Functional Properties and Resistant Starch Content of Banana Flour

and Its Application to Noodle Product

Jidapa Tangthanantorn

1

, Santad Wichienchot

1

and Piyarat Sirivongpaisal

2

1

Interdisciplinary Graduate School of Nutraceutical and Functional Food, Prince of Songkla University,

Songkhla, Thailand

2

Department of Food Technology, Prince of Songkla University, Songkhla, Thailand

Keywords: Banana Flour, Functional Properties, Noodle Product, Resistant Starch.

Abstract: Banana flour (BF) were prepared by using unripe banana due to it contains mainly carbohydrate especially

starch that is suited to use as the source of flour. For the functional properties of BF, the gelatinization

temperature ranges were 72.93 to 79.41°C and enthalpy of gelatinization (ΔH) was 10.93 J/g. The pasting

curves and viscosity parameters were including pasting temperature, peak viscosity, breakdown, setback and

final viscosity were 82.10ºC, 3573.33 mPa.s, 1567.33 mPa.s, 1794.67 mPa.s and 3800.67 mPa.s, respectively.

The flour paste samples showed shear thinning behavior of pseudo-plastic materials. BF was high in resistant

starch (RS) which contained 55.33%. Fresh noodle that substituted with BF of 10%, 20%, 30% and 40% were

investigated in their quality characteristics. While the substitution of BF increased, the RS content of noodles

increased from 9.00% to 22.01%. However, the RS had affected the lightness and texture properties of noodle

products.When the BF substitution increased at 10 to 40%, tensile strength and elasticity values were

decreased from 35.50 to 26.84 g

f

and 33.75 to 15.04 mm, respectively. The utilization of BF as an ingredient

in food products exerts a beneficial effect that provides high resistant starch or low carbohydrate digestibility.

1 INTRODUCTION

The nutritional properties of bananas are known to

provide health benefit because it is rich in fiber and

rich source of minerals (Singh et al., 2016).

The interesting substantial type of starch in an unripe

banana is resistant starch (RS). RS of banana has the

potential to provide health benefits similar to dietary

fiber that increased satiety, helps burn fat more

quickly and low calorie content as well as promote

a reduced glycemic response.

The alkaline noodle is one type of noodle that is

responsible for 48% of flour consumption in South

East Asia (Ho and Che, 2016). However, the noodle

is the major carbohydrate based food that lacks many

essential nutritional components. Therefore, the

consumption of this noodle could lead to malnutrition

that considers being high calories and leads to health

problems (Ramli et al., 2009). It would be desirable

if the incorporation of unripe banana flour can reduce

the rate of digestion in noodles due to its high

resistant starch content. It could be beneficial in the

management of health problems.

Therefore, the present study had two main

objectives. Firstly, to determine the functional

properties and resistant starch content of banana flour

( BF). The second was to investigate the effects of

wheat flour substitution with BF as a functional food

on qualities of fresh noodle.

2 MATERIALS AND METHODS

2.1 Materials

Unripe bananas ( Musa sapientum L. , ABB group) ,

were purchased from the local market in Hatyai,

Songkhla, Thailand. The basic ingredients for

alkaline noodle were purchased from the local

supermarket. Resistant Starch Assay Kit was

purchased from Megazyme, Ireland.

2.2 Banana Flour Preparation

Banana flour (BF) was prepared by adapted from

Tiboonbun et al. (2011). BF was stored at 4°C in

vacuum sealed aluminium foil containers.

Tangthanantorn, J., Wichienchot, S. and Sirivongpaisal, P.

Functional Properties and Resistant Starch Content of Banana Flour and Its Application to Noodle Product.

DOI: 10.5220/0009983300002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 317-321

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

317

2.3 Functional Properties

2.3.1 Gelatinization Properties

Gelatinization properties were analyzed using by a

Differential Scanning Calorimeter (DSC).

The temperatures of the characteristic transitions at

onset (T

o

), peak (T

p

) and completion (T

c

) were

recorded and the relative enthalpy (ΔH) of

the transition were calculated.

2.3.2 Pasting Properties

The pasting properties were determined using Rapid

Visco Analyzer ( RVA) . BF suspension ( 12% w/ w,

db) was poured into a RVA canister. The suspension

was equilibrated at 50°C then heated from 50-95°C at

a rate of 1. 5°C/ min, maintained at 95°C for 3 min.

The paste was cooled to 50°C and held for 5 min.

The parameters; pasting temperature, peak viscosity,

breakdown, setback and final viscosity were

recorded.

2.3.3 Flow Behaviour

Flow behavior was determined according to Noosuk

et al., (2003) using the rheometer. 4% (w/w) BF was

heated at 95°C for 15 min then flour paste was

measured viscosity values and shear stress with shear

rates between 10-1000 s

-1

at 60°C. The consistency

coefficient and flow behavior index also were

calculated.

2.4 Resistant Starch Content (RS)

Resistant starch content (RS) were determined using

the Megazyme RS assay kit (Wicklow, Ireland) by

McCleary and Monaghan (2002).

2.5 Noodle Production

Fresh noodles were prepared using a method

similar to Zhou et al. (2015) with modifications.

The formulations consisting of 100% wheat flour and

substitution wheat flour with 10%, 20%, 30% and

40% of banana flour. The noodle dough was passed

through the noodle machine to form a dough sheet

and then was slit into 2.5 mm width strands.

Afterward, the noodle strands were pre-cooked in

boiling water for 30 sec and cooled for further

analysis.

2.6 Color Analysis

Color analysis was performed on a colorimeter by

Hunter Lab Colorflex version 3.73, in triplicate, using

the CIE standard (L*, a*, b*).

2.7 Texture Properties

The texture properties were determined using

a texture analyser (TA-XT2i) as describe by Shan

et al. (2013). The fresh noodle strand will be

measured to the maximum tension force and the

maximum distance.

2.8 Statistical Analysis

The data were expressed as the means ± standard

deviation in triplicate. Data were analyzed by

using one-way analysis of variance (ANOVA),

followed by Duncan’s multiple-range test to apply for

the mean comparison when determines the significant

differences at p ≤ 0.05.

3 RESULTS AND DISCUSSION

3.1 Functional Properties and Resistant

Starch (RS) Content of Banana

Flour

3.1.1 Gelatinization Properties

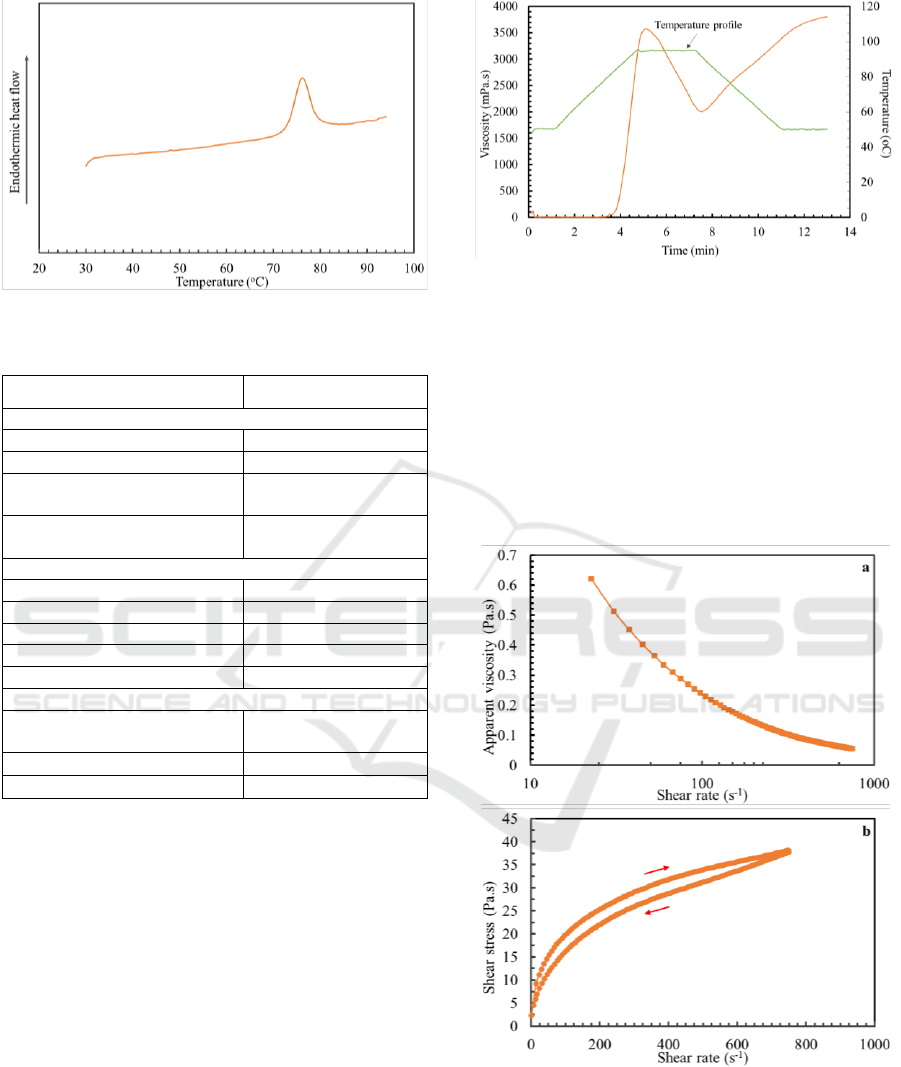

The gelatinization properties of BF measured by DSC

are presented in Figure 1. The gelatinization

parameters including onset temperature (T

o

), peak

temperature (T

p

), conclusion temperature (T

c

) and

enthalpy of gelatinization (ΔH) are presented in

Table1. BF had 10.93 J/g of ΔH value. It could reflect

the melting of the crystallites during gelatinization.

Thus ΔH of BF indicated that relative the energy was

required to break down the crystalline. Nimsung et al.

(2007) found the ΔH (15.37 J/g) and gelatinization

temperature (76.27ºC:T

o

, 80.5ºC:T

p

and 85.99ºC:T

c

) of

BF were higher than the results in this study.

3.1.2 Pasting Properties

The pasting profiles and viscosity parameters of BF

analyzed by Rapid Visco Analyzer (RVA) are

presented in Figure 2 and Table 1. The pasting

profiles is a measure of the viscosity behavior of

starch solution during the heating and cooling. Peak

viscosity shows resistance to swelling within the

granules. This value is depended on amylose and

amylopectin ratio and swelling of granules. The final

16th AFC 2019 - ASEAN Food Conference

318

Figure 1: The DSC endotherms of banana flour.

Table 1: Functional properties of banana flour.

Functional properties

Value

Gelatinization properties

- Onset temperature (T

o,

ºC)

72.93 ± 0.06

- Peak temperature (T

p,

ºC)

76.17 ± 0.00

- Conclusion temperature

(T

c,

ºC)

79.41 ± 0.16

- Enthalpy of gelatinization

(ΔH, J/g)

10.93 ± 0.00

Pasting properties

- Pasting temperature (ºC)

82.10 ± 0.65

- Peak viscosity (mPa.s)

3573.33 ± 31.94

- Breakdown (mPa.s)

1567.33 ± 35.73

- Setback (mPa.s)

1794.67 ± 38.18

- Final Viscosity (mPa.s)

3800.67 ± 39.11

Flow behavior

- Consistency coefficient

(k, Pa.s

n

)

3.54 ± 0.36

- Flow behavior index (n)

0.29 ± 0.01

- Area

1563.33 ± 240.58

Each value is mean of triplicate ± SD.

viscosity was related to recrystallization of

gelatinized starch. The pattern of pasting profile in

this study was similar to the result of Vatanasuchart

et al. (2012) and Babu et al. (2014).

3.1.3 Flow Behaviour

The relationship between apparent viscosity and

shear rate for BF, in shear rates range 10-1000 s

-1

are

showed in Figure 3a. The sample curves exhibited

similar shear thinning behavior of pseudo-plastic

materials because the viscosity decreased when shear

rate increased. The parameter values, consistency

coefficient (k) and flow behavior index (n) were

shown in Table 1. Moreover, Figure 3b showed that

both of BF occurred hysteresis loops, indicating that

it was the time-dependent non-newtonian flow

behavior of thixotropy as shown in Table 1.

Figure 2: Pasting profiles of banana flour at the

concentration of 12% w/w (db).

3.1.4 Resistant Starch Content (RS)

The resistant starch (RS) content of BF was 55.33%.

Goñi et al. (1996) classified classes of RS which very

high RS had RS content more than 15%. Therefore

this result indicated that BF containing very high RS

content. Several studies had reported that starch of

unripe banana is RS type 2 which consists of native

starch granular (Tiboonbun et al., 2011).

Figure 3: Flow curve of relationship between (a) apparent

viscosity and shear rate (b) shear stress and shear rate of

banana flour at 60°C over the shear rates range 10-1000 s

-1

.

Functional Properties and Resistant Starch Content of Banana Flour and Its Application to Noodle Product

319

Table 2: Quality characteristics and resistant starch content (RS) of fresh noodles substituted with banana flour.

Sample

Quality characteristics

Resistant starch

(%)

Color

Texture

L*

a*

b*

Tensile strength

(g

f

)

Elasticity distance

(mm)

0%BF

68.36 ± 0.05

a

0.74 ± 0.02

e

25.18 ± 0.08

a

52.97 ± 1.80

a

44.60 ± 1.97

a

5.25 ± 0.14

e

10%BF

57.99 ± 0.01

b

3.69 ± 0.02

d

21.26 ± 0.06

b

35.50 ± 1.73

b

33.75 ± 1.39

b

9.00 ± 0.12

d

20%BF

50.33 ± 0.03

c

4.34 ± 0.04

c

18.56 ± 0.08

c

33.62 ± 1.00

c

27.27 ± 1.56

c

12.62 ± 0.15

c

30%BF

47.53 ± 0.09

d

4.41 ± 0.04

b

17.07 ± 0.06

d

29.89 ± 1.62

d

22.98 ± 1.18

d

17.01 ± 0.48

b

40%BF

40.23 ± 0.03

e

5.01 ± 0.03

a

14.94 ± 0.05

e

26.84 ± 1.56

e

15.04 ± 1.23

e

22.01 ± 0.27

a

Each value is mean of triplicate ± SD.;

a-e

= Mean values in a column with different lowercase superscript letters are significantly different at

p ≤ 0.05.; BF10 = 10% Banana flour, BF20 = 20% Banana flour, BF30 = 30% Banana flour, BF40 = 40% Banana flour.

3.2 Application of Banana Flour to

Noodle Product

3.2.1 Color Characteristics of Noodle

Substituted with Banana Flour

The color characteristics of BF-substituted noodles

are shown in Table 2. The values were found

significantly decreased (p ≤ 0.05) in noodles replaced

with 10%, 20%, 30% and 40% of BF. The results

indicated that as the levels of BF substitution

increased, the color of the noodles grew darker which

affected a reduce L* and b* values and an increase a*

value. These results were similar to those reported by

Tiboonbun et al. (2011) and Vernaza et al. (2011).

3.2.2 Texture Properties of Noodle

Substituted with Banana Flour

The results of texture analysis, tensile strength and

elasticity distance of noodles substituted with BF

(Table 2). Increasing level of BF substitutions

significantly decreased (p ≤ 0.05) the texture values.

That was noodle from substituting BF for wheat flour

had lower tensile strength and elasticity distance than

the 0% BF noodles. This decrease might be explained

by the percent reducing of the wheat gluten, causing

the elasticity was decreased (Sirichokworrakit et al.,

2015 and Ritthiruangdej et al., 2011).

3.2.3 Resistant Starch of Noodle Substituted

with Banana Flour

Results of RS are shown in Table 2. A significant

increase in RS content was observed in the BF noodle

substitution. The 40% BF noodle had the highest RS

content (22.01%), whereas 0% BF noodle had the

lowest RS content (5.25%). As a result, these noodles

high resistant to hydrolysis by enzyme activities due

to the crystalline granular structure of BF. A similar

pattern was previously reported for rice noodle from

unripe banana flour by Tiboonbun et al. (2011).

4 CONCLUSIONS

The pasting curves of banana flour (BF) obtained by

RVA showed pasting temperature, breakdown, and

setback were 82.10ºC, 1567.33 mPa.s and 1794.67

mPa.s, respectively. The flour paste samples showed

shear thinning behavior of pseudo-plastic materials.

Banana flour is high in resistant starch type 2 (RS2)

which contains 55.33%. For the alkaline noodle,

while the substitution of BF increased, RS content of

noodles was increased. In addition, the RS had

affected the lightness and texture properties of noodle

products that decreased tensile strength and elasticity

value. Utilization of BF as an ingredient in food

products exerts a beneficial effect that provides high

nutritional quality containing resistant starch or low

carbohydrate digestibility.

ACKNOWLEDGEMENTS

The authors would like to thank and acknowledge the

financial support provided by Interdisciplinary

Graduate School of Nutraceutical and Functional

Food, Prince of Songkla University, Thailand.

REFERENCES

Babu, A.S., Mahalakshmi, M., Parimalavalli, R., 2014.

Comparative Study on Properties of Banana Flour,

Starch and Autoclaved Starch. Trends in Carbohydrate

Research, 6(1): 38-44.

Goñi, I., Garcia-Diz, L., Mañas, E., Saura-Calixto, F., 1996.

Analysis of resistant starch: a method for foods and

food products. Food chemistry, 56(4): 445-449.

16th AFC 2019 - ASEAN Food Conference

320

Ho, L.H., Che Dahri, N., 2016. Effect of watermelon rind

powder on physicochemical, textural, and sensory

properties of wet yellow noodles. CyTA-Journal of

Food, 14(3): 465-472.

McCleary, B.V., Monaghan, D.A., 2002. Measurement of

resistant starch. Journal of AOAC International, 85(3):

665-675.

Nimsung, P., Thongngam, M., Naivikul, O., 2007.

Compositions, morphological and thermal properties of

green banana flour and starch. Kasetsart Journal, 41:

324-330.

Noosuk, P., Hill, S.E., Pradipasena, P., Mitchell, J.R., 2003.

Structure‐viscosity relationships for Thai rice starches.

Starch‐Stärke, 55(8): 337-344.

Ramli, S., Alkarkhi, A.F., Shin Yong, Y., Min-Tze, L.,

Easa, A.M., 2009. Effect of banana pulp and peel flour

on physicochemical properties and in vitro starch

digestibility of yellow alkaline noodles. International

journal of food sciences and nutrition, 60(sup4): 326-

340.

Ritthiruangdej, P., Parnbankled, S., Donchedee, S.,

Wongsagonsup, R., 2011. Physical, chemical, textural

and sensory properties of dried wheat noodles

supplemented with unripe banana flour. Kasetsart

Journal (Natural Sciences), 45: 500-509.

Shan, S., Zhu, K.X., Peng, W., Zhou, H.M., 2013.

Physicochemical properties and salted noodle‐making

quality of purple sweet potato flour and wheat flour

blends. Journal of food processing and preservation,

37(5): 709-716.

Singh, B., Singh, J.P., Kaur, A., Singh, N., 2016. Bioactive

compounds in banana and their associated health

benefits–A review. Food Chemistry, 206: 1-11.

Sirichokworrakit, S., Phetkhut, J., Khommoon, A., 2015.

Effect of partial substitution of wheat flour with

riceberry flour on quality of noodles. Procedia-Social

and Behavioral Sciences, 197: 1006-1012.

Tiboonbun, W., Sungsri-in, M., Moongngarm, A., 2011.

Effect of replacement of unripe banana flour for rice

flour on physical properties and resistant starch content

of rice noodle. World Academy of Science, Engineering

and Technology, 81: 608-611.

Vatanasuchart, N., Niyomwit, B., Wongkrajang, K., 2012.

Resistant starch content, in vitro starch digestibility and

physico-chemical properties of flour and starch from

Thai bananas. Maejo International Journal of Science

and Technology, 6(2): 259-271.

Vernaza, M.G., Gularte, M.A., Chang, Y.K., 2011.

Addition of green banana flour to instant noodles:

rheological and technological properties. Ciência e

Agrotecnologia, 35(6): 1157-1165.

Zhou, M., Xiong, Z., Cai, J., Xiong, H., 2015. Effect of

cross‐linked waxy maize starch on the quality of non‐

fried instant noodles. Starch‐Stärke, 67(11-12): 1035-

1043.

Functional Properties and Resistant Starch Content of Banana Flour and Its Application to Noodle Product

321