Effect of Addition of Sea Water on Changes in Turbidity and Metal

Content in Industrial Wastewater Treatment into Drinking Water

using Electrocoagulation Process

Sutanto

1

and Rahmat

1

1

Department of Electrical Engineering, State Polytechnic of Jakarta, Depok, Indonesia

Keywords: Wastewater, sea water, electrocoagulation, turbidity, drinking water

Abstract: The treatment of industrial wastewater was studied by electrocoagulation process into drinking water. The

wastewater 4.5 liters was drained off into the three cells of electrocoagulation process tank. The process was

conducted at 12 Volt in voltage and observed of change of the turbidity and metal content in interval time

of 10 minutes. Subsequently, the same procedure was carried out by adding sea water with varying volumes

of 5,10 and 15 mL Based on the research results, the best processes are obtained 10 mL of sea water, 12 Volt

of voltage and 100 minutes for processing time, where turbidity can be removed from 44.08 NTU to 4.85

NTU or equivalent 88.99 %, copper content from 3.55 to 0.93 mg/L or equivalent 80.97 % and iron content

from 1.25 to 0.27 mg/L or equivalent 70,95 %.

1 INTRODUCTION

The wastewater is generally divided into two types,

industrial and domestic wastewater. The content of

pollutants in wastewater are organic and inorganic

materials. These two types of waste water can be

recycled into drinking water or clean water.

According to the regulation of the Minister of Health

of the Republic of Indonesia No. 492 / Menkes / Per /

IV / 2010, the maximum content of each parameter in

drinking water is as follows: are 5 NTU for turbidity,

0.3 mg/L for iron (Fe), 2 mg/L for copper (Cu), 0.01

mg/L for arsenic (As), 0.05 mg/L for chrome (Cr),

0,02 mg/L for aluminum (Al) and 0.003 mg/L for

cadmium (Cd).

One of the methods that can be used to treat

wastewater into clean or drinking water is the

electrocoagulation process. The

equipment needed to

carry out the electrocoagulation process are as

follows: direct current voltage source (DC), anode,

cathode, process tank made from insulating material,

voltage and current meter (Zaied et al,,2020) .

Aluminum or iron is a material that can be used as

anode or cathode (Salem,2020). When the

electrocagulation process is carried out, the anode

will release metal ions to form a coagulant which

absorbs all pollutants in the water. When aluminum is

used as an anode, the coagulant formed is the

compound Al(OH)

3

. However, if the anode used is

iron, the coagulant compound formed is Fe(OH)

3

.

Wastewater from domestic or restaurants contains

a lot of organic pollutants, so the electrical

conductivity is very weak. If the electrical

conductivity is very weak, the coagulant formed is

very small. So that the time needed to remove

pollutants is longer (Adegoke et al,2020).

Electrical conductivity can be increased by adding

seawater into wastewater. The sea water has the

ability to kill microorganisms and can also produce a

strong electrolyte solution (Pishgar et al,2020).

Sea water added into wastewater will accelerate

the removal of bacteria and pollutants in the

wastewater, while the electrocoagulation process is

being operated (Sefatjoo et al,2020).

The equation of the reaction in the

electrocoagulation process using aluminum as anode

is as follows ( Rigueto et al, 2020):

anode (oxidation process ):

2Al 2Al

+3

+ 6e

-

(1)

cathode (reduction process) :

6H

2

O+6e

-

6OH

-

+3H

2

(2)

in overall :

2Al+6H

2

O2Al(OH)

3

+3H

2

(3)

Sutanto, . and Rahmat, .

Effect of Addition of Sea Water on Changes in Turbidity and Metal Content in Industrial Wastewater Treatment into Drinking Water using Electrocoagulation Process.

DOI: 10.5220/0010536000003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 85-92

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

85

In equation 3 shows that the final result of the

chemical reaction from the electrocoagulation

process is the coagulant compound Al(OH)

3

.

Coagulant Al(OH)

3

is a compound that has the

characteristic of easily absorbing pollutants in the

water.

The cadmium removal efficiency from the

electrocoagulation process carried out at a voltage of

20 volts is 90%. The initial content of Cadmium is 50

mg/L and a pH of 7 (Alameen,,2020).

In the electrocoagulation process of restaurant

wastewater within 30 minutes, the results show that

the efficiency of removal of dissolved oxygen (DO),

color, chemical oxygen demand (COD), phosphorus

pentoxide (P

2

O

5

), soluble reactive polyphosphate

(PO

4

3-

) and particulate phosphorus (PP) are 20.12%,

-32.88%, 12.58%, 17.15%, 19.33%, 16.85%

respectively (Temitope, 2020).

The results of the continuous process

electrocoagulation research on iron pollutant removal

showed that the removal efficiency of iron reached

99.9%. The process was carried out at a current

density of 7.3 mA/cm

2

, a processing time of 50

minutes and an initial concentration of iron 10 mg/L

(Abdulhadi et al,2021).

The electrocoagulation process which is added

with sodium chloride (NaCl) salt can accelerate the

corrosion of aluminum electrodes, but can increase

the electrical conductivity. So that the formation

process of the Al(OH)

3

coagulant compound is

increasing and can also accelerating the process of

removing pollutants in wastewater

Research decoloration in wastewater using

anode and cathode Al only able to remove the color

reaches 95.50%, whereas when using the anode and

the cathode Fe were able to remove the color can

reach 97.24% (Ebba, 2021).

The results of a study on the electrocoagulation

process in in brackish water and sea water showed

that process can reduce silica content (Zhang et al,

2019). The silica content in brackish water is easier to

remove than silica in seawater. The

electrocoagulation process of brackish water

containing 17 mg/L of silica dioxide can remove 60%

of silica dioxide. Meanwhile, the electrocoagulation

process of seawater containing 17 m/L of silica

dioxide was only able to remove 40% of silica

dioxide.

Salinity was removed electrochemically from

saline water through electrocoagulation process

(Raad et al, 2020). In saline water contain ions of Br

−

,

Cl

−

, TDS, and SO

4

2−

.

The study on the electrocoagulation process in

brine which contain of lithium ions showed that more

than 95% of lithium ions (1000 mg/L) could be

recovered with a relatively low energy consumption

of 0.064 kWh/g Li, under operating conditions of

76.9 mA/cm

2

of current density, 6.45 of pH, and

reaction time of 150 minutes (Zhang et al, 2020). That

the lithium recovery from brine by electrocoagulation

was mainly attributed to the chemical precipitation of

aluminum hydroxide coagulants.

Research on aluminum removal from biomass

has been carried out using 7.1 mA/cm

2

current

density, asymmetrical aluminum electrodes and

10 minutes electrolysis time (Hawari et al, 2020). The

aluminum content in the harvested biomass which

decreased by 52% compared to the conventional

symmetrical electrocoagulation electrodes.

Research on cadmium removal in wastewater

containing high concentrations of inorganic salts

using electrocoagulation process. The results showed

that cadmium can be removed up to 99.5% (Xu et al,

2019).

Research on the removal of ammonia and nitrite

in seawater was carried out by electrocoagulation.

The results showed that ammonia can be removed up

to 95% (Song et al, 2020).

The study has been carried out on the effect of

adding sodium salt on electrocoagulation wastewater

treatment. The results of study shown that sodium salt

is very influential on the corrosion of aluminum

surface and found the aluminum metal in the

sediment (Wellner et al, 2018)

The combination of electrocoagulation and

osmosis processes can remove more than 90%

phosphate, more than 80% carbonate and more than

40% dissolved organic pollutants (Azerrad et al,

2019).

Electrocagulation process to completely

eliminate 41 mg/L lead content in wastewater

requires the following process conditions: electric

current density of 0.3 A, pH 6, processing time of 13

minutes and energy of 0.77 watt-hours per gram of

lead removal (Khan et al,2020)

Another alternative to kill or eliminate bacteria

or other microorganisms contained in wastewater can

be done by adding seawater into the wastewater

which is being processed electrocoagulation. Because

the content in seawater consists of 55% chloride salt,

31% sodium salt, 8% sulfate salt, 4% magnesium salt,

1% calcium salt, 1% potassium salt, and the

remaining less than 1% is bicarbonate, bromide, boric

acid, strontium, and fluoride salts. The composition

of the chloride salt content which reaches 55% is very

likely that sea water can be used as a disinfectant or

sterilizer for wastewater, because it will form a

compound hypochlorite (OCl

-

) when combined with

ASAIS 2020 - Annual Southeast Asian International Seminar

86

the electrocoagulation process. The hypochlorite

compound (OCl

-

) will act as a killing agent or oxidize

microorganisms (Wellner et al,2018).

The electrocoagulation process that is carried

out under strong acid conditions is the best choice,

because chlorine (Cl

2

) is the strongest oxidizing agent

compared to HClO. Therefore, a higher pH value

could theoretically increase the electrochemical

oxidation of pollutants where HClO and ClO

-

are not

affected by gas desorption and can act as oxidizing

agents (Anglada,2009). The following equation for

the reaction is the evolutionary reaction of chlorine in

the indirect oxidation process which is

influenced by

pH:

Cl → 1/2 Cl

2

+ e− (4)

Cl

2

+ H

2

O → HOCl + H

+

+ Cl

−

(5)

HOCl → ClO

−

+ H

+

(6)

Increasing the concentration of Cl

-

can increase

removal or decrease the content of pollutants, but

there is also an increase in the formation of

chlorinated organic compounds which are quite toxic.

High concentrations of electrolytes can increase the

conductivity of the solution and reduce the demand

for electrical voltage from the electrocoagulation cell.

Thus it can be explained that the electrochemical

oxidation process will be more economical or cheaper

if the treated wastewater has a high level of salinity.

An important phenomenon that occurs in the

electrocoagulation process is the formation of an

oxidizing agent such as HOCl, OCl

−

, ClO

2

and Cl

2

.

The oxidizing agent that is formed is to kill

microorganisms The reaction mechanism can be

explained as follows (Ghernaout et al,2020) :

2Cl

−

→ Cl2 + 2e− (7)

Cl

2

+ 2OH− → H

2

O + OCl

−

+ Cl

−

(8)

Cl

2

+ 4H

2

O → 2ClO

2

+ 8e

−

(9)

2 METHOD

The research method that has been carried out

consists of preparation of materials, preparation of

equipment and implementation of research

2.1 Materials

Materials needed include seawater, industrial

wastewater and aluminum HTC 16-35.

2.2 Equipments

The equipments needed include: electrocoagulation

cells, waste water tanks, settling tanks, clean water

storage tanks, electric power sources, electric voltage

measuring devices, flow meters, turbidimeter and

AAS (Atomic Absorption Spectrophotometer).

2.3 Implementation

2.3.1 Wastewater Quality Measurement

Several parameters are measured to determine the

quality of wastewater, including: turbidity is

measured by a turbidimeter, metal content is

measured by AAS and the level of acidity is measured

by a pH meter.

2.3.2 Constructing Research Equipments

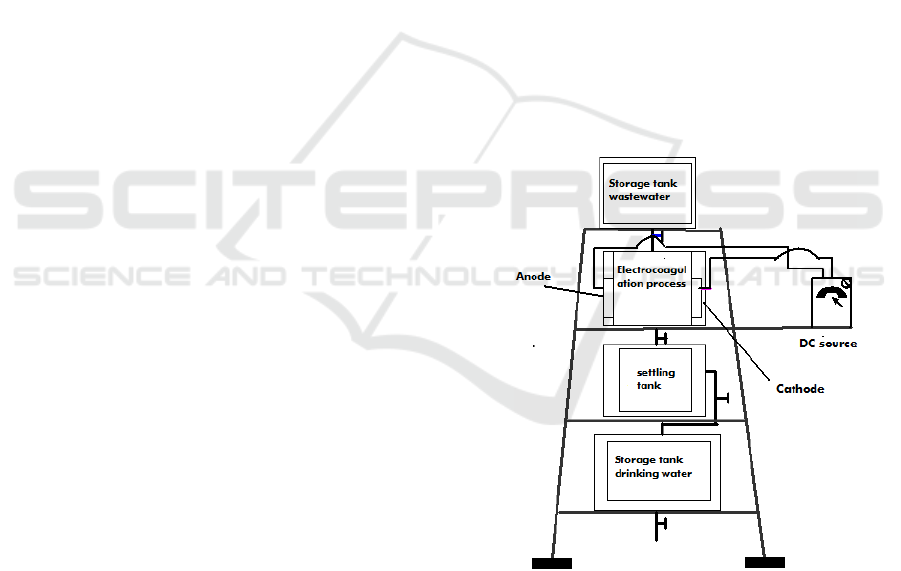

The equipments used for research can be seen in

Figure 1, consists of a voltage source,

electrocoagulation process cells, waste water tanks,

settling tanks, clean water tanks, electric current and

voltage meters.

Figure 1: The series of research tools

2.3.3 Research Implementation

The wastewater 4.5 liters was drained off into the

three cells of electrocoagulation process tank. The

process was conducted at 12 Volt in voltage and

observed of change of the turbidity and metal content

in interval time of 10 minutes. Subsequently, the

same procedure was carried out by adding sea water

with varying volumes of 5, 10 and 15 mL. The

Effect of Addition of Sea Water on Changes in Turbidity and Metal Content in Industrial Wastewater Treatment into Drinking Water using

Electrocoagulation Process

87

turbidity is measured using the turbidimeter and

metals content is measured using Atomic Absorption

Spectrophotometer (AAS).

3 RESULT AND ANALYSIS

Laboratory test results of electronics industry

wastewater parameters shown in table 1. According

to table 1, it appears that the initial content of the

metals in wastewater is 3.55 mg/L for copper, 0.78

mg/L for aluminum and 1.25 mg/L for iron.

According to the regulation of the minister of health

No.492/Menkes/Per/IV/2010, shown that all content

of metals in wastewater has not met the requirements

for drinking water standards.

Table 1: Results of measurements of electronics industry

wastewater

Parameters Measurement results

Copper (Cu) 3.55 mg/L

Aluminum (Al) 0.78 mg/L

Chrome (Cr) not detected

Iron (Fe) 1.25 mg/L

pH 7.54

Turbidity 44.08 NTU

The results of research by impact of addition of sea

water in wastewater treatment in electrocoagulation

process presented in 3 views, namely: impact of

addition of sea water to changes turbidity, impact of

addition of sea water to changes copper content and

impact of addition of sea water to changes iron

content. Each research result, then can be seen in the

sub-section discussion from 3.1 until 3.4.

3.1 Impact of Addition of Sea Water to

Changes in Water Turbidity

The laboratory test results of water turbidity, shown

in table 2. From table 2, can be seen that the addition

of sea water in the electrocoagulation process is able

to remove the turbidity in wastewater. The

electrocoagulation process which is carried out

without the addition of sea water, the turbidity level

can be reduced from 44.08 NTU to 18.20 NTU or

equal to 58.71% in 110 minutes for process time. If

the process is carried out for up to 120 minutes, it will

not be able to produce drinking water standard,

because the turbidity of the water is 12.21 NTU or

more than 5 NTU. Furthermore, the

electrocoagulation process which was carried out for

120 minutes with the addition 5 mL of sea water had

not yet obtained the water drinking standard. Because

turbidity of water is 6.27 NTU. Meanwhile, the

electrocoagulation process, which was carried out for

110 minutes with the addition of 10 mL of sea water,

was able to produce water that has a drinking water

standard with turbidity of 3.25 NTU or less than of 5

NTU. In this case the turbidity of water can be

reduced from 44.08 to 3.25 or equal to 92.63 %.

When the electrocoagulation process is carried

out using aluminum as an anode, an Al(OH)

3

coagulant will be formed. The Al(OH)

3

coagulant is

an adsorbant that can absorb pollutants in water, so

that the turbidity will be reduced in wastewater.

Table 2: Results of measurements of turbidity

Time addition of sea water

(minute) 0 mL 5mL 10 mL 15 mL

0 44.08 44.08 44.08 44.08

10 43.98 42.24 41.55 40.85

20 43.18 41.14 39.25 38.15

30 42.68 39.24 37.85 34.56

40 41.21 36.27 34.25 32.76

50 39.51 34.87 32.54 30.12

60 37.48 31.29 28.25 26.76

70 34.21 28.27 24.85 22.23

80 30.71 22.54 19.25 16.76

90 27.29 18.37 12.65 12.34

100 22.14 14.43 4.85 3.76

110 18.20 10.27 3.25 1.23

120 12.21 6.27 1.25 0.16

3.2 Impact of Addition of Sea Water to

Changes in Copper Content

The laboratory test results of copper content, shown

in table 3. From table 3, can be seen that the addition

of sea water in the electrocoagulation process is able

to remove the copper content in wastewater. The

copper content can be reduced from 3.55 mg/L to

2.02 mg/L or equal to 43.10 % at 80 minutes for

process time without adding sea water. If the

electrocoagulation process is carried out for up to 120

minutes, it will produce the water that is as drinking

water standard. Because the copper content in the

water was 0.98 mg/L or less than 2 mg/L. In this case

it is clearly shown that the copper content can be

reduced from 3.55 mg/L to 0.98 mg/L or equal to

72.39%. Furthermore, the electrocoagulation process

which was run for up to 70 minutes with the addition

of 5 mL of sea water has been able to produce

drinking water. Because copper content in the water

was 1.85 mg/L or less than 2 mg/L or copper content

can be reduced from 3.55 to 1.85 mg/L that was

ASAIS 2020 - Annual Southeast Asian International Seminar

88

equivalent of 47.44 %. Meanwhile, the

electrocoagulation process which was carried out for

60 minutes with the addition of 10 mL of sea water,

was able to produce water that has a drinking water

standard with copper content was 1.91 mg/L or less

than of 2 mg/L. In this case the copper content in the

water has been removed from 3.55 to 1.91 mg/L or

equal to 45.74 %. Furthermore, the electrocoagulation

process which was run for up to 50 minutes with the

addition of 15 mL of sea water has been able to

produce drinking water. Because copper content in

the water was 1.98 mg/L (less than 2 mg/L) or copper

content can be reduced from 3.55 to 1.98 mg/L that

was equivalent of 43.75 %.

Table 3: Results of measurements of copper content

Time addition of sea water

(minute) 0 mL 5mL 10 mL 15 mL

0 3.55 3.55 3.55 3.55

10 3.50 3.48 3.28 3.00

20 3.42 3.32 3.02 2.67

30 3.21 3.08 2.82 2.45

40 3.01 2.83 2. 45 2.18

50 2.86 2.54 2.12 1.98

60 2.56 2.21 1.91 1.57

70 2.21 1.85 1.74 1.23

80 2.02 1.56 1.54 1.01

90 1.83 1.32 1.12 0.91

100 1.47 1.03 0.93 0.73

110 1.21 0.89 0.67 0.54

120 0.98 0.67 0.47 0.32

3.3 Impact of Addition of Sea Water to

Changes in Iron Content

The laboratory test results of iron content, shown in

table 4. From table 4, can be seen that the addition of

sea water in the electrocoagulation process is able to

remove the iron content in wastewater.

If the process is conducted without the addition

of sea water, then to get water that is drinking water

standard it takes a minimum of 120 minutes. In this

case iron content can be removed from 1.25 to 0.21

mg/L or equivalent to 83.20 %. The maximum

recommended iron content in drinking water is 0.3

mg/L (according to drinking water requirements).

If the process is conducted with the addition 5

mL of sea water, then to get water that is drinking

water standard it takes a minimum of 100 minutes for

process time. In this case iron content can be reduced

from 1.25 to 0.26 mg/L (less than 0.3 mg/L) or

equivalent to 78.51%. It appears that the time

required for the process is 10 minutes faster than the

process without adding sea water.

If the electrocoagulation process is carried out

with the addition 10 mL of sea water, then to get water

that is drinking water standard it takes a minimum of

100 minutes. In this case iron content can be reduced

from 1.25 to 0.26 mg/L (less than 0.3 mg/L) or

equivalent to 79.20 %. It appears that the time

required for the process is 20 minutes faster than the

process without adding sea water or 10 minutes faster

than the process with adding 5 mL sea water.

If the electrocoagulation process is carried out

with the addition 15 mL of sea water, then to get water

that is drinking water standard it takes a minimum of

80 minutes. In this case iron content can be reduced

from 1.25 to 0.22 mg/L (less than 0.3 mg/L) or

equivalent to 82,40 %. It appears that the time

required for the process is 40 minutes faster than the

process without adding sea water or 20 minutes faster

than the process with adding 10 mL of sea water.

The addition of sea water must be limited so that

the quality of the water produced is maintained

according to drinking water standard. However,

turbidity and metal content are maintained so that the

quality of the water produced is in accordance with

drinking water standards. The volume of sea water

recommended is 10 mL and the time for the

processing is 100 minutes and 12 Volts in voltage.

The water turbidity in this condition is 4.85 NTU, the

copper content is 0.93 mg/L and the iron content is

0.27 mg/L.

The process of removing iron content in water

can be accelerated by adding seawater. Because the

added sea water can increase the electrical

conductivity, so that the electric current that flowed is

greater than the initial current. The increasing electric

current can accelerate the formation rate of the

Al(OH)

3

coagulant. The coagulant of Al(OH)

3

which

functions as an absorbent compound and precipitates

iron pollutants in the water.

Effect of Addition of Sea Water on Changes in Turbidity and Metal Content in Industrial Wastewater Treatment into Drinking Water using

Electrocoagulation Process

89

Table 4: Results of measurements of iron content

Time addition of sea water

(minute) 0 mL 5mL 10 mL 15 mL

0 1.25 1.25 1.25 1.25

10 1.20 1.18 1.12 1.10

20 1.19 1.09 1.01 0.99

30 1.12 0.93 0.90 0.87

40 1.00 0.89 0.76 0.71

50 0.91 0.72 0.67 0.58

60 0.82 0.63 0.56 0.47

70 0.71 0.52 0.43 0.31

80 0.62 0.43 0.38 0.22

90 0.55 0. 37 0.31 0.19

100 0.41 0.32 0.27 0.12

110 0.31 0.26 0.18 0.09

120 0.21 0.18 0.07 0.01

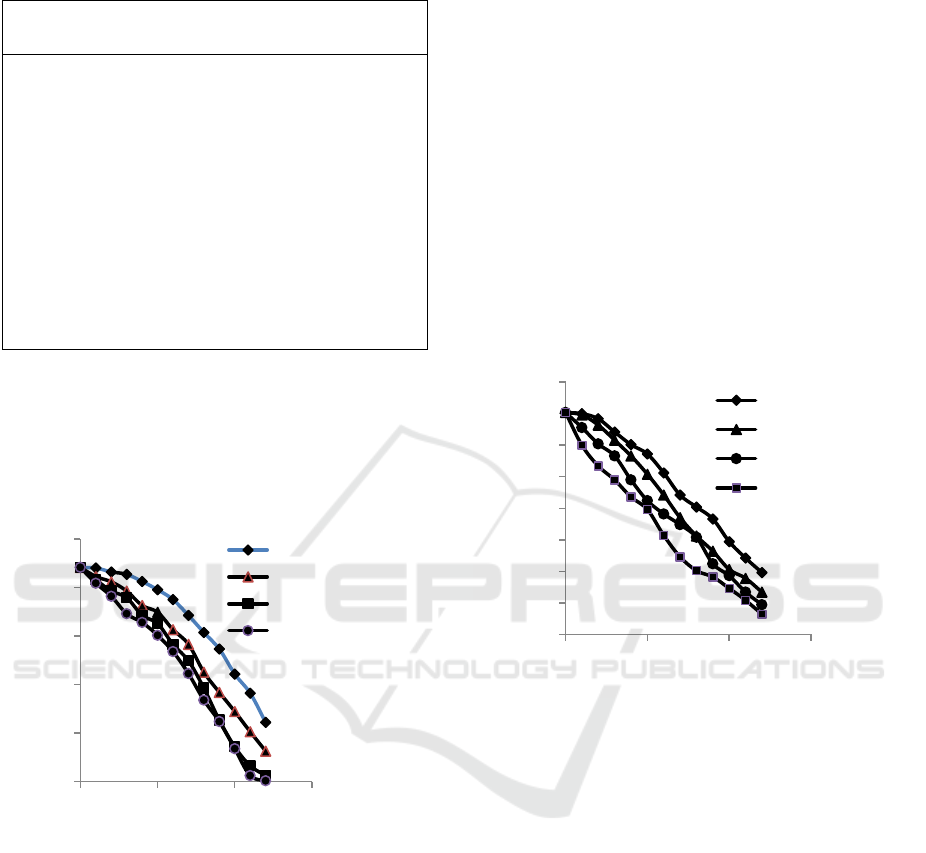

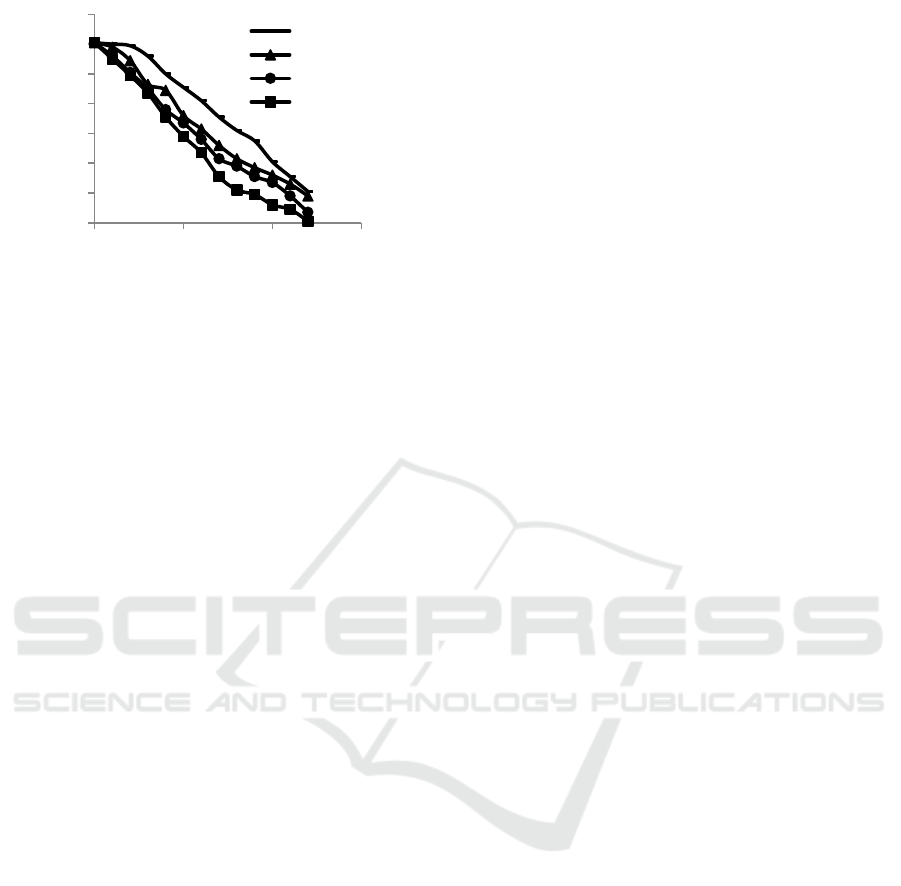

3.4 Curves of Changes of Turbidity

and Metal Content

Figure 2 is made from the data in table 2 which shows

the relationship of the effect of changes in sea water

addition to water turbidity.

Figure 2: The relationship between changes of sea water

additions to water turbidity

According to figure 2, it can be seen that the

performance of the electrocoagulation process to

remove turbidity increases when the sea water is

added into the wastewater. If more and more sea

water is added to the electrocoagulation process, the

process of reducing water turbidity will be

accelerated. The addition of sea water into

wastewater will increase the electrical conductivity.

The increasing electrical conductivity will accelerate

the formation of the Al(OH)

3

coagulant. The Al

(OH)

3

compound is a material that absorbs pollutants

in water and precipitates it to the bottom of the

process tank, so that the water is getting clearer.

Figure 3 is made from the data in table 3 which

shows the relationship of the effect of changes in sea

water addition to remove copper content in water.

According to figure 3, it can be seen that the

performance of the electrocoagulation process to

remove copper content increases when the sea water

is added into the wastewater. If more and more sea

water is added to the electrocoagulation process, the

process of reducing copper content in water will be

accelerated. The addition of sea water to wastewater

will increase the electrical conductivity. The

increasing electrical conductivity will accelerate the

formation of the Al(OH)

3

coagulant. The Al(OH)

3

compound is a material that absorbs copper content

in water and precipitates it to the bottom of the

process tank, so that the copper content in the water

is getting lower.

Figure 3: The relationship between changes of sea water

additions to copper content

Figure 4 is made from the data in table 4 which

shows the relationship of the effect of changes in sea

water addition to remove iron content in the water.

According to figure 4, it can be seen that the

performance of the electrocoagulation process to

remove iron content increases when the sea water is

added into the wastewater. If more and more sea

water is added to the electrocoagulation process, the

process of reducing iron content in water will be

accelerated. The addition of sea water into

wastewater will increase the electrical conductivity.

The increasing electrical conductivity will accelerate

the formation of the Al(OH)

3

coagulant. The Al

(OH)

3

compound is a material that absorbs iron

content in water and precipitates it to the bottom of

the process tank, so that the iron content in the water

is getting lower.

0

10

20

30

40

50

050100150

Turbidity,NTU

Time, minute

seawater0mL

seawater5mL

seawater10mL

seawater15mL

0

0,5

1

1,5

2

2,5

3

3,5

4

050100150

Copper content, mg/L

Time, minute

sea water 0 mL

sea water 5 mL

sea water 10 mL

sea water 15 mL

ASAIS 2020 - Annual Southeast Asian International Seminar

90

Figure 4: The relationship between changes of sea water

additions to iron content

4 CONCLUSION

Sea water added to wastewater which is being

processed electrocoagulation can remove turbidity,

copper and iron content. The recommended variable

values to operate the electrocoagulation process are

12 V for voltage, 10 mL for seawater requirements

and 100 minutes for processing time. Efficiency

removal of turbidity is 88.99 %, copper content is

80.97% and iron content is 70.95 % repectively.

ACKNOWLEDGEMENTS

The Authors would like to thank the head of research

and community unit, Jakarta State Polytechnic for

financial support, so that the authors are able to

complete this research. Thank a lot also to Afiliation-

Laboratory FMIPA University of Indonesia UI for

giving laboratory equipment support.

REFERENCES

Abdulhadi, B., Kot, P., Hashim, K., Shaw, A., Muradov, M.

and Khaddar, R.A., 2021. Continuous-flow

Electrocoagulation (EC) Process for Iron Removal

from Water: Experimental, Statistical and Economic

Study, Science of The Total Environment.

Adegoke, A.T, Abayomi and Temitayo, E.,2020. A

Preliminary Study on The Treatment of Restaurant

Wastewater Using Electrocoagulation Technique,

Journal of Degraded and Mining Lands Management.

Alameen, M. and Majeed, N., 2020. Removal of Cadmium

from Industrial Wastewater using Electrocoagulation

Process, Chemical, Petroleum and Environmental

Engineering.

Anglada, A., Urtiaga, A. and Ortiz, I., 2009. Contributions

of Electrochemical Oxidation to Waste-water

Treatment: Fundamentals and Review of Applications,

Society of Chemical Industry.

Azerrad, S. P., Isaacs, M. and Dosoretz, C. G., 2019.

Integrated Treatment of Reverse Osmosis Brines

Coupling Electrocoagulation with Advanced Oxidation

Processes, Chemical Engineering Journal.

Ebba, M., 2021. Application of Electrocoagulation for the

Removal of Color from Institutional Wastewater:

Analysis with Response Surface Methodology, Journal

of Environmental Treatment Techniques.

Ghernaout, D. and Elboughdiri, N., 2020.

Electrocoagulation Process in the Context of

Disinfection Mechanism, Scientific Research.

Hawari, A.H., Alkhatib, A.M., Das, P., Thaher, M. and

Benamor, A.,2020. Effect of the Induced

Dielectrophoretic Force on Harvesting of Marine

Microalgae (Tetraselmis sp.) in Electrocoagulation,

Journal of Environmental Management.

Khan, S.U., Mahtab, M.S.and Izharul Haq Farooqi, I.H.,

2020. Enhanced Lead (II) Removal with Low Energy

Consumption in an Electrocoagulation Column

Employing Concentric Electrodes: Process

Optimisation by RSM Using CCD, International

Journal of Environmental Analytical Chemistry.

Pishgar, Z., Samimi, A., Kalhori, D.M. and

Shokrollahzadeh, S.,2020. Comparative Study on The

Harvesting of Marine Chlorella Vulgaris Microalgae

from a Dilute Slurry Using Autoflocculation-

Sedimentation and Electrocoagulation-Flotation

Methods, International Journal of Environmental

Research.

Raad, A. A. A., Hanafiah, M. M, Naje, A. S., Ajeel, M.A.,

2020. Optimized parameters of the electrocoagulation

process using a novel reactor with rotating anode for

saline treatment, Environmental Pollution.

Rigueto,C.V.T., Nazari,M.T., Souza,C.F.D, Cadore,J.S.,

Brião, V.B. and Jeferson Steffanello Piccin, J.S, 2020.

Alternative Techniques for Caffeine Removal from

Wastewater: an Overview of Opportunities and

Challenges, Journal of Water Process Engineering

Salem, M. A., 2020. Removal of Cadmium from Industrial

Wastewater Using Electrocoagulation Process, Journal

of Engineering.

Sefatjoo, P.,Moghaddam,M.R.A.and Mehrabadi,A.R.,

2020. Evaluating Electrocoagulation Pretreatment Prior

to Reverse Osmosis System for Simultaneous Scaling

and Colloidal Fouling Mitigation: Application of RSM

in Performance and Cost Optimization, Journal of

Water Process Engineering

Song, J., Yin, Y., Li, Y.,Gao, Y. and Liu,Y.,2020. in-Situ

Membrane Fouling control by Electrooxidation and

Microbial Community in Membrane electro-bioreactor

Treating Aquaculture Seawater, Bioresource

Technology.

Wellner, D. B., Couperthwaite, S. J. and Millar, G.J.,2018.

Influence of Operating Parameters During

Electrocoagulation of Sodium Chloride and Sodium

0

0,2

0,4

0,6

0,8

1

1,2

1,4

050100150

Ironcontent,mg/L

Time,minute

seawater0mL

seawater5mL

seawater10mL

seawater15mL

Effect of Addition of Sea Water on Changes in Turbidity and Metal Content in Industrial Wastewater Treatment into Drinking Water using

Electrocoagulation Process

91

Bicarbonate Solutions Using Aluminium Electrodes,

Journal of Water Process Engineering.

Xu, L., Wu, D., Liu, W., Xu, X., Cao, G., 2019.

Comparative Performance of Green Rusts Generated in

Fe

0

–Electrocoagulation for Cd

2+

Removal from High

Salinity Wastewater: Mechanisms and Optimization,

Journal of Environmental Management.

Zaied, B.K, Rashid, M., Nasrullah,,M..Zularisam,

A.W.,Pant,D.and Singh, L., 2020. A Comprehensive

Review on Contaminants Removal from

Pharmaceutical Wastewater by Electrocoagulation

Process, Science of The Total Environment.

Zhang, X.,Lu, M., Idrus, M.A.M., Crombie,C.,Veeriah and

Jegatheesan,V., 2019. Performance of Precipitation and

Electrocoagulation as Pretreatment of Silica Removal

in Brackish Water and Seawater, Process Safety and

Environmental Protection.

Zhang,Y., Xu, R., Sun, W. , Wang, L. and Tang, H., 2020.

Li Extraction from Model Brine via Electrocoagulation:

Processing, kinetics, and Mechanism, Separation and

Purification Technology.

.

.

ASAIS 2020 - Annual Southeast Asian International Seminar

92