Characteristic of Garcinia Mangostana’s Pericarp Prepared by

Mechanical Milling

Dwi Wahyu Nugroho

1,3

, Dyah Ayu Daratika

1

, Elly Kristiyanti Agustin

2

, Muthia Kamila

1

,

Mohammad Aulia Rifada

1

, Lusiana Togatorop

4

, Wahyu Bambang Widayatno

5

, Syahrizal Maulana

6

,

Damai Ria Setyawati

7

, Etik Mardliyati

7

and Nurul Taufiqu Rochman

5

1

Center of Research and Development Product, Nano Center Indonesia, Puspiptek, South Tangerang, Banten, Indonesia

2

Center for Plant Conservation Botanic Gardens-LIPI Jakarta, Bogor, Indonesia

3

Department of Industrial Engineering, Nahdlatul Ulama Indonesia University, Jakarta, Indonesia

4

Department of Chemical Engineering, Pamulang University, South Tangerang, Banten, Indonesia

5

Center for Physics, Indonesian Institute of Sciences, Puspiptek, South Tangerang, Banten, Indonesia

6

Center for Innovation, Indonesian Institute of Sciences, Cibinong, Indonesia

7

Center for Pharmaceutical and Medical Technology, Agency for the Assessment and Application of Technology,

Puspiptek, South Tangerang, Banten, Indonesia

lusianatoga28@gmail.com, syahrizal.maulan@ymail.com, etik@nano.or.id, nurul@nano.or.id

Keywords: Nano Mangosteen Pericarp, Solubility, Potential Zeta, Phenolic Content, Functional Group.

Abstract: Garcinia mangostana, commonly known as mangosteen is a tropical fruit that grows in Asian region. Nano

Mangosteen’s Pericarp have successfully been made by ball milling method with variations in milling time

(30, 90, 150, 210 minutes), and non milling as a comparison. Mangosteen pericarp was dried in an oven at

70 ˚C for 12 hours, then continued by grinding and sieving using mesh 80, then milled. The effect of

variations in milling time on the functional groups of nano mangosteen pericarp, also the correlation on total

phenolic content and antioxidant activity in previous research were investigated. The morphology of the

mangosteen pericarp shows that the grain size of mangosteen pericarp is getting finer along with increasing

milling time. It can provide a clear reason for explaining the increasing solubility value of the samples. The

zeta potential data shows that after being milled the mangosteen pericarp becomes unstable, thus it is easy to

agglomerate. It was obtained that the total phenolic content and the antioxidant activity increased followed

by longer milling times. The FTIR analysis indicated that the enhancement in total phenolic content is not

due to transformation in functional groups of phenolic compounds.

1 INTRODUCTION

Free radicals are atoms or molecules that have

unpaired electron. The unpaired electron cause free

radicals to be very reactive then take electron from

other compounds such as proteins, lipids,

carbohydrates, and DNA to neutralize themselves

(Liochev, 2013). The negative effects of free

radicals on the body can be prevented by compounds

called antioxidants. Antioxidants have the ability to

give electron, bind, and end free radical chain

reactions (Halliwell, 2012). Antioxidants are

electron-giving compounds (donor electrons), which

are able to inactive the development of oxidation

reactions by preventing radical formation.

Antioxidants are compound that can slow or

prevent the oxidation process. This compound can

significantly slow down or inhibit the oxidation of

substances that are easily oxidized even in low

concentrations. Based on (Buck, 1991) sources of

antioxidants are divided into two, namely natural

antioxidants and synthetic antioxidants. Synthetic

antioxidants are antioxidants obtained from the

synthesis of chemical reactions and are produced for

commercial purposes. Examples of synthetic

antioxidants include Butyl Hydroxy Anisol (BHA),

Butyl Hydroxy Toluene (BHT), Propyl galate, Tert-

Butyl Hydroxy Quinon (TBHQ), Tocopherol and

others. Natural antioxidants can generally be

obtained from phenolic compounds or plant

polyphenols which can be in the form of alkaloids,

322

Nugroho, D., Daratika, D., Agustin, E., Kamila, M., Rifada, M., Togatorop, L., Widayatno, W., Maulana, S., Setyawati, D., Mardliyati, E. and Rochman, N.

Characteristic of Garcinia Mangostana’s Pericarp Prepared by Mechanical Milling.

DOI: 10.5220/0009991700002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Oppor tunities of Food Technology and Culinary for Tourism Industry, pages 322-329

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

flavonoids, saponins, quinones, tannins, sterids/

triterpenoids (Gordon, 1994). Natural antioxidants

are generally more desirable than synthetic

antioxidants. Many natural antioxidants are plants,

vegetables and fruits (Winarsi, 2007). Among fruits

that contain a lot of antioxidant compounds are

mangosteen fruit, especially on the mangosteen

pericarp. Based on phytochemical research,

mangosteen pericarp contains phenolic antioxidant

compounds. These phenolic compounds are

xanthones, anthocyanins, tannins, epikatekin and

other phenolic acid compounds (Zadernowski et al.,

2009).

One of the problems that occur in the utilization

of mangosteen pericarp waste, that is the active

compound, the source of natural antioxidants tends

to be less practical, has instability to the color, low

solubility, and bioavailability that still tends to be

low. Currently, nanotechnology is developed in food

and drug products that can accelerate the rate of

release of compounds of active compound, increase

solubility and increase absorption in the body.

(Ningsih et al., 2017).

In the previous study, it was observed the effect

the time of milling of mangosteen pericarp powder

with a variation of time 0, 30, 90, 150 and 210

minutes using ballmill on its effect on antioxidant

activity and total phenolic. It was reported that the

particle size of mangosteen pericarp powder affects

levels of total phenol and antioxidant activity seen

from IC

50

values. Mangosteen pericarp with the

smallest particle size has the largest total phenol

content and the smallest IC

50

. The largest total

phenol content indicates the content of polyphenol

compounds in samples with a large amount of

content. IC

50

values describe the total antioxidants

needed to capture free radicals as much as 50%. The

results of Daratika et al., 2018 reported that there

was an increase in total phenol content along with an

increase in milling time.

According to (Garcia's, 1999) study, the relative

ability of flavonoids from olive leaves to absorb

radical cations using the ABTS + method is

influenced by the presence of different functional

groups, especially in the number and position of free

hydroxyl groups in their structure. This is possible

because of changes in functional groups along with

changes in particle size. FTIR testing is carried out

to analyze whether there is a change in functional

groups in the organic compounds of mangosteen

pericarp powder. This research are in accordance

with the result that there was a positive correlation

between flavanoid content and particle size in rice

accession (Shen, 2009). There is also a study in

(Luthria, 2008), that the value of total phenol

content extracted from parsley leaves is obtained

when the particle size of the extraction results is

getting smaller.

In addition, it was reported that agglomeration in

the morphology of mangosteen pericarp powder

samples. According (Darusman, 2014) study, there

was clumping or agglomeration of pure GMP

(Glimepirid) drug particles which caused GMP to be

hydrophobic so it was difficult to dissolve in water.

Therefore, in this paper we will discuss potential

zeta in each sample to find out its relation to

solubility. The greater the potential zeta value, the

better the stability of the solution will be to reject

aggregation (Sari et al., 2013). The purpose of this

study was to characterize mangosteen pericarp

samples including zeta analysis of potential

mangosteen peel nano powder which might be

influenced by the process when milling and identify

the increase in the value of total phenol content with

the hypothesis influenced by changes in functional

groups.

2 MATERIAL AND METHODS

The raw material for grade A mangosteen is taken

from Purwakarta, West Java. The material used

consists of water, potassium bromide (KBr), Ethyl

Alcohol. Whereas the tools used consist High

Energy Milling Machine- Ellipse 3 Dimension

(HEM-E3D), Bruker Tensor 37 FTIR Spectroscopy,

Delsa Nano C-Particle Size Analyzer, and FEI

Quanta 650-Scanning Electron Microscopy.

2.1 Preparation of Mangosteen

Pericarp

Preparation of mangosteen pericarp powder samples

was carried out in according with previous studies.

In Daratika’s et al,. research 2018, the raw material

for mangosteen fruit is obtained from Purwakarta,

Indonesia plantations. The pericarp of the

mangosteen is boiled at a temperature of 200-250 °C

for 15 minutes. Then the soaking process is done by

using cold water to accelerate the cooling of the

sample. Furthermore, the mangosteen pericarp

slashed into small sizes around 50 mm in size. Then

the mangosteen pericarp is dried at 65 °C. According

to Afifah and Niwat, 2015 drying samples at

temperatures below 75 °C can protect the damage of

polyphenols. The mangosteen pericarp is then milled

and sifted on 80 mesh. The process of removing the

mangosteen powder particles in this study is the top

Characteristic of Garcinia Mangostana’s Pericarp Prepared by Mechanical Milling

323

down method using the HEM-Ellipse 3 Dimension

machine. Variations in milling time were observed

as parameters to determine the relationship between

milling time and particle size.

2.2 Characterization of Mangosteen

Pericarp

Mangosteen pericarp powder was characterized by

particle size and potential zeta using Delsa Nano C-

Particle Size Analyzer. The sample was dissolved

with ethyl alcohol solvent and measured at

temperature 25 °C with refractive index 1.3611,

liquid viscosity 1.1015 cPoise and scattering

intensity 8238 cps. While potential zeta is analyzed

to determine the nature of nanoparticle surface loads

and distribution potential particle samples. The

sample was dissolved in a water solvent then 0.9 mL

of the sample was measured under conditions of

temperature 24.8 °C, refractive index 1.3328,

viscosity 0.8919 and dielectric constant 78.4.

SEM testing is also done to find out information

about surface topography, composition, and other

characteristics such as electrical conductivity. Tests

are carried out using Scanning Electron Microscopy-

FEI Quanta 650. To determine the solubility, the

method of Al-Kahtani and Hassan (1990) was

applied. By10 grams of sample and 100 mL of

distilled water was put into a beaker glass. Rotate

using magnetic bar at a speed of 200 rpm at room

temperature 25 ° C (Jittanit, 2011).

2.3 Fourier Transform Infrared

Spectroscopy- Bruker Tensor 37

Making pellets is done by entering 200 mg KBr into

the mortar and mixing with 2 mg of sample. Mix

until homogeneous and done quickly. The

homogeneous mixture then made pellet with a mini

hand press tool and pay attention to the process. The

resulting pellets are stored in a dry place.

3 RESULT AND DISCUSSION

The morphology of the mangosteen pericarp

samples measured using Scanning Electron

Microscopy (SEM) can be seen in Fig. 1 and 2

indicating that the grain size getting finer along with

increasing holding time of milling. Daratika et al.,

(2018) reported that non milling mangosteen

pericarp (escaped mesh 80) with a particle size of

438 nm had grain sizes around 82,142 nm, milled for

90 minutes with a particle size of 257 nm had grain

sizes around 21,613 nm, and milled for 210 minutes

with a particle size of 205 nm had grain sizes around

1,855 nm.

Naturally, the process of milling on a material in

order to produce nanoparticles has two

consequences, namely fracture and agglomeration.

The first possible condition that occur when milling

is fracture of the particle as a result of a sufficiently

high stress field inside the particle which buildup

during the impact between the media (Knieke C.,

2012). The second possible condition is

agglomeration, when the particle size are below 1

µm, the particles tend to agglomerate because of

Browns’s motion increased and smaller interparticle

distances. Both of them enhancing the collision rate

of the particles (Knieke C., 2012).

In mangosteen pericarp samples before milling

(Fig. 1) and mangosteen pericarp samples which

were milled 90 minutes and 210 minutes (Fig.2)

there was a difference that the morphology of the

mangosteen pericarp samples before milling did not

occur between small particles and larger particles.

Whereas in the mangosteen pericarp sample after

milling there is a clumping or collision between

smaller particles and larger particles. This indicates

that there is agglomeration. Particle agglomeration

can be interpreted as forming a collection of

particles in solution and is one of the mechanisms

that causes destabilization of colloids. There are

several things that cause agglomeration, including

the smaller particle size.

In DLVO theory, (Derjaguin and Landan, 1941),

the agglomeration and stability of particle dispersion

are determined by the sum of the attractive and

repulsive force between individual particle. The

attraction between particle is due to the van der

Waals force. The interaction of the electrical double

layer surrounding each particles is called

electrostatic repulsive force. This theory indicate

that agglomeration is related to the potential zeta

value. The potential zeta value is used to

characterize the characteristic of particle surface

charge associated with nanoparticle electostatic

interactions (Couvreur et al., 2002). Electrostatic

interactions are resistive repulsive forces between

particles that affect stability in the suspension so that

they can prevent particle aggregation.

16th AFC 2019 - ASEAN Food Conference

324

(a) (b) (c)

Figure 1: The morphologies of mangosteen pericarp (non milling) mag 250x and 500x (a); milling 90 minutes (b); milling

210 minutes (mag. 250x and 1500x) (c).

Reflect the electrical potential of particle and is

influenced by the composition of the particle and the

medium in which it is dispersed (Singh et al., 2009).

The greater the electrostatic ability of a charge, the

more stable it is rejecting aggregation. Conversely

the smaller the electrostatic ability, the weaker it is

to resist aggregation.

Table 1 shows the solubility time of the

mangosteen pericarp milled in a certain time

variation (30, 90, 150, and 210 minutes) and non

milling as a comparison. Along with the addition of

milling time in the mangosteen pericarp samples

dissolved in certain water with a temperature of 25

ºC. It can be understood because the longer milling

time of mangosteen pericarp samples has a smaller

grain size, also followed by the smaller particle size.

Solubility of a substance will increase along with the

reduces particle size of substance.

Table 1: Solubility time and zeta potential of mangosteen

pericarp samples.

Sample

Measurement Method

Solubility Time

(s)

Zeta Potential

(mV)

Before milling 312.67±9.50 118.96

After milling

30 minutes 196.33±2.08 -18.03

90 minutes 58.03±3.50 -16.56

150 minutes 44.73±1.95 -20.3

210 minutes 33.4±2.19 -14.08

30 minutes 196.33±2.08 -18.03

Zeta potential is a parameter of electrical charge

between particles in colloids. The magnitude of zeta

potential provides information about stabilization of

the samples Patel et al., (2011) informing about the

guidelines for classifying nanoparticles dispersions

with zeta potential value (±) 0 – (±) 10 mV are very

unstable, (±) 10 – (±) 20 mV are relatively stable,

(±) 20 – (±) 30 mV are quite stable, and > (±) 30 mV

are very stable. The higher zeta potential value, the

more it will prevent flocculation. Zeta potential of

mangosteen pericarp samples can be observed in

Table 2. Non-milling mangosteen pericarp have a

very high zeta potential value, which shows the

repulsive forces of the particle are stronger, then the

samples have a high stability to resist aggregation.

While, for mangosteen pericarp samples that are

milled at a certain time variation (30, 90, 150, and

210 minutes) have a potential zeta value of less than

30 mV. The low potential zeta represents the

attractive forces between the dispersion particles

exceeding the repulsive forces.This causes these

particles to be easy to agglomerate, further causing

flocculation.

In the previous work, the correlation between

total phenolic content and antioxidant activity

against particle size of Garcinia mangostana’s

Pericarp has obtained that non milling sample with a

particle size had total phenolic content around 14.52

x 104 µg GAE/g samples, while the sample which is

milled for 210 minutes having the highest total

phenolic content (17.44 x 104 µg GAE/g samples)

accompanied by the lowest IC

50

value (254.84

µg/ml) that shows strong antioxidant activity

(Daratika et al., 2018). It can be observed that by

applying milling to reduce the particle size of the

sample produces a different total phenolic content.

In the initial hypothesis, it is caused by the

transformation of functional groups from phenolic

compounds. A functional group is defined as a group

of atoms joined in a specific manner, that gives the

chemical properties of the organic compound and

are the centers for chemical reactivity.

Characteristic of Garcinia Mangostana’s Pericarp Prepared by Mechanical Milling

325

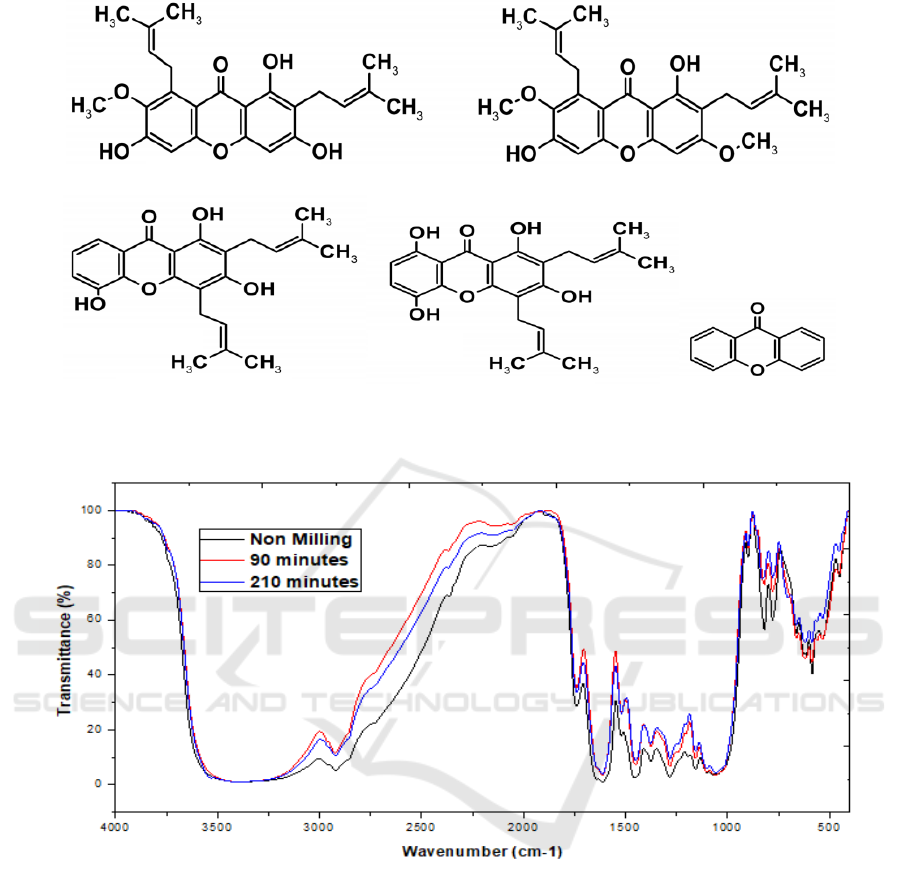

Figure 2: Chemical structure of xanthones and their derivatives: α-mangostin (a); β-mangostin (b); gartanin (c); 8-

desoxygartanin (d); xanthone (e) (Walker E. B., 2007).

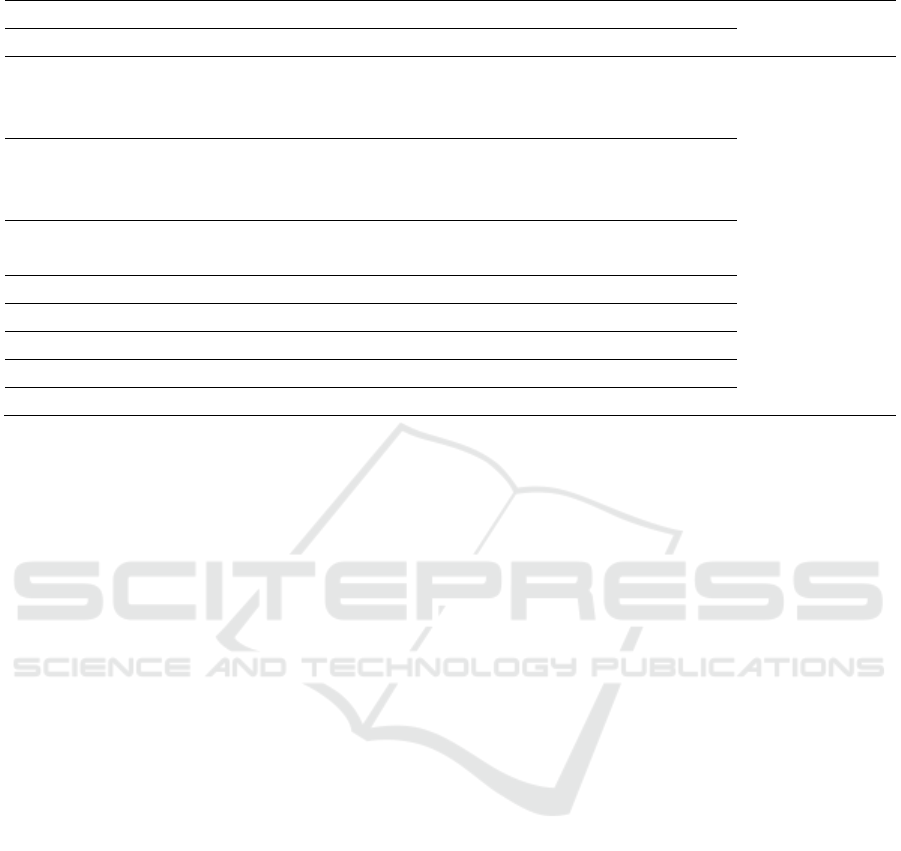

Figure 3: FTIR spectra of mangosteen pericarp.

In this study, Fourier-transform infrared

spectroscopy (FTIR) measurement accomplished to

obtain the functional group of mangosteen pericarp.

The FTIR spectra were collected in transmission

mode and covering the spectral range from 400 to

4000 cm-1 using Bruker Tensor 37 FTIR

spectrophotometer. The band intensities in different

regions of the spectrum for non-milling mangosteen

pericarp as a control and milled samples (90 and 210

minutes) were analyzed and are shown in Figure 3.

Naturally, mangosteen fruit is a rich source of

phenolic compound such as xanthones,

proanthocyanidins, anthocyanins, and phenolic acids

(Naczk et al., 2011). Mangosteen pericarp contains

of α-, β-, γ- mangostin, 8-deoxygartanin,

mangostinone a and b, gartanin, garcinone b and

mangostanol (Muchtaridi et al., 2016), (Jung et al.,

2006) reported that mangosteen pericarp conceived

xanthones as the major phenolic, with the chemical

structures can be observed in Figure 2.

The analysis using FTIR spectrophotometer

shows the presence of C-H, C=C aromatic, C-O eter,

O-H fenol. This functional group is appropriate with

functional groups in compounds xanthone, and their

derivatives with the structure as in Figure 2.

Xanthones is a cyclic polyphenol ketone compound

with the chemical formula C

13

H

8

O

2

, basic structure

xanthones consists of three benzene with one

benzene in the middle which is a ketone.

(a)

(b)

(e)

(d)

(c)

16th AFC 2019 - ASEAN Food Conference

326

Table 2: The functional groups of mangosteen pericarp.

Wavenumber (cm-1) Bond

Functional

Group

0' 90' 210' 0' 90' 210'

780, 45 780,61 780,11 C-H C-H C-H

Aromatic ring 817,58 816.76 830.79 C-H C-H C-H

899,78 898.54 898.51 C-H C-H C-H

1073,82 1053.20 1053.87 C-O C-O C-O

Eter

1156,42 1156.50 1156.62 C-O C-O C-O

1281,6 1282.29 1282.03 C-O C-O C-O

1375,12 1374.97 1376.73 C-H C-H C-H

Alkana

1453,33 1451.53 1450.67 C-H C-H C-H

1505 1518.83 1518.88 C=C C=C C=C Aromatik ring

1610,97 1612.02 1612.58 C=C C=C C=C Alkena

1740.14 1738.86 1739.18 C=O C=O C=O Keton

2922.69 2925.99 2923.37 C-H C-H C-H Alkana

3396.31 3397.68 3396.73 O-H O-H O-H Phenol

Almost all derivative molecules of xanthones

have a phenolic group in consequence xanthones

often called as polyphenols. Thus, it can be seen that

these compounds are polyphenols compounds

contained in the mangosteen pericarp (Muchtaridi et

al., 2016) and have antioxidant activity. The results

of FTIR data analysis showed that the functional

groups of the samples (non milling and milled with

variations of time 90 and 210 minutes) did not

indicate a significant difference in their spectra.

Therefore, it can be seen that there is no functional

group transformation in the mangosteen pericarp

samples. It can be understood by reason because

there is no chemical treatment that causes changes in

functional groups.

(Zhou et al., 2004) have reported that micro-

milled aleurone of Switzerland red wheat extracted

with 50% acetone showed significantly higher

sovent-extractable phenolic content compared to

untreated counterpart, which each individual

phenolic compound is examined increased for

different extents. Recent work carried out (Rosa et

al., 2013) reported that wheat bran’s antioxidant

activity was linearly correlated with specific surface

area, the medium particle size, and the proportion

particles smaller than 50 µm in diameter. Particle-

size reduction processes using ball milling, nano-ball

milling, and ultra-fine grinding have been shown

increase the accessibility of phenolic compounds to

extraction solvents (Wang et al., 2014). The basic

principles of engineering nanoparticle materials is

by utilizing the influence of particle size, the effect

of surface area, and the interaction between

nanoparticles and other materials.

In the previous study, it was found that the

increase in milling time on mangosteen pericarp

sample produces higher total phenolic content

accompanied by stronger antioxidant activity

(Daratika et al., 2018). The fact obtained from the

FTIR analysis stated that the difference values of

total phenolic content that are milled with a certain

time variation is not caused by the transformation of

functional groups so that there are changes in the

type and amount of phenolic compounds which

present in the samples. However, there are physical

processes that occur when reducing particle size.

The small size of nanoparticles has a greater

comparison between surface area and volume when

compared to similar particle with the larger size.

Consequently, there will be more atoms on the

surface of the nanoparticle material that come in

direct contact with material, causing this

nanoparticle to be more reactive. For this reason, an

increase in antioxidant activity and total phenol

content is caused by the better exposition of

phenolic compounds when samples milled, thereby

improving the accessibility of hydrogen to bind free

radicals from DPPH as synthetic free radicals to

form complex antioxidants that are stable.

4 CONCLUSIONS

Mechanical treatment of milling results in finer

particles and smaller zeta potential than samples

without milling. However, the milling treatment did

not change the functional group of mangosteen

Characteristic of Garcinia Mangostana’s Pericarp Prepared by Mechanical Milling

327

pericarp. Characterization using SEM shows that the

mangosteen pericarp that is milled in a longer time

have a finer grains which causes agglomeration.

This has an effect on increasing the solubility time

along with the small particle size. This has an effect

on increasing the solubility time along with the

small particle size. Besides the smaller particle size

also affects the total phenol content and antioxidant

activity as in previous studies.

ACKNOWLEDGEMENTS

This research was partly supported by The National

Innovation System Research Incentive program, The

Ministry of Research, Technology, & Higher

Education, Indonesia, 2018.

REFERENCES

Afifah, R.A., Niwat, C., 2015. The Use of Mangosteen

Pericarp (Garcinia mangostana L.) Extract to Fortify

the Green Tea Drink Enchanced Antioxidant Activity.

KKU Research Journal: 20(3) : 305-313.

Al-Khatani Hassan, Hassan B.H., 1990. Spray Drying of

Roselle (Hibiscus Sabdariffa L.) Extract. Journal of

Food Science Volume 55, No. 4.

Buck DF. Antioksidant. J. Smith (eds)., 1991. Food

Additive User’s Handbook. Galsgow-UK : Blakie

Academic & Profesional.

Daratika Dyah Ayu, Kamila Muthia, Nugroho D.W,

Widayatno W.B, Maulana Syahrizal, Mardliyati Etik,

Rochman Taufiqu Nurul., 2018. The Correlation

between Total Phenolic Content and Antioxidant

Activity Against Particle Size of Garcinia

mangostana’s Pericarp. Proceedings of The 2nd

International Seminar and Workshop of Plant Industri.

Jember, Indonesia 1-2 November 2018.

Derjaguin BV, Landau LD., 1941. Theory of the stability

of strongly charged lyophobic sols and of the adhesion

of strongly charged particles in solutions of

electrolytes. Acta Physicochim URSS 14:733-762.

Garcia O.Benavente, Castillo J, Lorente .J, Ortuno .A, Rio

J.A.D., 1999. Antioxidant Activity of Phenolics

Extracted From Olea Europaea L. Leaves. Food

Chemistry,68, 457-462.

https://doi.org/10.1016/S0308-8146(99)00221-6.

Gordon L. 1994. Functional Food, Food Design,

Pharmafood, Newyork : Champman and Hall.

Jittanit W, Khuenpet K, Charoenjarasrerk N, Jaijit S,

Arayapoonpong S.M., 2016. Agriculture and Natural

Resources Journal.Vol. 50, Pages 139-145.

Jung, H.A., Su, B.N., Keller, W.J., Mehta, R.G.,

Kinghorn, D., 2006. Antioxidant Xanthones from

pericarp of Garcinia mangostana (Mangosteen). J.

Agric. Food. Chem. 54, 2077-2082.

Knieke, Catharina., 2012 Fracture at the Nanoscale and

the Limit of Grinding. Cuviller Verlag; 20.

https://books.google.co.id/books/about/Fracture_at_th

e_Nanoscale_and_the_Limit.html.

Luthria DL., 2008. Influence of experimental conditions

on the extraction of phenolic compounds from parsley

(Petroselinum crispum) flakes using a pressurized

liquid extractor. Food Chem. 107(2):745-752.

Liochev, S.I., 2013 Reactive oxygen species and the free

radical theory of aging. Free Radical Biology and

Medicine,60,14.doi:10.1016/j.freeradbiomed.2013.02.

01.

Naczk, M., Towsend, M., Zadernowski, R., Shahidi, F.

2011. Protein-binding and antioxidant potential of

phenolics of mangosteen fruit (Garcinia mangostana).

Food Chem. 128, 292–298.

https://doi.org/10.1016/j.foodchem.2011.03.017.

Ningsih Nirmala, Yasni Sedarnawati, Yuliani Sri., 2017.

Nanoparticle of red mangosteen peel extract synthesis

and the functional characteristics of its encapsulated

product. IPB, Technology Journal and food industry

vol. 28(1):27-35.

Muchtaridi, Qosim W.A., 2016. Quantitative analysis of

A-mangostin in mangosteen (Garcinia mangostana L.)

pericarp extract from four district of West Java by

HPLC method. International Journal of Pharmacy and

Pharmaceutical Sciences Vol 8, Issue 8, 232-236.

Rosa, N. N., Barron, C., Gaiani, C., Dufour, C., & Micard,

V., 2013. Ultra-fine grinding increases the antioxidant

capacity of wheat bran. Journal of Cereal Science, 57,

84–90.

Sari, T. P., Mann, B., Sharma, R., & Kumar, R., 2013.

Process Optimization for the Production of

Nanoencapsulated Curcumin and Analysis for

Physicochemical Characteristics and Antioxidant

Mechanism. International Journal of Biotechnology

and Bioengineering Research, 4(6), 581–586.

Shen Yun, Jin Liang, Xiao Peng, Lu Yan, Bao Jinsong.,

2009. Total phenolics, flavonoids, antioxidant capacity

in rice grain and their relations to grain color, size and

weight. Zhejiang University; Journal of Cereal

Science 49, 106–111.

Couvreur P, Barratt G, Fattal E, Legrand P, Vauthier C.,

2002. Nanocapsule technology: a review. Crit Rev

Ther Drug Carrier Syst. 19:99-134.

V.R. Patel, Y.K., 2011. Agrawal. Nanosuspension: an

approach to enhance solutibility of drugs. J. Adv.

Pharm. Technol. Res. 2. 81-87.

Wang Tao, He Fuli, Chen Guibing., 2014. Improving

bioaccessibility and bioavailability of phenolic

compounds in cereal grains through processing

technologies: A concise review. Journal Of Functional

Foods 7 101–111.

http://dx.doi.org/10.1016/j.jff.2014.01.033.

Winarsi Hery., 2007. Natural Antioxidants and Free

Radicals. Yogyakarta: Kanisius. Page. 189-90.

Zadernowski, R., Czaplicki, S. and Nacz, M., 2009.

Phenolic acid profiles of mangosteen fruits (Garcinia

mangostana). Food Chemistry 112: 685-689.

16th AFC 2019 - ASEAN Food Conference

328

Zhou Kequan, Laux J.J, Yu Liangli., 2004. Comparison of

Swiss Red Wheat Grain and Fractions for Their

Antioxidant Properties. Journal of Agricultural and

Food Chemistry, Vol. 52, No. 5. Doi:

10.1021/jf030640w

Characteristic of Garcinia Mangostana’s Pericarp Prepared by Mechanical Milling

329