Matching of Mechanical Properties of Biological Tissues and

Technical Materials for the Fabrication of Anatomical Models by

Material Jetting

Alexander Preis

a

, Hannah Riedle

b

, Elisabeth Benke

c

and Jörg Franke

d

Institute for Factory Automation and Production Systems, Friedrich-Alexander-Universität Erlangen-Nürnberg,

Egerlandstraße 7-9, Erlangen, Germany

Keywords: Surgical Models, Anatomical Models, Surgical Training, Medical Education, Medical Device Evaluation,

Biomechanics, Biomechanical Testing, Additive Manufacturing, 3D Printing, Material Jetting,

Standardization.

Abstract: Realistic, high-fidelity anatomical models with material properties corresponding to those of human tissue

can be used for surgical planning and training, medical education and medical device testing and validation.

Conventional manufacturing of anatomical models is a time consuming, and expensive process, which

nevertheless is not able to fully mimic the complex nature of the human body regarding geometry and

mechanical properties. To create models closer to reality in a fast and cost-effective way, additive

manufacturing, especially the process of material jetting, can be a solution. Utilizing this process, it is possible

to fabricate multi-color, multi-material objects with complex geometries, high resolution, and even gradients

in material properties. To replicate the mechanical properties of biological tissues, they must be matched with

the technical materials or material combinations available for the utilized manufacturing process. Therefore

the authors propose to conduct measurements according to standardized testing procedures like ISO 37 for

tensile and ISO 48-4 for indentation tests, which allows matching to the manufacturing materials and thus

will result in the possibility to create more accurate replicas of the human body that provide realistic haptic

feedback.

1 INTRODUCTION

Anatomical models provide benefits in a multitude of

different fields. In preoperative planning, they

support the familiarization with the patient’s specific

anatomy and provide a hands-on approach of testing

different surgical strategies. Especially in physicians

specialties which require very delicate surgical

procedures, the annual likeliness of a malpractice

claim can be up to 19 % (Anupam et al., 2011), which

shows that accurate planning and preparation is

critical to avoid mistakes during surgery. Here the

field of reconstructive surgery is a good example,

where, for optimal results in the recreation of

appearance and healing of functional losses, a deep

a

https://orcid.org/0000-0003-3469-5982

b

https://orcid.org/0000-0003-1338-2127

c

https://orcid.org/0000-0002-6610-4430

d

https://orcid.org/0000-0003-0700-2028

knowledge of the pathology is needed, which can be

aided by a realistic and tangible representation of the

situation (Chae et al., 2015). Detailed models can be

used to show the planned procedure to the patient,

explain the difficulties and thus support patient

education and informed consent. They even can

support the physician during surgery by providing

information regarding orientation. (Malik et al., 2015)

All of this leads to a reduced duration of the surgery,

less trauma to the patient and overall better results

(Chae et al., 2015). The use of anatomical models can

also aid the understanding of the human body in

general by conducting research activities on additive

manufactured anatomical structures (Birkholz et al.,

2020).

Preis, A., Riedle, H., Benke, E. and Franke, J.

Matching of Mechanical Properties of Biological Tissues and Technical Materials for the Fabrication of Anatomical Models by Material Jetting.

DOI: 10.5220/0010384201890194

In Proceedings of the 14th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021) - Volume 1: BIODEVICES, pages 189-194

ISBN: 978-989-758-490-9

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

189

Studies have shown that additively manufactured

anatomical models are able to represent the human

anatomy and pathologies realistic enough to be used

in medical education (Riedle et al., 2019). Training

by using high fidelity anatomical models providing

haptic feedback was shown to result in a better

performance and more profound understanding than

conventional methods like educational texts, 2D

images, or virtual 3D models (AlAli et al., 2018)

(Ström et al., 2006). Since the use of cadaveric

materials or animal tissue for the teaching of

anatomics has been a controversy regarding ethics

and health since its introduction, issues can be

avoided by using artificial, but realistic

representations of the human body (McMenamin et

al., 2014).

Another important use of anatomical models is

the testing and validation of medical devices. Such a

mock-up does not always have to replicate the

complete anatomy or all the physiological properties

of the intended usage environment (Yoo et al., 2020).

However, often good representation of the anatomy

as well as the mechanical properties is needed to

conduct meaningful research (Sulaiman et al., 2008).

Conventional manufacturing of individual, high-

fidelity anatomical models is a time consuming, and

expensive process, which nevertheless is not able to

fully mimic the complex nature of the human body

regarding geometry and diversity of mechanical

properties. This problem can be solved by additive

manufacturing, which allows the creation of highly

complex geometries utilizing multiple materials.

(Maragiannis et al., 2015)

2 POSSIBLE PROCESSES FOR

ADDITIVE MANUFACTURING

The process of additive manufacturing was first

presented by Chuck Hull in a 1984 patent. The

presented process of stereolithography is a form of

vat photopolymerization, where the resin is

selectively cured by using a laser scanner (Hull,

1984). Generally speaking, additive manufacturing is

a process where material is, in contrast to subtractive

manufacturing, automatically added, mostly as

layers, to create a physical object based on 3D-data

(DIN EN ISO/ASTM 52900). Important key facts of

the process are:

The geometry is based on 3D-CAD data.

No product specific tools are needed.

No need for fixation of the product.

Complex geometries, like undercuts, can be

manufactured effortlessly. (Gebhardt, 2016)

DIN EN ISO 17296-2 defines the seven different

additive manufacturing processes binder jetting,

directed energy deposition, material extrusion,

material jetting, powder bed fusion, sheet lamination,

and vat photopolymerization, which are described

more closely in table 1. Additionally, the processes

can be differentiated according to the aggregate state

of the raw material into generation from the solid,

liquid or gas phase (Gebhardt, 2016).

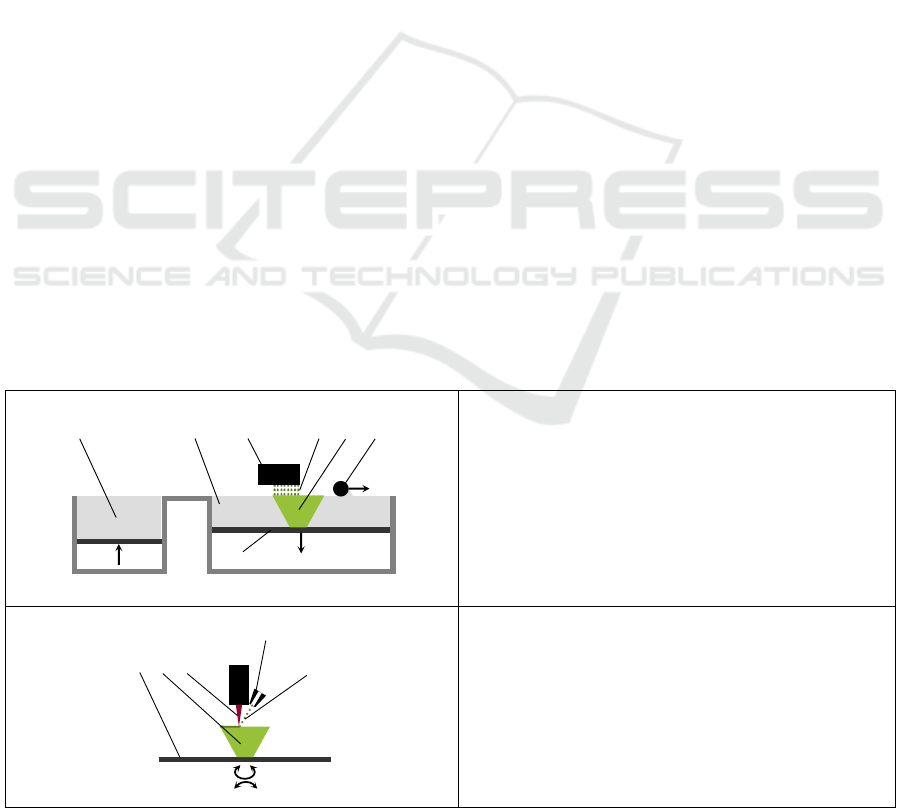

Table 1: Additive manufacturing processes according to DIN EN ISO 17296-2 and Gebhardt et al. 2016.

Binder Jetting

Binder jetting is a process, where a liquid (4) binder is

applied by a print head (3) to selectively bond powdered

raw material (2). New layers of material are added by a

roller (6) out of the material reservoir (1), which is made

possible by lowering the build platform (7). The process

often consists two steps, where the additive manufacturing

is creating a green body (5) which afterwards is infiltrated

or cured. By using different binder colors, a multi-color,

single-material part can be fabricated.

Directed Energy Deposition

Directed energy deposition uses a directed energy beam

(3) to bond the raw material (5), often jetted through a

nozzle (4), via melting to the product (2). The process is

mostly used for the creation of metal parts and often does

not depend on support structures due to the possibility of

5-axis movement of the build platform (1). By using

different raw materials, multi-material or gradient parts

can be fabricated.

23 456

7

1

1

2 3

4

5

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

190

Table 1: Additive manufacturing processes according to DIN EN ISO 17296-2 and Gebhardt et al. 2016 (cont.).

Material Extrusion

One of the most known processes is material extrusion, where

the raw material (4) is extruded through a nozzle (3). Layers

are created by lowering the build platform (1) or raising the

nozzle. Products (5) with complex geometries depend on

support structures (2). By using different raw materials, multi-

material and multi-color parts can be fabricated.

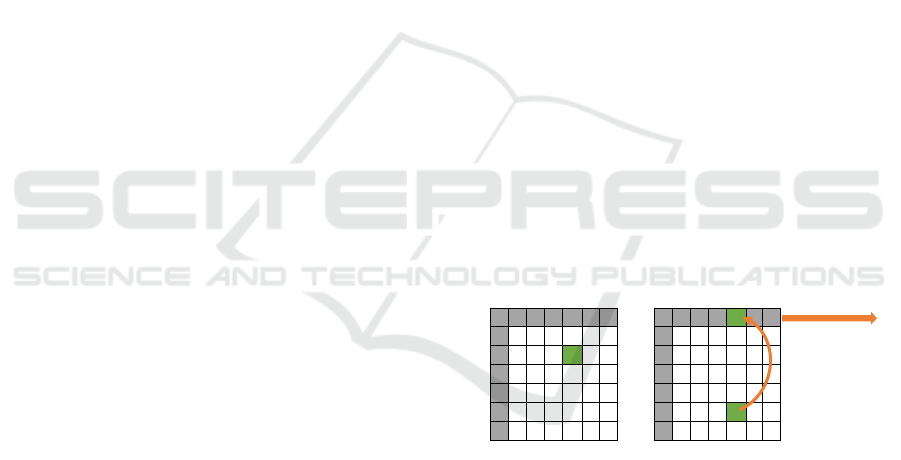

Material Jetting

In material jetting the print head (3) deposits the raw material

(4) in form of droplets. The layers mostly are created by

lowering the build platform (1). For the fabrication of the

product (5), support structures (2) are required most of the

time. Due to the voxel-based approach, multi-material, multi-

color, and gradient parts can be fabricated.

Powder Bed Fusion

Powder bed fusion uses thermal energy (3) to selectively bond

powdered raw material (2) by melting or sintering. New layers

of material are added by a roller (5) out of the material

reservoir (1), which is made possible by lowering the build

platform (6). Depending on the material used, support

structures (7) can be necessary for heat dissipation to prevent

the product (4) from deforming. Only single material parts can

be fabricated.

Sheet Lamination

Using sheet lamination, the three-dimensional part (3) is

created by bonding sheets of material (1). Here a thermal

energy source (2) can be used, but also a separated system

consisting of a cutter and a lamination tool are common. The

layers are created by lowering of the build platform (4). By

coloring the sheets, multi-color parts can be fabricated.

Vat Photopolymerization

In the process of vat photopolymerization, a liquid

photopolymer (1) is selectively cured inside a vat by a light

source (5), often through a transparent bottom (6) of the vat.

Layers can be created by raising the build platform (2) out of

the photopolymer. Single material parts (3) can be fabricated,

depending on support structures (4) for complex geometries.

3 ADDITIVE MANUFACTURING

OF ANATOMICAL MODELS

For the creation of anatomical models, a wide variety

of direct or indirect additive manufacturing processes

has been used so far with varying degrees of success

(AlAli et al., 2015). To generate high fidelity replicas

of the human anatomy with a realistic haptic behavior

that can possibly be used to replace human or animal

tissue for medical education, surgical training, and

medical device testing, a suitable manufacturing

process is needed. Based on the specifics of the

structure of biological tissues (Fung, 1993), certain

requirements can be derived:

High resolution

Ability to create complex geometries

Ability to replicate different tissues

Ability to manufacture gradients and create

anisotropic material properties

To achieve these, material jetting is the best-

suited process. Because of the voxel-based approach

and multi-material capabilities of typical machines

utilizing this approach (stratasys, 2020), gradients

1 2

3

4

5

1 2

3

4

5

23 45

6

1

7

2

3

4

1

2

34

6

1

5

Matching of Mechanical Properties of Biological Tissues and Technical Materials for the Fabrication of Anatomical Models by Material

Jetting

191

and anisotropic materials can be manufactured.

Additionally, the process has a high resolution and

can create complex geometries using water-soluble

support materials, which allows the removal from

areas inaccessible to conventional tools. The selection

of the proper materials or material mixtures to

accurately resemble the mechanical properties of the

corresponding human tissue is one of the most

important points in the creation of realistic high-

fidelity anatomical models.

4 MATCHING OF BIOLOGICAL

AND TECHNICAL MATERIALS

To be able to match a material or material

combination to the corresponding tissue, the

mechanical properties of that tissue must be known

and be comparable to the technical materials

available. When it comes to mechanical

characterization of tissue, especially soft tissue like

muscle, tendons, ligaments, internal organs, and

vascular tissue, researchers face special challenges. A

lot of the times the desired tissue cannot be isolated

for testing, the size of the specimen is too small for

regular characterization procedures and it is difficult

to keep the tissue in physiological condition. In

addition, soft tissues show nonlinear, history

dependent stress-strain relations, and large

deformations, which leads to complex constitutive

equations. (Fung, 1993) The tissue properties vary

largely depending on sex and age, harvesting site,

pathophysiological condition, environmental and

physical testing conditions, temperature and time

since extraction (Mattei et al., 2016).

To fully be able to predict the mechanical

behavior of these materials, a multitude of different

testing procedures like uniaxial tension tests, uniaxial

ring tests, planar biaxial tests, inflation tests, whole-

body measurements, membrane bulge tests, and many

more where developed (Macrae et al., 2016).

However, it has been shown, that complex testing

protocols are probably not necessary for the

acquisition of mechanical data with the intention to

match a tissue to a technical material. The well-

established process of preconditioning biological

tissues before mechanical characterization might not

be suitable for the creation of anatomical models as

the behavior of human tissue during surgery does not

correspond to a preconditioned state (Cotin et al.,

2004). It also was shown that a long relaxation time

between loads "resets" the materials behavior to pre-

preconditioning state (Sacks, 2000). Because of this,

it is recommended to characterize the mechanical

properties of the tissues using industry standard

testing procedures for technical materials to get

matchable parameters (Riedle et al., 2018). Here

especially the measurement of the stress-strain

relation using tensile tests and the measurement of the

tissues hardness using indentation tests will deliver

meaningful results (McKee et al., 2011) and allow the

comparison to technical materials usable for additive

manufacturing ( Riedle et al., 2019).

5 HOW TO CREATE REALISTIC

ANATOMICAL MODELS

As shown in the previous sections, the demand for

realistic and high-fidelity anatomical models utilizing

different materials to replicate the complex tissue

structures of the human body is high. Currently the

most promising way to achieve this in a fast and cost-

effective manner is the fabrication by additive

manufacturing. Here especially the material jetting

process is a good choice, since it has a high resolution

and can utilize multiple materials, which allows the

production of multi-color and multi-material models.

Even gradients of material properties can be

produced. The ability to use soluble support

structures makes the creation of complex geometries,

like those occurring in anatomy, possible.

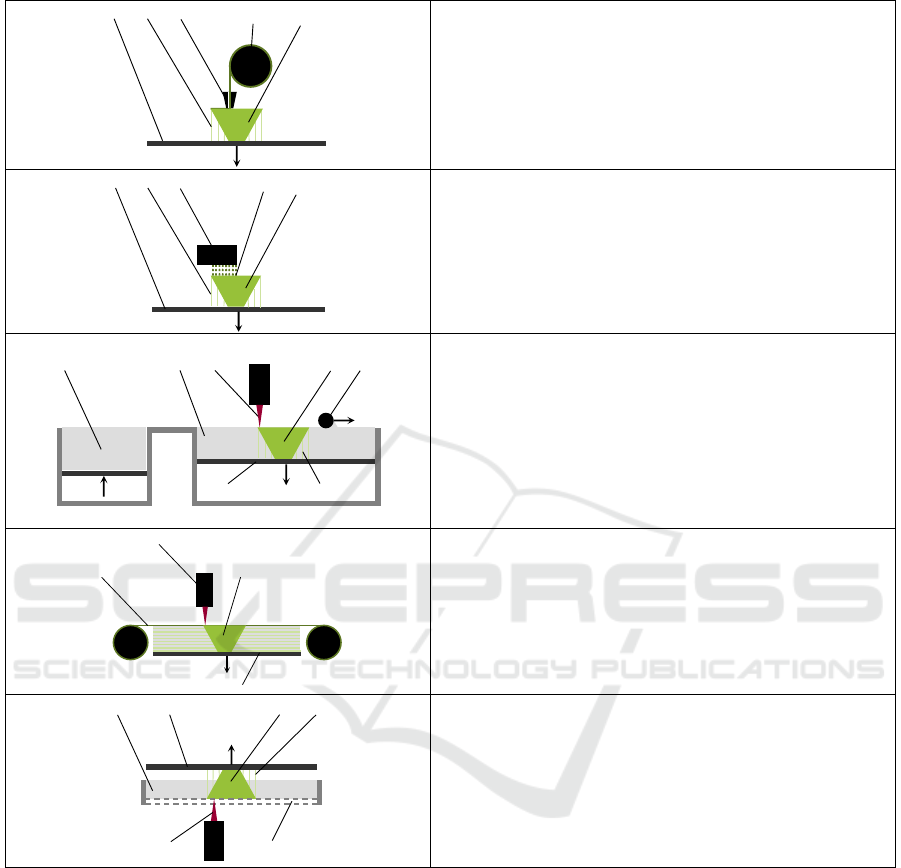

Figure 1: Matching different tissues to available materials

or material combinations, the creation of highly detailed

anatomical models with realistic mechanical properties will

be possible.

The goal of future research is now to compare the

mechanical properties of materials available for

processing via material jetting with those of

biological tissues. To utilize a standardized testing

process increases comparability between biological

and technical materials and seems to be suitable for

the usage in production of anatomical models. Here

especially the execution of uniaxial tension tests

according to ISO 37, which mostly corresponds to

DIN 53504 available for the authors, and indentation

tests according to ISO 48-4 should be conducted.

Tissue

Mechanical properties

Material /

material combination

Mechanical properties

Application in

anatomical models

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

192

While doing this, the general considerations

regarding the mechanical characterization of

biological tissue, like respecting its anisotropic

properties, and keeping it as close to physiological

condition as possible, still have to be made.

By matching the different tissues to the available

technical materials for the material jetting process, as

shown in Figure 1, it will be possible to create highly

detailed anatomical models with realistic mechanical

properties, which can be used for surgery planning

and training, medical education and medical device

testing without raising concerns about health or

ethical issues.

6 CONCLUSIONS

This paper shows that there is a demand for realistic,

high-fidelity anatomical models for surgical planning

and training, medical education, and medical device

testing. Since conventional manufacturing of

anatomical models is a time consuming, and

expensive process, which is not able to fully mimic

the complex nature of the human body regarding

geometry and mechanical properties, the creation of

such models by additive manufacturing, especially

the process of material jetting, is proposed. By

utilizing this process, it is possible to fabricate multi-

color, multi-material objects with complex

geometries, high resolution, and even gradients in

material properties. To be able to generate

appropriate mechanical properties, which resemble

those of biological tissues, the conduction of

biomechanical measurements according to

standardized testing procedures for technical

materials like ISO 37 for tensile and ISO 48-4 for

indentation tests is proposed, since it eases the

matching to the manufacturing materials and thus will

result in the possibility to create more accurate

replicas of the human body, which provide realistic

haptic feedback.

REFERENCES

DIN EN ISO 17296-2: Additive Fertigung - Grundlagen -

Teil 2: Überblick über Prozesskategorien und

Ausgangswerkstoffe.

DIN EN ISO/ASTM 52900: Additive Fertigung –

Grundlagen – Terminologie.

Ahmad B. AlAli; Michelle F. Griffin; Peter E. Butler

(2015): REVIEW Three-Dimensional Printing Surgical

Applications.

AlAli, Ahmad B.; Griffin, Michelle F.; Calonge, Wenceslao

M.; Butler, Peter E. (2018): Evaluating the Use of Cleft

Lip and Palate 3D-Printed Models as a Teaching Aid.

In: Journal of surgical education 75 (1), S. 200–208.

DOI: 10.1016/j.jsurg.2017.07.023.

Birkholz, Peter; Kürbis, Steffen; Stone, Simon; Häsner,

Patrick; Blandin, Rémi; Fleischer, Mario (2020):

Printable 3D vocal tract shapes from MRI data and their

acoustic and aerodynamic properties. In: Scientific data

7 (1), S. 255. DOI: 10.1038/s41597-020-00597-w.

Chae, Michael P.; Lin, Frank; Spychal, Robert T.; Hunter-

Smith, David J.; Rozen, Warren Matthew (2015): 3D-

printed haptic "reverse" models for preoperative

planning in soft tissue reconstruction: a case report. In:

Microsurgery 35 (2), S. 148–153. DOI:

10.1002/micr.22293.

Charles W. Hull (1984): Apparatus For Production of

Three-dimensional Objects By Stereolthography am

08.08.1984. Anmeldenr: 638,905. Veröffentlichungsnr:

4,575,330.

Dimitrios Maragiannis, M. D.; Matthew S. Jackson, MSc;

Stephen R. Igo, BSc; Robert C. Schutt, M. D.; Patrick

Connell, PhD; Jane Grande-Allen, PhD et al. (2015):

Replicating Patient-Specific Severe Aortic Valve

Stenosis With Functional 3D Modeling.

DIN ISO 48-4: Elastomere oder thermoplastische

Elastomere – Bestimmung der Härte – Teil 4:

Eindruckhärte durch Durometer-Verfahren (Shore-

Härte).

Gebhardt, Andreas (2016): Additive Fertigungsverfahren.

Additive Manufacturing und 3D-Drucken für

Prototyping - Tooling - Produktion. 5. Aufl. 1 Band.

München: Carl Hanser Verlag.

Gebhardt, Andreas; Kessler, Julia; Thurn, Laura (2016):

3D-Drucken. Grundlagen und Anwendungen des

Additive Manufacturing (AM). 2., neu bearbeitete und

erweiterte Auflage. München: Hanser (Hanser-

eLibrary).

Hannah Riedle; Barbara Mukai; Pirmin Molz; Jorg Franke

(2018): Determination of the Mechanical Properties of

Aortic Tissue for 3D Printed Surgical Models. In:

BMWiCON-2018.

Hannah Riedle; Kim Braunias; Barbara Mukai; Jorg Franke

(2019): Experimental Mechanical Examination of

Artificial 3D Printed and Post Processed Vascular

Silicone Models

*

.

Jena Anupam B.; Seabury Seth; Lakdawalla Darius;

Chandra Amitabh (2011): Malpractice Risk According

to Physician Specialty.

Macrae, R. A.; Miller, K.; Doyle, B. J. (2016): Methods in

Mechanical Testing of Arterial Tissue: A Review. In:

Strain 52 (5), S. 380–399. DOI: 10.1111/str.12183.

Malik, Hammad H.; Darwood, Alastair R. J.; Shaunak,

Shalin; Kulatilake, Priyantha; El-Hilly, Abdulrahman

A.; Mulki, Omar; Baskaradas, Aroon (2015): Three-

dimensional printing in surgery: a review of current

surgical applications. In: The Journal of surgical

research 199 (2), S. 512–522. DOI: 10.1016/j.jss.2015.

06.051.

Matching of Mechanical Properties of Biological Tissues and Technical Materials for the Fabrication of Anatomical Models by Material

Jetting

193

Mattei, Giorgio; Ahluwalia, Arti (2016): Sample, testing

and analysis variables affecting liver mechanical

properties: A review. In: Acta biomaterialia 45, S. 60–

71. DOI: 10.1016/j.actbio.2016.08.055.

McKee, Clayton T.; Last, Julie A.; Russell, Paul; Murphy,

Christopher J. (2011): Indentation versus tensile

measurements of Young's modulus for soft biological

tissues. In: Tissue engineering. Part B, Reviews 17 (3),

S. 155–164. DOI: 10.1089/ten.TEB.2010.0520.

McMenamin, Paul G.; Quayle, Michelle R.; McHenry,

Colin R.; Adams, Justin W. (2014): The production of

anatomical teaching resources using three-dimensional

(3D) printing technology. In: Anatomical sciences

education 7 (6), S. 479–486. DOI: 10.1002/ase.1475.

Michael S. Sacks (2000): Biaxial Mechanical Evaluation of

Planar Biological Materials.

DIN 53504: Prüfung von Kautschuk und Elastomeren –

Bestimmung von Reißfestigkeit, Zugfestigkeit,

Reißdehnung und Spannungswerten im Zugversuch.

Riedle, Hannah; Burkhardt, Andrea E.; Seitz, Vera; Pachaly,

Bernd; Reid, Russell R.; Lee, Justine C.; Franke, Jörg

E. (2019): Design and fabrication of a generic 3D-

printed silicone unilateral cleft lip and palate model. In:

Journal of plastic, reconstructive & aesthetic surgery:

JPRAS 72 (10), S. 1669–1674. DOI: 10.1016/j.bjps.

2019.06.030.

Stéphane Cotin; Dimitris Metaxas (Hg.) (2004): Medical

Simulation. International Symposium, ISMS 2004.

Berlin, Heidelberg: Springer.

stratasys (2020): J750 Digital Anatomy. Online verfügbar

unter https://www.stratasys.com/de/3d-printers/j750-

digital-anatomy, zuletzt geprüft am 20.11.2020.

Ström, P.; Hedman, L.; Särnå, L.; Kjellin, A.; Wredmark,

T.; Felländer-Tsai, L. (2006): Early exposure to haptic

feedback enhances performance in surgical simulator

training: a prospective randomized crossover study in

surgical residents. In: Surgical endoscopy 20 (9), S.

1383–1388. DOI: 10.1007/s00464-005-0545-3.

Sulaiman, Abdulrazzaq; Boussel, Loîc; Taconnet, Frédéric;

Serfaty, Jean Michel; Alsaid, Hasan; Attia, Cherif et al.

(2008): In vitro non-rigid life-size model of aortic arch

aneurysm for endovascular prosthesis assessment. In:

European journal of cardio-thoracic surgery : official

journal of the European Association for Cardio-

thoracic Surgery 33 (1), S. 53–57. DOI:

10.1016/j.ejcts.2007.10.016.

Yoo, In Seong; Preis, Alexander; Franke, Jörg E. (2020):

Development of a test bench for the urodynamic

simulation of the lower urinary tract. In: IEEE Xplore,

S. 2337–2341. DOI: 10.1109/EMBC44109.2020.91

76198.

Yuan-Cheng Fung (1993): Biomechanics. Mechanical

Properties of Living Tissues. 2. Aufl. New York:

Springer.

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

194