Rheology of Sunflower, Citrus and Apple Low Methoxyl Pectin

Uray Ulfah Nabilah

a

, Azis Boing Sitanggang

b

and Eko Hari Purnomo

c

Department of Food Science and Technology, IPB University, Bogor 16680, Indonesia

Keywords: Rheology, Low Methoxyl Pectin, Flow Behaviour, Consistency Index.

Abstract: Pectin is a hydrocolloid which widely used to form a specific desired texture and viscosity of food products.

Therefore, it is important to observe the rheological characteristics of pectin. There are three sources of

commercial pectin commonly used in the food industry i.e. sunflower, citrus, and apple. These three pectins

were characterized rheologically in this study using MCR 92 Rheometer (Anton Paar, GmbH, Germany). The

sunflower pectin had the highest viscosity and consistency index number (k) compared to citrus and apple

pectin. The sunflower pectin exhibited shear-thinning behaviour at, especially at concentrations 2.5% and

3.0% (i.e., with flow behaviour index number (n) was less than 1.0). The higher the pectin concentration, the

lower n value obtained with the increased k value. The information found in this study is considered useful

for consumers, industry, and researchers especially when pectin is used to modify the rheological properties

of food products.

1 INTRODUCTION

Pectin is a natural food additive which can be used as

a gelling agent, emulsifier, stabiliser, and thickening

agent (Yapo, 2011). The potential of pectin is closely

related to its chemical characteristics. Commonly, the

pectin structure consists of main chain (1→4)–β-D-

GalA (galacturonic acid) which is partly esterified by

methyl alcohol or acetic acid at the carboxylate acid

side (Round et al., 2010). Pectin has varied molecular

weights (MWs), ranging from 60 to 130,000 g mol

−1

.

The molecular weight of pectin depends on the

number of glucose-side and esterification level of

methyl (Khan et al., 2012). Commercial pectin, in

general, has at least 65% galacturonic acid content

(May, 1990). There are two types of commercial

pectin that commonly used: High Methoxyl Pectin

(HMP) and Low Methoxyl Pectin (LMP). Degree of

esterification (DE) number for HMP is more than 50

%, while LMP is less than 50% (De Oliveira et al.,

2015; Sundar Raj et al., 2012). LMP produced from

orange and apple is a derivative of its HMP (Fertonani

et al., 2009; Morales-Contreras et al., 2020).

Meanwhile, LMP produced from sunflower seed is

naturally formed (Iglesias & Lozano, 2004;

a

https://orcid.org/0000-0002-8741-7460

b

https://orcid.org/0000-0002-

1378-5367

c

https://orcid.org/0000-0002-4146-2549

Corresponding author

Miyamoto & Chang, 1992). Different kinds of pectin

have different properties due to variation of structure

in methyl ester chain located along the main chain.

Naturally, DE number of each pectin is different for

different resources (plant species), plant maturity, and

cell wall properties (Round et al., 2010). Varied

pectin properties might also be due to differences in

extraction methods and post-extraction treatments

(Constenla & Lozano, 2003).

Water-soluble pectin has potential as a thickening

or stabiliser agent for water-based food products

(Razak et al., 2018). The thickening process is the

transition condition from free flow behaviour

molecules (dilute) to binding molecules in a network

(Saha & Bhattacharya, 2010). Each pectin has

different concentrations to reach certain rheological

consistency, which is related to the chemical structure

of each pectin (Alba et al., 2015; Axelos et al., 1989;

Dimopoulou et al., 2019; Morales-Contreras et al.,

2020). The mechanism of pectin as a thickening agent

is closely related to viscosity. Hydrocolloid

molecules flow freely at a dilute solution and show no

thickening properties. Meanwhile, at viscous

solution, molecules interact with each other, and the

flow is limited (Saha & Bhattacharya, 2010).

178

Nabilah, U., Sitanggang, A. and Purnomo, E.

Rheology of Sunflower, Citrus and Apple Low Methoxyl Pectin.

DOI: 10.5220/0010568600003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 178-184

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: Properties of pectin.

Sunflower (M) Citrus (C) Apple (A)

Degree of esterification (%DE) 31.2 29.34 27.6

De

g

ree of amidation

(

%DA

)

0 19.2 22.6

Galacturonic acid (%GA) 85.45 88.7 65

The thickening process of pectin is also related to

the ability of pectin to form a gel, emulsify and

stabilise (Ngouémazong et al., 2015). Gel forming

capacity in LMP is not dependent on the glucose

content of the product, and not pH-sensitive, the same

as HMP. Based on the previous study by Yang et al.

(2018), LMP could form a gel ranging from acidic

(pH 3.5) to saline condition (pH 9.5), by the addition

of divalent cation such as calcium. One of the main

purposes of pectin used in the food product is to form

a specific food texture, which makes rheological

study important. Prior to product formulation, it is

crucial to know the rheological characteristics of

pectin. Raw material selection is a crucial factor to

make the desired product. The important rheological

parameters, especially in the liquid system, are flow

behaviour index (n) and consistency index (k). It is

generally known that the greater the concentration

and viscosity of pectin, the higher the shear thinning

properties. However, the effect of concentration is

unique for each pectin. Therefore, the purpose of this

study was to investigate the effect concentration and

source of LMP (i.e. sunflower, citrus, and apple) on

the rheological properties of pectin solution. This

study can be used as a source of information to choose

suitable pectin source for certain food product

formulation.

2 MATERIALS AND METHODS

2.1 Materials

The three sources of pectin used in this study were

sunflower, citrus and apple with the specifications as

indicated in Table 1. The pectins were purchased

from Hunan Zhengdi Biological Resources

Development Co., Ltd., China. The solvent used was

deionised water.

2.2 Preparation of Pectin Solution

Pectin from each source was dissolved in 100 mL

deionised waters, stirred overnight at room

temperature. For each, there were eight

concentrations prepared (i.e., 0.1, 0.25, 0.5, 1.0, 1.5,

2.0, 2.5, 3.0 % (w/v)).

2.3 Viscosity Measurements

The flow properties of prepared pectin samples were

measured by using MCR 92 Rheometer (Anton Paar,

GmbH, Germany); with geometric cone and plate

(diameter = 50 mm and angle = 2 °). A sample of 5.0

mL was applied on the surface of the plate with a 0.1

mm gap between plates. The instrument was operated

at shear rates of 0.01 - 1000 s

-1

and temperature of 25

°C (Kontogiorgos et al., 2012). The data points were

set as 51 points, logarithmic ramp duration, 10 s

initial time and 1 s final time. The data set value was

at a shear rate variable, logarithmic ramp profile, 0.01

s initial time and 1000 s final time. Flow curve

analysis was done using RheoCompass

TM

software,

and the measurement of each sample was repeated

twice.

The information obtained were shear rate, shear

stress, and viscosity of the samples used to determine

flow behaviour. Experimental data were fitted using

the power-law model (Equation 1), where τ is shear

stress (Pa), ( 𝛾 ) is the shear rate (s

-1

), n is the

dimensionless flow behaviour index value and k is the

consistency index (Pa.s

n

). Slope of flow behaviour

curve plotted as log τ vs log 𝛾 shows the flow

behaviour index (n). The results show Newtonian

typical flow when n = 1, shear-thinning if 0 < n < 1

and shear thickening fluid if n > 1 (Rao, 2007; Steffe,

1996).

𝜏𝐾 𝛾

(1)

2.4 Statistical Analysis

The experimental design of this study was factorial

completely randomised design (CRD), and all tests

were repeated in duplo (N = 2). Statistical research

was carried out using two-way variance analysis

(ANOVA) to evaluate significant differences

between mean values, and continued by Duncan test.

3 RESULT AND DISCUSSION

3.1 Flow Curve Behaviour

The rheological properties indicate the ability of

pectin to fulfil a specific role in modifying the food

Rheology of Sunflower, Citrus and Apple Low Methoxyl Pectin

179

texture. One of the important parameters in

rheological studies of pectin as a thickening agent is

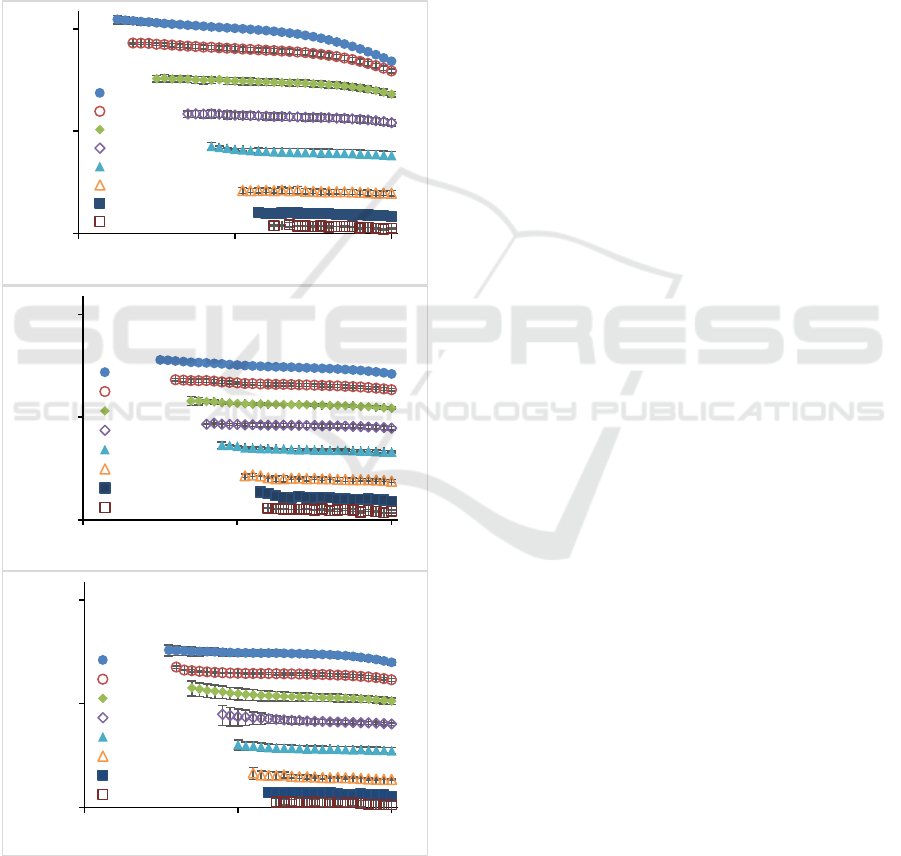

viscosity (Saha & Bhattacharya, 2010). The data of

pectin viscosity as function of shear rate measured at

different concentrations are shown in Figure 1. It was

found that increased concentration leads to the

increasing flow resistance in sunflower (M), citrus

(C) and apple (A) pectin, as indicated by higher value

of viscosity. This condition could be attributed to the

interaction between dispersed solids which caused

limited movement of water (Saha & Bhattacharya,

2010; Vinogradov & Titkova, 1968).

Figure 1: Viscosity of pection solution as function of shear

rate for (a) sunflower, (b) citrus and (c) apple.

In general, at low shear rates, there is a plateau or

Newtonian flow of the pectin. When the shear rate

increases, or after passing the critical shear rate, the

viscosity starts to decrease or displays shear thinning

behaviour. At high concentrations, the Newtonian

flow region is shorter than at low concentrations. The

lower the concentration, the longer the Newtonian

flow region and could extend to the highest shear rate.

At low concentrations, the dominant flow pattern is

Newtonian and there is no indication of viscosity

decrease under high shear rate conditions. At low

concentrations, pectin has Newtonian properties,

shown by the constant viscosity as the shear rate

increases. This condition can be linked to the fact that

of coil disentanglement due to shear forces is lower

than the rate of coil re-entanglement in all shear rate

range. Therefore, the shear force has no significant

effect on the decrease in viscosity. This condition is

similar to the study conducted by Li et al. (2013),

Chan et al. (2017) and Kalegowda et al. (2017),

where at low shear rates, pectin shows a Newtonian

flow pattern and become shear thinning at higher

shear rates. The ability of the coil to reconfigure a

network can be based on the ability of pectin to form

hydrogen bonds. LMP at low concentrations have

more probability to form hydrogen bonds and

consequently increasing re-entanglement rate of the

coil and thus, viscosity decrease was not observed.

3.2 Pectin Rheological Parameters

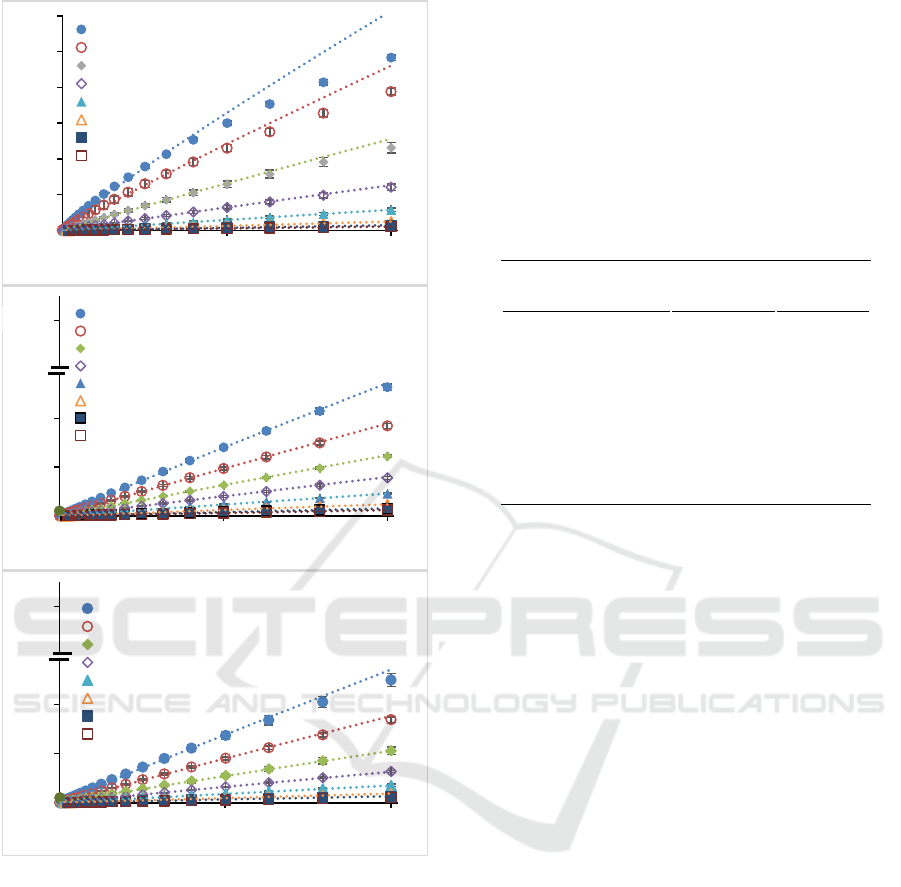

Quantitatively, Newtonian and non-Newtonian flow

patterns can be described using the power-law model

(Equation 1), extracted from the relationship between

shear rate and shear stress (Figure 2). Power law

model is widely used in viscosity modelling in food

processing during handling, heating, or cooling (Rao,

2007; Steffe, 1996). Coefficient of determination

obtained from the relationship between shear rate and

shear stress are shown in Table 2. The results showed

that the power-law model describes the flow

behaviour of all three pectin types. This is indicated

by the coefficient of determination which is close to

one. The results provided confidence in extracting the

fitting parameters (n and K) from the model for

further analysis.

0,001

0,01

0,1

0,1 10 1000

Viscosity (Pa.s)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

a

0,001

0,01

0,1

0,1 10 1000

Viscosity (Pa.s)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

b

0,001

0,01

0,1

0,1 10 1000

Viscosity (Pa.s)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

c

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

180

Figure 2: Flow curves of pectin solutions ((a) sunflower, (b)

citrus, and (c) apple)) measured at different concentrations.

Dotted lines are Power Law Model used to describe the

experimental data.

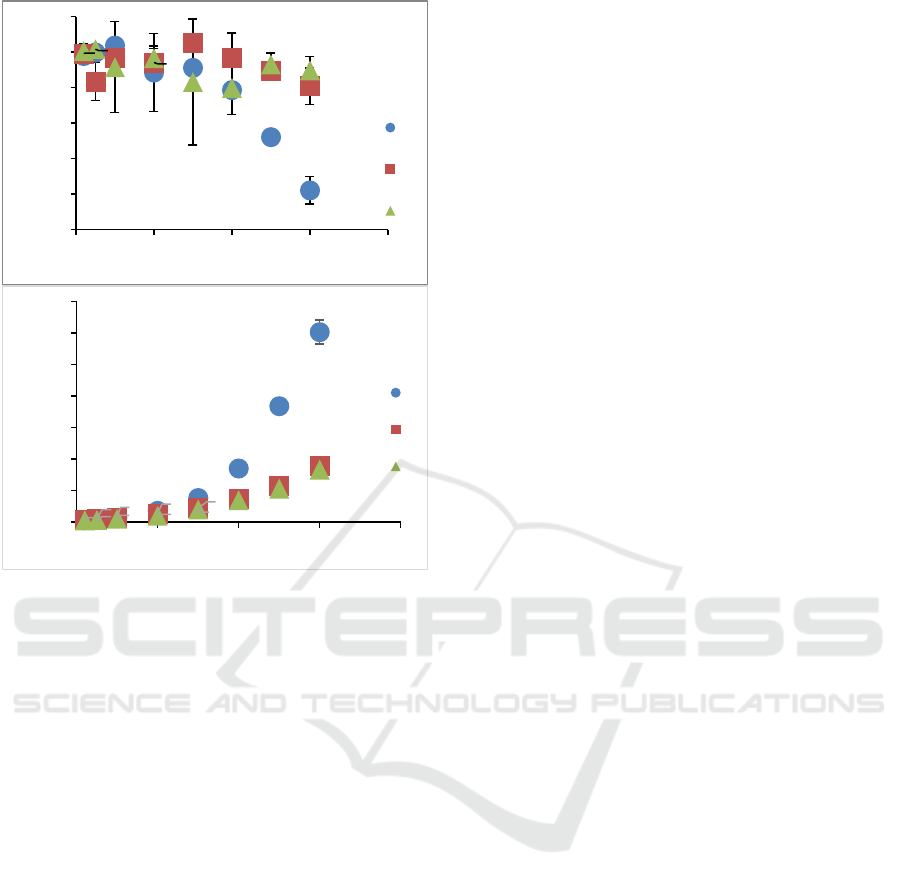

Figure 3 shows the effect of concentration of the

flow behaviour index (Figure 3a) and consistency

index (Figure 3b) of pectin solution. Flow behaviour

indexes (n) at various LMP concentrations decreased

as pectin concentration increased. A behaviour of

typical Newtonian-to-slightly shear thinning was

observed, as shown by the value of n <1. Based on

two-way ANOVA, it was known that the

concentration of pectin and their interactions had a

significant effect on n value. Pectin solutions showed

more shear thinning behaviour at higher

concentration. For example, at concentrations of

2.5% and 3.0 % for sunflower pectin, showed the

smallest flow behaviour index value which was

significantly different from other concentrations.

Whereas at low concentrations, the results showed

that n values close to one (less shear thinning). Pectin

solution practically has Newtonian characteristics

when the concentration was below 1% w/v.

Table 2: Coefficient of determination (R

2

) of linear

regressing between shear rate and shear stress for

sunflower, citrus and apple pectin.

Conc.

(%)

Coe

ff

icient o

f

determination

(

R

2

)

Sunflowe

r

Citrus A

pp

le

3 0.9985 1 0.9998

2.5 0.9993 1 0.9999

2 0.9997 1 0.9999

1.5 0.9999 1 0.9999

1 0.9999 0.9999 0.9999

0.5 1 0.9999 0.9999

0.25 0.9999 0.9996 0.9998

0.1 0.9999 0.9999 0.9999

Other study by Kontogiorgos et al. (2012) showed

similar observation. Okra pectin showed Newtonian

properties at a concentration below 1% w/v, and when

the concentration increased, it exhibited shear-

thinning properties. Whereas in the study of okra fruit

pectin DE 58% by Methacanon et al. (2013) showed

Newtonian flow behaviour at concentrations below

0.4% w/v. Based on the type of pectin used, sun

flower pectin (M) had the lowest n value and was

significantly different from the other two pectin

sources. At 3% concentration, n value of sunflower

pectin showed the lowest value (0.9021) or displayed

more shear-thinning behaviour than the other two

pectin sources (p < 0.05). The overall n values for all

pectin were close to one: M (0.9021- 0.9838), C

(0.9608 - 0.9855), and A (0.9599- 0.9817). The shear-

thinning behaviour of pectin solutions can be linked

to the inter-polymer chain. At high shear rate, the

formation rate of polymer entanglements is smaller

than the breaking rate. This causes the number of

cross-link bonds between polymers to decrease.

Moreover, the breakdown of previously formed

polymer-polymer hydrogen bonds reduces the final

polymer dimension. Thereby, the water or solvent can

easily flow out of the entangled polymer coils

(Thirawong et al., 2008). On the other side, the

aggregation that occurs between pectin polymers is

due to the formation of polymer-polymer hydrogen

bonds. This eventually leads to the formation of a

stable network that can trap water, leading to the

increase of viscosity (Karimi et al., 2016).

0

10

20

30

40

50

60

0 500 1000

Shear stress (Pa)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

a

0

10

20

30

40

0 500 1000

Shear stress ( Pa)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

60

b

0

10

20

30

40

0 500 1000

Shear streess ( Pa)

Shear rate (1/s)

3%

2.50%

2%

1.50%

1%

0.50%

0.25%

0.10%

60

c

Rheology of Sunflower, Citrus and Apple Low Methoxyl Pectin

181

Figure 3: Flow behaviour index (a) and consistency index

(b) of pectin solution.

Two-way ANOVA showed that source of pectin,

concentration, and polymer interaction significantly

affected the consistency index (k) (Figure 3b). In

general, a higher concentration of pectin solution

yields higher k value, because at higher concentration,

the polymer chains overlap, so it increases

competition for free water access, leading to stronger

binding of the polymer chains. The overall k values

for all sources of pectin as follows: M (0.0013 -

0.1206), C (0.0014 - 0.0357) and A (0.0012- 0.0334).

Sunflower (M) pectin had the highest k value and was

significantly different from the other two pectin

sources, especially at 3% concentration (k = 0.1206

Pa.s

n

) (p < 0.05). This result was corresponding to the

viscosity profile of sunflower pectin as shown in

Figure 1.

Pectin M, C and A had different degrees of

esterification (DE), degrees of amidation (DA) and

galacturonic acid concentrations (GA) (see Table 1).

Differences in rheological properties of each source

of pectin can be influenced by chemical factors, such

as content of anhydrous galacturonic acid (AGA),

degree of methylation (DM) or DE, molecular size,

distribution of carboxyl groups, and charge of pectin

molecules (Constenla & Lozano, 2003; Cullen, 2012;

Singh & Heldman, 2009; Zhong & Daubert, 2013). In

some cases, the viscosity can be affected by

physicochemical properties and temperature of the

material (Cullen, 2012; Singh & Heldman, 2009;

Zhong & Daubert, 2013). Based on the chemical

properties of the pectin used (Table 1), the pectin with

the highest to lowest DE was M, C and A pectin.

Pectin A had higher DA than pectin C, while pectin

M had no DA. Based on the results, it can be shown

that there was a tendency for higher DE and low DA

to have a higher fluid consistency. Based on existing

study, higher DE showed higher intrinsic viscosity

(Morris et al., 2000; Pippen et al., 1953; Yoo et al.,

2006), but this condition occurred at the same pectin

source. Based on these results, it can be seen that the

chemical structure of pectin sourced from sunflowers

has the potential to increase viscosity higher than the

other two.

The information on dynamic viscosity can

provide information regarding material flow

characteristics, especially to mitigate product

handling during processing at food industry. In

general, sunflower pectin had a higher viscosity as

compared to citrus and apple pectin. Thus, it can be

considered for product formulation which requires

moderate-to-high viscosity level. In addition to this,

one must also consider the power input or energy

needed during mixing process of such highly viscous

solution.

4 CONCLUSIONS

Source and concentration of pectin were shown to

have influence on the rheological properties of pectin-

containing solution. In general, pectin solution

showed Newtonian behaviour at very low shear rate

distinctly exhibited shear thinning behaviour at

higher shear rate. Shear thinning behaviour of pectin

solution was more pronounced at higher

concentrations. Sunflower pectin had the lowest flow

behaviour index and displayed vivid shear-thinning

behaviour compared to other sources. Herein,

sunflower pectin might be useful as an alternative

thickening agent for formulating viscous food

products.

ACKNOWLEDGEMENTS

The authors are grateful to PT. Equiva Ligand

Indonesia for providing access to MCR 92 Rheometer

to perform this study. This study was funded by

Master of Education towards Doctoral Scholarship

a

b

c

c

c

c

c

c

c

c

c

a

c

c

c

c

c

c

c

c

c

c

c

c

0,88

0,9

0,92

0,94

0,96

0,98

1

01234

n

c % (b/v)

M

C

A

a

a

b

c

ef

hi

i

i

i

c

d

fg

fghi

i

i

i

i

c

de

fgh

ghi

i

i

i

i

0

0,02

0,04

0,06

0,08

0,1

0,12

0,14

01234

k (Pa.s

n

)

c % (b/v)

M

C

A

b

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

182

Program for Excellent Undergraduate (PMDSU)

from The Ministry of Research, Technology, and

Higher Education of The Republic of Indonesia.

REFERENCES

Alba, K., Laws, A. P., & Kontogiorgos, V. (2015). Isolation

and characterization of acetylated LM-pectins extracted

from okra pods. Food Hydrocoll, 43, 726–735.

https://doi.org/10.1016/j.foodhyd.2014.08.003

Axelos, M., Thibault, J., & Lefebvre, J. (1989). Structure of

citrus pectins and viscometric study of their solution

properties. Int. J. Biol. Macromol., 11, 186–191.

Chan, S. Y., Choo, W. S., Young, D. J., & Loh, X. J. (2017).

Pectin as a rheology modifier: Origin, structure,

commercial production and rheology. Carbohydr.

Polym., 161, 118–139.

https://doi.org/10.1016/j.carbpol.2016.12.033

Constenla, D., & Lozano, J. E. (2003). Kinetic model of

pectin demethylation. Lat. Am. Appl. Res., 33, 91–96.

Cullen, P. J. (2012). Fluid rheology in novel thermal and

non-thermal processes. In Novel Thermal And Non-

Thermal Technologies For Fluid Foods (pp. 35–61).

Academic Press. https://doi.org/10.1016/B978-0-12-

381470-8.00003-7

De Oliveira, C. F., Giordani, D., Gurak, P. D., Cladera-

Olivera, F., & Marczak, L. D. F. (2015). Extraction of

pectin from passion fruit peel using moderate electric

field and conventional heating extraction methods.

Innov Food Sci Emerg Technol, 29, 201–208.

https://doi.org/10.1016/j.ifset.2015.02.005

Dimopoulou, M., Alba, K., & Kontogiorgos, V. (2019).

Pectin recovery and characterization from lemon juice

waste streams. J Sci FoodAgric.

https://doi.org/10.1002/jsfa.9891

Fertonani, H. C. R., Scabio, A., Carneiro, E. B. B.,

Schemim, M. H. C., Nogueira, A., & Wosiacki, G.

(2009). Extraction model of low methoxyl pectin from

apple pomace effects of acid concentration and time on

the process and the product. Braz. Arch. Biol. Technol,

52(1), 177–185.

Iglesias, M. T., & Lozano, J. E. (2004). Extraction and

characterization of sunflower pectin. J Food Eng, 62,

215–223. https://doi.org/10.1016/S0260-

8774(03)00234-6

Kalegowda, P., Singh Chauhan, A., & Mysore NanjarajUrs,

S. (2017). Opuntia dillenii (Ker-gawl) haw fruit peel

pectin: Physicochemical, rheological, and functional

behavior. J. Food Process. Preserv., 41(5), 1–8.

https://doi.org/10.1111/jfpp.13165

Karimi, N., Sani, A. M., & Pourahmad, R. (2016). Influence

of carboxy methyl cellulose (CMC) and pectin on

rheological, physical stability and sensory properties of

milk and concentrated jujuba mixture. J. Food Meas.

Charact., 10(2), 396–404.

https://doi.org/10.1007/s11694-016-9318-z

Khan, M., Nakkeeran, E., & Umesh-Kumar, S. (2012).

Potential Application of Pectinase in Developing

Functional Foods. Annu Rev Food Sci Technol

, 4(1),

21–34. https://doi.org/10.1146/annurev-food-030212-

182525

Kontogiorgos, V., Margelou, I., Georgiadis, N., &

Ritzoulis, C. (2012). Rheological characterization of

okra pectins. Food Hydrocoll, 29(2), 356–362.

https://doi.org/10.1016/j.foodhyd.2012.04.003

Li, X., Al-Assaf, S., Fang, Y., & Phillips, G. O. (2013).

Characterisation of commercial LM-pectin in aqueous

solution. Carbohydr. Polym., 92(2), 1133–1142.

https://doi.org/10.1016/j.carbpol.2012.09.100

May, C. D. (1990). Industrial pectins: sources, production

and applications. Carbohydr. Polym., 12(1), 79–99.

https://doi.org/10.1016/0144-8617(90)90105-2

Methacanon, P., Krongsin, J., & Gamonpilas, C. (2014).

Pomelo (Citrus maxima) pectin: Effects of extraction

parameters and its properties. Food Hydrocoll, 35, 383–

391. https://doi.org/10.1016/j.foodhyd.2013.06.018

Miyamoto, A., & Chang, K. C. (1992). Extraction and

physicochemical characterization from sunflower head

residues of pectin. J. Food Sci., 57(6), 1439–1443.

Morales-Contreras, B. E., Wicker, L., Rosas-Flores, W.,

Contreras-Esquivel, J. C., Gallegos-Infante, J. A.,

Reyes-Jaquez, D., & Morales-Castro, J. (2020). Apple

pomace from variety “Blanca de Asturias” as

sustainable source of pectin: Composition, rheological,

and thermal properties. LWT, 117. https://doi.org/

10.1016/j.lwt.2019.108641

Morris, G. A., Foster, T. J., & Harding, S. E. (2000). The

effect of the degree of esterification on the

hydrodynamic properties of citrus pectin. Food

Hydrocoll, 14(3), 227–235. https://doi.org/10.1016/

S0268-005X(00)00007-2

Ngouémazong, E. D., Christiaens, S., Shpigelman, A., Van

Loey, A., & Hendrickx, M. (2015). The emulsifying

and emulsion-stabilizing properties of pectin: A

Review. Compr. Rev. Food Sci. Food Saf., 14(6), 705–

718. https://doi.org/10.1111/1541-4337.12160

Pippen, E. L., Schultz, T. H., & Owens, H. S. (1953). Effect

of degree of esterification on viscosity and gelation

behavior of pectin. J. Colloid Sci., 8(1), 97–104.

https://doi.org/10.1016/0095-8522(53)90010-5

Rao, M. A. (2007). Rheology of Fluid and Semisolid Foods:

Principles and Applications (2nd ed.). Springer.

Razak, R. A., Karim, R., Sulaiman, R., & Hussain, N.

(2018). Effects of different types and concentration of

hydrocolloids on mango filling. Int Food Res J, 25

(3),

1109–1119.

Round, A. N., Rigby, N. M., MacDougall, A. J., & Morris,

V. J. (2010). A new view of pectin structure revealed

by acid hydrolysis and atomic force microscopy.

Carbohydr. Res., 345(4), 487–497. https://doi.org/

10.1016/j.carres.2009.12.019

Saha, D., & Bhattacharya, S. (2010). Hydrocolloids as

thickening and gelling agents in food: a critical review.

Int. J. Food Sci. Technol., 47(6), 587–597.

https://doi.org/10.1007/s13197-010-0162-6

Singh, R., & Heldman, D. (2009). Introduction to Food

Engineering (4th ed.). Academic Press.

Rheology of Sunflower, Citrus and Apple Low Methoxyl Pectin

183

Steffe, J. (1996). Rheological Method in Food Procces

Engineering. Freeman Press.

Sundar Raj, A., Rubila, S., Jayabalan, R., & Ranganathan,

T. (2012). A Review on pectin: Chemistry due to

general properties of pectin and its pharmaceutical uses.

Sci. Rep., 1(12), 10–12. https://doi.org/10.4172/

scientificreports.5

Thirawong, N., Kennedy, R. A., & Sriamornsak, P. (2008).

Viscometric study of pectin – mucin interaction and its

mucoadhesive bond strength. Carbohydr. Polym., 71,

170–179.

https://doi.org/10.1016/j.carbpol.2007.05.026

Vinogradov, G. V., & Titkova, L. V. (1968). Critical

concentrations of polymers in solutions according to

measurements of the viscosity and specific surface area

of aerogels resulting after sublimation of the solvent.

Rheologica Acta, 7(4), 297–306. https://doi.org/

10.1007/BF01984842

Yang, X., Nisar, T., Liang, D., Hou, Y., Sun, L., & Guo, Y.

(2018). Low methoxyl pectin gelation under alkaline

conditions and its rheological properties: Using NaOH

as a pH regulator. Food Hydrocoll, 79, 560–571.

https://doi.org/10.1016/j.foodhyd.2017.12.006

Yapo, B. M. (2011). Pectic substances: From simple pectic

polysaccharides to complex pectins - A new

hypothetical model. Carbohydr. Polym., 86(2), 373–

385. https://doi.org/10.1016/j.carbpol.2011.05.065

Yoo, S., Fishman, M. L., Hotchkiss, A. T., & Gyu, H.

(2006). Viscometric behavior of high-methoxy and

low-methoxy pectin solutions. Food Hydrocoll, 20, 62–

67. https://doi.org/10.1016/j.foodhyd.2005.03.003

Zhong, Q., & Daubert, C. R. (2013). Food Rheology. In

Handbook of Farm, Dairy and Food Machinery

Engineering: Second Edition (Vol. 1, pp. 403–426).

Academic Press. https://doi.org/10.1016/B978-0-12-

385881-8.00015-X

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

184