Physical Properties and Sensory Acceptability of Spent Coffee

Ground as a Food Ingredient in Edible Cups

Punya-in Sutthida

*

, Rongngam Keetakawee, Wongsuwan Thiti

and Manosan Busba

Agro Industry Department, Science and Agricultural Technology Faculty,

Rajamangala University of Technology Lanna Nan, 59 M .13 Fai Keao, Nan, Thailand

Keywords: Physical Properties, Sensory Acceptability, Edible Cups and Spent Coffee Grounds.

Abstract: This study aims to develop the optimal formula for spent coffee ground edible cups. The results indicated that

the second formula which consist of wheat flour 55.42%, butter 16.90%, ground brown sugar 14.91 %, eggs

(white and yolk) 11.92%, salt 0.60% and spent coffee ground 0.25% is the optimal ratio. The average size of

the produced spent coffee ground edible cup was present are the as 67.42±1.69, 65.11±2.46,

66.72±0.72 and 57.27±3.27 mm. of outside height, internal height, outside diameter and internal diameter of

the cup, respectively. The color parameter L*, a* and b* represented as 37.67±1.08, 7.20±0.37

and 27.63±0.63. The water activities value of products is about 0.78. The sensory evaluation was used 9

points hedonic scales by 30 examiners. The sensory score of formula 2 was demonstrated that shape, color,

aroma, flavor, texture, and overall acceptability were 7.00±1.41, 6.53±0.94, 6.20±1.38, 6.63±1.13,

6.40±1.25 and 7.03±1.13, respectively.

1 INTRODUCTION

Coffee is the most importance of food commodity.

The coffee brew and coffee beverage are important in

the economic, which are prepared from roasted coffee

bean and ground coffee. There are several health

functional components in the coffee brew for

example, caffeine, chlorogenic acid and caffeic acid.

They might cause an environmental problem (Patricia

and Victor, 2012). There are about 6 million ton of

spent coffee ground from the coffee industry annually

(Solange et al., 2011, Nuria et al., 2017 and Lina et

al., 2014). Several studies of using spent coffee

ground such as apply in cosmetic, fertilizer and

pesticide, etc. However, spent coffee ground are a

source of health benefit compounds (Rocio et al

2015).

This day, the edible packaging is useful to

conventional packaging to reduce waste and to create

a novel application. The aim of this study was to use

of spent coffee ground as the food ingredient in

innovative cups, while contributing an acceptance

product quality.

*

Corresponding author email.

2 MATERIALS AND METHODS

2.1 Spent Coffee Grounds Preparation

Spent coffee ground (SCG) were obtained from the

Rabbit coffee cafe, Nan, Thailand. The raw material

with 80% humidity approximately was dried at

70±2oC until constant weight (about 5%moisture

content). The dried SCG was stored for edible cups

processing and product quality testing.

2.2 Edible Cups Processing

The weight of ingredient of each formula were shown

in Table1. Initially, flour and SCG were sifted to

separate the impurity and make them to a smaller

particle. Salt was added into the melt butter and

stirred at room temperature until homogenous. After

that, the ground brown sugar was mixed with eggs at

room temperature until uniformly. Then, melt butter

with salt was added into the liquid mixture (the

mixture of butter, brown sugar, egg and salt). Flour

was divided into three parts. Subsequently, each part

was added little by little and mixed until homogenous.

Sutthida, P., Keetakawee, R., Thiti, W. and Busba, M.

Physical Properties and Sensory Acceptability of Spent Coffee Ground as a Food Ingredient in Edible Cups.

DOI: 10.5220/0009982200002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 15-18

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

15

Finally, the mixtures of the SCG edible cup were

baked at 120-130

o

C for 1 hour and 45 min in the

bakery oven.

2.3 Edible Cup Formulations

The formulas of SCG edible cup were illustrated in

Table1. The SCG edible cups were prepared using as

basic ingredients wheat flour, butter, brown sugar.

SCG was supplemented as coloring and flavor agents.

The amount of SCG added to edible cups between 0-

15% in order to achieve the most consumer

acceptance.

2.4 Physical Analysis

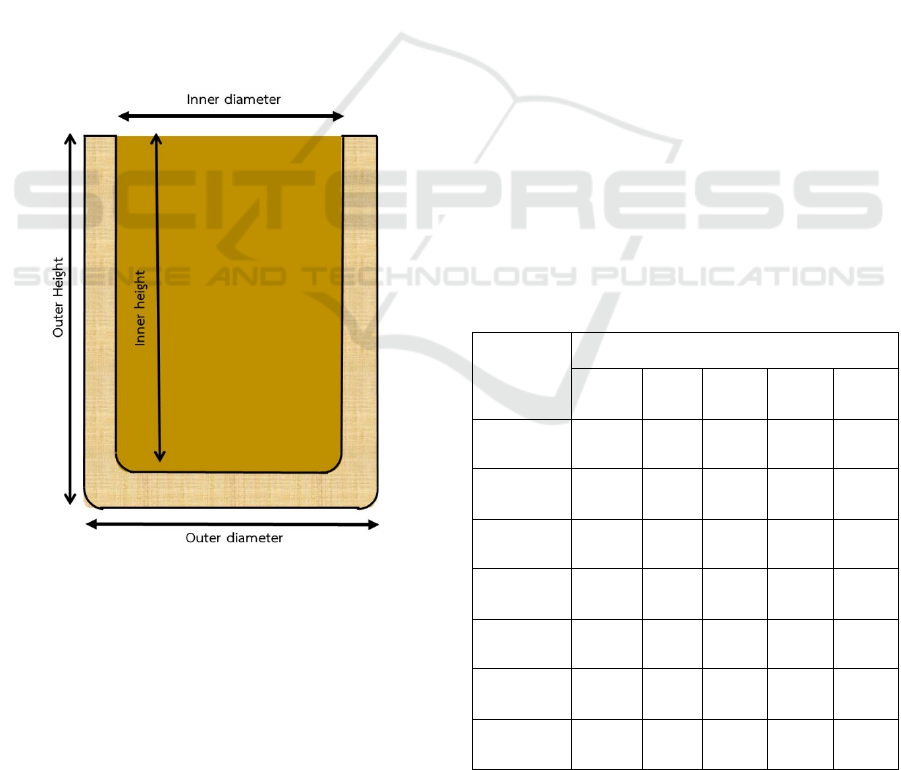

2.4.1 Size Measuring

Size of edible cups was measure for consistency

processing. The size was quantified by outer height,

inner height, outer diameter and inner diameter. Size

data are represented in the figure 1.

Figure 1: Cross section of the SCG edible cup.

2.4.2 Color Analysis

The color of SCG edible cups was determined by CIE

color scale L*, a* and b* using a Lab digital

colorimeter (Model CR-10, Minolta, Japan). Color

values were recorded as L*= Lightness (0=black,

100= white); a* (-a*= greenness, +a*=redness); b* (-

b*= blueness, +b*=yellowness).

2.4.3 Water Activity (a

w

) Analysis

It was measured in a water activity system at 25

o

C.

The calibration was carried out as indicated by the

manufacturer. Water activity (a

w

) was as certain by

the chilled mirror technique using an Aqua lab (C3

TE, USA).

2.4.4 Sensory Evaluation

Sensory evaluation of SCG edible cups (SEC1, SEC2,

SEC3, SEC4 and SEC5) was carried out applying a

hedonic sensory test. Sensory evaluation was

performed in the same session involving in total 30

untrained panelists. Shape, color, aroma, flavor,

texture and overall acceptance of the selected SCG

edible cup were observed. The results of rhetorical

scale test were converted into a 9-point scale scoring

1 (lowest) – 9 (highest) and the average of the

panelists' score was calculated.

2.4.5 Statistical Analysis

The data were expressed as the mean value ± standard

deviation (SD). Analysis of variance (ANOVA) and

Duncan’s post hoc test was applied to establish

differences between means. The differences were

examined to be significant at p<0.05. IBM SPSS

version 17.0 was used for data processing. The

physical properties data was using a completely

randomized design (CRD).

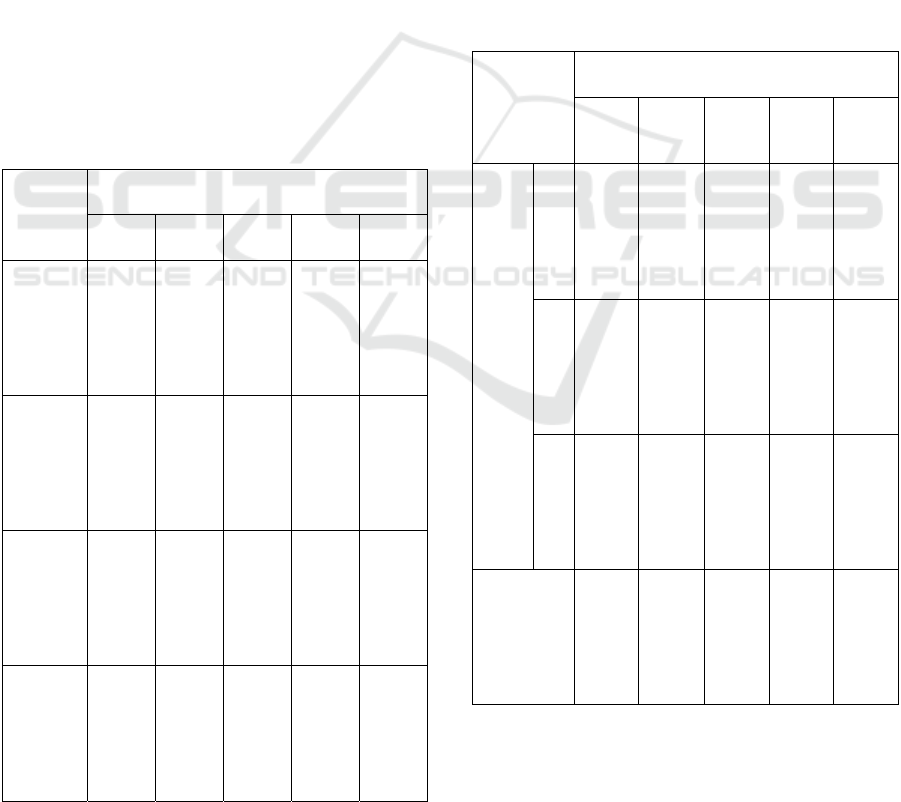

Table 1: SCG edible cups formulations.

Ingredients

(g)

Treatments

SEC 1

SEC

2

SEC 3 SEC 4 SEC 5

Wheat flour 55.67 55.42 55.17 54.42 54.17

Butter 16.90 16.90 16.90 16.90 16.90

Brown

sugar

14.91 14.91 14.91 14.91 14.91

Egg 11.92 11.92 11.92 11.92 11.92

Salt 0.60 0.60 0.60 0.60 0.60

SCG 0 0.25 0.5 1.25 1.50

Total 100 100 100 100 100

16th AFC 2019 - ASEAN Food Conference

16

3 RESULTS AND DISCUSSION

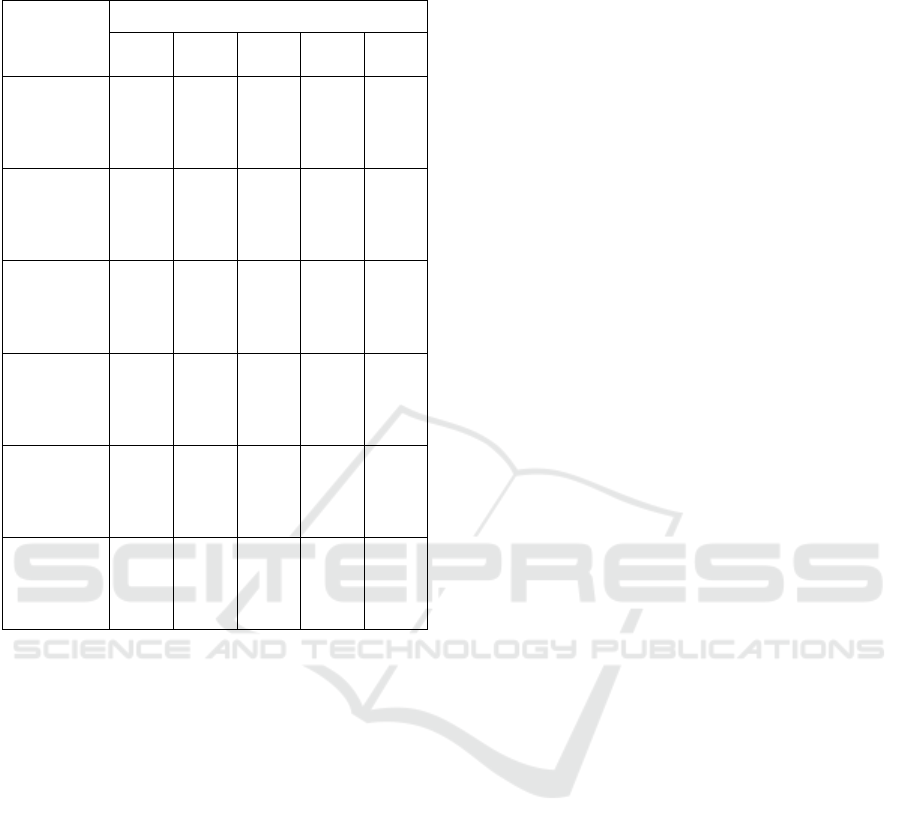

3.1 The SCG Edible Cups Size

The size of the cups is represented in table 2. All the

formulas, size was consistency. As a result, the outer

height was in rage 67.29 to 69 mm. The inner height

was present from 62.37 to 65.11 mm. Moreover, the

outer diameter and the inner diameter were in

between 66.40 to 68.13 mm. and 57.27 to 58.94

respectively.

3.2 The Color of SCG Edible Cups

Physiochemical properties are illustrated in table 3.

The lightness (*L) lowest is formula 4 and 5, which

evidence the more darkness of these products.

However, the (*a) values were in between 2.69 to

8.53 in formula 5 and 1 respectively. These represent

more SCG therefore, redder products. The (*b) values

were low in formula 4 and 5 as 21.79 and 21.83

respectively, which represent more yellowish in the

more SCG in products.

Table 2: Size of SCG edible cups (mm.)

Treatments

SEC 1 SEC 2 SEC 3 SEC 4 SEC 5

Outer

height

67.29

±

1.51

67.42

±

1.69

69.33

±

1.22

68.89

±

1.29

69.00

±

1.46

Inner

height

62.85

±

2.49

62.37

±

2.62

65.11

±

2.46

64.75

±

1.53

62.71

±

3.24

Outer

diameter

66.71

±

1.63

66.72

±

0.72

66.40

±

1.43

66.49

±

0.48

68.13

±

1.74

Inner

diameter

58.94

±

2.12

57.27

±

3.27

57.38

±

0.63

57.45

±

0.76

58.34

±

2.02

Results are expressed as mean (n=3)

3.3 Water Activity (a

w

) of the SCG

Edible Cups

Water activity (a

w

) content ranging from 0.68 to 0.78.

Therefore, these might spoil from the microorganism.

3.4 Sensory Evaluation of the SCG

Edible Cups

Shape, color, aroma, flavor, texture and overall liking

were evaluated as present in table 4. All properties

were given a score higher than six. As a result, the

shape of the formula 2 present the highest points. The

color of formula 1 indicated the highest. The aroma,

flavor, texture and overall acceptance were present no

significant outcome. However, formula 2 illustrates

the highest point.

Table 3: Physical characterization: color value, water

activity (a

w

).

Treatments

SEC

1

SEC

2

SEC

3

SEC

4

SEC

5

color

value

L*

39.45

±

2.50

a

37.67

±

1.0.8

b

35.46

±

0.86

c

33.13

±

0.87

d

32.44

±

0.65

d

a*

8.53

±

0.45

a

7.20

±

0.37

b

4.97

±

0.40

c

3.06

±

041

d

2.69

±

0.39

c

b*

29.41

±

1.07

a

27.63

±

0.63

b

24.73

±

0.99

c

21.79

±

0.70

d

21.83

±

0.72

d

water

activity

(a

w

)

0.77

±

0.02

a

0.78

±

0.02

a

0.75

±

0.01

a

0.77

±

0.08

a

0.68

±

0.07

b

Data are present as mean ± standard deviation (n=3).

Different letters indicate significant differences (p<0.05)

between the samples of the same column.

Physical Properties and Sensory Acceptability of Spent Coffee Ground as a Food Ingredient in Edible Cups

17

Table 4: Sensory evaluation (1-9 scale) of different SCG

edible cup.

Treatments

SEC1 SEC2 SEC3 SEC4 SEC5

Shape

6.93

±

1.36

b

7.00

±

1.41

a

6.13

±

1.66

b

6.53

±

1.63

ab

6.70

±

1.49

ab

Color

6.87

±

1.35

a

6.53

±

0.94

ab

6.10

±

1.19

ab

6.40

±

1.71

ab

6.03

±

1.83

ab

Aroma

ns

6.13

±

1.43

6.20

±

1.38

6.17

±

1.32

6.43

±

1.33

6.20

±

1.42

Flavor

ns

6.17

±

1.42

6.63

±

1.12

6.43

±

1.43

6.83

±

1.46

6.53

±

1.85

Texture

ns

6.10

±

1.62

6.40

±

1.25

6.13

±

1.46

6.43

±

1.43

6.17

±

1.82

overall

accepatnce

ns

6.67

±

1.09

7.03

±

1.13

6.73

±

1.23

6.80

±

1.32

6.77

±

1.71

Data are present as mean ± standard deviation (n=30).

Different letters indicate significant differences (p<0.05)

between the samples of the same column. The ns indicated

non-significant data.

4 CONCLUSIONS

This study has demonstrated the potential of using

SCG to apply the edible cup. The most proper

formula of SCG edible cup is formula 2. Due to the

highest sensory score such as shape, color, aroma,

flovor, texture and overall acceptance. There are also

the appropriate of water activity value and color

value. This may present a value-added

opportunity

for SCG which is coffee by-products.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge financial support

from the Rajamangala University of Technology

Lanna, via the otop mentor project. In addition, we

also thank for the rabbit café and the Thanamol

Limited partnership for SCG supply.

REFERENCES

Inkum, R, Namkane, K, Ramsiri, P & Punya-in, S, (2018)

“Chemical Attractant to Trap Bactrocera latifrons

(Diptera: Tephritidae) in Chilli Field” Journal of

Advanced Agricultural Technologies [online] 5(4),

298-301. Available from http://www.joaat.com/

uploadfile/2018/1218/20181218103028979.pdf

[Accessed 8th March 2019]

Lina, F.B., Jose, A.T. and Solange, I.M., 2014. Chemical,

Functional, and Structural Properties of Spent Coffee

Grounds and Coffee Silver skin. FOOD BIOPROCESS

TECH. 7(2014). 3493-3503. https://link.springer.com/

article/10.1007/s11947-014-1349-z. Accessed March

18, 2019

Nuria, M., Alba, T.G., Ines, D.P., Miguel, R., Marta, M.,

Francisco, J.M., Maria, A.M. and Maria, D.C., 2017.

Use of spent coffee grounds as food ingredient in

bakery products. FOOD CHEM. 216(2017). 114-122.

https://www.sciencedirect.com/science/article/pii/S030

8814616312067. Accessed March 16, 2019

Patricia, E. and Victor M.J., 2012. Functional properties of

coffee and coffee by-product. FOOD RES INT.46 (2012).

488-495. https://www.sciencedirect.com/science/article/

pii/S0963996911003449. Accessed March 14, 2019

Punyain., S. 2014. Effects of Postharvest Processing on the

Bioactive Compounds in Arabica Coffee. Doctor of

Philosophy Thesis, The University of New South

Wales. Australia.

Punya-in, S, Koonsena, N & Kanauey, S, (2015)

“Comparison of physical properties and Sensory

evaluation of Suan Ya Luang coffee with other brands”

The 6th Rajamangala University of Technology

International Conference 2015, 1st-3rd September,

2015, Rajamangala University of Technology Isan,

Nakhonratchasima, Thailand

. (Poster presentation).

Punya-in, S, Sitichai, R & Seantui, B, (2017) “Study on

Optimization of Drying Temperature of Sterculia

Monosperma, ventenat Flour” The 8th Rajamangala

University of Technology International Conference

2017, 7th-9th August, 2017, Bangkok, Thailand (Poster

presentation).

Rocio, C.V., Guadalupe, L., Hayde A.V. and Dave, O.,

2015. Spent coffee grounds: A review on current

research and future prospects. TRENDS FOOD SCI

TECH. 45(2015). 24-36. https://www.sciencedirect.

com/science/article/pii/S0924224415001193.

Accessed March 18, 2019

Solange, I.M., Livia M.C., Joao P.A.S., Ines C.R. and Jose

A.T., 2011. A study on chemical constituents and

sugars extraction from spent coffee grounds.

CARBOHYD POLYM. 83(2011). 368-374.

https://www.sciencedirect.com/science/article/pii/S014

4861710006119. Accessed March 16, 2019

16th AFC 2019 - ASEAN Food Conference

18