Preliminary Design of Tofu Factory Wastewater Treatment with

Ozonation Method

Ignatius Y. P. Welerubun

1

, Kris Tri Basuki

1

, Dhita Ariyanti

1

, N. Aziz

2

and D. Gemarefa

1

1

Sekolah Tinggi Teknologi Nuklir, Badan Tenaga Nuklir Nasional, Indonesia

2

Pusat Teknologi Bahan Bakar Nuklir, Badan Tenaga Nuklir Nasional, Indonesia

Keywords: Tofu Wastewater, Dimension, Quality Standards, Ozonation.

Abstract: Tofu is a food that is often consumed in Indonesia. Every 100 g of tofu contains macronutrients such as 7.8 g

protein, 4.6 g fat, and 1.6 g carbohydrates. Tofu also contains micronutrients like phosphorus, potassium,

calcium, vitamin B, and vitamin E. The process of making tofu produces liquid waste. Based on one of the

tofu factories in Indonesia the qualities of COD, BOD, and Total Coliform are 5964.48 mg/L, 734.1 mg/L,

and 59.13 MPN/100 mL. The purpose of this study is to obtain the unit dimensions of the tofu wastewater

treatment system using the ozonation method so that the water released will meet the available quality

standards. The research was carried out by studying the liquid waste treatment using the ozonation method

until the wastewater treatment system was obtained and then calculating the effluent of the system design.

Based on the calculation results, the dimensions of the tank are cylindrical and the units can be determined.

The treatment system able to reduce COD, BOD, and TC with the qualities of system are 178.67 mg/L, 24

mg/L, and 0 MPN/100 mL, which values are meet quality standards so that they can be released into the

environment.

1 INTRODUCTION

Tofu is a side dish that is commonly found. Every 100

g of tofu contains macronutrients such as 7.8 g of

protein; 4.6 g fat; and 1.6 g carbohydrates. Tofu also

contains micronutrients such as phosphorus,

potassium, calcium, B vitamins, and E vitamins. In

addition to its low price, tofu is rich in protein so that

it is a source of nutrition and is widely consumed by

Indonesian people (Seftiono, 2016).

Factory production activity usually produces

waste. The tofu production results in liquid and solid

wastes. Liquid tofu waste will immediately dispose of

the water around the factory (Yudhistira et al., 2016).

According to Ratnani, there are organic and inorganic

pollutants in waste that can contaminate the

environment (Ratnani, 2011). COD (Chemical

Oxygen Demand), BOD (Biological Oxygen

Demand), TSS (Total Suspended Solid), and TC

(Total Coliform) are parameters that can be used to

assess environmental pollution.

Tofu waste needs to be processed until it meets the

disposal requirements. The wastewater treatment

must meet the release criteria or the quality standard

value of waste according to the regulation of the state

minister of the environment number 5 of 2014 which

states the levels of COD, BOD, and TSS of

wastewater for soybean processing businesses and/or

activities in the form of tofu are 300 mg/L, 150 mg/L,

and 200 mg/L.

Ozone can be used to treat wastewater, namely

ozonation. Ozone has some functions, such as

disinfectant (Basuki et al., 2017), COD, BOD, and

TSS values reduction in the waste (Isyuniarto et al.,

2006; Isyuniarto and Andrianto, 2009; Estikartini et

al. 2016; Karamah et al., 2019).

The plant design of wastewater treatment using

the ozonation method consist of several processes

such as equalization, coagulation, flocculation-

sedimentation, and ozonation unit (Basuki et al.,

2017; Isyuniarto et al., 2006) which is environment

friendly (Usada et al., 2005). This research was

conducted to design the dimensions of the

equalization, coagulation, flocculation, and ozonation

unit in tofu wastewater treatment using the ozonation

method so that the water released will meet the

quality standards. The waste parameters reviewed

include the levels of COD, BOD, TSS, and Total

Coliform as the basis calculation design of the

wastewater treatment system.

Welerubun, I., Basuki, K., Ariyanti, D., Aziz, N. and Gemarefa, D.

Preliminary Design of Tofu Factory Wastewater Treatment with Ozonation Method.

DOI: 10.5220/0010546600003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutr ition and Health, pages 127-131

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

2 BASIC THEORY

2.1 Equalization

The equalization unit is needed as an initial container

for waste output before it is processed in the

coagulation tank. In the equalization tank, there is an

adjustment of the discharge and pH before entering

the next process (Wang et al., 2006) such as

coagulation process in coagulation tank.

2.2 Coagulation: Flocculation

The function of the coagulation unit is to mix the

coagulants to form the floc core. The floc core later

enlarges in the flocculation unit. The large floc

formed will be deposited. These deposits are formed

and accommodated in the sedimentation section

(Priambodo and Indaryanto, 2017). Coagulation,

flocculation, and sedimentation units can be designed

as a single unit to facilitate maintenance (Rosidi and

Razif, 2017).

2.3 Ozonation

The ozonation method can oxidize contaminants in

the wastewater, reduce microorganisms, color, taste,

smell, and release NOM (Natural Organic Matter) in

water (Chen and Wang 2014).

Wastewater having high COD, BOD, TSS values

can be reduced using ozone. Ozone is a strong

oxidizing agent with an oxidation potential of 2.08

eV. Ozone can be decomposed into hydroxyl radicals

(OH•) with an oxidation potential value of 2.80 eV.

This shows that ozone can oxidize organic or

inorganic compounds in water effectively and

efficiently (Sururi et al., 2012).

Ozone that is discharged into the waste also kills

the bacteria present in the waste (Basuki et al., 2017).

Ozone kills bacterial cells by attacking glycoproteins

and glycolipids in the bacterial cell membrane

resulting in the breakdown of the bacterial cell (lysis)

(Megahed et al., 2018).

3 METHODS

3.1 Literature Review

Review literature about tofu industrial wastewater

treatment techniques, choose tofu industrial

wastewater treatment system designs, plan the chosen

design.

3.2 Data Collection and Data Analysis

Characterization of COD, BOD, and Total Coliform

values of tofu industrial wastewater was carried out at

PT SARASWANTI INDO GENETECH and for

wastewater, discharge measurements were carried out

by storing wastewater within a certain period and

stored in a bottle container.

3.3 Data Processing

Calculating the results of the characterization of the

wastewater with its quality standard value,

determining the quality standards for the design basis,

and calculating the unit dimensions in each of the tofu

wastewater treatment processes (Basuki, 2016).

3.4 Results Assessment

Calculating the dimensions of the wastewater

treatment unit using guide from Reynolds and

Richards (1996) and Basuki (2016), calculating the

final effluent design of the wastewater treatment unit,

and comparing the effluent of the waste treatment

design with its quality standards (Indonesian

Goverment).

4 RESULT AND DISCUSSION

4.1 Design of Tofu Wastewater

Treatment System

The wastewater treatment process starts with the

equalization tank. After that, the coagulation-

flocculation process – an integral part of the primary

waste treatment process, is used to reduce the

processing load before the waste is treated by using

ozone. The ozonation unit was utilized for a

disinfection unit (Basuki et al., 2017) which can

simultaneously reduce the COD, BOD, and TSS

values in treated waste (Karamah et al., 2019).

Figure 1: Block diagram of tofu wastewater treatment

process (Basuki, 2016).

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

128

4.2 Calculation of the Dimensions of

Tofu Wastewater Treatment Unit

4.2.1 Equalization Tank

In this equalization tank, the wastewater was

collected and then the debit was changed before

entered the coagulation tank. The purpose of

changing the discharge is to adjust the processing

time of the waste. The addition of lime was carried

out in the equalization tank and it aims to create

optimum process conditions (Isyuniarto et al., 2005).

The equalization tank design is as follows:

Lime requirement = 2.0818 g/process

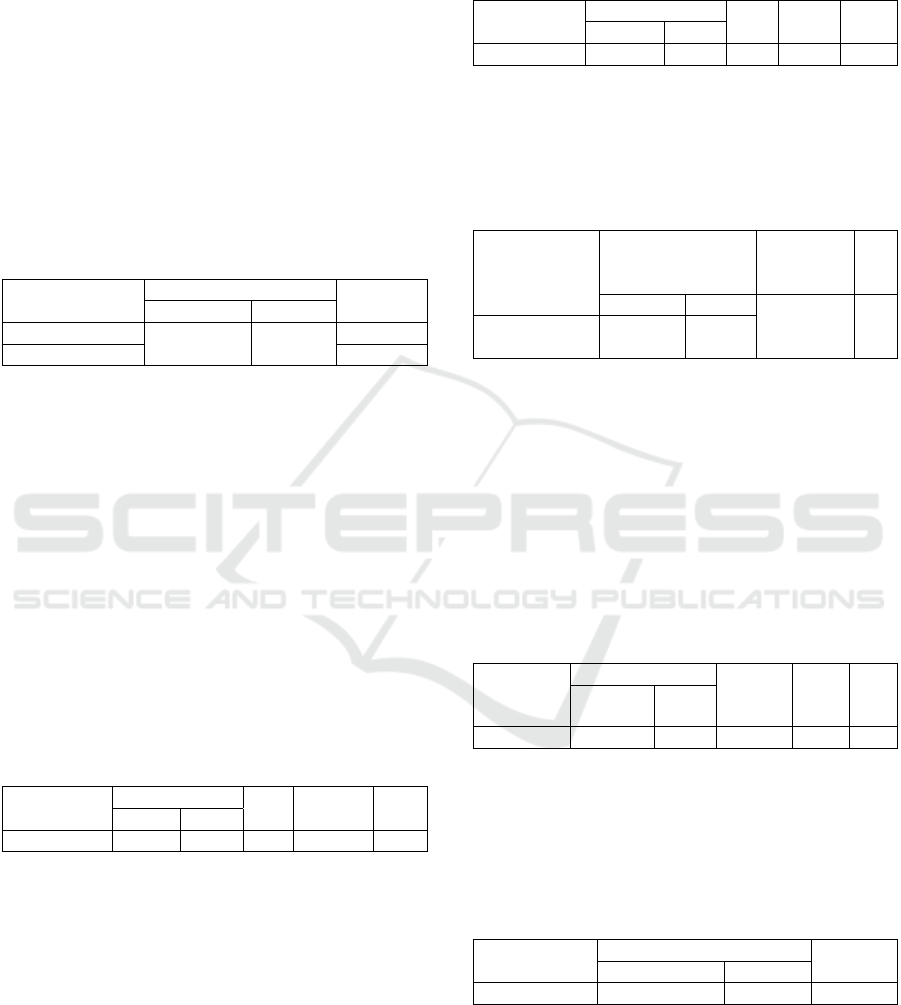

Table 1: Equalization tank design.

Unit

Dimension (m)

t

d

(h)

D

d

E

q

ualization 1

0,5 0,8

0,517

E

q

ualization 2 1

4.2.2 Coagulation Tank

The function of the coagulation tank is to agglomerate

organic substances in tofu liquid waste by mixing it

with a coagulant. The coagulation system was stirred

relatively quick. Stirring was carried out rapidly to

disperse the coagulants well and to create the

collisions between particles required to achieve good

coagulation conditions. Alum was used as the

coagulant. The results of the calculation of the

coagulation unit are as follows:

Alum concentration = 1% by weight

Need for alum = 6.5 kg/process

Impeller diameter = 0.437 m

Impeller height = 0.127 m

Table 2: Coagulation tank design.

Unit

Dimension

rpm P (W)

t

d

(s)

D

d

Coa

g

ulation 0,874 0,874 100 393,183 40

4.2.3 Flocculation Tank

The flocculation unit located after the coagulation

unit. The stirring speed in the flocculation bath was

relatively slower than the coagulation bath. This

makes the coagulation bath called a fast stirring bath,

while the flocculation bath is called a slow stirring

bath. A slow stirring of the flocculation unit can result

in an increase in particle size from the

submicroscopic micro-floc to visible soluble particles

(Ismail et al., 2019). The results of the calculation of

the flocculation unit are as follows:

Impeller diameter = 0.381 m

Impeller height = 0.129 m

Table 3: Flocculation tank design.

Unit

Dimension (m)

rpm

P

(W)

t

d

(m)

D

d

Flocculation 0,762 0,762 20 1,575 20

The sedimentation zone is designed at the bottom

of the flocculation unit. The sedimentation zone

functions to accommodate sediment resulting from

the coagulation-flocculation process.

Table 4: Sedimentation zone design.

Unit

Dimension (m)

Drain

period

(/day)

t

d

(h)

D

d

1 1

Sedimentation

zone

0,762 0,164

4.2.4 Ozonation Tank

The ozonation unit is the main unit of the installation,

which provide ozone to reduce the number of bacteria

(Total Coliform) and also reduce the value of COD

and BOD as well as TSS. In that case, ozonation

replaced two units, namely the COD, BOD, and TSS

removal unit, and the disinfection unit. The

determination of ozone dosage uses the approach

from previous studies (Isyuniarto et al., 2005).

Table 5: Ozonation tank design.

Unit

Dimension

(

m

)

Ozone

Dosage

(

m

g

/s

)

P

(W)

t

d

(m)

D d

Ozonation 0,6 1,007 60 3900 20

4.2.5 Sump Tank

The final container aims to collect water generated

from the waste treatment process with the intention

that the water can be controled to release or reused.

Table 6: Sump tank design.

Unit

Dimension (m)

t

d

(h)

D

d

Sump 1,44 1,74 14

4.3 Calculation Effluent of Tofu

Wastewater System

Calculations were carried out on the values of COD,

BOD, TSS, and Total Coliform with the management

Preliminary Design of Tofu Factory Wastewater Treatment with Ozonation Method

129

of each unit based on previous studies (Isyuniarto et

al., 2006; Isyuniarto and Purwadi, 2007). The

calculation of the influent and effluent of each

process is as follows (Basuki, 2016):

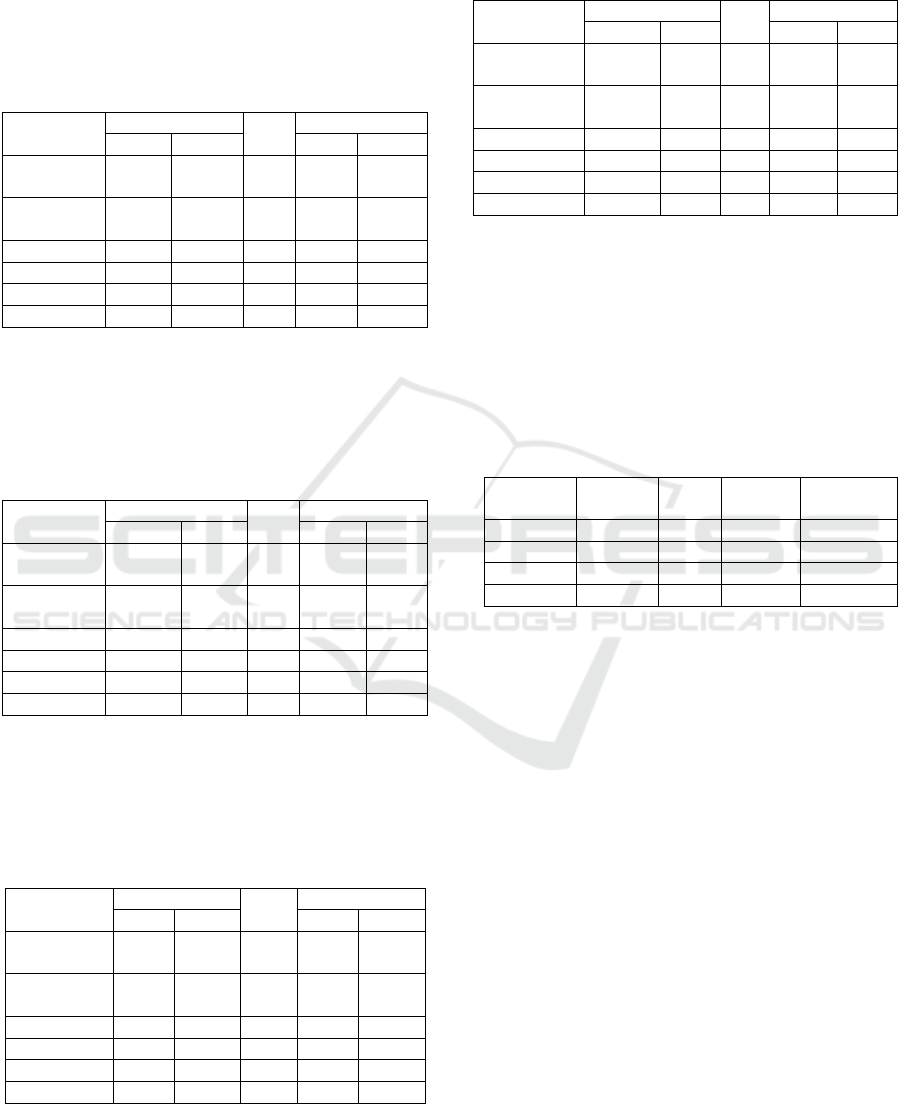

4.3.1 COD

Table 7: COD processing results.

Unit

COD influent

EP

COD effluent

Q C Q C

Equalization

1

0,8947 5964,48 0 0,8947 5964,48

Ekualization

2

0,8947 5964,48 0 0,8947 5964,48

Coagulation 0,8947 5964,48 0 0,8947 5964,48

Flocculation 0,8947 5964,48 66,16 0,3028 5964,48

Ozonation 0,3028 2018,4 91,15 0,0268 5964,48

Sum

p

0,0268 178,67 0 0,0268 5964,48

Notes:

Q in kg/hour

C in mg/L

4.3.2 BOD

Table 8: BOD processing results.

Unit

BOD influent

EP

BOD effluent

Q C Q C

Equalization

1

0,1101 734,1 0 0,1101 734,1

Equalization

2

0,1101 734,1 0 0,1101 734,1

Coa

g

ulation 0,1101 734,1 0 0,1101 734,1

Flocculation 0,1101 734,1 66,12 0,0373 248,67

Ozonation 0,0373 248,67 90,35 0,0036 24

Sump 0,0036 24 0 0,0036 24

Notes:

Q in kg/jam

C in mg/L

4.3.3 TSS

Table 9: TSS processing results.

Unit

TSS influent

EP

TSS effluent

Q C Q C

Equalization

1

0,18 1200 0 0,18 1200

Equalization

2

0,18 1200 0 0,18 1200

Coa

g

ulation 0,18 1200 0 0,18 1200

Flocculation 0,18 1200 70 0,054 360

Ozonation 0,054 360 53,75 0,025 166,67

Sump 0,025 166,67 0 0,025 166,67

Notes:

Q in kg/hour

C in mg/L

4.3.4 TC

Table 10: TC processing results.

Unit

TC influent

EP

TC effluent

QC Q C

Equalization

1

88695 59,13 0 88695 59,13

Equalization

2

88695 59,13 0 88695 59,13

Coagulation 88695 59,13 0 88695 59,13

Flocculation 88695 59,13 0 88695 59,13

Ozonation 88695 59,13 100 0 0

Sum

p

0 0 0 0 0

Notes:

Q in MPN/hour

C in MPN/100 mL

4.3.5 Comparison of Effluent Water Quality

The quality of water effluent from the waste treatment

system was compared to the regulations governing

wastewater standards.

Table 11: Effluent water quality.

Parameter Before After

Quality

standards

Information

COD 5964,48 178,67 300* Fulfill

BOD 734,1 24 150* Fulfill

TSS 1200 166,67 200* Fulfill

TC 59,13 0 50** Fulfill

Notes:

*PERMENLH number 5 years 2014

**PERMENKES number 32 years 2017

Based on the regulations referred to the quality

standard, the value of water output from the system is

appropriate to be released into the environment.

5 CONCLUSIONS

The results of the preliminary design calculation of

tofu factory wastewater treatment systems using the

ozonation method with a semi-batch system with a

capacity of 0.15 m

3

of waste/hour of processing

obtained several conclusions, i.e:

1. The dimensions of each unit in the tofu liquid

waste treatment system by the ozonation

method are shown in the following table:

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

130

Table 12: The results of design calculations.

Unit

Dimension (m)

Diameter Depth

Equalization 1 & 2 0,5 0,8

Coagulation 0,874 0,874

Flocculation 0,762 0,762

Sedimentation zone 0,762 0,164

Ozonation 0,6 1,007

Sump 1,44 1,74

2. The wastewater treatment system uses the

ozonation method for tofu wastewater

produced effluent water suitable for

environmental quality standards, so it safe to

be released. The outputs of COD, BOD, TSS

and Total Coliform at these installations were

178.67 mg/L respectively; 24 mg/L; 166.67

mg/L and 0 MPN/100 mL.

REFERENCES

Basuki, KT, Wasito, B, Nurimaniwathi & Purwadi, A 2017,

‘Use of ozoniser to kill bacteria in the beverage industry

and water wells revile population’, 11

th

Joint

Conference on Chemistry in conjunction with 4

th

Regional Biomaterial Scientific Meeting: Proceeding of

Chemistry Conferences, vol. 2, pp. 72-78.

Basuki, KT, 2016, Diktat pengolahan air, lecture handout,

STTN-BATAN, Yogyakarta.

Chen, K. and Wang, Y 2014, ‘The effects of Fe-Mn Oxide

and TiO2/α-Al2O3 on the formation of disinfection by-

products in catalytic ozonation’, Chemical Engineering

Journal, pp. 84-92.

Estikarini, HD, Hadiwidodo, M & Luvita, V 2016,

‘Penurunan kadar COD dan TSS pada limbah tekstil

dengan metode ozonasi’, Jurnal Teknik Lingkungan,

vol. 5, no. 1 2016.

Indonesian government 2014, Peraturan Menteri Negara

Lingkungan Hidup Nomor 5 Tahun 2014 tentang Baku

Mutu Air Limbah bagi Usaha dan/atau Kegiatan

Pengolahan Kedelai, Indonesia.

Indonesian government 2017, Peraturan Menteri Kesehatan

Republik Indonesia Nomor 32 Tahun 2017 tentang

Standar Baku Mutu Kesehatan Lingkungan dan

Persyaratan Kesehatan Air untuk Keperluan Higiene

Sanitasi, Kolam Renang, Solus Per Aqua, dan

Pemandian Umum, Indonesia.

Ismail, AF, Khulbe, KC, & Matsuura, T 2019, Reverse

Osmosis: RO Membrane Fouling, Elsevier Inc, 1

st

edition.

Isyuniarto & Andrianto 2009, ‘Pengaruh waktu ozonisasi

terhadap penurunan kadar BOD, COD, TSS dan fosfat

pada limbah cair rumah sakit’, GANENDRA, vol. XII,

no. 1, pp. 45-49.

Isyuniarto & Purwadi, A 2007, ‘Pengaruh ph dan oksidan

ozon terhadap jumlah bakteri coliform pada limbah

rumah sakit (studi kasus limbah RSUD kota

Yogyakarta)’, Prosiding PPI – PDIPTN.

Isyuniarto, Usada, W, Suryadi, and Purwadi, A 2006,

‘Pengolahan limbah cair industri tahu dengan teknik

lucutan plasma’, Prosiding PPI-PDIPTN 2005, pp. 20-

26.

Karamah, EV, Anindita, L, Amelia, D, Kusrini, E & Bismo,

S 2019, ‘Tofu industrial wastewater treatment with

ozonation and the adsorption method using natural

zeolite’, International Journal of Technology, vol. 10,

no. 8, pp. 1498-1504.

Megahed, A, Aldridge, B, & Lowe, J, “The microbial

killing capacity of aqueous and gaseous ozone on

different surfaces contaminated with dairy cattle

manure,” PLoS ONE, vol. 13, no. 5.

Priambodo, EA & Indaryanto, H 2017, ‘Perancangan unit

instalasi pengolahan air minum kampus institut

teknologi sepuluh nopember’, JURNAL TEKNIK ITS,

vol. 6, no. 1, pp. D51-D56.

Ratnani, RD 2011, ‘kecepatan penyerapan zat organik pada

limbah cair industri tahu dengan lumpur aktif’,

Momentum, vol. 7, no. 2, pp. 18-24.

Reynold TD & Richard, PH 1996, Unit operations and

processes in environmental engineering, PWS

Publishing Company, Boston, 2

nd

edition.

Rosidi, M & Razif, M 2017, “Perancangan instalasi

pengolahan air limbah (IPAL) industri kertas halus,”

JURNAL TEKNIK ITS, vol. 6, no. 1, pp. D40-D43.

Seftiono, H. 2016, ‘Perubahan sifat fisiko kimia protein

selama proses pembuatan tahu sebagai rujukan bagi

posdaya’, Jurnal Kesejahteraan Sosial Maret 2017, vol.

3, no. 1, pp. 85-92.

Sururi, MR, Pharmawati, K & Paramanita 2012,

‘Penyisihan bahan organik alami pada air permukaan

dengan ozonisasi dan ozonisasi – filtrasi’, Jurnal

Purifikasi, vol. 13, no. 1, pp. 1-8.

Usada, W, Suryadi, Purwadi, A, Isyuniarto & Mintolo

2005, ‘plasma ozonizer 20 W terkendali sederhana

untuk penyimpanan buah dan sayur’, Prosiding PPI –

PDIPTN, pp. 39-46.

Wang, LK, Yung-Tse, H & Shammas, NK 2005,

‘Handbook of environmental engineering volume 3:

physicochemical treatment processes’, Humana Press,

New Jersey.

Yudhistira, B, Andriani, M & Utami, R 2016,

‘Karakterisasi: limbah cair industri tahu dengan

koagulan yang berbeda (asam asetat dan kalsium

sulfat)’, Journal of Sustainable Agriculture, vol. 31, no.

2, pp. 137-145.

Preliminary Design of Tofu Factory Wastewater Treatment with Ozonation Method

131