Convolutional Neural Networks for Quantitative Prediction of Different

Organic Materials using Near-Infrared Spectrum

Dagmawi Delelegn Tegegn

1,2 a

, Italo Francesco Zoppis

1 b

, Sara Manzoni

1 c

, Cezar Sas

3 d

and Edoardo Lotti

2

1

Department of Computer Science, University of Milano-Bicocca, Milan, Italy

2

SeleTech Engineering Srl, Milan, Italy

3

Independent Researcher, Italy

Keywords:

Convolutional Neural Network (CNN), Near-Infrared (NIR), Quantitative Analysis.

Abstract:

Advances in Near-infrared (NIR) spectroscopy technology led to an increase of interest in its applications

in various industries due to its powerful non-destructive quantization tool. In this work, we used a one-

dimensional CNN to determine simultaneously quantities of organic materials in a mixture using their NIR

infrared spectra. The coefficient of determination (R

2

) and the root mean square error (RMSE) is used to test

the performance of the model. We used six materials to make pairwise combinations with distinct quantities

of each pair. We obtained 13 different pairwise mixtures, afterward, their near-infrared spectrum profiles is

extracted. The model predicted for each mixture their percentage of composition with a result of 0.9955 R

2

and

RMSE 0.0199. Furthermore, we examined the performance of our model when predicting unseen composition

percentages with unseen mixtures. To do so, two scenarios are carried out by filtering the training and testing

set: the first one where we test on unseen composition percentage (UP) of mixtures, and the second one where

we test on unseen composition percentage of unseen mixtures (UPM). The model achieved an R

2

of 0.947 and

0.627 scores respectively for UP and UPM.

1 INTRODUCTION

Near-infrared (NIR) spectroscopy has been around for

decades and a lot of research has been done in this

field (Windham et al., 1997; Berzaghi and Riovanto,

2009; Osborne, 2006;

´

Eva Szab

´

o et al., 2019; Teye

et al., 2019). In the last years, it has been mainly used

to analyze the chemical composition of organic sam-

ples, drugs, food, and other compounds. In particular,

in the food industry, it is used for the quantitative and

qualitative analysis of foods such as meat, fruit, grain,

dairy products, and beverages (Cen and He, 2007; Za-

reef et al., 2020; Huang et al., 2008).

NIR spectra of biological materials are signals

composed of peaks because of molecular vibrations

of mostly O-H, C-H, and N-H groups (Li et al., 2019;

Chen et al., 2015) caused by their interaction with in-

frared light within the NIR wavelength region (800-

a

https://orcid.org/0000-0002-5031-7589

b

https://orcid.org/0000-0001-7312-7123

c

https://orcid.org/0000-0002-6406-536X

d

https://orcid.org/0000-0002-3018-0140

2500 nm). The spectral data measured in this region

are generally composed of high noises and overlap-

ping peaks associated with the chemical composition

of the sample. The spectral information extracted

from these broad peaks for the quantitative determina-

tion of the chemical composition is often analysed us-

ing chemometry and other linear based methods (i.e.

partial least square, multivariate regression) to cap-

ture the various possible infrared spectra patterns of a

single material.

There are many applications in the field of NIR

spectroscopy and mixture analysis. However, this

work focuses on their use in the food analysis in-

dustry. Initial works in this field used Multivariate

Analysis (MVA) like Principal Component Analysis

(PCA), Partial Least Square (PLS), and Support Vec-

tor Machine (SVM). For instance, (Wu et al., 2008)

used least squares support vector machine (LS - VM)

to analyse NIR spectra of milk powder and they also

determined contents of fat, protein, and carbohydrate.

(Windham et al., 1997) and (Qingyun et al., 2007) as-

sessed the potential of NIR to determine the quality of

rice using respectively PLS and a multi-linear regres-

Tegegn, D., Zoppis, I., Manzoni, S., Sas, C. and Lotti, E.

Convolutional Neural Networks for Quantitative Prediction of Different Organic Materials using Near-Infrared Spectrum.

DOI: 10.5220/0010244101690176

In Proceedings of the 14th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021) - Volume 4: BIOSIGNALS, pages 169-176

ISBN: 978-989-758-490-9

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

169

Table 1: Relevant works in the field of Near-infrared for the qualitative and quantitative analysis of organic materials.

Reference Sample Range Target Task Method Performance

(Qingyun et al., 2007) Indica Rice 540,640,970 nm Indica Rice Reg MVA R

2

= 0.71

(Wu et al., 2008) Infant Milk Powder 800-1025 nm Fat, Protein, Carbohydrates Reg, Class ICA-LS-SVM R

2

= 0.983, 0.231, 0.982 Pred = 98%

(Grossi et al., 2015) Olive Oil 569,835 nm Peroxide, Phenol Reg Undefined (Excel) R

2

= 0.883 (Peroxide), 0.895 (Phenol)

(V

´

asconez et al., 2018) Cocoa Powder 1100–2500 nm Adulterant Reg, Class PLS-DA R

2

= 0.974, Acc = 98%

(Sun et al., 2019) Tubers 1000-2500 nm Sugars Reg PLS, LS-SVM R

2

= 0.950

(Wang et al., 2019) Wheat and Potato Flour 1000-2500 nm Potato Flour Reg PLS R

2

= 0.8865

(Teye et al., 2019) Rice 740-1070 nm Rice Class KNN, SVM ACC = 91.88%

(Ng et al., 2019) Soil 350-25000 nm Sand, Clay, Organic Content Reg PLSR,Cubist-tree, CNN R

2

= 0.85-0.95, 0.91–0.97, 0.95–0.98

(Ni et al., 2019) Masson Pine Seedlings 780-2500 nm Nitrogen Reg 1D-CNN R

2

= 0.984

(Liu et al., 2020) Rice 1000-2500 nm Rice Reg PLS-DA, SVM R

2

= 0.96

(de Lima et al., 2020) Cumin, Black Pepper 1100-2500 nm Adulterant Reg MLR,PLS R

2

= 0.90

(Zhang et al., 2020) Tobacco 1000-2500 nm Tobacco Class 1D-CNN,2D-CNN Acc = 93.15%, 93.05%

sion (MLR). (V

´

asconez et al., 2018) used rapid meth-

ods, like NIR technology combined with multivariate

analysis (PCA and partial least squares discriminant

analysis (PLS-DA)), to detect fraud of cocoa powder.

Other methods improved the multivariate analy-

sis by using kernel-based methods like Support Vec-

tor Machines (SVM), for example, (Sun et al., 2019)

investigated the feasibility of NIR spectroscopy com-

bined with kernel PLS regression algorithm for quan-

titative determination of reducing sugar content in

potato flours.

Further improvements are revealed by models that

use machine learning. In fact, machine learning ap-

proaches for spectral profiles analysis (Galli et al.,

2016; Galli et al., 2017; Zoppis et al., 2011), and

in particular Convolutional Neural Networks (CNN)

for spectroscopy signal classification have reported

promising results in the literature. (Zhang et al.,

2020) proposed a one-dimensional CNN (1D-CNN)

to classify the origin of tobacco using their NIR spec-

trum, and concluded that the performance of 1D-CNN

and 2D-CNN was better than traditional PLS mod-

els. Similarly, (Ni et al., 2019) use a 1D-CNN to per-

form a regression task, instead of classification task

as (Zhang et al., 2020), to find the amount of nitrogen

in the Masson pine seedling leaves using NIR spec-

trum. We can view a summary of works that use NIR

spectrum with their relative task and methods in Table

1.

Compared to our model, (Ni et al., 2019) per-

forms regression on a single variable (the nitrogen

content). In this work we propose a modified ver-

sion of the 1D-CNN model proposed by (Ng et al.,

2019). Their model is used on data coming from

the visible/near-infrared, mid-infrared, and a combi-

nation of both while ours uses information only on

NIR data. Moreover, they don’t perform experiments

with unseen combinations and unseen percentages.

2 CONTRIBUTIONS

Considering the promising results reached with CNNs

in the literature for spectroscopy analysis, we adopt a

1D-CNN based approach for the regression analysis

of NIR spectroscopy to predict quantities of organic

mixtures. We used six materials to make pairwise

combinations at different quantities of each, obtain-

ing 13 different mixtures. Subsequently, we extracted

their near-infrared spectrum profiles. We tested the

model performance in three different scenarios to an-

swer the following research questions:

• RQ1 - How well can we predict unseen

1

percent-

ages of mixtures?

• RQ2 - How well can we predict unseen percent-

ages of unseen mixtures?

The first scenario, Whole Prediction (WP), where

we test the model ability to predict the same com-

position percentages of mixtures seen in the training

set. In this scenario, given two materials A, B, and

their combination (A, B), the model sees the spectral

profiles with the same percentage and combination

(A=25, B=75)

2

in training and in testing set. The

WP is used as a baseline for the other scenarios.

We used the second scenario, Unseen Percentages

(UP), to test the model’s ability to predict the un-

seen composition percentage of the same mixtures.

In this scenario, the model sees the same mixtures of

materials in the training set, but with different com-

position percentages. For example, with the combi-

nation set {(A=15, B=85),(A=35, B=65), (C=85,

D=15)} in training set, the model is tested using

{(A=25, B=75),(A=50, B=50), (C=75, D=25)}.

The last scenario, Unseen Percentage and Mix-

ture (UPM), used to test the model’s ability to pre-

dict the unseen composition percentage of unseen

1

Unseen refers to the samples that are not present in the

training set.

2

The mixture of two materials A and B, where A is at 25%

of the total composition and B at 75%.

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

170

mixtures. UPM is similar to UP, but here the pri-

mary goal is to train and test the model with differ-

ent composition percentage and mixtures. This means

that the model will see the following pairs and per-

centages in the training set {(A=25, B=75),(A=50,

B=50), (C=75, D=25)}, and in the testing set it will

only see {(A=15, C=85), (A=35, D=65), (B=85,

C=15)}.

This paper is structured as follows. Section 3

presents the materials and the model architecture.

Section 4 examines the experiments’ setup and the re-

sults. Section 5 presents the discussion of the results

and Section 6 closes with the conclusions.

3 MATERIALS AND METHODS

In this section, we present the data collection pro-

cess and the neural network model architecture used

to predict the quantitative measure for the mixed or-

ganic materials. The data collection is made of sev-

eral steps that includes the sample preparation proce-

dure of the six organic powders, the data acquisition

that describes the mechanism of acquiring the spectral

data. Furthermore, we describe the 1D-CNN architec-

ture and its parameters.

3.1 Sample Preparation

Each sample was prepared by carefully mixing a

given fraction in weight of two base materials and

placing the mixture in a container of the Petri dish

type. However, because of the unique characteristics

of the powders used, such as grain size and tendency

to form lumps, it is not possible to guarantee that the

mixture is homogeneous.

The powders used are cocoa (Cocoa), ice sugar

(IceSugar), baby milk powder (BabyMilk), potato

starch (Potato), rice starch (Rice) and baking soda

(NaHCO3). We made a total of 13 pairwise combi-

nations using the six basic powders, summarized in

Table 2. We prepared 56 samples of pairwise mixtures

with different weight proportions of the two compo-

nents, in total 62, adding the six base materials at

Table 2: The pairwise mixtures overview. Value 1 indicates

presence of powder mixture while 0 means that the powders

are not mixed. The diagonal values correspond to the base

materials at 100%.

BabyMilk IceSugar NaHCO3 Cocoa Potato Rice

BabyMilk 1

IceSugar 1 1

NaHCO3 1 1 1

Cocoa 1 1 1 1

Potato 1 1 0 1 1

Rice 1 1 1 1 0 1

100%. In particular, the percentage of each compo-

nent in a mixture is assigned from set P = {15, 25, 35,

50 , 65, 75, 85}, such that the composition percentage

of a given mixture of two materials add up to 100%,

e.g. (A=15, B=75).

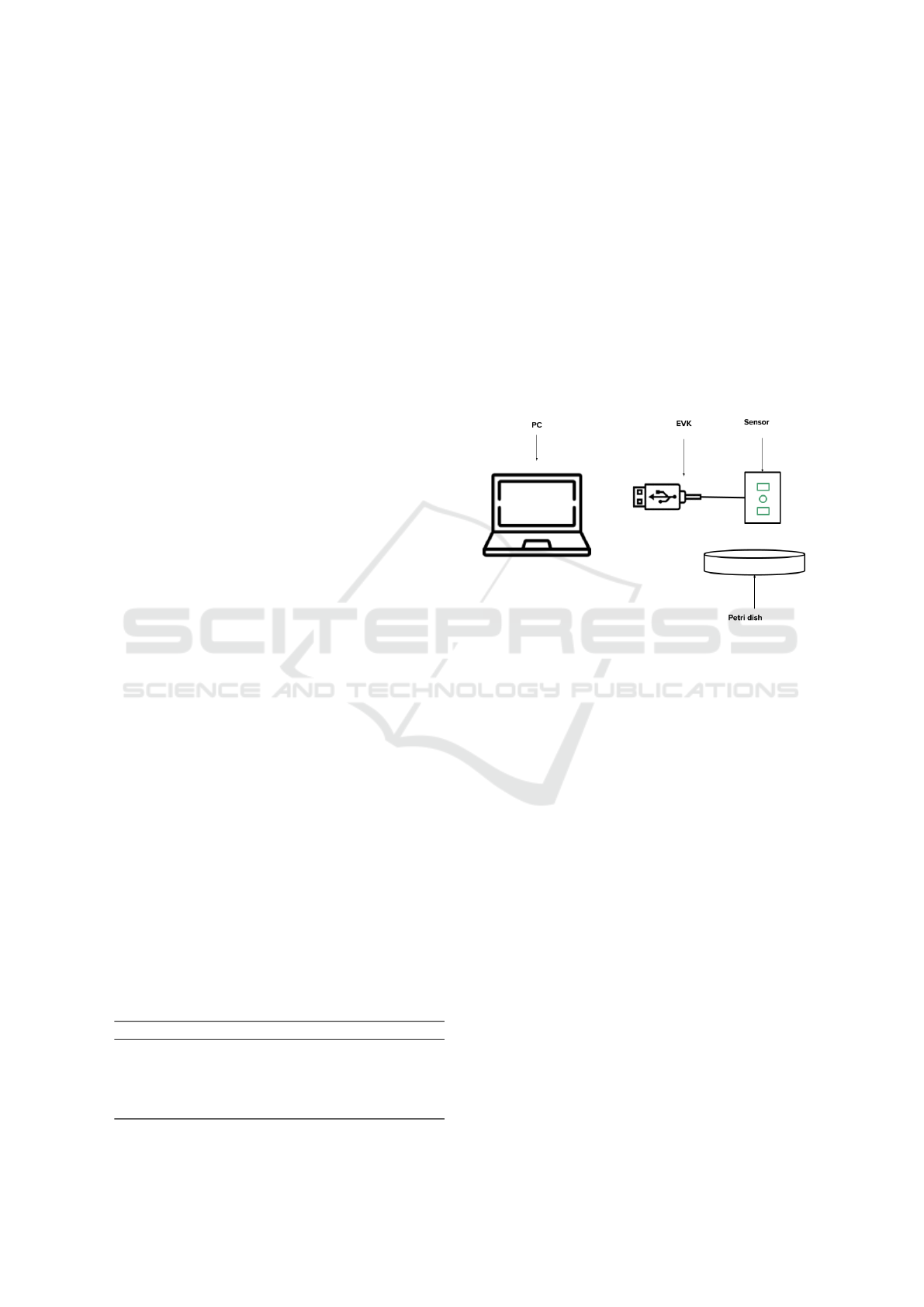

3.2 Data Acquisition

We took the measurements using an automatized me-

chanical setup. Figure 1 illustrates the tools used to

collect spectral profiles. We put the NIR sensor and

the Petri dish into a dark box to avoid any external

interference. The data is then viewed using a custom

made software for the sensor.

Figure 1: The figure shows the tools used for collecting NIR

spectrum data. The setup is composed of a Petri dish where

the powders are mixed and put inside, the sensor that col-

lects NIR spectra, an Evaluation kit (EVK) used to transfer

data from the sensor and a PC that includes a custom made

software to visualize spectrum.

3.2.1 Sensor Used

We used a device that captures two ranges of wave-

length points: [1350−1650]nm and [1750−2150]nm.

Resulting in a total of 702 wavelength points cap-

tured. We calibrated the NIR sensor with SRS-99-

020 Reflectance Standard (a white diffuse reflectance

sample) by collecting the spectra of the “white” refer-

ence at the minimum distance allowed by the scanner

and with the maximum level of light bulb ignition.

3.2.2 Capture Mode

We set the Petri dish and the NIR sensor inside a box

and inside a dark room along with the automatic ac-

quiring mechanical setup to avoid any outside inter-

ference. The NIR sensor captured the spectra of the

samples at different sensor-sample distances, mov-

ing the vertical axis of the scanner with 1mm pitch

along the entire 20mm useful range. The minimum

distance between the outer surface of the Petri dish

Convolutional Neural Networks for Quantitative Prediction of Different Organic Materials using Near-Infrared Spectrum

171

window and the detector is 5mm. For each distance,

we examined three different areas of the sample’s ex-

posed surface. We have acquired three spectra for

each zone, hence there are nine spectra acquired at the

same distance from each sample. Assuming the sam-

ple is homogeneous, the spectra of the same mixture

should be the same with each other with minor differ-

ences due to measurement noise. Instead, we found

that there are some differences, particularly between

zones. In isolated cases, we also found differences

between spectra acquired at the same location, proba-

bly because of measurement errors related to electri-

cal disturbances or mechanical vibrations. We mea-

sured all samples by varying the level of lamp inten-

sity (parameter varied between 200 and 250 with step

1).

3.2.3 Reflectance Values

The measured reflectance R of a generic sample is cal-

culated by the sensor at each wavelength as follows:

R =

I

C

− I

F

I

SRS

− I

F

R

SRS

(1)

where I

C

is the intensity of light received from the

sample, I

SRS

the intensity of light received from the

reference SRS-99-020 placed at a given distance dur-

ing calibration, I

F

the intensity of background light

(cross-talk), measured during calibration with lamp

on but without target, and R

SRS

the reflectance of the

reference SRS-99-020. In practice, since cross-talk

levels are generally small, the measured reflectance is

proportional to the ratio of the light intensity received

by the sample in question to the one measured dur-

ing calibration using the SRS-99-020 reference. For

this reason, although reflectance is an intrinsic prop-

erty of the sample, the reflectance measured using the

same sample at different distances from that used dur-

ing calibration is different. A similar effect occurs if

the measurement uses a different light bulb ignition

level than the one used when calibrating.

3.2.4 Dataset

Following the sample preparation and the acquisition

of the NIR spectra, we collected 454896 samples

3

.

Each sample has 702 features representing the cap-

tured wavelengths, and for each composition percent-

age of a mixture we have ∼ 7300 samples. The target

variable of each sample is a percentage distribution

over the six base materials describing the quantity of

that material in the spectral sample. Given that each

spectral sample represents only the mixture of two

3

The dataset is available upon request.

materials, only two elements in the target vector con-

tain the value of the individual materials represented

in the spectral sample while we set the remaining four

elements to 0. Whereas, for the mixtures containing

only one powder, we set the five remaining target vari-

ables to 0 and assigned the value 100% to the material

represented by the spectra.

3.3 Method

3.3.1 Convolutional Neural Network

Convolutional Neural Networks (CNNs) (Nebauer,

1998) are a specific type of neural networks (NN)

used to process data having a known, grid-like struc-

ture (i.e. time-series data, which can be thought of as

a 1D grid taking samples at regular time intervals, and

image data, which can be thought of as a 2D grid of

pixels).

The basic blocks of CNNs consist of convolu-

tion layers, pooling layers, and fully connected lay-

ers (Shin et al., 2016). The convolution layer uses

filters to perform convolution operations over the in-

put producing the activation map. The pooling layer

is usually after a convolution layer and performs the

down sampling of the activation map. The fully con-

nected layers are usually found at the end of the net-

work. They are used to producing an output that can

be optimized for targets like classification of the in-

put. In this work we adopted a one-dimensional CNN

for our one-dimensional spectral data. The convolu-

tional neural network consists of seven trainable lay-

ers - four convolutional layers and two fully con-

nected layers, similar to the one presented by (Ng

et al., 2019), but with different hyper-parameter val-

ues to fit our data. The output of every convolutional

layer is passed to the pooling layer. The convolution

layer contained 32 filters with a filter size of 3, stride

as one and zero padding. The number of filters on

every two convolutional layers is increased by a fac-

tor of two, while other parameters are kept the same.

The pooling size of the first layer is set to two, and

the last one to 4. The final feature maps from the

pooling layer are then flattened and used as input to

Table 3: Architecture of the 1D-CNN used in our work.

Layer Output Shape # Param Kernel Filter Attributes

Conv1D (702, 32) 128 3 32

MaxPooling1D (351, 32) 0 size = 2

Conv1D (351, 32) 3104 3 32

MaxPooling1D (175, 32) 0 size = 2

Conv1D (175, 64) 6208 3 64

MaxPooling1D (87, 64) 0 size = 2

Conv1D (87, 64) 12352 3 64

MaxPooling1D (21, 64) 0 size = 4

Flatten (1344) 0

Dropout (1344) 0 rate = 0.3

Dense (512) 688640

Dense (6) 3078

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

172

a fully connected layers. The dropout layer acted as a

regularization layer to mitigate over-fitting. The final

model has 713,510 parameters, the detailed architec-

ture is summed up in Table 3. The input of the 1D-

CNN is a one dimensional spectral vector containing

values of the 702 wavelength points, and the target is

also a one dimensional vector containing the percent-

age distributions of the six materials.

3.3.2 Hyper-Parameters

Since we have to predict the percentage of composi-

tion in a mixture we use the Kullback-Leibler (KL)

divergence (Equation 2) as our loss function.

The KL is a measure of distance between two distri-

butions defined as:

D

KL

(QkZ) =

∑

x∈X

Q(x)log

Q(x)

Z(x )

(2)

Where Q and Z are two probability distributions,

that in our case correspond respectively to the true

and the predicted distribution of percentages. The KL

gives a score close to 0 when Q and Z are similar and

increases as the distributions differ.

We used Adam as the optimization algorithm

(Kingma and Ba, 2015), with a scheduled learning

rate, starting from lr = 0.001, and exponentially de-

creasing it every epoch. We also use early stopping

and limit the number of epochs to 100. However, the

training always stopped earlier.

We used the Keras as our machine learning frame-

work and we used for the entire work the Asus Vivo-

Book X580GD with an Intel(R) Core (TM) i7-8750H

CPU.

4 RESULTS

The quantitative analysis of the NIR spectra based on

the multi-modal 1D-CNN is studied in three scenarios

as detailed in Section 2. For each scenario is reported

a table that summarises the model’s overall perfor-

mance for each material, this is done by filtering the

model’s output for each of the six materials for the

corresponding scenario. In the Appendix is reported

the full output of each mixture for each scenario and

it is available here

4 5

.

4.1 Whole Prediction (WP)

The first scenario (WP) we used all the composition

percentages of all mixtures. We use this scenario as

4

https://github.com/dtegegn/CNN-NIR-Spectra

5

https://www.seletech.com

a baseline result for the next experiments, as this one

shows the ideal case where both the mixtures and the

percentages have been seen during training.

Given the 454896 samples, we split them into

train, validation, and test set, respectively with the ra-

tio of 45%, 22%, and 33% which is a good amount of

data to train and test the model’s performance.

All the three dataset have the same type and bal-

anced number of the 62 different composition per-

centage of all mixtures including the six base mate-

rials of 100%. In Table 4 we report the metrics of the

overall performance of our model for this experiment.

We can see that most of the materials have good per-

formances except for Babymilk, which has a higher

Mean Absolute Error (MAE).

Table 4: The overall performance for the WP scenario.

Material MAE MSE RMSE R

2

BabyMilk 0.0161 0.0009 0.0298 0.9910

IceSugar 0.0065 0.0002 0.0143 0.9976

NaHCO3 0.0046 0.0001 0.0114 0.9983

Cocoa 0.0089 0.0005 0.0228 0.9941

Potato 0.0060 0.0003 0.0167 0.9961

Rice 0.0073 0.0004 0.0189 0.9958

4.2 Unseen Percentage (UP)

The WP experiment settled the baseline result for the

prediction for all the mixtures and their quantities,

and we use it to see the best case scenario for our

model. Therefore, we created specific subsets from

the whole dataset used in WP, by filtering specific set

of composition percentage of the mixtures, therefore

we can test the model’s performance on predicting

unseen composition percentage of the same mixture

and compare it with the baseline scenario. Thus, in

the second experiment UP we created two subsets of

P = {15, 25,35,50,65, 75, 85}: P1 = {15,35,65, 85}

and P2 = P − P1 = {25,50,75}, then defined the set

MP1 as the mixtures of materials belonging in set P1

and used it to train the model. We also defined the set

MP2 that comprises of the mixtures of materials be-

longing to set P2 and the six base materials at 100%,

and used it for testing. We use 33% of the training set

MP1 for the validation set, totaling 118380 samples

for the training, 58308 for the validation and 278208

for the testing sets.

With the UP experiment, the number of mixtures

in the training (13 mixtures) set outnumbered the ones

in the test set (6 mixtures), therefore, the set of mix-

tures in the training set is a subset of the mixtures in

the test set but in different quantities. This setup al-

lows us to test the model’s predicting ability only on

Convolutional Neural Networks for Quantitative Prediction of Different Organic Materials using Near-Infrared Spectrum

173

Table 5: The overall performance for the UP scenario.

Material MAE MSE RMSE R

2

BabyMilk 0.166 0.013 0.115 0.865

IceSugar 0.060 0.003 0.052 0.969

NaHCO3 0.046 0.001 0.031 0.989

Cocoa 0.069 0.003 0.058 0.950

Potato 0.041 0.002 0.046 0.969

Rice 0.062 0.004 0.063 0.941

the composition percentage. We can see from Table 5

the model’s overall performance for each material.

4.3 Unseen Percentage and Mixture

(UPM)

The goal of the UPM experiment is to evaluate the

model performance on predicting the unseen com-

position percentage of the unseen mixtures, thus the

model’s ability to extract from the mixture spectral

data the single component’s features and its ability to

use these to generalize on the unseen percentage with

unseen mixtures.

The experiment UP had already two sets for the

training and testing, MP1 and MP2 respectively. In

the UP experiment, the set MP1 contained a greater

number of different mixtures than those found in

MP2. While in the UPM experiment, we used the

MP2 set as the training set and the MP1 set as the test-

ing set. Consequently, this procedure had the num-

ber of mixtures for the test set outnumbering the ones

found in the training set, unlike for the UP experi-

ment. This allowed us to test the different portions

of the test set, as we created subsets of the testing

set. For the first testing subset (MP1

S1

), we used mix-

tures that are found also in the training set, while for

the second testing subset (MP1

S2

), we used the mix-

tures that are not found in the training set. Reminding

that the composition percentage of the mixtures in the

training and test sets are totally different.

Finally, we obtained three results, the whole test

set for this scenarios (MP1), the first subset (MP1

S1

),

and the second subset (MP1

S2

). The subset MP1

S1

contained all mixtures that are also included in the

training set except the base materials at 100%. The

MP1

S2

subset contained all mixtures that not found in

the training set, which is the experiment for the UPM

scores. The total test set MP1 contained MP1

S1

and

MP1

S2

. Our focus here is to see the model prediction

on the subset MP1

S2

for the composition percentage

of unseen mixtures, and we can see the model’s per-

formance for each material in Table 8. In Table 6 and

7 we can see the overall performance of the model for

each material respectively using the whole testing set

MP1 and the subset MP1

S1

.

Table 6: The overall performance for the UPM scenario.

The results are for the whole test set (MP1) of the UPM

scenario.

MAE MSE RMSE R

2

BabyMilk 0.123 0.0426 0.2063 0.5135

IceSugar 0.0566 0.0136 0.1165 0.8361

NaHCO3 0.0434 0.0146 0.1209 0.791

Cocoa 0.0703 0.0201 0.1419 0.7933

Potato 0.0425 0.0168 0.1297 0.7765

Rice 0.0593 0.0175 0.1322 0.813

Table 7: The overall performance for the UPM scenario.

The table shows the results for the MP1

S1

subset.

MAE MSE RMSE R

2

BabyMilk 0.0489 0.0048 0.0696 0.9535

IceSugar 0.0115 0.0007 0.0257 0.991

NaHCO3 0.014 0.0011 0.0336 0.9883

Cocoa 0.0135 0.0017 0.0411 0.97

Potato 0.0078 0.0006 0.0236 0.9901

Rice 0.0144 0.0016 0.0396 0.9723

Table 8: The overall performance for the UPM scenario.

The table shows the main results for the UPM experiment

using MP1

S2

testing subset.

MAE MSE RMSE R

2

IceSugar 0.0972 0.0252 0.1587 0.718

NaHCO3 0.0699 0.0267 0.1635 0.3653

Cocoa 0.1213 0.0367 0.1916 0.6769

Potato 0.0737 0.0314 0.1773 0.6486

Rice 0.0996 0.0318 0.1783 0.7266

5 DISCUSSION

The results achieved from the WP experiment are en-

couraging. The 1D-CNN predicted all the composi-

tion percentages of the mixtures with a very low error

as seen from Table 4, with an average of R

2

= 0.99.

This result is promising since the model is able to ex-

tract the features of the specific composition percent-

ages of mixtures. The outcome of the WP experiment

encouraged us for the much harder tasks that are the

UP an the UPM experiments.

The UP experiment is created to see how well we

can predict the unseen composition percentages by

training the model with the same mixtures as in the

testing set but different composition percentage of the

same mixtures. Training the model with MP1 and

testing it with MP2 gave good results in terms of the

determination coefficient, R

2

= 0.9471, with a 5% de-

crease in respect to the WP average R

2

score.

The UPM experiment have fewer variation of mix-

tures and quantities in the training set than in the test

set and scored an average of R

2

= 0.7539 using all the

test set MP1, with 25% decrease in respect to WP av-

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

174

erage R

2

score. Using the MP1

S1

subset led to better

result since the model had to predict only the unseen

composition percentage but same mixture, just as the

UP experiment, the average determination coefficient

for this testing subset is R

2

= 0.9775 with less that 2%

decrease in respect to the WP experiment. The results

for the MP1

S1

set can be compared also to the UP ex-

periment: the MP1

S1

results showed a 3% improve-

ment in respect to UP experiment. This is because

the UPM training set contained uniformly distributed

composition percentage of each material that are in

{25,50,75} and the six base materials at 100%, while

the UPM missed the mixtures that contains 65% of

one material and 35% of the other leading to unevenly

distributed composition percentage for one mixture.

While using the MP1

S2

subset as the test set, we

have an average determination coefficient of R

2

=

0.627, with a significant 36% loss in respect the aver-

age R

2

of the WP experiment. This experiment is set

up to to see if the model learned the representation of

the single materials in different compositions so that it

can predict unseen composition percentage of unseen

mixtures. We must take into account also the fact that

the materials quantities are prepared by weight rather

than volume, this mean that we can have powders

like BabyMilk that have a greater volume for a small

amount. This characteristic can affect the spectral ac-

quisition since the material with higher volumes tend

to occupy most of the Petri dish causing little signal

for the other materials mixed with them. In this spe-

cific test case scenario of UPM the model is trained

with mixtures containing only BabyMilk mixed with

the other 5 materials in different compositions and

one other mixture of IceSugar and NaHCO3, in par-

ticular the subset MP1

S2

of the test set for this exper-

iment doesn’t contain any combination of BabyMilk,

but it is trained with mixtures that contain BabyMilk.

The worst results in terms of the R

2

score NaHCO3

gave the worst results because we have only two com-

bination of this materials in the test set, with Cocoa

and Rice, while in the training set there is no such

mixture, adding also the fact that the NaHCO3 have

higher density in terms of g/cm

3

in respect to Cocoa

and Rice. Therefore, the spectra of of NaHCO3 mixed

with Cocoa and then with Rice can be very difficult to

interpolate without being trained.

In WP experiment the model was able to over-

come the errors during mixtures and the weight-

volume ratio and gave good result this is thanks to the

huge amount of sample it is trained on. In the UP and

especially the UPM experiments the errors due to the

preparation of the materials and the the models ability

to overcome them became very clear.

The UP and UPM experiments hold the answers

for the questions RQ1 and RQ2:

• A1 - The UP experiment let us predict the un-

seen new percentages of the same mixtures with

a good approximation, and also the WP experi-

ment model, that have all the percentages, can pre-

dict every composition percentage in the range of

[0 − 100] with higher accuracy.

• A2 - The model’s prediction on unseen com-

position percentage of unseen mixtures showed

promising results. We think that if we take into

account the weight-volume ratio, we can improve

the spectra acquired and therefore the final results.

6 CONCLUSION

In this work, we analysed the problem of predicting

composition percentage of organic material mixtures.

The NIR spectra of organic materials holds intrinsic

information on the analyte, including its quantity. To

uncover these intrinsic characteristics of the 1D-CNN

showed great performance, in the WP experiment, by

extracting directly relevant wavelength (feature) from

the NIR spectrum that described the quantity of the

analyte. This led to better performance of the model

avoiding the accumulation of errors caused by manual

wavelength selection.

The NIR spectra of the mixtures are most probably

affected by the density, in terms of g/cm

3

, of each

material in the mixture. Thus, affecting the result of

each experiment especially in the UPM experiment.

The research question RQ2 leads to future devel-

opments of this work. The results of the UPM using

the MP1

S2

testing subset can be improved by taking

into account the weight-volume ratio and by model-

ing new 1D-CNN architecture for the unseen compo-

sition of unseen mixtures. It also interesting to extend

the WP experiment’s model by testing it on different

composition percentage of more than two mixtures to

see if the model is acquire a good generalizing ability.

REFERENCES

Berzaghi, P. and Riovanto, R. (2009). Near infrared spec-

troscopy in animal science production: principles

and applications. Italian Journal of Animal Science,

8(sup3):39–62.

Cen, H. and He, Y. (2007). Theory and application of near

infrared reflectance spectroscopy in determination of

food quality. Trends in Food Science and Technology,

18(2):72 – 83.

Convolutional Neural Networks for Quantitative Prediction of Different Organic Materials using Near-Infrared Spectrum

175

Chen, Q., Zhang, D., Pan, W., Ouyang, Q., Li, H., Ur-

mila, K., and Zhao, J. (2015). Recent developments of

green analytical techniques in analysis of tea’s quality

and nutrition. Trends in Food Science & Technology,

43(1):63 – 82.

de Lima, A. B. S., Batista, A. S., de Jesus, J. C., de Je-

sus Silva, J., de Ara

´

ujo, A. C. M., and Santos, L. S.

(2020). Fast quantitative detection of black pepper and

cumin adulterations by near-infrared spectroscopy and

multivariate modeling. Food Control, 107:106802.

Galli, M., Pagni, F., De Sio, G., Smith, A., Chinello, C.,

Stella, M., L’Imperio, V., Manzoni, M., Garancini, M.,

Massimini, D., et al. (2017). Proteomic profiles of thy-

roid tumors by mass spectrometry-imaging on tissue

microarrays. Biochimica et Biophysica Acta (BBA)-

Proteins and Proteomics, 1865(7):817–827.

Galli, M., Zoppis, I., De Sio, G., Chinello, C., Pagni, F.,

Magni, F., and Mauri, G. (2016). A support vector ma-

chine classification of thyroid bioptic specimens using

maldi-msi data. Advances in bioinformatics, 2016.

Grossi, M., Di Lecce, G., Arru, M., Gallina Toschi, T., and

Ricc

`

o, B. (2015). An opto-electronic system for in-

situ determination of peroxide value and total phenol

content in olive oil. J. of Food Engineering, 146:1 – 7.

Huang, H., Yu, H., Xu, H., and Ying, Y. (2008). Near in-

frared spectroscopy for on/in-line monitoring of qual-

ity in foods and beverages: A review. J. of Food Engi-

neering, 87(3):303 – 313.

Kingma, D. P. and Ba, J. (2015). Adam: A method for

stochastic optimization. In Bengio, Y. and LeCun,

Y., editors, 3rd International Conference on Learn-

ing Representations, ICLR 2015, San Diego, CA, USA,

May 7-9, 2015, Conference Track Proceedings.

Li, Z., Tang, X., Shen, Z., Yang, K., Zhao, L., and Li,

Y. (2019). Comprehensive comparison of multiple

quantitative near-infrared spectroscopy models for as-

pergillus flavus contamination detection in peanut. J.

of the Science of Food and Agriculture, 99(13):5671–

5679.

Liu, Y., Li, Y., Peng, Y., Yang, Y., and Wang, Q. (2020). De-

tection of fraud in high-quality rice by near-infrared

spectroscopy. Journal of Food Science.

Nebauer, C. (1998). Evaluation of convolutional neural net-

works for visual recognition. IEEE Transactions on

Neural Networks, 9(4):685–696.

Ng, W., Minasny, B., Montazerolghaem, M., Padarian, J.,

Ferguson, R., Bailey, S., and McBratney, A. B. (2019).

Convolutional neural network for simultaneous pre-

diction of several soil properties using visible/near-

infrared, mid-infrared, and their combined spectra.

Geoderma, 352:251 – 267.

Ni, C., Wang, D., and Tao, Y. (2019). Variable weighted

convolutional neural network for the nitrogen content

quantization of masson pine seedling leaves with near-

infrared spectroscopy. Spectrochimica Acta Part A:

Molecular and Biomolecular Spectroscopy, 209:32 –

39.

Osborne, B. G. (2006). Near-infrared spectroscopy in food

analysis. Enc. of analytical chemistry: applications,

theory and instrumentation.

Qingyun, L., Yeming, C., Mikami, T., Kawano, M., and

Zaigui, L. (2007). Adaptability of four-samples sen-

sory tests and prediction of visual and near-infrared

reflectance spectroscopy for chinese indica rice. J. of

Food Engineering, 79(4):1445 – 1451.

Shin, H., Roth, H. R., Gao, M., Lu, L., Xu, Z., Nogues,

I., Yao, J., Mollura, D., and Summers, R. M. (2016).

Deep convolutional neural networks for computer-

aided detection: Cnn architectures, dataset charac-

teristics and transfer learning. IEEE Trans. on Med.

Imaging, 35(5):1285–1298.

Sun, X., Zhu, K., and Liu, J. (2019). Nondestructive detec-

tion of reducing sugar of potato flours by near infrared

spectroscopy and kernel partial least square algorithm.

Journal of Food Measurement and Characterization,

13(1):231–237.

Teye, E., Amuah, C. L., McGrath, T., and Elliott, C.

(2019). Innovative and rapid analysis for rice authen-

ticity using hand-held nir spectrometry and chemo-

metrics. Spectrochimica Acta Part A: Molecular and

Biomolecular Spectroscopy, 217:147 – 154.

´

Eva Szab

´

o, Gergely, S., Spaits, T., Simon, T., and Salg

´

o,

A. (2019). Near-infrared spectroscopy-based methods

for quantitative determination of active pharmaceuti-

cal ingredient in transdermal gel formulations. Spec-

troscopy Letters, 52(10):599–611.

V

´

asconez, M.,

´

Edgar P

´

erez-Esteve, Arnau-Bonachera, A.,

Barat, J., and Talens, P. (2018). Rapid fraud detection

of cocoa powder with carob flour using near infrared

spectroscopy. Food Control, 92:183 – 189.

Wang, H., Lv, D., Dong, N., Wang, S., and Liu, J. (2019).

Application of near-infrared spectroscopy for screen-

ing the potato flour content in chinese steamed bread.

Food science and biotechnology, 28(4):955–963.

Windham, W. R., Lyon, B. G., Champagne, E. T., Bar-

ton, F. E., Webb, B. D., McClung, A. M., Molden-

hauer, K. A., Linscombe, S., and McKenzie, K. S.

(1997). Prediction of cooked rice texture quality us-

ing near-infrared reflectance analysis of whole-grain

milled samples. Cereal Chemistry, 74(5):626–632.

Wu, D., Feng, S., and He, Y. (2008). Short-wave near-

infrared spectroscopy of milk powder for brand iden-

tification and component analysis. Journal of Dairy

Science, 91(3):939 – 949.

Zareef, M., Chen, Q., Hassan, M. M., Arslan, M., Hashim,

M. M., Ahmad, W., Kutsanedzie, F. Y., and Agyekum,

A. A. (2020). An overview on the applications of

typical non-linear algorithms coupled with nir spec-

troscopy in food analysis. Food Engineering Reviews,

pages 1–18.

Zhang, L., Ding, X., and Hou, R. (2020). Classification

modeling method for near-infrared spectroscopy of to-

bacco based on multimodal convolution neural net-

works. Journal of Analytical Methods in Chemistry,

2020.

Zoppis, I., Gianazza, E., Borsani, M., Chinello, C., Mainini,

V., Galbusera, C., Ferrarese, C., Galimberti, G., Sorbi,

S., Borroni, B., et al. (2011). Mutual information opti-

mization for mass spectra data alignment. IEEE/ACM

transactions on computational biology and bioinfor-

matics, 9(3):934–939.

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

176