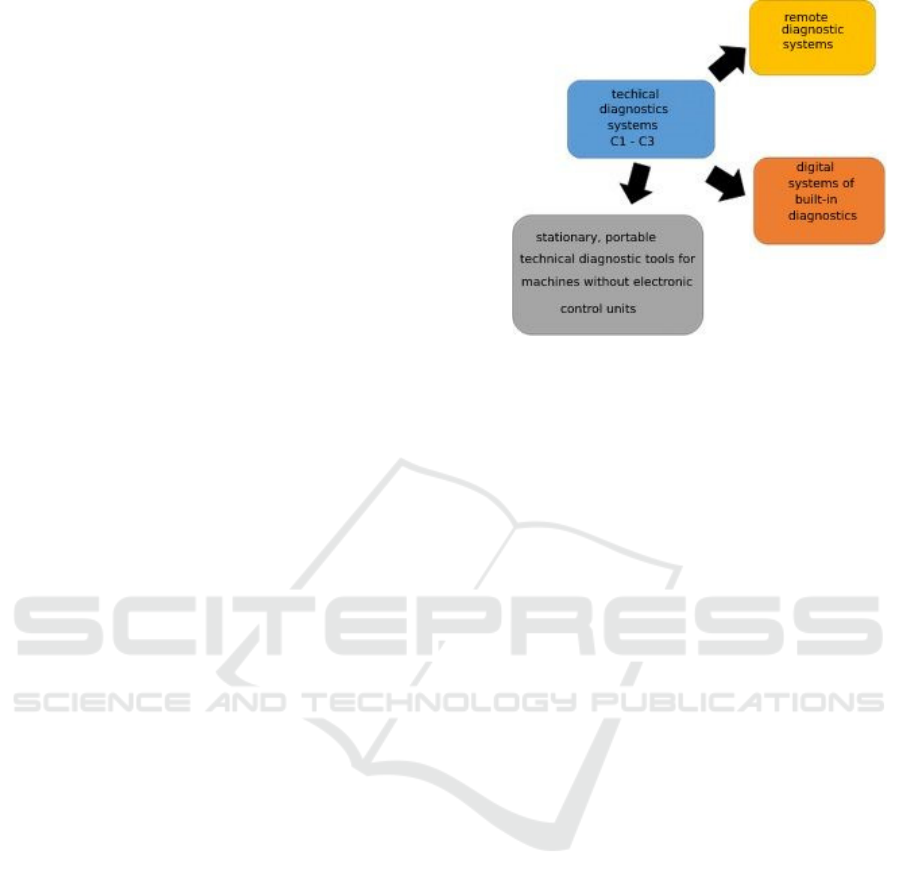

Figure 1 shows the classification of technical

diagnostics systems, depending on the equipment of

the self-propelled vehicle with the means of internal

diagnostics implemented by digital devices.

Let us consider how the types of technical

diagnostics systems are combined with the strategies

for the maintenance and repair of machines (MRO)

identified in (Lebedev, 2019).

Figure 1: Classification of technical diagnostic systems.

The strategy of reactive maintenance (RM) on

demand - carrying out maintenance and repair in

cases of the machine's transition to an inoperative

state, is obviously implemented with the C0 and C1

diagnostic systems.

The preventive maintenance (PM) strategy for

operating time and scheduled maintenance is also

implemented with the C0 and C1 diagnostic systems.

A condition based maintenance (CBM) strategy

will require a C2 diagnostic system.

Predictive maintenance (PdM) strategy Predictive

maintenance and reliability centered maintenance

(RCM) reliability maintenance will require a C3

diagnostic system.

Currently, farms producing agricultural products

use a complex of mobile equipment of Russian and

foreign production without electronic control units,

modern Russian and foreign equipment with

electronic control units and built-in diagnostic

systems. And the problematic at the regional level for

Russian conditions is the absence of a unified strategy

for technical diagnostics of mobile agricultural

machines.

2 MATERIALS AND METHODS

The Omsk region is one of the most developed

agricultural regions of Siberia. The region provides

The region provides more than 3% of the all-Russian

volume of state grain purchases. The share of crop

production is up to 40% of gross agricultural

production, including grain crops - 15-20%, fodder

crops - 10-15%. Thus, the level of development of the

agro-industrial complex, including the technical

equipment of crop production, has a significant

impact on the socio-economic situation of the region

Application of Tools of the Technical Diagnostics System to Increase the Efficiency of Mobile Equipment og the Agro-industrial Complex

in the Conditions of Sustainable Development

375

(Order of the Government of the Omsk Region,

2020).

The paper presents studies carried out in various

agricultural enterprises of the region in order to

determine the types of applied technical diagnostics

(TD) systems, assess the effectiveness of the applied

TD systems and the possibility of developing a

unified territorial approach. For the study, methods of

measuring the parameters of mobile equipment were

used in order to determine its condition, the survey

method of farm workers and statistical processing of

the results.

The territory of the Omsk region covers the

following natural zones: forest, forest-steppe and

steppe, each of which is further subdivided into

subzones. Each natural zone is characterized by its

own conditions due to the latitudinal distribution of

heat and moisture, which affect the possibilities and

efficiency of farming (Aleshchenko, 2013).

Figure 2 shows the territorial division of the Omsk

region into natural zones, and Figure 3 shows the

distribution of agricultural sown areas.

Figure 2: Natural zones of the Omsk region.

On the territory of the region, there are more than

10 agro-soil regions, more than 50 soil varieties in

arable land. These circumstances cannot but influence

the choice of agricultural machinery for crop

production. As noted in a study conducted in (Boyko,

2018), the reduction in unit costs largely depends on

the introduction of resource-saving and agro

technologies in crop production, which also depend

on the technical re-equipment of farms.

Figure 3: The area of farmland in the Omsk region.

To study the applied TD systems and assess their

effectiveness, commodity producers from various

natural zones were selected, with a tractor fleet of at

least 10 units and a fleet of grain harvesters of at least

5 units, used for the production of work in crop

production.

To determine the initial technical state of the

mobile equipment of the farm, diagnostic measures

were carried out with the measurement and recording

of both direct and indirect indicators, such as: engine

oil pressure, injector pressure, compression in

cylinders, engine oil quality, exhaust smoke. Further,

the same parameters were measured during spring

and autumn works and before the conservation of

equipment for the winter period. The study of the

quality of engine oil on the basis of samples taken

from the engines was carried out in a certified

laboratory.

The main task of the analysis of the measured

values of diagnostic parameters was to determine the

type of technical diagnostics system used by the farm

and to form the trajectory of the operation of the

mobile device.

The formation of the trajectory of the operation of

the mobile device consisted in determining the

current technical condition, assessing the residual

resource and calculating the forecast of critical

events.

In the process of determining the type of TD

system, the economic effect that the economy could

receive from changing the type of TD system was

calculated.

WFSDS 2021 - INTERNATIONAL SCIENTIFIC FORUM ON SUSTAINABLE DEVELOPMENT OF SOCIO-ECONOMIC SYSTEMS

376

3 RESULTS

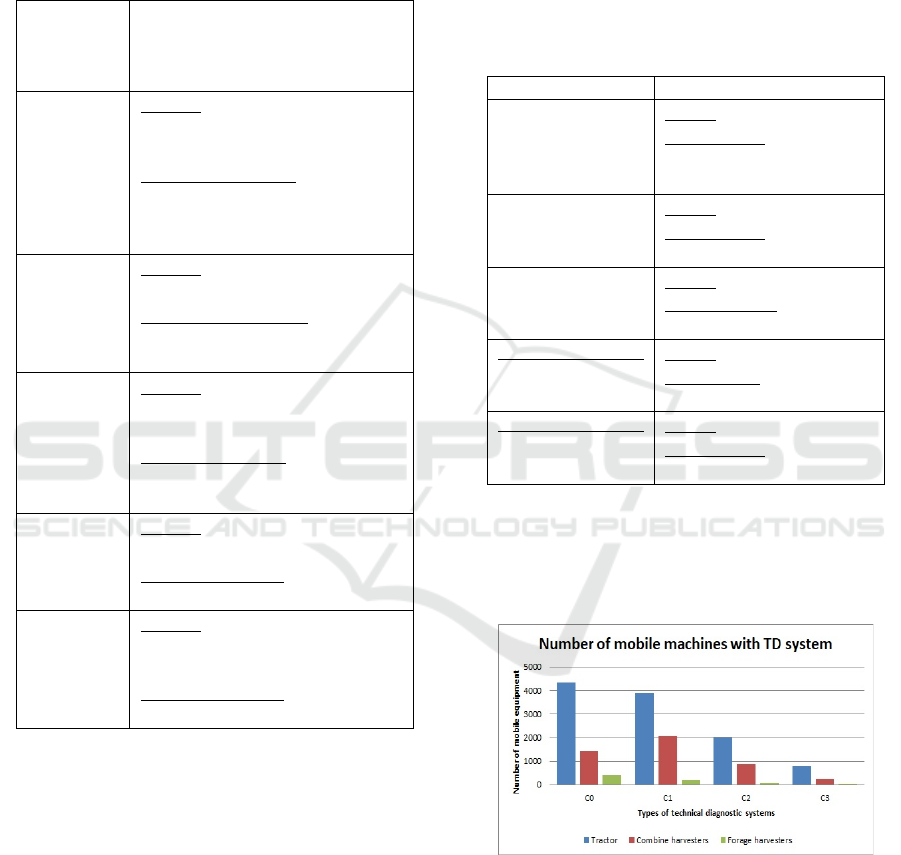

Table 1 shows the economic entities selected for the

study.

Table 1: Mobile equipment of selected farms in different

natural areas.

Zone /

territorial

area

Mobile equipment

(Recommendations for the

diagnosis of the technical condition

of agricultural machinery, 2020)

Northern

forest-

steppe /

Bolshereche

nsky

Tractors KIROVETS K-701,

KIROVETS K-700A, MTZ-80,

MTZ-82.1

Combine harvesters KZS-812

"PALESSE GS812 (2), UES-280"

PALESSE U280, CLAAS

TUCANO 430

Stepnaya /

Cherlaksky

Tractors CLAAS AXION 850,

CLAAS AXION 950, MTZ -80 (2)

Combine harvesters СLAAS

TUCANO 450 (3), СLAAS

TUCANO 570

Stepnaya /

Cherlaksky

Tractors MASSEY FERGUSON

MF8737, CLAAS AXION 900,

MTZ 80, MTZ 1221

Combine harvesters ACROS 550,

VECTOR 410, VECTOR 430

СLAAS TUCANO 570

Southern

forest-

steppe /

Omsk

Tractors KIROVETS K-701 (2),

MTZ 82, MTZ 80, Т-150

Combine harvesters KZS -812 (3),

KZS -7 (2)

Podtaezhna

ya /

Znamensky

Tractors BUHLER VERSATILE

2375, NEW HOLLAND T8040,

MTZ 82, MTZ 1221.2

Combine harvesters KZS -812 (2),

KZS -7 (3)

As follows from Table 1, farms, as a rule, use

various mobile equipment, both by model,

manufacturer and year of manufacture. Note that,

despite the difference in natural zones noted above,

farms use the same type of machines.

Table 2 summarizes the data on the mobile devices

used on the farms.

In the conditions of a significant spread in the

brands, models and years of production of mobile

devices, shown in Table 2 for one of the surveyed

farms, and a similar picture is observed in others, it is

very difficult and costly for farms to provide

diagnostics and maintenance of all equipment used.

For mobile devices without built-in diagnostics, it is

necessary to have a set of technical tools and a

specialist, for new generations of mobile technology,

as a rule, third-party services are used. As a rule, such

organizations are located in the regional center, which

for remote areas, in emergency cases, does not provide

sufficient service.

Table 2: Characteristics of mobile equipment used on

farms.

Mobile equipment Параметры

Tractor MTZ -80

Engine D-240

Year of issue 1990

Running time, m / h

10500

Tractor KIROVETS

K-701

Engine ЯМЗ-240 БМ

Year of issue 1986

Running time, m / h 250

Трактор

KIROVETS K-

700А

Engine ЯМЗ-238 НД

Year of issue а 1990

Running time, m / h 180

Combine harvesters

KZS 7 « PALESSE

GS 07»

Engine Д-260.4

Year of issue 2011

Running time, m / h 1680

Combine harvesters

KZS -812 «

PALESSE GS812»

Engine Д-260.4

Year of issue 2009

Running time, m/h 1700

Based on the indicative data collected in farms,

the distribution of the number of mobile assets for

which farms use one or another TD system, shown in

Figure 4, has been constructed.

Figure 4: Diagram of the distribution of TD systems.

The diagram of the distribution of the availability

and use of diagnostic systems in farms reflects the

real picture at the regional level. A significant number

of mobile equipment that has already exhausted its

resource (according to various estimates, about 60%),

a large percentage of equipment from foreign

Application of Tools of the Technical Diagnostics System to Increase the Efficiency of Mobile Equipment og the Agro-industrial Complex

in the Conditions of Sustainable Development

377

manufacturers with a significant service life does not

contribute to the transition to C

3

diagnostic systems,

and the use of modern PdM and RCM maintenance

strategies. The most widespread in farms is

diagnostics by organoleptic indicators and routine

maintenance, which, as studies show (Komarov,

2018), are the reason for the low MTBF.

4 SUMMATION

The conducted studies have shown that farms in the

region lack a strategy for the formation of a complex

of mobile means for performing work in crop

production.

Research and statistical data (Analytical report,

2016) show that the region's farms are dominated by

mobile equipment from foreign manufacturers. The

operation of foreign equipment in each region has a

number of features that impose their own

requirements on the organization of the technical

diagnostics system, in particular:

mobile equipment of foreign manufacturers, as

a rule, has a higher reliability, and as a result, a

significant operating time. The high cost of

such equipment increases the economic losses

of the economy in the event of its breakdown

and shutdown, this makes special requirements

for diagnostics and maintenance (Gabitov,

2007);

as a rule, the farm cannot carry out diagnostics

of foreign equipment on its own, but only with

the involvement of specialists from specialized

enterprises or dealers of this equipment, which

worsens the overall logistics of the farm.

At the same time, the economic policy of the state

aimed at subsidizing the purchase of domestic

equipment has led to its growth in farms (Analytical

report, 2016). However, the reliability of this

technique is lower than that of foreign counterparts,

which also significantly increases the requirements

for technical diagnostics, maintenance and repair and

forecasting of the residual resource.

5 CONCLUSIONS

A significant number of works, both Russian and

foreign authors devoted to the development of new

tools for CIP technical diagnostics, show the

relevance and importance of this topic.

New diagnostic tools have increased requirements

for the accuracy of measuring the diagnosed

parameters, a high probability of detecting defects

that can lead to critical breakdowns. The development

of new tools goes in several directions:

modernization of already used diagnostic

tools, with the possibility of connecting a

computer and the possibility of computer

processing of the results (Livshits, 2010),

with the possibility of using it for machines

without electronic control units;

the development of developed specialized

software and hardware, which allows not

only to identify failures in a mobile device,

but also to predict the failure time and

estimate the required repair time (Silva,

2019);

the development of remote diagnostics and

monitoring technologies that allow not only

to control the parameters of a mobile device,

but to collect information on non-productive

use, optimal movement, etc.

However, many of these funds will be

inaccessible to small farms, with the absence of their

own diagnostic and repair facilities, with the lack of

qualified personnel and a variety of equipment, both

by type and model. In these conditions, the optimal

solution seems to be the formation of a strategy at the

regional level, which should:

to stimulate farms to get rid of outdated

models of mobile equipment, with excess

operating time;

to stimulate the development of exemplary

complexes of mobile equipment for plant

growing, corresponding to the natural, agro-

climatic, soil conditions of farms; - to

stimulate the creation of a regional center for

digital technologies to ensure the conduct of

technical diagnostics, the development of

remote diagnostics systems.

REFERENCES

MacDonald G.K., Braun K.A., Sun S., Carlson K.M.,

Cassidy E.S., Gerber J.S., West P.C. (2015).

BioScience.

Silva C.A.G., Sa J.L.R., Menegatti R. (2019).

AgriEngineering.

GOST 20911-89. (1989). Technical diagnostics. Terms and

definitions. Moscow.

GOST 25044-81. (1982). Technical diagnostics. Diagnosis

of motor vehicles, tractors, agricultural, construction

and road machinery. Basic principles. Moscow.

Lebedev A.T., Seregin A.A., Arzhenovskiy A.G., (2019).

Bulletin of Agrarian Science of the Don.

WFSDS 2021 - INTERNATIONAL SCIENTIFIC FORUM ON SUSTAINABLE DEVELOPMENT OF SOCIO-ECONOMIC SYSTEMS

378

Order of the government of the Omsk region, (2020).

Omsk.

Aleschenko V.V., Aleshchenko O.A., Karpov V.V.,

Korableva A.A. LLC IC "Omsk Scientific Bulletin".

Monograph.

Boyko V.S., Chekusov M.S. (2018). LITER. Monograph.

Komarov V.A. (2018). Bulletin of the Mordovian

University.

Analytical report. (2016). Analytical center of the Omsk

region. Monograph

Gabitov I.I, Portnov V.I. (2007). Tractors and agricultural

machines.

Livshits V.M., Krasheninnikov S.V., Pyatin S.P., (2010).

Bulletin of the IrGSKhA.

Panov S. A., Mamaev O. A., Chemisenko O. V., Breiter Yu.

L., Levochkina N. A. (2020). Recommendations for the

diagnosis of the technical condition of agricultural

machinery Methodological recommendations for

technical service specialists. Omsk.

Application of Tools of the Technical Diagnostics System to Increase the Efficiency of Mobile Equipment og the Agro-industrial Complex

in the Conditions of Sustainable Development

379