Modification of Composite Structure on Cobalt Free Cathode

for Solid Oxide Fuel Cells

Iwan Susanto

1,2

, Dianta Mustofa Kamal

1

, Fitri Wijayanti

1

, Belyamin

1

, Tia Rahmiati

1

, Fuad Zainuri

1

,

Rahmat Subarkah

1

, Yen-Pei Fu

2

, Adi Subardi

3

, Sulaksana Permana

4

1

Department of Mechanical Engineering, Politeknik Negeri Jakarta, Depok 16424, Indonesia

2

Department of Materials Science and Engineering, National Dong Hwa University, Hualien 97401, Taiwan ROC

3

Faculty of Vocational, Institut Teknologi Nasional Yogyakarta, Yogyakarta 55281, Indonesia

4

Center of Mineral Processing and Corrosion Research, Department of Metallurgy and Materials Engineering,

Universitas Indonesia, Depok 16424, Indonesia

Keywords: Composite Cathode, IT-Solid Oxide Fuel Cells, Perovskite Structure, Cobalt-Free Cathode

Abstract: A novel cobalt-free cathode of composite Sm

0.5

Sr

0.15

Ba

0.35

Fe

3-δ

for IT-SOFCs is developed using the solid-

state reaction technique. Thermal gravimetric was carried out for monitoring the weight loss on the cathode

system. In contrast, the X-ray diffraction was employed for the structure phase constructed on the model.

Reduction of weight value during the calcination process was achieved to be 10.5%. Thus, a low temperature

of the reduction reaction was obtained less than 920 °С. The decomposition reaction related to oxygen vacancy

in the composite cathode-free cathode was begun at 410 °С. It takes the advantage in the device system for

IT-SOFCs in application. The established structure of the composite cathode system was in the perovskite

phase

1 INTRODUCTION

Intermediate temperature solid oxide fuel cells (IT-

SOFCs) is an exciting device with high energy

conversion efficiency (Zhang et al., 2017). In

traditional SOFCs, its device operated approximately

at 1000 °С, which limited to using the material (Shao

& Haile, 2004). Today, IT-SOFCs offer an excellent

device with a wide range of material uses due to a

lower temperature application (Mahato et al., 2015).

However, decreasing operating temperature led to an

oxygen reduction reaction that suffers the mobility of

its atom in the system (Kulkarni et al., 2016). The

perovskite structure for cathode material was

introduced to SOFCs due to its mixed ionic-electronic

conducting (Zhou et al., 2016). It facilitates the

oxygen reduction reaction on both the triple-phase

boundary and along with the cathode bulk (Julián et

al., 2020). So, developing the perovskite structure

could also be interesting to reduce the area-specific

resistance in the IT-SOFCs cathode system.

The perovskite structure containing cobalt have

been studied, namely SmBa

0.5

Sr

0.5

Co

2

O

5+δ

,

Sm

0.5

Sr

0.5

CoO

3−δ

(Subardi et al., 2017 and Li et al.

2012). Attending cobalt in the cathode system could

demonstrate the high electro-catalyst activity.

However, a higher thermal expansion coefficient

(TEC) these cathodes than electrolyte such as

Sm

0.2

Ce

0.8

O

1.9

(SDC) restricted it for long term

application (Li et al. 2012). It is caused by the damage

structure in the interface between cathode layer and

electrolyte. So, the reduction of TEC difference value

for both cathode and electrolyte was considered to

develop the IT-SOFCs system (Zhang et al., 2014 and

Zhang et al., 2013). Thus, many TEC value

differences can spoil the cathode/electrolyte layer,

accelerating cell degradation initiated from the

interface up to the surface of the layers (Susanto et al.,

2019). So that, the attending of composite cathode-

free with a novel oxide composition was in interesting

study to be investigated.

In the report, the composite cathode

Sm

0.5

Sr

0.15

Ba

0.35

Fe

3-δ

was produced by the solid-state

reaction method. The characterization will be

employed to observe the decomposition step and the

structure constructed on the model. The thermal

gravimetric related to the analysis of weight loss and

reduction reaction will be discussed in detail. While,

the perovskite structure of the cathode model was

Susanto, I., Kamal, D., Wijayanti, F., Belyamin, ., Rahmiati, T., Zainuri, F., Subarkah, R., Fu, Y., Subardi, A. and Permana, S.

Modification of Composite Structure on Cobalt Free Cathode for Solid Oxide Fuel Cells.

DOI: 10.5220/0010538000003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 97-100

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

97

further identified comprehensively by XRD

characterization and it be analysed in detail as well.

2 EXPERIMENTAL METHOD

The cathode material composition consists of Sm

2

O

3

,

SrCO

3

, BaCO

3

, and Fe

2

O

3

powders (>99%) was

calculated by the stoichiometry method. The

synthetic of composites cathode was preparation via

the solid-state reaction (Susanto, et al., 2020). The

cathode powder was milled using alumina balls in

liquid alcohol for 12 hours (to obtain an even mixture)

and then dried at 65 °С for 24 hours. The cathode

material was subsequently filtered using 200 mesh

screening. The cathode material of 10 µg was heated

using the thermal gravimetric machine from room

temperature to 1200 °С, heating rate of 10 ℃/minute.

It cooled it(SBSF35) to room temperature in the air.

Further, the 5 gr cathode powders put on the Al

2

O

3

-

cup and calcined it up to 1000 °С with 3 °С/minute in

a heating rate and it cooled to room temperature as

well. The SBSF35 cathode structure was detected by

Rigaku D/MAX-2500V of XRD using a scanning of

3

o

/minute with a degree range of 20–80

o

. The total of

The sample crystal structure was analyzed by

applying the JADE 5 program to match the XRD

pattern obtained from the XRD database at the

International Center for Diffraction Data.

3 RESULT AND DISCUSSION

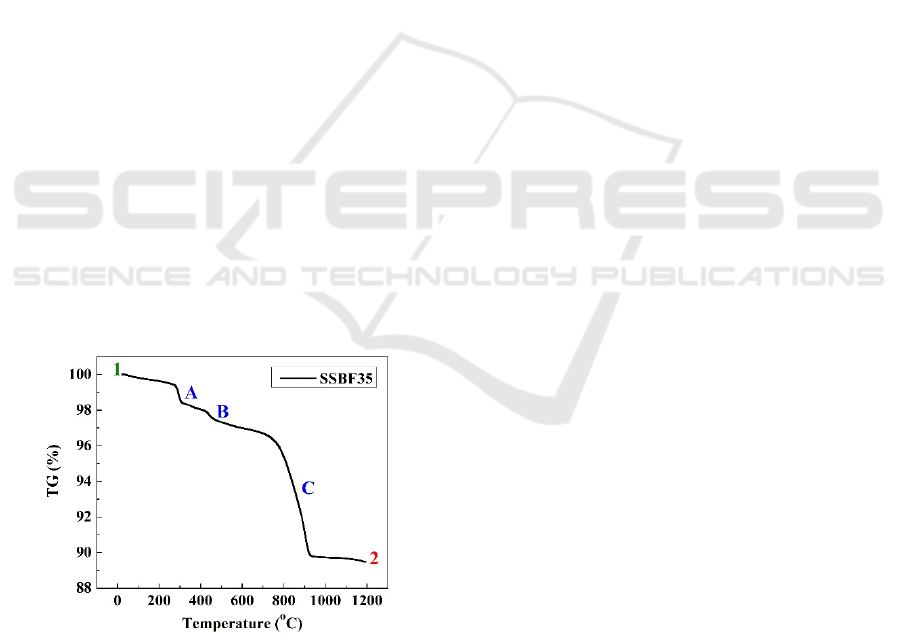

Figure 1. Thermal gravimetric of calcination process for

SSBF35 cathode powders

Fig. 1 shows curve thermal gravimetric (TG) of

SBSF35 oxide powders, which are calcined in the

range of 1200 °С from the room temperature. There

are three steep decreasing on the curve attended at

300 °С, 440 °С, and 760 °С for point A, B and C,

serially. At point A, the TG value reduction was

0.8%, and 0.4 % was in point B. In comparison, the

decreasing in its value was 7 % at point C. The total

TG % value was 10.5 % as long as 900 °С in range.

The thermal gravimetric was monitored the

stability of SBSF35 related to a reduction of the

weight on temperature. The calcination process of

composite powders was carried out to generate the

reaction of solid-state in the system. It decreasing the

TG curve from point 1 to 2 corresponded to the

reduction of weight loss of composite powders. For

the calcination process, the curve's reduction at the

first phase occurred at room temperature to 400 °С.

In point A, reduction of TG related to the release of

water content from the materials. The water content

could evaporate due to the system's heat energy in the

composite powders (Zhang and Zhao, 2020).

Furthermore, in the point B, The decreasing of TG

value suspected with purity of the materials. The

evaporating was demonstrated by the samarium

powder, which was performed by the lost weight in

the range temperature (Susanto, et al., 2020). It also

is proven by the endothermic process at the same

temperature due to the dehydration of materials.

Furthermore, in point C, the rate of subsequent weight

loss occurs that is caused by the decomposition of

strontium carbonate, forming the oxide materials of

SBSF35. The solid-state reaction was generated on

which held from this temperature up to 920 °С [31].

The endothermic could be constructed the formation

of the perovskite structure, confirmed by XRD in

Fig.3.

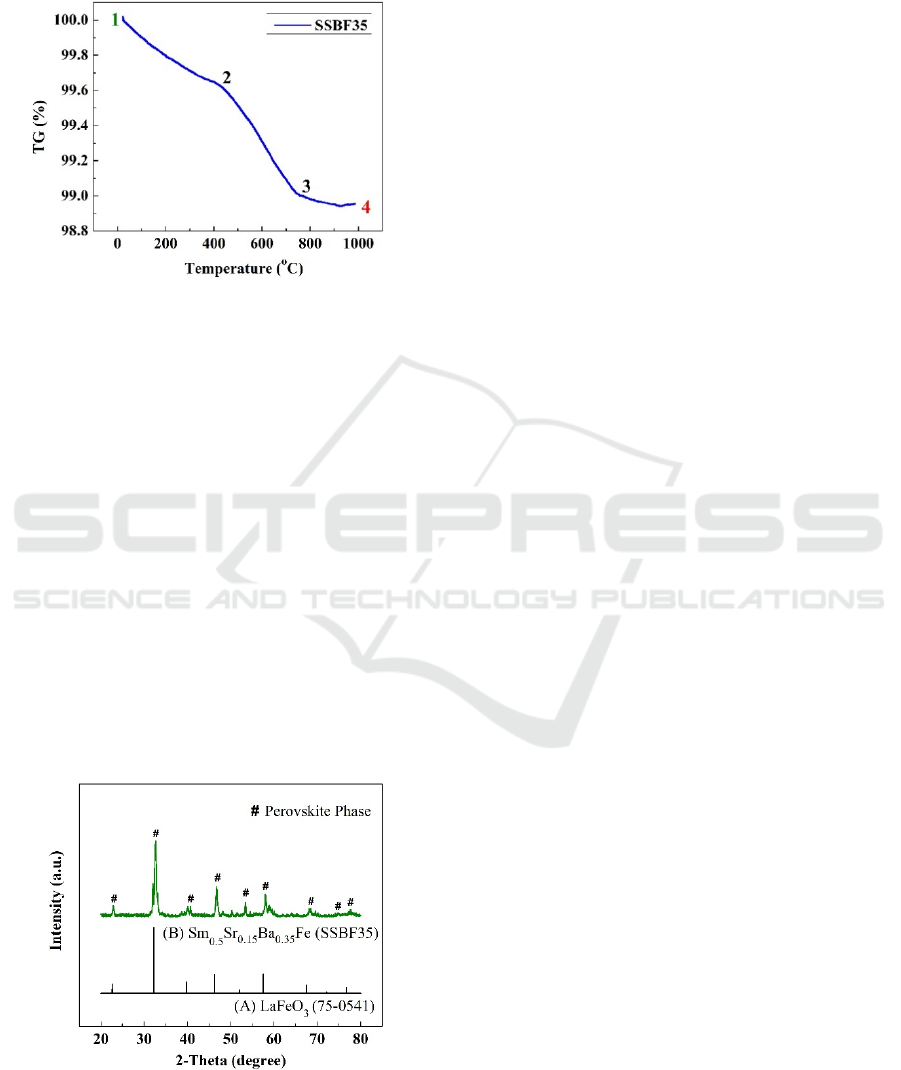

Moreover, the TG curve of SSBF35 after

calcination was displayed in Fig 2. The heating

process was given to 1000 °С. Three regions on the

curve related to lost weight on the materials during

calcination. The decreasing curve gradually in the

range of point one to point two, about 0.36 TG %, was

created from room temperature to 410 °С. It

demonstrated the lost weight influenced by the water

content that evaporated in the air. Furthermore, the

degradation of a curve from point 2 to 3 was

simultaneous to be 1% at 755 °С. Finally, the

reduction curve trend was only 0.2% which was

relatively stable up to 1000 °С. The total reduction in

the curve value was about 1.2 % which is smaller than

the lost weight during the calcination process. The

decreasing of weight corresponded with heat energy

encourage the oxygen atom to loose from the bonding

system. Decomposition process correlated with the

release of oxygen atoms in the structure system at

higher temperature, which was generating oxygen

vacancy. It could also facilitate the transport of

mobility oxygen in the cathode to be easier when

ASAIS 2020 - Annual Southeast Asian International Seminar

98

applied in the IT-SOFC system. So, based on the

thermal gravimetric characterization, the transport

mobility of oxygen ion make it possible to be started

at 410 °С.

Figure 2. Thermal gravimetric of SSBF35 cathode powders

after calcination

Fig 3 displays the XRD pattern of a composite

system of SSBF35 cathode (B) and the LaFeO3 (A)

as a reference. The observation was carried out from

20 to 80° of 2θ with a scan rate of 3°/minute. There

are nine peaks namely 22.88°, 32.64°, 40.46°, 46.68°,

52.32°, 57.68°, 67.42°, 72.48°, and 77.14° closed

with reference, respectively. The structure of the

cathode model system has a mixture phase of

rhombohedral with PDF number of 20-0130 and the

structure of cubic phase with PDF number of 14-0180

(Liu. et al., 2018). It indicates that the structure of the

cathode system was the perovskite phase. Based on

the XRD result, the composite cathode structure

related to design in the beginning for creating the

perovskite structure. Its structure could be fasilitated

the oxygent ions to be easier for movement in the

cathode element. At the device system, it takes the

avantages for IT-SOFCs system in application.

Figure 3. The XRD pattern of composite SSBF35 cathode

4 CONCLUSIONS

In this research, the composite cathode was

successfully modified using the solid-state reaction.

Thermal gravimetric confirmed that weight loss was

created during the heated process up to 1000 °С. The

decomposition reaction influenced the weight loss of

model SSBF35 in the range of 410 to 755 °С

drastically. The calcination temperature for

generating the perovskite structure was obtained less

than 920 °С, which can be used to references for the

calcination process. The perovskite phase related to

the structure modified was successfully constructed

on the composite cathode related to XRD result.

ACKNOWLEDGMENTS

The authors are grateful to the financial support

provided by Unit Penelitian dan Pengabdian

Masyarakat, Politeknik Negeri Jakarta (UP2M-PNJ)

under contract number:B.150/PL3.18/PN.00.03/2020

that made this work possible. The authors are also

grateful for the financial support of this research by

Ministry of Science and Technology of Taiwan under

contract number: MOST 106-2113-M-259-011.

REFERENCES

Julián A. Y, et al. (2020). The oxygen reduction reaction in

solid oxide fuel cells: from kinetic parameters

measurements to electrode design. J. Phys. Energy. doi:

10.1088/2515-7655/abb4ec

Kulkarni. A, et al. (2016). Enhancing Oxygen Reduction

Reactions in Solid Oxide Fuel Cells with Ultrathin

Nanofilm Electrode–Electrolyte Interfacial Layers. J.

Phys. Chem. doi: 10.1021/acs.jpcc.5b09345

Li. C. H, et al. (2012). Electrochemical characterization of

gradient Sm

0.5

Sr

0.5

CoO

3−δ

cathodes on Ce

0.8

Sm

0.2

O

1.9

electrolytes for solid oxide fuel cells, Ceramics

International, doi.org/10.1016/j.ceramint.2011.09.041

Liu. et al. (2018). Structure and electrochemical properties

of cobalt-free perovskite cathode materials for

intermediate-temperature solid oxide fuel cells,

Electrochimica Acta. doi:

org/10.1016/j.electacta.2018.05.086

Mahato. N, et al. (2015). Progress in material selection for

solid oxide fuel cell technology: A review, Progress in

Materials Science, 72 (2015) 141–337

Shao Z. P. & Haile S. M. (2004). A high-performance

cathode for the next generation of solid-oxide fuel cells,

Letter to Nature, Nature. doi: 10.1038/nature02863

Subardi. A, et al. (2017). Oxygen transportation, electrical

conductivity and electrochemical properties of layered

perovskite SmBa

0.5

Sr

0.5

Co

2

O

5+δ

, International Journal

Modification of Composite Structure on Cobalt Free Cathode for Solid Oxide Fuel Cells

99

of Hydrogen Energy.

doi:org/10.1016/j.ijhydene.2016.11.123

Susanto, I., Tsai, C., et al. (2019) ‘Morphology and surface

stability of GaN thin film grown on the short growth

time by Plasma Assisted Molecular Beam Epitaxy’, J.

Phs : Conference Seriese, 1364(012067). doi:

10.1088/1742-6596/1364/1/012067.

Susanto. I, et al. (2020) Development of cobalt-free oxide

(Sm

0.5

Sr

0.5

Fe

0.8

Cr

0.2

O

3-δ

) cathode for intermediate-

temperature solid oxide fuel cells (IT-SOFCs). Eastern-

European Journal of Enterprise Technologies. doi:

10.15587/1729-4061.2020.217282.

Zhang. Y, et al. (2017). Recent Progress on Advanced

Materials for Solid-Oxide Fuel Cells Operating Below

500 °C. Adv. Mater. doi: 10.1002/adma.201700132

Zhang. L, et al. (2013). Electrical conductivity, thermal

expansion and electrochemical performances of Ba-

doped SrCo

0.9

Nb

0.1

O

3−δ

cathodes for IT-SOFCs.

International Journal of Hydrogen Energy.

doi:org/10.1016/j.ijhydene.2013.04.107

Zhang. L, et al. (2014). Improved thermal expansion and

electrochemical performances of

Ba

0.6

Sr

0.4

Co

0.9

Nb

0.1

O

3−δ

–Gd

0.1

Ce

0.9

O

1.95

composite

cathodes for IT-SOFCs, International Journal of

Hydrogen Energy.

doi:org/10.1016/j.ijhydene.2014.03.055.

Zhang.C and Zhao. H, (2020). A novel cobalt-free cathode

material for proton-conducting solid oxide fuel cells,”

J. Mater. Chem. doi: 10.1039/c2jm32627b.

Zhou. Y, et al. (2016). Strongly correlated perovskite fuel

cells, Letter Nature. doi: 10.1038/nature17653

ASAIS 2020 - Annual Southeast Asian International Seminar

100