Development of Vegan Ice Cream from Jackfruit

(Artocarpus Heterophyllus) Seed-based Milk

Erika Lumbantobing

1

, Samantha Tanardi

2

and Agus Budiawan Naro Putra

1

1

Department of Food Science and Nutrition, Indonesia International Institute for Life Sciences, Jakarta, Indonesia

2

Department of Food Technology, Indonesia International Institute for Life Sciences, Jakarta, Indonesia

Keywords: Crude Fiber, Food Product Development, Jackfruit Seed, Low-fat, Vegan Ice Cream.

Abstract: Modern lifestyle has initiated a vegan diet through the uptrend in plant-based or non-dairy milk that is

subsequently incorporated in ice cream making. This research aimed to alter the under-utilized jackfruit seed

into an alternative milk base for vegan, nutrient-rich ice cream. Jackfruit seeds were processed and filtered to

obtain the liquid. A control and two variables of emulsifier [lecithin and surface perfectant (SP)] were

formulated to produce ice cream. The ice cream was then analyzed for proximate analysis (crude fiber, total

carbohydrate, fat, and protein content), physicochemical analysis (color and viscosity), followed by a 9-point

hedonic scale acceptance test. Data were analyzed by analysis of variance (ANOVA) and Fisher’s Least

Significant Difference (LSD) test. Results showed that all ice cream formulations contained the beneficial

crude fiber except for the commercial dairy ice cream. In addition, jackfruit seed-based milk ice cream was

also low in fat content. Viscosity of lecithin-treated ice cream was significantly different (p < 0.05) compared

to the others. Hedonic test (n=39) results showed that there were significant differences among the samples

(p < 0.05) with the control group as the most preferred in terms of overall liking and flavor. In conclusion,

changing dairy milk with jackfruit seed-based milk may deliver the potential creation of vegan, low-fat, and

crude fiber-rich ice cream with reasonable consumer acceptability.

1 INTRODUCTION

Vegan ice cream is a type of ice cream that is made

from non-animal based products, usually non-dairy

milk, such as soy milk, coconut milk, almond milk,

cashew milk, etc. Nowadays, plant-based or non-

dairy milks are rising and fast growing as a trend in

food development. Cow’s milk allergy and lactose

intolerance are some of the reasons for the consumers

to choose vegan diet as an alternative (Sethi, Tyagi,

and Anurag, 2016).

Jackfruit, one of the tropical fruits, has been used

as a meat substitute in Indonesia, renowned for

gudeg. Jackfruit flesh has been incorporated in many

food products. However, reported publication about

the beneficial use of jackfruit seed in food industry is

scanty. Generally, the jackfruit seed is processed by

boiling, steaming, or roasting to provide an

economical source of protein, fiber, and minerals.

Furthermore, the safety and toxicity studies (in vivo)

of jackfruit seeds was conducted and it gave no

physiological change in the behavior of the subjected

animal (Suryadevara, Lankapalli, Danda, Pendyala,

and Katta, 2017).

According to Suprapti (2004), jackfruit seed

contains 4.2 g of protein, 0.1 g of fat, 36.7 g of

carbohydrate, 33 mg of calcium, as well as other

vitamins and minerals. Even though jackfruit seed

contains a high value of starch, it is categorized as a

low glycemic index (GI) food due to the role of

dietary fiber and un-gelatinized starch granules.

Therefore, it is good to be consumed as it does not

strongly increase the glucose blood level

(Hettiaratchi, Ekanayake, and Welihinda, 2011). In

term of valuable health benefits, jackfruit seed is

acknowledged to contain antioxidant

prenylflavonoids along with the finding of isolated

Jacalin for immune stimulation of human

immunodeficiency virus HIV-1 infected patients

(Suresh Kumar, Appukuttan, and Basu, 1982;

Pereira-da-Silva et al., 2006).

In addition, jackfruit seed-based ice cream can be

consumed by those people suffering from lactose

intolerance and it also contains dietary fiber for health

bowel function by preventing constipation and

66

Lumbantobing, E., Tanardi, S. and Putra, A.

Development of Vegan Ice Cream from Jackfruit (Artocarpus heterophyllus) Seed-Based Milk.

DOI: 10.5220/0009983700002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 66-71

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

lowering the risk of colorectal cancer. The nutritional

value of jackfruit seed compared to cow’s milk and

soy milk can be seen in Table 1.

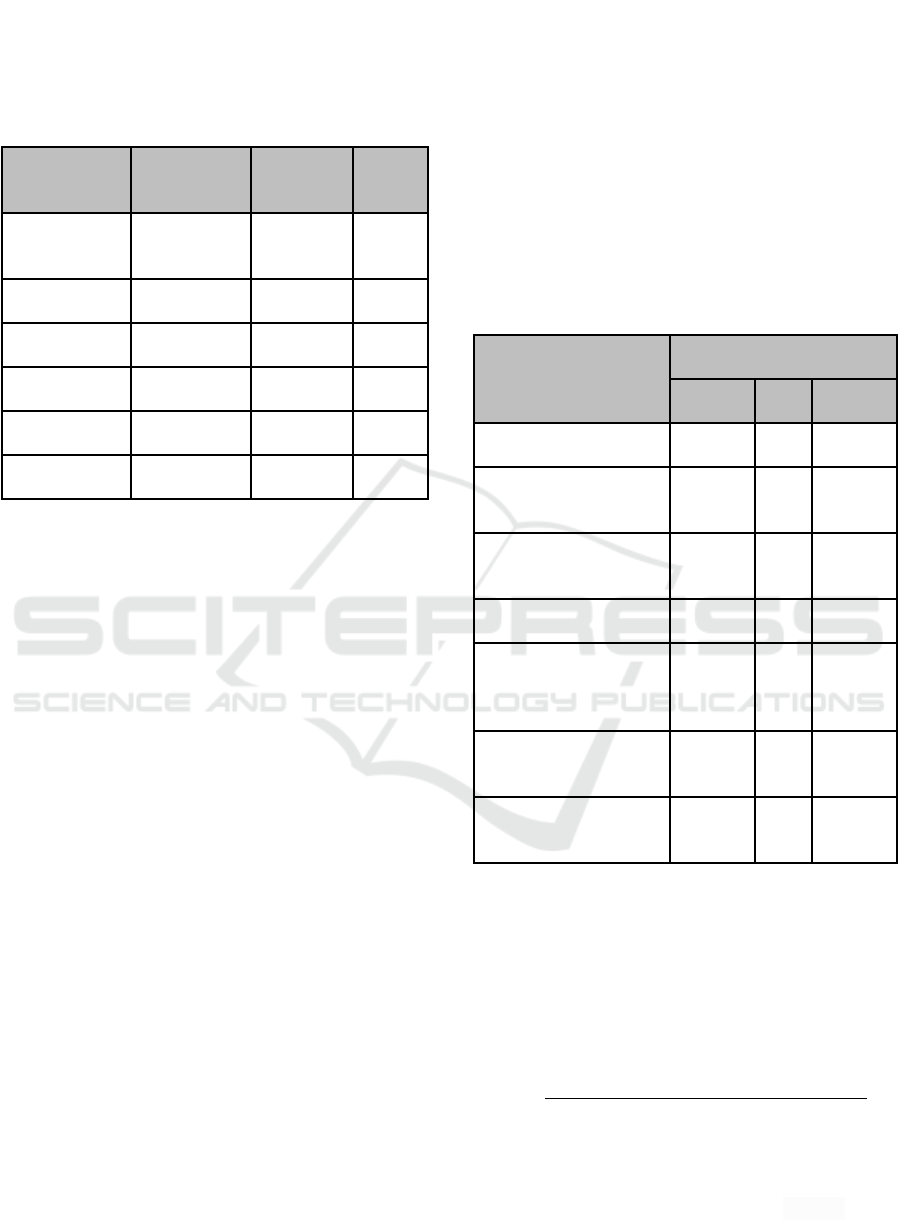

Table 1: Comparison of nutritional value of jackfruit seed,

regular dairy cow’s milk, and soy milk per 100 g.

Nutrient

Jackfruit

seed

†

Cow’s

milk

‡

Soy

milk

‡

Carbohydrate

(g)

38.40 4.8 3.45

Protein (g) 6.60 3.15 2.94

Dietary fiber (g) 1.50 0.00 0.40

Fat (g) 0.40 3.25 2.00

Ash (g) 1.25 - 1.50 0.70 1.80

Moisture (%) 51.60 - 57.77 88.13 90.98

Sources:

†

List of food ingredients composition, Directorate of Nutrition

Department, RI Health,

‡

USDA National Nutrient Database for Standard

Reference.

The objective of the research was to manage the

unusable waste to be a valuable and possible

alternative food products and to utilize the jackfruit-

seed-based milk as the main ingredient in vegan ice

cream making which is also safe to be consumed by

lactose-intolerance consumers.

2 METHOD

2.1 Sample Preparation and Jackfruit

Seed Milk Making

Jackfruits (Artocarpus heterophyllus, purchased from

a traditional market in Bandung, West Java) were

separated into the flesh and seeds. The jackfruit seeds

were soaked in 2% salt water (NaCl) with the addition

of 5 drops of lemon juice. The soaked jackfruit seeds

were filtered to separate from the water and cooked in

a pressure cooker with the addition of water (ratio 1:1

w/v) for 1 minute, starting when the pressure

regulator of pressure cooker emitted sound and

released the steam. The jackfruit seeds were then

cooled down to room temperature. After cooling

down, the jackfruit seeds were weighed, and blended

with water (ratio 1:1.5 w/v). The blended mixture was

then filtered through cheesecloth into a glass jar. The

jackfruit seed milk was then stored in a refrigerator at

4°C overnight.

2.2 Ice Cream Making

The ice cream was made with different emulsifiers as

the variables: control group, SP group, and lecithin

group. The ice cream formulation was stated in Table

2 below. The ice cream mixture was then

homogenized. An ice cream maker was then set for

30 minutes to freeze the ice cream mixture. Final ice

cream was stored in the freezer at -12°C.

Table 2: Ingredients used for ice cream formulation.

Ingredients

Sample

Control SP Lecithin

Jackfruit seed milk (mL) 200 200 200

Jackfruit juice* (as

flavoring) (mL)

50 50 50

Coconut milk (Kara Sun)

(mL)

50 50 50

Ground sugar (g) 20 20 20

Xanthan gum powder -

stabilizer (Titan Baking

Supply, Jakarta) (g)

1 1 1

SP (Koepoe Koepoe SP

emulsifier) (g)

- 1 -

Lecithin (PT. United

Chemicals Inter Aneka) (g)

- - 1

*Note: the flesh of jackfruit was blended with water (ratio 1:1) to obtain the

liquid.

2.3 Protein Analysis

Kjeldahl method approved by AOAC 930.33 (2000)

was used to analyze the protein. The Kjeldahl

machine used was Gerhardt ISO 8968-1. The

calculation was done by the formula below.

% N =

.

(1)

2.4 Fat Analysis

Soxhlet method approved by AOAC 952.06 (2000)

was used to analyze the fat content using Fat

Development of Vegan Ice Cream from Jackfruit (Artocarpus heterophyllus) Seed-Based Milk

67

Extractor Det-Gras-N (JP Selecta) machine. The fat

content was calculated by the following formula.

% Fat =

x

100%

(2)

2.5 Crude Fiber Analysis

Crude fiber analysis was conducted by the

gravimetric method reapproved by AOAC 978.10

(2017). The crude fiber was calculated by the formula

shown below.

% Crude Fiber =

x 100%

(3)

2.6 Total Carbohydrate Analysis

Phenol-Sulfuric method, AOAC 988.12 (44.1.30),

was used to analyze the total carbohydrate. Glucose

standard solutions were prepared with the dilutions of

100, 200, 400, 600, 800, and 1000 μg/mL. The

absorbance of samples were then read at 490 nm

wavelength using a UV - VIS spectrophotometer

(Shimadzu 1280).

2.7 Color Analysis

All ice cream mix samples were tested for the L*a*b*

values using general colorimeter AMT-507 Kingwell.

2.8 Viscosity Analysis

All ice cream mix samples were subjected to Lamy

Rotational Rheometer model First RM with thermal

sensor (spindle no. 3, ASTM 3, 100 rpm, 30 seconds)

to analyze and compare the viscosity.

2.9 Sensory Analysis

Three random codes (709: control, 881: SP, and 551:

lecithin) were assigned for each sample. Forty one

panelists were selected randomly from Indonesia

International Institute for Life Sciences (i3L) with 18

and 23 of them were male and female, respectively.

A 9-scale hedonic test was performed.

2.10 Statistical Analysis

IBM SPSS Statistics version 20 was used to conduct

the statistical analysis. The sensory analysis result

was analyzed by analysis of variance (ANOVA),

followed by Fisher’s least significant difference (LSD)

test.

3 RESULT AND DISCUSSION

Ice cream sample was collected from the ice cream

machine and then used for further analysis as the data

shown and discussed below.

3.1 Proximate Analysis

As shown in Table 3, difference in protein content

was found which indicated that both control and

lecithin groups had higher protein content (3.04% and

1.23%, respectively) compared to that of SP (0.12%).

The lecithin used in this experiment was soy lecithin

which is the most common lecithin. Standard soy

lecithin contains between 0.23% and 1.34% protein.

According to Martín-Hernández, Bénet, and Marvin-

Guy study (2005), this amount of protein in standard

soy lecithin is higher compared to de-oiled soy

lecithin (0.34%), sunflower lecithin from different

supplier (0.89% and 0.41%), and egg lecithin

(0.05%). Therefore, the ice cream with lecithin had

higher protein content compared to that of SP.

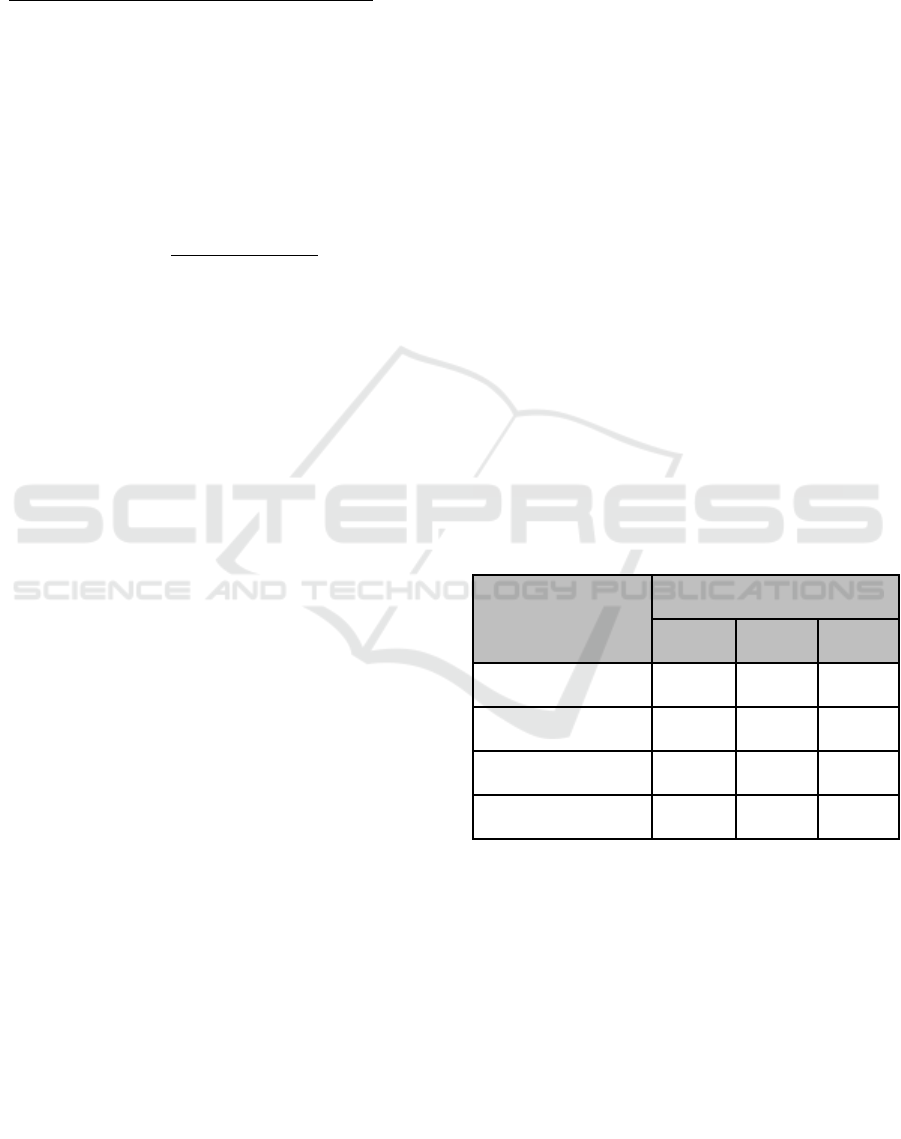

Table 3: Proximate composition of jackfruit seed ice cream

with different emulsifiers.

Proximate composition

Sample

Control SP Lecithin

Protein (%) 3.04 0.12 1.26

Fat (%) 0.19 7.77 0.20

Crude fiber (%) 0.59 0.94 0.80

Total carbohydrate (%) 0.24 0.28 0.24

In terms of fat content, SP group had a significant

fat content (7.77%) compared to those of control and

lecithin (0.19% and 0.20%, respectively). It is

because of the utilization of Ryoto ester SP. Ryoto

ester SP is one type of sucrose ester which is

synthesized by esterification of fatty acids/natural

glycerides with sucrose. Fatty acids in C8-C22 range

are able to be reacted with sucrose to form esters with

long chain fatty acids of palmitic (C16), oleic (C18),

and stearic acid (C18). Thus, the highest fat content

detected in ice cream with SP emulsifier supports the

scientific theory stated by Nelen and Cooper (2004).

16th AFC 2019 - ASEAN Food Conference

68

All ice cream samples contained crude fiber

(Table 3) which came from jackfruit seed. Moreover,

the jackfruit flesh itself was also used as the flavoring

material. According to USDA (2016), the jackfruit

flesh contains 1.5 g of dietary fiber (per 100 g of

jackfruit). Compared to dairy ice cream, this jackfruit

seed-based ice cream contains higher fiber. Regular

dairy ice cream products found in the market contain

0% of fiber.

Through the equation with an excellent-fit R-

squared value (0.99), the amount of total

carbohydrate for each variable was calculated and

there was no significant difference in total

carbohydrate content between all variables. SP group

had the highest total carbohydrate content (0.28%),

meanwhile both control and lecithin groups had the

same percentage of total carbohydrate (0.24%). These

results showed that the use of emulsifier does not

significantly affect the total carbohydrate content.

Additionally, the amount of sugar used mostly

determined the total carbohydrate content.

3.2 Physicochemical Analysis

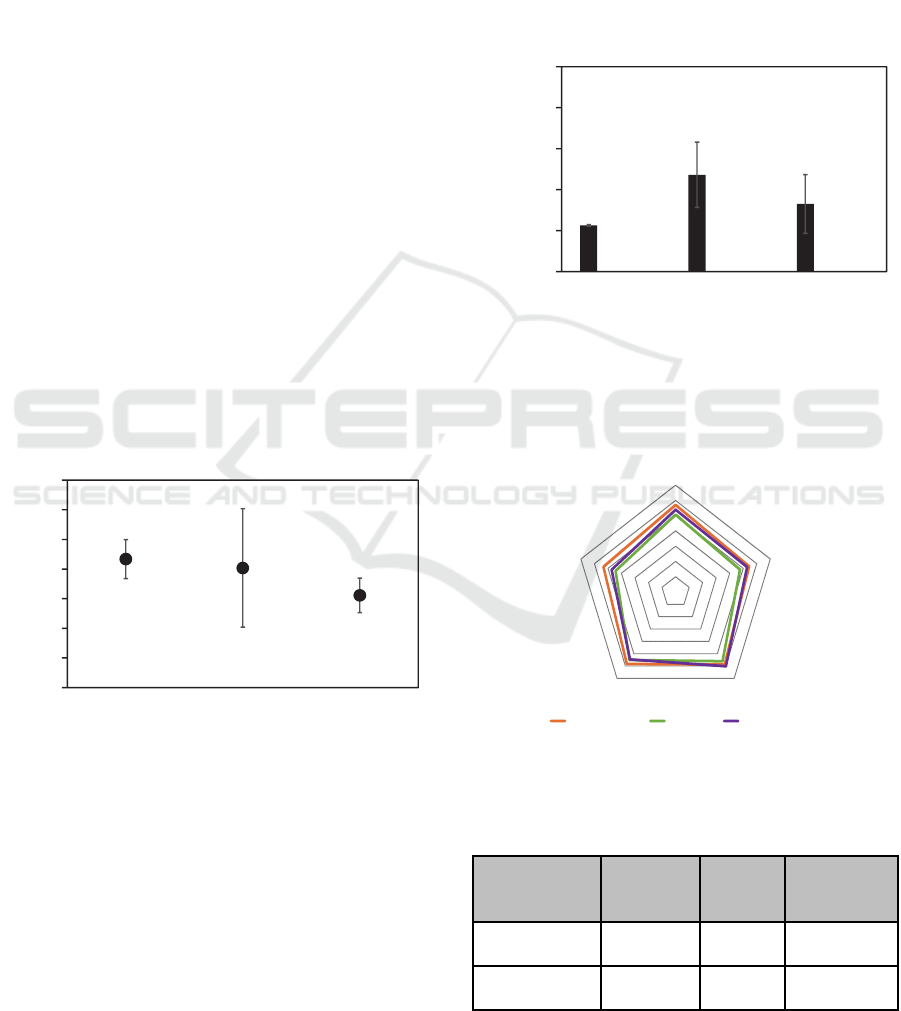

The lightness of the ice cream was measured and

shown in Figure 1 below. The result showed there is

no significant difference in terms of lightness among

samples.

Figure 1: The lightness of the ice cream samples showed no

significant difference between samples. The data were

collected in two batches (independent measurement) with

three replications in each batch.

Besides, the viscosity of the samples were also

measured. As shown in Figure 2 the viscosity was

significantly different

(p < 0.05) with lecithin group

had the highest viscosity, followed by SP group, and

control group to be the lowest. These results indicate

that emulsifier contributes the most on the rheological

properties of the ice cream.

3.3 Sensory Analysis

According to Figure 3, the difference of each sample

can be roughly seen in both overall liking and flavor

attributes. On the other hand, the sweetness,

smoothness, and consistency of the ice cream are not

significantly different. Thus, subsequent one-way

ANOVA and LSD test were conducted for all

samples to find the difference among samples and the

results were shown in Table 4.

Figure 2: The viscosity of the ice cream samples (p =

0.012). The a and b indicate viscosity without common

alphabet differ between samples (p < 0.05). The data were

collected in two batches (independent measurement) with

three replications in each batch.

Figure 3: Spider chart of all jackfruit seed ice creams for

five different attributes. Significant difference (p < 0.05)

can be observed in overall liking and flavor.

Table 4: The result of consumer preference test.

Attribute

Control

(709)

SP

(881)

Lecithin

(551)

Overall liking 5.82

a

5.13

b

5.46

ab

Flavor 5.49

a

4.44

b

4.79

ab

a,b

means of the attribute without a common superscript differ

between the samples (p < 0.05).

0

5

10

15

20

25

30

35

L*

LightnessoftheIceCreamSamples

lecithin SPcontrol

0

400

800

1200

1600

2000

Viscosity(mPa.s)

ViscosityoftheIceCreamSamples

a

b

ab

lecithin SPcontrol

0

1

2

3

4

5

6

7

overall*

sweetness

smoothnessconsistency

flavor*

HedonicScoresforEachAttribute

control(709) SP(881) lecithin(551)

Development of Vegan Ice Cream from Jackfruit (Artocarpus heterophyllus) Seed-Based Milk

69

The emulsifier indeed affects the overall liking

attribute and the flavor of the ice cream (p < 0.05).

Meanwhile the sweetness, smoothness, and

consistency between all samples were not

significantly different. According to Baer, Wolkow,

and Kasperson (1997), the flavor of the ice cream

should not be affected by the level of emulsifier used.

The most preferred ice cream by overall liking and

flavor was the control group, while the least preferred

ice cream by overall liking and flavor was the SP

group. Emulsifier might negatively affect the flavor

of the ice cream (Baer, Wolkow, and Kasperson,

1997). According to the results above, consumers

prefer the jackfruit seed ice cream without emulsifier.

However, lecithin group was not significantly

different compared with control group. Thus, lecithin

group was also accepted by the consumers.

Certain properties of emulsifier are meant to

enhance the whipping ability and product uniformity,

improve meltdown resistance, and promote smooth

texture as well as desirable mouthfeel. Emulsifier

reduce the icy texture and coarse, as well as reduce

the cold intensity of the ice cream (Baer, Wolkow,

and Kasperson, 1997). All emulsifiers are made of a

molecule with a mixture of both lipophilic and

hydrophilic groups. The functionality of emulsifier

towards the type of emulsion (either O/W or W/O) is

highly determined by the Hydrophilic-Lipophilic

Balance (HLB) numerical value. HLB is a number of

the ratio between the balance of hydrophilic and

hydrophobic groups of a surfactant. Nelen, Bax, and

Cooper (2014) reported that a typical water-in-oil

emulsions (W/O) require low HLB surfactants (3.5-

6.0), meanwhile a higher HLB emulsifiers (8-18) are

preferred for oil-water emulsion (O/W) which have

more hydrophilic nature. Ryoto ester SP, as one type

of sucrose esters, is water-soluble, resulting in higher

HLB value (between 1-18) that contributes to the

stabilization of ice cream in the O/W emulsion (Nelen

and Cooper, 2004). As a commercial emulsifier, the

type of fatty acids used somehow influences the

properties of sucrose esters. The shorter the length of

the fatty acid chain, the higher the HLB value.

It was also reported that due to the higher HLB

value, sucrose ester is more suitable to develop better

emulsion compared to lecithin due to its lower HLB

value. In this experiment, the unknown type of fatty

acid used in the SP might influence the functionality

of the emulsifier towards ice cream mixture. Thus, the

results of the sensory test was not as expected. There

is no significant difference in terms of smoothness

and consistency between the emulsifiers. The proper

condition of ice cream samples during sensory test

(i.e., ice cream temperature at serving, consistent

quantity and physical appearance per sample) must be

taken into consideration in order to obtain accuracy in

the data.

4 CONCLUSIONS

Jackfruit seed can be used as the main ingredient for

vegan ice cream. Jackfruit seed vegan ice cream

contains crude fiber as its beneficial health effects.

Moreover, the addition of different emulsifiers did

not affect the lightness of the ice cream. Emulsifier

mostly increases the ice cream’s viscosity, which in

turn, affects its sensorial properties with lecithin as

the potential emulsifier in jackfruit seed vegan ice

cream.

Further analysis such as iciness and coldness

intensity should be included in the sensory

evaluation. Additionally, microscopic analysis of the

ice crystal should also be done.

ACKNOWLEDGEMENTS

Authors would like to express gratitude to the

laboratory assistant members at Indonesia

International Institute for Life Sciences (i3L).

REFERENCES

"FoodData Central". USDA National Nutrient Database

For Standard Reference, 2019,

https://fdc.nal.usda.gov/.

Baer, R. J., Wolkow, M. D., and Kasperson, K. M. (1997).

Effect of emulsifiers on the body and texture of low fat

ice cream. Journal of Dairy Science, 80(12), 3123-

3132.

Hettiaratchi, U. P. K., Ekanayake, S., and Welihinda, J.

(2011). Nutritional assessment of a jackfruit

(Artocarpus heterophyllus) meal. Ceylon Medical

Journal, 56(2).

List of food ingredients composition, Directorate of

Nutrition Department, RI Health

Martín-Hernández, C., Bénet, S., and Marvin-Guy, L. F.

(2005). Characterization and quantification of proteins

in lecithins. Journal of Agricultural and Food

Chemistry, 53(22), 8607-8613.

Nelen, B. A., and Cooper, J. M. (2004). Sucrose esters.

Emulsifiers in Food Technology, 131-161.

Pereira-da-Silva, G., Moreno, A. N., Marques, F., Oliver,

C., Jamur, M. C., Panunto-Castelo, A., and Roque-

Barreira, M. C. (2006). Neutrophil activation induced

by the lectin KM+ involves binding to CXCR2.

16th AFC 2019 - ASEAN Food Conference

70

Biochimica et Biophysica Acta (BBA)-General

Subjects, 1760(1), 86-94.

Sethi, S., Tyagi, S. K., and Anurag, R. K. (2016). Plant-

based milk alternatives an emerging segment of

functional beverages: a review. Journal of Food

Science and Technology, 53(9), 3408-3423.

Suprapti, I. M. L. (2004). Teknologi Tepat Guna Keripik,

Manisan Kering, dan Sirup Nangka. Kanisius.

Suresh, K. G., Appukttan, P. S., and Basu, D. K. (1982). α-

D-galactose-specific lectin from jack fruit (Artocarpus

integra) seed. Journal of Biosciences, 4, 257-261.

Suryadevara, V., Lankapalli, S. R., Danda, L. H., Pendyala,

V., and Katta, V. (2017). Studies on jackfruit seed

starch as a novel natural superdisintegrant for the design

and evaluation of irbesartan fast dissolving tablets.

Integrative Medicine Research, 6(3), 280-291.

USDA, N. (2016). Natural Resources Conservation

Service. United States Department of Agriculture.

Development of Vegan Ice Cream from Jackfruit (Artocarpus heterophyllus) Seed-Based Milk

71