Effects of the Type and Concentration of Starch on

the Quality of Alginate-based Edible Film

Giyatmi

1

, Eka Ngadi Parida

1

, Hari Eko Irianto

2

, Dina Fransiska

2

and Agusman

2

1

Study Program of Food Technology, Sahid University, Jakarta,

Jl. Prof. DR. Soepomo, Tebet, South Jakarta, Indonesia

2

Research and Development Center for Marine and Fisheries Product Processing and Biotechnology,

Jl. KS Tubun Petamburan VI, Slipi, Central Jakarta, Indonesia

mr.agusman@gmail.com

Keywords: Alginate, Edible Film, Starch, Mocaf, Breadfruit, Canna.

Abstract: Edible film is a thin layer as an alternative packaging or food coatings that can be consumed. Ingredients that

can be used for manufacturing edible film are alginate and starch. Alginate is normally extracted from brown

seaweed and starch. The advantages of using seaweed and starch as edible film ingredients are low cost and

non-toxic. This study employed a Completely Randomized Factorial Design with two factors of, namely the

type of starch (A1 = canna starch, A2 = mocaf starch, A3 = breadfruit starch) and concentration of starch (B1

= 0 %, B2 = 0,1%, and B3 = 0,3%, and B4 = 0,5%). Experiment was conducted three replications. The

results showed that the different type of starch had a significant effect (α<0.05) on the thickness, tensile

strength, elongation, and water solubility. The concentration of starch had significant effects (α<0.05) on the

moisture content, thickness, tensile strength, elongation, water solubility, and water vapor transmission rate

(WVTR). The best alginate-based edible film was processed using 0.5% mocaf. Mechanical and physical

properties of that alginate-based edible film were 9,91% moisture content, 5,21 Mpa tensile strength, 28,90%

elongation, 97,93% water solubility, and 1709,287 g/cm

2

/24 hour water vapor transmission rate.

Morphological analysis using SEM (Scanning Electron Microscopy) revealed that the surface of alginate-

based edible film was quite smooth and dense but a few starch granules was still found.

1 INTRODUCTION

Edible film is a thin layer that can be used as a food

packaging or coating which can be consumed

together with the packaged products. Edible film is

employed by wrapping, brushing or spraying to

provide selective control of the movement of gas,

water vapor, and solutes as well as protection against

mechanical damage (Sitompul and Zubaidah, 2017).

The main components for producing edible film

can be grouped into three categories, namely

hydrocolloids, lipids, and composites. Some types of

hydrocolloids that can be used for edible film

materials include gelatine, alginate, starch and others

(Milani and Maleki, 2012).

Alginate is a natural polymer which is the main

component of brown algae (Phaeophyceae sp) and an

important compound in the cell walls of algae species

belonging to the Phaeophyceae class. Edible films

from alginate have high hydrophilic properties. The

hydrophilic nature of alginates promotes edible films

made from alginate to absorb water molecules

(Anward, et al, 2013). According to Murdinah, et al.

(2007), alginate has a potential to be processed into

edible film, because alginate is rigid, edible and

renewable nature. Producing edible film from

alginate is one of the efforts to increase the utilization

of seaweed.

Starches are composed of amylose and

amylopectin molecules. Amylose is a fraction that

plays a role in gel formation. Starch has properties

that are easy to form gelatinization making it easily

applied as a forming material and can produce good

plastic (Afriyah, et al, 2015). Breadfruit flour,

Modified Cassava Flour (mocaf) and canna flour are

sources of starch that have not been widely used in

the development of edible films. Breadfruit flour have

amylose and amylopectin contents of 23.95% and

76.05% respectively (Afriyah, 2015). According to

Diniyah, et al (2018), starch content of mocaf is

Giyatmi, ., Parida, E., Irianto, H., Fransiska, D. and Agusman, .

Effects of the Type and Concentration of Starch on the Quality of Alginate-based Edible Film.

DOI: 10.5220/0009998000002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 97-103

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

97

relatively high, i.e. 85-87%. Whereas canna flour

contain starch with amylose and amylopectin levels

of 24.44% and 78.86% correspondingly (Santoso, et

al, 2007).

Based on previous study on edible films with

various natural polymers such as edible film

consisting of alginate-gluten-beeswax (Murdinah, et

al, 2007), the results revealed that edible films with

the best composites of alginate composites, gluten

and beeswax (1: 1: 2) did not affect the moisture

content, thickness, and tensile strength but

significantly affected the elongation and water vapour

transmission rate of the film.

This study developed edible films made from

natural polymers including alginate and three

different types of starch, i.e. canna starch, mocaf

starch and breadfruit starch with sorbitol as

plasticizer.

2 MATERIAL AND METHODS

2.1 Material

The main ingredients used for developing alginate-

based edible films were alginate, canna starch, mocaf

starch and breadfruit starch. Alginate was extracted

from brown seaweed (Sargassum sp) purchased from

Gunung Kidul. Other ingredients were distilled

water, sorbitol and beeswax. The characteristics of

alginate and starches are shown in Table 1.

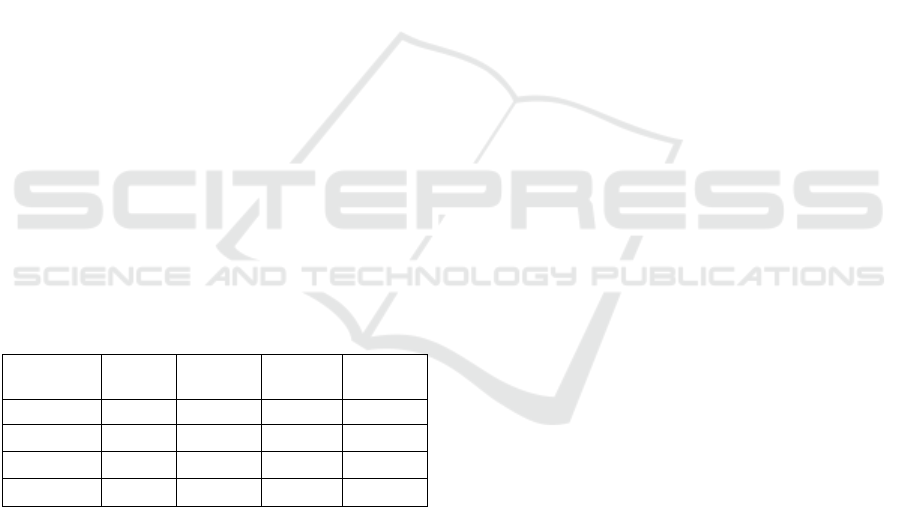

Table 1: Characteristics of Alginate and Starches.

Parameters of

Analyses

Alginate Canna

Starch

Mocaf

Starch

Breadfruit

Starch

Moisture (%) 9.99±0.48 15.00±0.13 9.78±1.13 11.13±0.09

Ash (%) 23.27±0.17 0.25±0.14 1.69±0.04 2.79±0.01

Viscosity (cP) 30.83±4.73 15.83±1.44 18.33±1.44 14.00±1.32

Brightness 33.77±0.80 74.53±0.23 84.87±0.23 70.73±0.12

Moisture content of alginate was in accordance with

the quality standards of Kennedy and Bradshaw

(1987), which was <13%. The moisture content of

mocaf and breadfruit starch met the Indonesian

National Standard (SNI) of mocaf flour which was

<13%, while the moisture content of canna starch was

higher than SNI quality standards. The ash contents

of alginate and starch met the quality standards of

Kennedy and Bradshaw (1987), i.e. <23%. Viscosity

value of alginate produced in this study was in

accordance with the quality standards of Kennedy and

Bradshaw (1987) which is 10 - 5000 cP. In terms of

brightness, the higher value of the white field, the

higher level of material brightness.

2.2 Method

2.2.1 Edible Film Making Process

Alginate-based edible film was processed according

to the method applied by Murdinah (2007), through

modification of the types and concentration of main

ingredients namely alginate and starch as well as the

use of sorbitol as plasticizer. The three types of starch

were canna starch, mocaf starch and breadfruit starch,

meanwhile the starch concentrations levels were 0%,

0.1%, 0.3% and 0.5%. Alginate and starch according

to the type and concentration level of use were mixed

with distilled water in a beaker glass and stirred. The

mixture was then heated to 70ºC. Sorbitol was poured

according to the formulation into the solution while

still stirring the beeswax was subsequently added and

heated at 70ºC. The film solution was then transferred

into 16 x 16 cm acrylic plates. The plates were

allowed to cool at room temperature for 24 hours and

dried in an oven at 45ºC for 24 hours. The plates were

taken out from the oven and the films were then

peeled. The films known as alginate-based edible

films were put in a plastic clip and stored in a

desiccator at room temperature.

2.2.2 Experimental Design and Data

Analysis

This research employed Completely Randomized

Factorial Design (CRFD) with two factors, i.e.

types of starch (A1 = Canna, A2 = Mocaf, A3 =

Breadfruit) and concentration levels of starch (B1 = 0

%, B2 = 0,1%, and B3 = 0,3%, and B4 = 0,5%). All

experiments were run with three replications. The

data were analysed using Univariate Analysis of

Variance (ANOVA) with post host test Tukey’s, and

the level of significance was set at α

<0.05.

2.2.3 Edible Film Characterization

Moisture Content. The moisture content of

alginate-based edible films was determined

following the method described by (Farhan & Hani,

2017). Edible film samples (2 cm × 2 cm) were

cut each of the three random positions and then

placed on a porcelain dish. The edible films were

dried in an oven at 103-105°C until a constant

weight obtained. The moisture content of edible films

was calculated from the weight lost after drying and

initial weight of edible films.

16th AFC 2019 - ASEAN Food Conference

98

Thickness. A digital micrometer (Mitutoyo) with

0,001 mm accuracy level was used to measure the

thickness of alginate-based edible films. Thickness

of ten different random spots of each films were

measured, and the averages values in millimeters

(mm) were reported as thickness.

Tensile Strength and Elongation. Tensile strength

and elongation of alginate-based edible films were

measured using TAXT Plus - Texture Analyzer

(Balqis, et al, 2017), with slight modification. Edible

films were cut into 2 cm x 15 cm. The measurements

were conducted under following condition: 10 cm

initial distance of grip separation, 3 mm/s test speed,

and 3 g trigger forces. Tensile strength (force/initial

cross-sectional area) and elongation at break were

determined using Texture Expert V.1.15 software

package.

Water Solubility. Water solubility of alginate-based

edible film was measured using a method described

by Murni, et al. (2013). Edible film

samples (~3x3 cm

2

) were weighed, placed in

aluminium cups contained 50 ml distilled water, and

then the cups contained films were heated in oven

at 100°C for 30 minutes. In order to avoid evaporation

of water, the cups were tightly closed and kept at

25°C for 24 h and occasionally shaken. Undissolved

films matters were dried in an oven at 40°C until the

constant weight achieved. The water solubility of the

film was determined according to the ratio of weight of

diluted film matter with initial films weight.

Water Vapor Transmission Rate. Water Vapor

Transmission Rate (WVTR) of alginate-based edible

films were determined according to the slightly modified

methods as described by Razzag, et all (2016). WVTR

was gravimetrically measured using metal cups

equipped with an exposed area metal disc. Edible

films were sealed on metal cups containing distilled

water, and then metal cups were placed in an

incubator (37°C, ±24 %RH) for 24 h. The water loss

was measured. The WVTR is the mass of water loss

rate at the specific area for 24 h (g/m

2

/24h).

Morphological Test. Morphological analysis of the

cross section of the alginate-based edible films was

carried out using SEM (Scanning Electron

Microscopy) - JEOL JSM-6360LA referring to a

method as described by Setiani, et al (2013) and

modified in term of the size of the zoom. Edible film

samples were affixed to the set holder which had

double adhesive, then gold metal is coated under

vacuum. The sample was subsequently put into the

SEM, then the topographic image was observed and

magnified 400-500 times.

3 RESULTS

3.1 Characteristics of Edible Film

3.1.1 Moisture Content

Based on Table 2, it is recognised that the higher the

concentration of the starch used, the higher moisture

content of alginate-based edible films will be. It was

probably due to the nature of the hydrophilic starch

molecule, thus the higher the starch concentration

added the higher the moisture content of the alginate-

based edible film. Results of Tukey test showed that

the moisture contents of alginate-based edible film

prepared with various starch concentrations were

significantly different each other at α

<0.05.

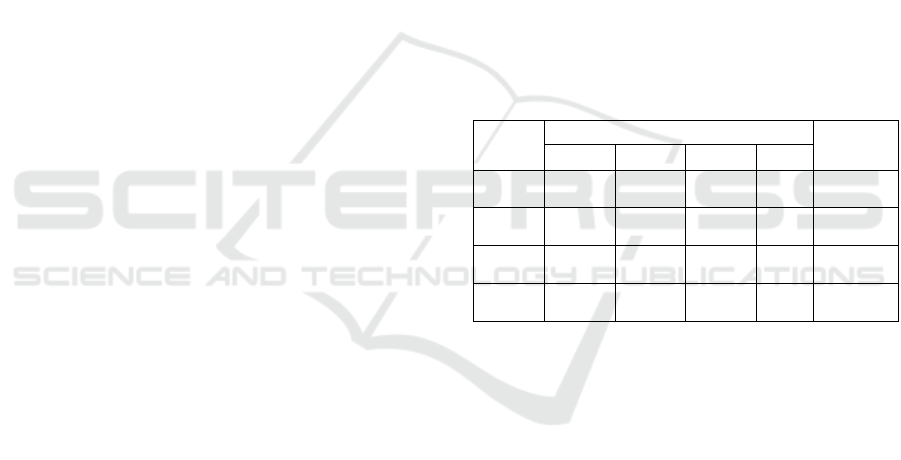

Table 2: Moisture content of alginate-based edible film (%).

Type of

Starch

Concentrations (%)

Average

0 0.1 0.3 0.5

Canna 8.37±

0.32

9.33±

0.02

9.34±

0.24

9.65±

1.95

9.17±

0.56

Mocaf 8.37±

0.32

8.97±

0.31

9.18±

0.66

9.19±

0.15

8.93±

0.39

Breadfrui

t

8.37±

0.32

9.01±

0.12

9.22±

0.25

9.27±

0.43

8.97±

0.41

Average 8.37±

0.00

a

9.10±

0.20

ab

9.25±

0.08

b

9.37±

0.25

b

Murdinah, et al. (2007) informed that moisture

contents of edible films made from alginate, gluten

and beeswax composites were ranging from 21.95 to

24.63%. Edible film prepared from Aloe vera with

breadfruit flour and canna had moisture content

ranging from 4.22 to 22.20% (Afriyah et al., 2015).

Compared to those moisture contents, alginate-based

edible films from this study had lower moisture

contents, i.e. in the range of 8.37 - 9.65%.

3.2 Thickness

Statistically, types of starch (canna, mocaf,

breadfruit) significantly affected the thickness of the

alginate-based edible film. There are two types of

starch polymers namely amylose and amylopectin.

The difference in the structure of the two polymers

influenced the functional properties of starch (Teti,

2006). Increasing edible film thickness was also

affected by the unique colloidal compound properties

as thickener and suspender, and the interaction

Effects of the Type and Concentration of Starch on the Quality of Alginate-based Edible Film

99

between edible film constituent components (Galus

and Lenart, 2013).

Likewise, the higher the starch concentration

used, the higher the thickness of alginate-based edible

films. It was probably due to the higher the amount of

ingredient used in the film matrix, the higher the total

solids. McHugh, et al (1994) noted that film thickness

was mainly influenced by the concentration of

dissolved solids in the film-forming solution.

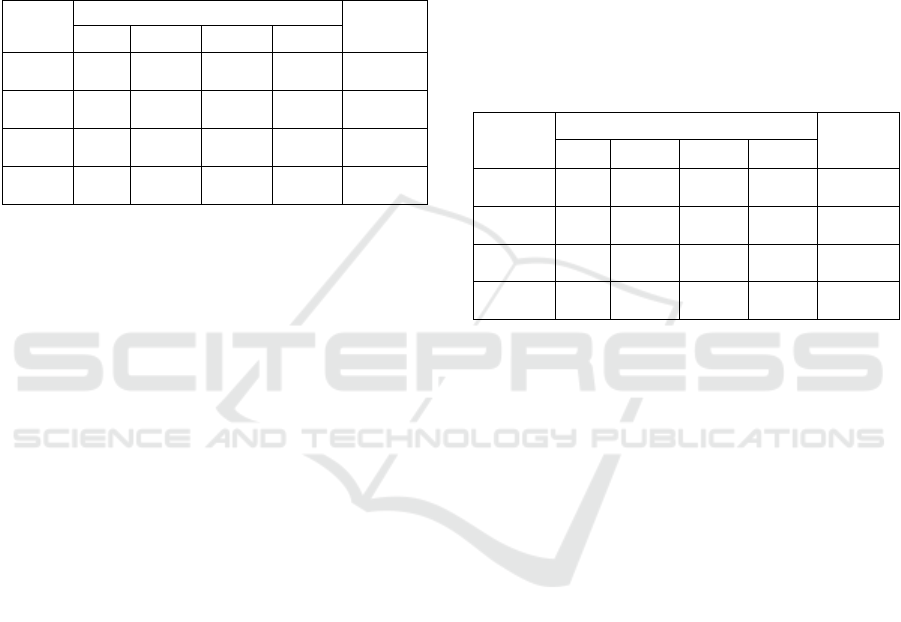

Table 3: Thickness of alginate-based edible film (mm).

Type of

Starch

Concentrations(%)

Average

0 0.1 0.3 0.5

Canna 0.06±

0.00

a

0.06±

0.00

a

0.06±

0.01

a

0.06±

0.00

ab

0.06±

0.00

a

Mocaf 0.06±

0.00

a

0.06±

0.00

a

0.06±

0.00

ab

0.07±

0.01

ab

0.06±

0.01

a

Breadfruit 0.06±

0.00

a

0.08±

0.01

c

0.10±

0.01

cd

0.10±

0.01

d

0.08±

0.02

b

Average 0.06±

0.00

a

0.07±

0.01

b

0.07±

0.02

ab

0.08±

0.02

c

Tukey test results showed that the thickness of

alginate-based edible film processed using canna,

mocaf and breadfruit starches with different

concentration levels were significantly different each

other at

α <0.05. There were significant interaction

effects between starch type and starch concentration

on the thickness of alginate-based edible film.

As shown in Table 3, the thickness of alginate-

based edible films was in the range of 0.0557 - 0.1028

mm. Those values were comparable to the thickness

of edible film produced by Murdinah, et al (2007)

using alginate, gluten and beeswax composites as raw

materials, i.e. 07 - 0.11 mm. According to Japanese

Industrial Standard, the maximum film thickness

value is 0.25 mm. So, the alginate-based edible film

produced in this study is in accordance with the

quality standards set by the Japanesse Industrial

Standard.

3.3 Tensile Strength

Edible films with high tensile strength are required

for packaging food products to provide protection of

food during handling, transportation and marketing

(Pitak and Rakshit, 2011). Table 4 showed that

breadfruit starch produced alginate-based edible film

with the lowest tensile strength compared to others. It

was also revealed that the higher the concentration of

starch used, the higher the tensile strength of edible

film. The higher use of starch provided a stronger

structure to the film matrix so that the tensile strength

value was high. It was possible that polysaccharides

could function in maintaining the cohesiveness and

stability of edible films. Increased tensile strength due

to increased starch concentration probably related to

the presence of amylose and amylopectin, in which

both components played an important role in the

formation of edible films. Amylose levels increased

with increasing starch concentration.

The results of Tukey test showed that the tensile

strength of alginate-based edible films processed

using canna, mocaf, and breadfruit starches with

various starch concentration levels were significantly

different each other at α

<0.05. There were significant

interaction effects between starch type and starch

concentration on the tensile strength of edible films.

Table 4: Tensile Strength of alginate-based edible film

(MPa).

Type of

Starch

Concentrations(%)

Average

0 0.1 0.3 0.5

Canna

1.90±

0.05

a

2.75±

0.56

a

4.63±

0.99

b

4.95±

0.21

b

3.56±

1.47

b

Mocaf

1.90±

0.05

a

4.15±

0.27

b

4.69±

0.53

b

5.21±

0.79

b

3.99±

1.46

b

Breadfruit

1.90±

0.05

a

2.10±

0.19

a

2.32±

0.19

a

2.78±

0.38

a

2.28±

0.38

a

Average

1.90±

0.00

a

3.00±

1.05

b

3.88±

1.35

c

4.31±

1.33

c

Table 4 showed that tensile strength values of

alginate-based edible film processed using alginate

and various starches were in the range of 1.90-5.21

MPa. Those tensile strength values were greatly

different compared to the tensile strength values of

edible films produced by Murdinah, et al. (2007) and

Afriyah et al. (2015). Tensile strength of edible films

made from alginate, gluten and beeswax composites

was 13.41-34.87 MPa (Murdinah, et al., 2007).

While, tensile strength of edible film using aloe vera,

breadfruit flour and canna flour as raw materials was

in the range of 1.76-16.23 MPa (Afriyah, et al., 2015).

According to the Japanese Industrial Standard, the

minimum tensile strength value of edible film is 3.92

MPa. In regard to that standard, alginate-based edible

film produced using breadfruit starch in this study is

not in accordance with the standard, on the other hand

the ones prepared using mocaf and canna starches

meet the Japanese Industrial Standards.

3.4 Elongation

Elongation is the percentage increase in the length of

the alginate-based edible film when pulled until torn

or broken. Table 5 shows that the higher the

concentration of starch used, the higher the

elongation of alginate-based edible film. Increasing

the concentration of starch in edible film formulation

16th AFC 2019 - ASEAN Food Conference

100

resulted in increased elongation value. High amylose

content and the addition of plasticizer was suspected

to cause a high elongation of edible film. This

indication is supported by the fact that a flexible and

strong film can be made from the starch containing

amylose, while amylopectin provides stability and

elasticity in the formation of edible films. Elongation

of alginate-based edible film using 0.5% breadfruit

and 0.5% canna starch was significantly different

from the others at α

<0.05.

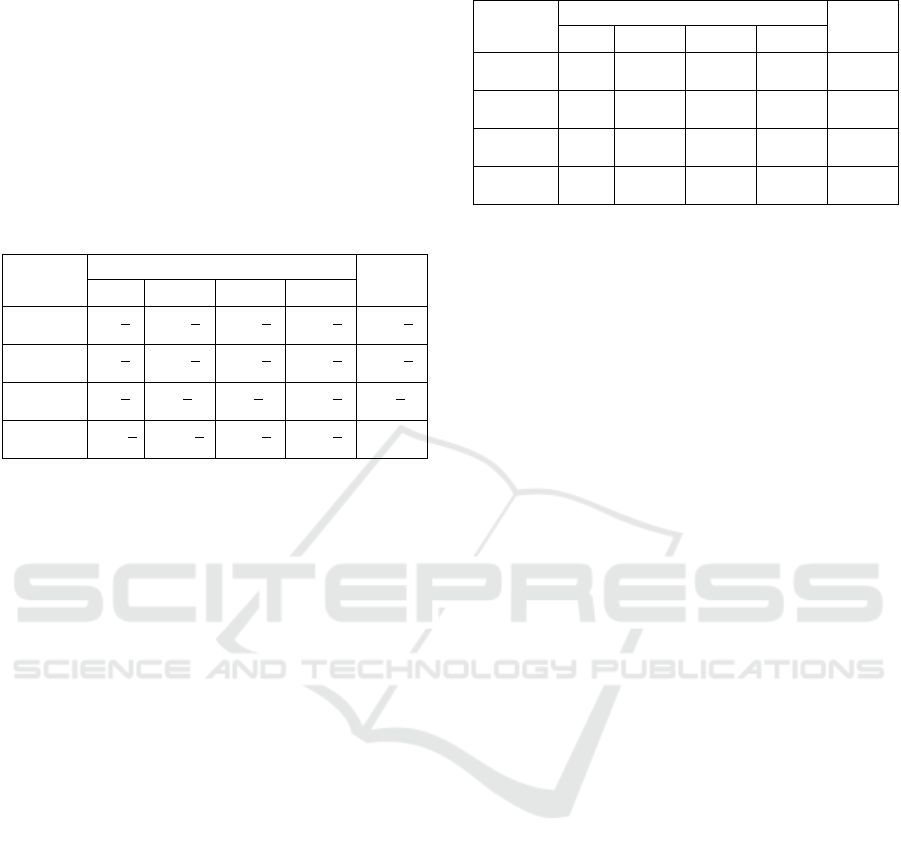

Table 5: Elongation of alginate-based edible film (%).

Type of

Starch

Concentrations(%)

Average

0 0.1 0.3 0.5

Canna 4.60+

0.10

a

21.13+

0.80

c

29.23+

0.59

d

33.00+

2.74

e

21.99+

12.61

c

Mocaf 4.60+

0.10

a

20.67+

0.85

c

28.53+

1.97

d

28.90+

1.57

d

20.68+

11.37

b

Breadfruit 4.60+

0.10

a

7.23+

0.40

a

7.80+

0.26

a

15.73+

0.87

b

8.84+

4.80

a

Average 4.60 +

0.10

a

16.34 +

0.79

b

21.85+

0.94

c

25.88+

1.73

d

Murdinah et al. (2007) reported that elongation of

edible films made from alginate, gluten and beeswax

composites was ranging from 1 - 2.5%. Afriyah, et al.

(2015) noted that elongation of edible films made of

aloe vera, breadfruit flour and canna was in the range

of 9.23-50.22%. Meanwhile, elongation of alginate-

based edible film produced in this study was

comparable to both above results, i.e. in the range of

4.60 - 33.0%. Japanese Industrial Standard mentioned

that the minimum film elongation value of edible film

is 5%. Alginate-based edible film produced in this

study is in accordance with the Japanese Industrial

Standard.

3.5 Water Solubility

Table 6 shows that the water solubility value of

alginate-based edible films produced using various

starch concentrations was insignificantly difference,

but the trend informed that the higher the

concentration of starch used, the lower the water

solubility of alginate-based edible film. Edible films

with high water solubility values were suitable to be

used in ready-to-eat food products because they

dissolve easily when consumed (Pitak and Rakshit,

2011).

Table 6: Water solubility of alginate-based edible film (%).

Type of

Starch

Concentrations (%)

Average

0 0.1 0.3 0.5

Canna 99.20±

0.23

e

97.33±

0.31

bc

97.20±

0.10

b

95.07±

0.32

a

97.20±

1.69

a

Mocaf 99.20±

0.23

e

98.83±

0.93

cde

98.23±

0.51

bcde

97.93±

1.07

bcde

98.55±

0.57

b

Breadfruit 99.20±

0.23

e

99.10±

0.30

de

97.83±

0.47

bcde

97.63±

0.46

bcd

98.44±

0.82

b

Average 99.20±

0.20

c

98.42±

0.95

b

97.75±

0.52

b

96.88±

1.57

a

Statistically, the type of starch, concentration of

starch and their interactions significantly affected the

water solubility of alginate-based edible films.

Siswanti, et al (2009) reported that the water

solubility of edible film processed from iles-iles and

maizena glucosamanan composite was 50.58%.

Alginate-based edible film produced in this study had

a higher water solubility compared to that value, i.e.

95.07 - 99.20%. Low water solubility value is one of

the important requirements for edible film, especially

for use as food packaging of high moisture content

and high water activity products (Singh, et al, 2014).

3.6 Water Vapor Transmission Rate

(WVTR)

WVTR is the amount of water vapor that passes

through the film surface per area (Fransiska, et al,

2018). Table 7 shows that the WVTR of alginate-

based edible film produced from breadfruit starch was

significantly different from alginate-based edible

films processed using canna and mocaf starches. The

significant effect was shown by the fact that the

higher concentration of starch used, the lower the

WVTR of alginate-based edible films.

Results of Tukey test revealed that WVTR of

alginate-based edible films using starch

concentrations of 0.1%, and 0.3% was insignificantly

different, but WVTR of alginate-based edible films

using starch concentration of 0% and 0.5% was

significantly different. WVTR of alginate-based

edible films in this study showed a trend to decrease

with increasing starch concentration levels. The

decrease of WVTR was probably due to due to a

stronger polymer bonding with the increase of the

starch concentrations used. Increasing the bond

strength between polymers will reduce the water

vapor transmission of edible films to gas, vapor and

porosity, so that the function of edible film as a barrier

to water vapor entry will increase (Pramadita, 2011).

Effects of the Type and Concentration of Starch on the Quality of Alginate-based Edible Film

101

Table 7: Water vapor transmission rate of alginate-based

edible film (g/m

2

/24 hours).

Type of

Starch

Concentrations (%)

Average

0 0.1 0.3 0.5

Canna

1513.94

±

339.05

2191.58

±204.70

2374.17

±

471.42

1997.23

±

162.50

2019.23

±370.35

a

Mocaf

1513.94

±

339.05

2326.72

±284.84

2374.95

±

156.83

1709.29

±

366.58

1981.22

±434.62

a

Bread

fruit

1513.94

±

339.05

2698.67

±235.06

3048.75

±

192.41

2047.43

±

118.62

2327.20

±682.71

b

Average

1513.94

±

0.00

a

2405.66

±262.60

c

2599.29

±

389.24

c

1917.98

±

182.47

b

Murdinah, et al (2007) noted that WVTR of edible

films made from alginate, gluten and beeswax

composites was ranging from 154.34 - 284.40 g/m

2

/

24 hours. Afriyah, et al (2015) obtained that WVTR

of edible film formulated using aloe vera, canna flour

and breadfruit was in the range 2.83 - 4.66 g/m

2

/24

hours. WVTR of alginate-based edible film

developed in this study was ranging between 1513.94

– 3048.75 g/m

2

/24 hours, and those values were

pronouncedly higher compared the above studies.

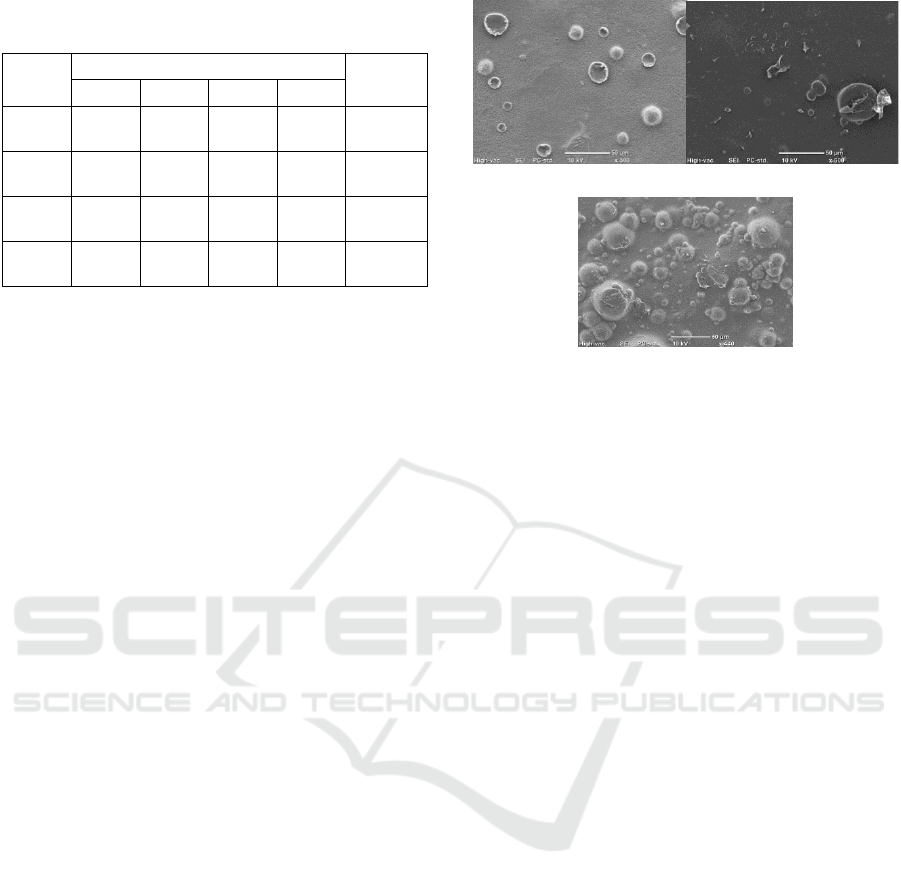

3.7 Morphological Test

Scanning Electron Microscope (SEM) is a tool that

can form surface shadows microscopically. SEM

technique is a surface examination and analysis

(Wirjosentono, 1995). Results of surface morphology

analysis of alginate-based edible film can be seen in

Figure 1.

The results of SEM test on alginate-based edible

film with the addition of canna starch (Fig 1.a)

revealed that the molecular structure of the alginate-

based edible film surface was less smooth, in which

starch granules and beeswax were still found. A rather

rough surface of edible was due to beeswax which

was insoluble in water. The result of SEM test on the

alginate-based edible film with the addition of mocaf

starch showed that the surface structure of the

alginate-based edible film molecule looked quite

smooth and flat but a few starch granules was still

encountered (Fig. 1.b).

Whereas the result of SEM test on alginate-based

edible film with the addition of breadfruit starch (Fig.

1.c), indicated that the surface of the film was rough

and many starch granules mixed with other

components such as water and sorbitol were still

found. The size of breadfruit starch granules was

larger than the other starches because the mixture in

the alginate-based edible film was difficult to

dissolve.

(a) (b)

(c)

Figure 1: Morphological test on the surface of alginate-

based edible film and (a) Canna starch; (b) Mocaf starch,

and (c) Breadfruit starch.

4 CONCLUSIONS

The type of starch used for manufacturing alginate-

based edible film, namely canna, mocaf, and

breadfruit starches significantly affected the

mechanical and physical properties of the edible films

at α

<0.05. The type of starch significantly affected

thickness, tensile strength, elongation, water

solubility and WVTR of alginate-based edible films.

The recommended type of starch for producing

alginate-based edible film was mocaf starch.

The starch concentrations significantly influenced

the characteristics of alginate-based -at α

<0.05.

Moisture content, thickness, tensile strength,

elongation, water solubility and WVTR of alginate-

based edible films were pronouncedly influenced by

starch concentration levels. Alginate-based edible

films were suggested to use 0.5% starch to obtain the

best quality.

Interactions between starch types and starch

concentrations significantly affected on the quality of

alginate-based edible films at significant level <α

(0.05). Thickness, tensile strength, water solubility

and elongation of alginate-based edible films were

markedly affected by the interaction of starch type

and starch concentration. The best alginate-based

edible films was obtained by using 0.5% mocaf in

their formulation. Characteristics of the film were

9.19% moisture content, 0.0713 mm thickness, 5.21

MPa tensile strength, 28.90% elongation, 97.93%

water solubility and 1709.287 g / m2 / 24 hours

WVTR. The surface properties of the film according

to SEM test were quite smooth and dense, although

few starch granules were still found.

16th AFC 2019 - ASEAN Food Conference

102

ACKNOWLEDGMENTS

The Ministry of Research, Technology and Higher

Education of the Republic of Indonesia supported

financially, through 2019 PTUPT program. The

authors declare that there is no conflict of interest

regarding the publication of this manuscript.

REFERENCES

Afriyah, Y., Putri W.D.R., Wijayanti, S.D. 2014.

Penambahan Aloe vera L. Dengan Tepung Sukun

(Artocarpus communis) Dan Ganyong (Canna edulis

Ker.) Terhadap Karakteristik Edible Film [In Press

September 2015]. Jurnal Pangan dan

Agroindustri, 3(4).

Anward, G., Hidayat, Y., Rokhati, N. 2013. Pengaruh

Konsentrasi serta Penambahan Gliserol terhadap

Karakteristik Film Alginat dan Kitosan. Jurnal

Teknologi Kimia dan Industri. Vol. 2. No. 3. Hal : 51 –

56.

Balqis, A. I., Khaizura, M. N., Russly, A. R., Hanani, Z. N.,

2017. Effects of plasticizers on the physicochemical

properties of kappa-carrageenan films extracted from

Eucheuma cottonii, International journal of biological

macromolecules, 103, 721-732.

Diniyah, N., Subagio. A., Sari. R.N. L., Vindy, P.G.,

Rofiah, A.A. 2018. Effect of fermentation time and

cassava varieties on water content and the yield of

starch from modified cassava flour

(MOCAF). Indonesian Journal of Pharmaceutical

Science and Technology, 5(2), 71-75.

Farhan, A., Hani, N. M., 2017. Characterization of edible

packaging films based on semi-refined kappa-

carrageenan plasticized with glycerol and sorbitol,

Food Hydrocolloids, 64, 48-58.

https://doi.org/10.1016/j.foodhyd.2016.10.034

Fransiska, D., Giyatmi, G., Irianto, H. E., Darmawan, M.,

Melanie, S., 2018. Karakteristik Film k-karaginan

dengan Penambahan Plasticizer Polietilen Glikol--

Characteristics of k-Carrageenan Film with

Polyethylene Glycol as Plasticizer. Jurnal Pascapanen

dan Bioteknologi Kelautan dan Perikanan, 13(1), 13-

20.

Galus, S., & Lenart, A. (2013). Development and

characterization of composite edible films based on

sodium alginate and pectin. Journal of Food

Engineering, 115(4), 459-465.

Kennedy, J.F., Bradshaw, I.J. 1987. The Rapid Quantitive

Determination of Alginates by Poly hexa methyl

enebiguanidinium chloride Complexation in Industrial

Liquors Extracted from Brown Seaweed. Carbohydrate

Polymers. Vol. 7 : 35-50

McHugh, T. H., Aujard, J. F., Krochta, J. M. 1994.

Plasticized Whey Protein Edible Film : Water Vapor

Permeability Properties. Journal of Food Science. 59 :

416-419 : 423.

Milani, J., Maleki, G. 2012. Hidrocolloids in Food

Industry. In Food Industrial Processes-Methods and

equipment; Valdez, B. Ed. Croatia : InTech, 17-38.

https://doi.org/10.1016/j.ijbiomac.2017.05.105

Murdinah, M., Darmawan, M., Fransiska, D., 2007.

Karakteristik Edible Film dari Komposit Alginat,

Gluten dan Lilin Lebah (Beeswax), Jurnal Pascapanen

Dan Bioteknologi Kelautan Dan Perikanan, 2(1), 19–

25.

https://doi.org/10.15578/jpbkp.v2i1.30

Murni, S. W., Pawignyo, H., Widyawati, D., Sari, N., 2013.

Pembuatan Edible Film dari Tepung Jagung (Zea Mays

L.) dan Kitosan, In Prosiding Seminar Nasional Teknik

Kimia Kejuangan (p. B17 1-9).

Pitak, N., Rakshit, S. K., 2011. Physical and antimicrobial

properties of banana flour/chitosan biodegradable and

self sealing films used for preserving Fresh-cut

vegetables. LWT - Food Science and Technology,

44(10), 2310–2315.

https://doi.org/10.1016/j.lwt.2011.05.024

Razzaq, H. A. A., Pezzuto, M., Santagata, G., Silvestre, C.,

Cimmino, S., Larsen, N., Duraccio, D., 2016. Barley β-

glucan-protein based bioplastic film with enhanced

physicochemical properties for packaging. Food

Hydrocolloids, 58, 276–283.

https://doi.org/10.1016/j.foodhyd.2016.03.003

Santoso, B. 2006. Karakterisasi Komposit Edible Film Biah

Kolang-Kaling (Arenga pinnata) dan Lilin Lebah

(Beeswax). Jurnal Teknol. dan Industri Pangan,

17(2):125-135.

Setiani, W., Sudiarti & Rahmidar. 2013. Preparasi dan

karakterisasi edible film dari poliblend pati sukun-

kitosan. Jurnal Kimia Valensi, 3(2).

Siswanti, S., Anandito, R. B. K., Manuhara, G. J. (2009).

Characterization of composite edible film from

glucomanan of iles-iles (Amorphopallus muelleri) tuber

and cornstarch. Biofarmasi Journal of Natural Product

Biochemistry, 7(1), 10-21.

Sitompul, A. J. W. S., Zubaidah, E. 2017. Pengaruh jenis

dan konsentrasi plasticizer terhadap sifat fisik edible

film kolang kaling (Arenga pinnata). Jurnal Pangan

dan Agroindustri, 5(1).

Wirjosentono, B., 1995. Perkembangan Polimer di

Indonesia. Orasi Ilmiah Lustrum 6. Medan: USU.

Singh, T. P., Chatli, M. K., Sahoo, J., 2015. Development

of chitosan based edible films: process optimization

using response surface methodology. Journal of Food

Science and Technology, 52(5), 2530–2543.

https://doi.org/10.1007/s13197-014-1318-6

Sitompul, A. J. W. S., Zubaidah, E., 2017. Pengaruh Jenis

dan Konsentrasi Plasticizer terhadap Sifat Fisik Edible

Film Kolang Kaling (Arenga pinnata). Pangan dan

Agroindustri, 5(1), 13–25

Effects of the Type and Concentration of Starch on the Quality of Alginate-based Edible Film

103