The Role of Single Layer Immobilized Cells in Mead Fermentation

Rate

Monika Rahardjo

1

, Lindayani

2

and Laksmi Hartayanie

2

1

Food Technology Study Program, Satya Wacana Christian University, Salatiga, Indonesia

2

Food Technology Study Program, Soegijapranata Catholic University, Semarang, Indonesia

Keywords: Fermentation, Food Innovation, Honey, Immobilized Cells, Mead.

Abstract: The research consisted of the making of honey-must, the making of single layer immobilized cells, and

mead fermentation. Mead fermentation carried out with variation of treatments which were control (C) and

single layer immobilized cells (SL). The analysis performed were analysis of alcohol content, sugar content,

and yeast assimilable nitrogen (YAN) concentration which determine fermentation rate. The result of this

research explained that during mead fermentation, sugar content decreased with latest sugar content varied

namely 4,30-4,70

o

Brix, alcohol content with the latest value namely 8,5-9,5%, and fermentation rate for SL

was faster than C namely 0,105 g.ml

-1

.hr

-1

.

1 INTRODUCTION

Honey is one of bee’s derivative product with

various health benefits and also contributes to

enhance community’s economical state. Mead (as

known as honey wine) is one way to innovate honey

by fermenting honey solution (Pereira et al., 2013).

Mead is probably the oldest fermented beverage in

the world that was produced, but its production has

declined in recent years partly due to a lack of

scientific progress in this field.

Based on studies of wine, wine is considered as a

safe and healthy beverage in the moderate amount of

consumption because it had a positive effect on the

cardiovascular system (German & Walzem, 2000;

Snopek et al., 2018; Wurz, 2019). Alcohol that

contained in wine included as macro nutrition and

worked as an energy source, able to provide calories

for biological activities for humans, energy for

physical work, and thermogenesis (Joshi et al.,

2012). It is also studied before that antioxidant

content, especially honey phenolic compounds,

increased from mead fermentation process

(Wintersteen et al., 2005). In addition, the fermented

ethanol compounds in mead can enhance the

solubility and extraction strength for beneficial

compounds contain in mead (Roldán et al., 2011).

Over past few decades, the use of immobilized

cells methods had received attention of researchers

and had been successfully applied in the production

of alcohol (ethanol), organic acids, enzymes, and

fermented food products (beer and wine) (Liouni et

al., 2008; Reddy et al., 2008) and proved can

overcome some common problems that occur in the

fermentation process. During mead fermentation

process, some common problems were the inability

to obtain the desired alcohol content, a long

fermentation process, heterogeneity of the final

product (Pereira et al., 2014), and the re-

fermentation from the yeast that increase volatile

acids thus produced unwanted aroma (Ramalhosa et

al., 2011). Immobilized cells also allow easier

handling of yeast cells, clear end products, and

continuity of use (Kourkoutas et al., 2004; Park &

Chang, 2000). The purpose of this research was to

study the role of single layer immobilized cells in

mead fermentation rate including its alcohol and

sugar content.

2 MATERIALS AND METHODS

The main and chemical ingredients that used in this

research were honey from Ceiba pentandra,

Saccharomyces cerevisiae var. bayanus (dry yeast),

malic acid (C

4

H

6

O

5

), formaldehyde (CH

2

O),

distilled water, sodium alginate, natrium hydroxide

(NaOH), and calcium chloride (CaCl

2

). The

192

Rahardjo, M., Lindayani, . and Hartayanie, L.

The Role of Single Layer Immobilized Cells in Mead Fermentation Rate.

DOI: 10.5220/0009981800002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 192-196

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

equipment used in this research were refractometer

(Hanna Instrument 96801), pH meter (Hanna

Instrument pH 213), and autoclave.

The research steps were the making of honey-

must, the making of single layer immobilized cells,

and mead fermentation. Honey-must is a solution

resulting from dilution of honey in distilled water.

At the stage of making honey-must, dilution of

honey in distilled water done until the concentration

of sugar reach 15

o

Brix (Srimeena et al., 2014).

Insoluble materials then filtered so the clear honey-

must solution was obtained. The honey-must then

adjusted to pH around 3,7 using malic acid

(C

4

H

6

O

5

). The parameters measured before and after

honey-must adjustment were sugar content (

o

Brix),

pH, and yeast assimilable nitrogen concentration

(YAN). YAN was determined by the formaldehyde

method (Pereira et al., 2014). The next step was

honey-must pasteurization by heating at temperature

of 65

o

C for 10 minutes (Mendes-Ferreira et al.,

2010) using a water bath and then cooled it to room

temperature.

The making of single layer immobilized cells

began with preparing starter yeast culture. The

starter yeast culture was prepared by rehydrating two

grams of dry yeast in 20 ml of distilled water at

38oC to obtain a suspension of yeast ca. 108 CFUs

per ml (Pereira et al., 2014). Sodium alginate was

dissolved in distilled water at a concentration of 4%

(w/v) and sterilized by autoclaving at temperature of

121

o

C for 20 minutes. To inoculate honey-must

solution with 106 CFU per ml, the appropriate

amount of the yeast suspension was added to sodium

alginate solution. This polymer cells mixture was

added drop wise to a 180 mM calcium chloride

sterile solution and allowed to harden for 30 minutes

at 4

o

C.

For mead fermentation step, firstly honey-must was

divided into 6 polyethylene terephthalate (PET)

gallons. Honey-must in the first three gallons were

used as control (C) where only 106 CFU per ml

yeast added, and the rest three gallons were added

with single layer immobilized cells (SL). Each

mixture was then incubated at room temperature

(Roldán et al., 2011) and batch fermented under

anaerobic condition. Each gallons were closed and

clamped, the remaining air was removed using a

pump. Fermentation was considered complete when

the YAN concentration, alcohol content, and sugar

content were constant. Measurement of YAN

concentration, alcohol content, and sugar content

carried out every two days and with thrice

replications.

3 RESULTS

The free cells yeast in control (C) and wet beads

yeast in single layer immobilized cells (SL) were

weighted before being put into honey-must. In

addition, the pH value, sugar content (

o

Brix), and

YAN concentration after adjustment were measured.

The initial physicochemical characteristics of honey-

must can be seen in Table 1.

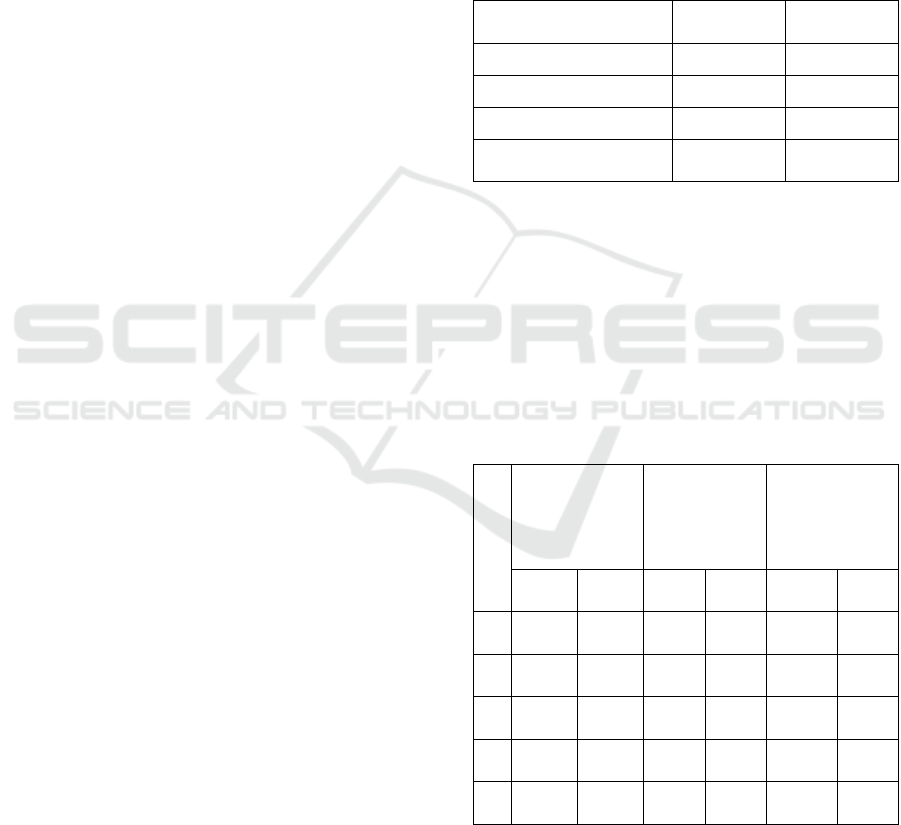

Table 1: Initial characteristics of honey-must after

adjustment.

Control

Single

Layer

Total yeast weight (g)

26.49±0.02

31.61±0.01

pH

3.72±0.00

3.72±0.00

Sugar content (

o

Brix)

15.30±0.00

15.20±0.00

Yeast Assimilable

Nitrogen (mg/L)

248.00±0.00

249.10±0.01

The YAN value after honey-must adjustment

could be included in high levels (>225 mg/L) so it

didn’t require additional nutrients. Changes in sugar

content (

o

Brix), alcohol content (%), and YAN

concentration during mead fermentation can be seen

in Table 2 and the ANOVA result for each

parameters can be seen in Table 3.

Table 2: Sugar content, alcohol content, and yeast

assimilable nitrogen concentration during mead

fermentation.

D

a

y

Sugar content

(

o

Brix)

Alcohol content

(%)

Yeast

assimilable

nitrogen

concentration

(mg/L)

Control

Single

layer

Control

Single

layer

Control

Single

layer

1

14.47±

0.00

13.4±

0.00

0±0.00

0±0.00

256.67±

0.00

270.67

±0.00

3

14.13±

0.00

11.77±

0.00

0±0.00

1.83±

0.08

275.33±

0.00

254.33

±0.00

6

12.50±

0.00

10.73±

0.00

3.17±

0.08

4.67±

0.08

270.67±

0.00

228.67

±0.00

8

11.13±

0.00

9.73±

0.00

4.17±

0.08

6.67±

0.08

263.67±

0.00

212.33

±0.00

10

10.57±

0.00

7.30±

0.01

5.00±

0.00

8.60±

0.03

254.33±

0.00

189.00

±0.00

The Role of Single Layer Immobilized Cells in Mead Fermentation Rate

193

Table 2: Sugar content, alcohol content, and yeast

assimilable nitrogen concentration during mead

fermentation (Cont.)

D

a

y

Sugar content

(

o

Brix)

Alcohol

content (%)

Yeast

assimilable

nitrogen

concentration

(mg/L)

Control

Single

layer

Control

Single

layer

Control

Single

layer

13

9.70±

0.00

5.53±

0.00

6.00±

0.00

9.17±

0.00

249.67±

0.00

168.00

±0.00

15

7.57±

0.00

4.37±

0.00

7.00±

0.00

9.43±

0.00

238.00±

0.00

165.67

±0.00

17

5.53±

0.00

4.30±

0.00

7.70±

0.03

9.50±

0.00

235.67±

0.00

163.33

±0.00

20

4.97±

0.00

4.30±

0.00

8.00±

0.00

9.50±

0.00

224.00±

0.00

161.00

±0.00

22

4.90±

0.00

4.30±

0.00

8.27±

0.00

9.50±

0.00

219.33±

0.00

163.33

±0.00

24

4.87±

0.00

4.27±

0.00

8.47±

0.00

9.50±

0.00

217.00±

0.00

161.00

±0.00

27

4.73±0.

00

4.30±

0.00

8.50±

0.00

9.50±

0.00

214.67±

0.00

161.00

±0.00

29

4.7±

0.00

4.30±

0.00

8.50±

0.00

9.50±

0.00

214.67±

0.00

158.67

±0.00

30

4.7±

0.00

4.30±

0.00

8.50±

0.00

9.50±

0.00

212.33±

0.00

158.67

±0.00

31

4.7±

0.00

4.30±

0.00

8.50±

0.00

9.50±

0.00

212.33±

0.00

158.67

±0.00

32

4.7±

0.00

4.30±

0.00

8.50±

0.00

9.50±

0.00

212.33±

0.00

158.67

±0.00

Control (C) hadn’t significant difference with

single layer immobilized cells (SL). During mead

fermentation, the value of sugar content (

o

Brix) will

decrease over time until it finally stabilized. The

final value of the sugar content was almost the same,

ranging from 4,3 to 4,7. SL had lower latest sugar

content compared to C.

Changes in the value of alcohol content hadn’t

significant difference from C and SL. During mead

fermentation, the value of alcohol content (%)

increase over time until finally stabilized. The value

of alcohol content varied from 8,5 to 9,5%. SL

produced higher alcohol content compared to C.

From table 2, the relationship between sugar content

and alcohol content can be addressed, the higher the

alcohol content along with the decrease in sugar

content of mead.

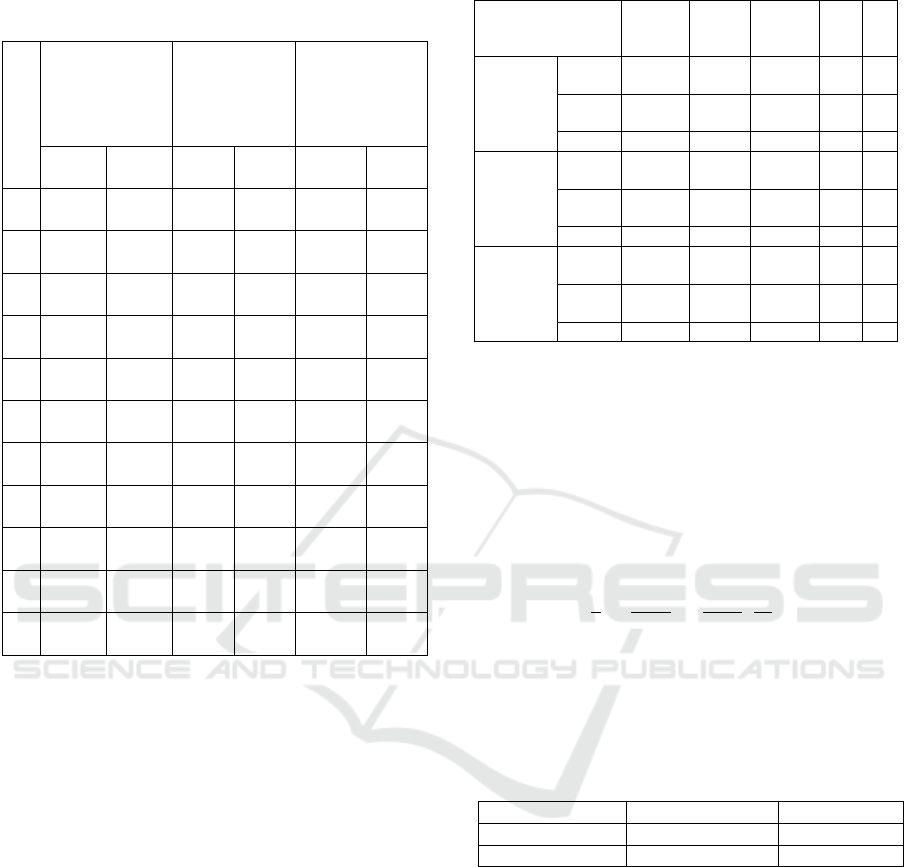

Table 3: Analysis of variance (ANOVA) result.

Sum of

squares

Degree

of

freedom

Mean

square

F

Sig.

Sugar

content

(

o

Brix)

Between

groups

15.60

1

15.60

1.30

0.26

Within

groups

360.04

30

12.00

Total

375.64

31

Alcohol

content (%)

Between

groups

20.46

1

20.46

2.26

0.14

Within

groups

272.27

30

9.08

Total

292.74

31

Yeast

assimilable

nitrogen

(mg/L)

Between

groups

22171.97

1

22171.97

23.00

0.00

Within

groups

28920.53

30

964.02

Total

51092.50

31

Fermentation rate of wine was associated with

yeast assimilable nitrogen (YAN) value, where an

increase in fermentation rate is associated with a

decrease in the number of YAN (Pereira et al.,

2014). There was a significant difference in the

value of YAN between C and SL. The value of mead

fermentation rate is calculated using Michaelis

Menten equation (Levenspiel, 1999) which was

approached by the linear equation as follows:

1

𝑉

=

1

𝑉𝑚𝑎𝑥

+ (

𝐾𝑚

𝑉𝑚𝑎𝑥

)

1

[𝑆]

(1)

Vmax values (maximum reaction speed) and Km

(Michaelis Menten constant) can be obtained from

the equation and can be seen in Table 4. When

compared, SL had faster fermentation rate than C.

Table 4: Vmax and Km value from mead fermentation.

Vmax (g.ml

-1

.hr

-1

)

Km (g.ml

-1

)

Control

0.035

6.641

Single layer

0.105

23.627

4 DISCUSSION

4.1 Effect of Immobilized Cells on

Alcohol Content (%) and Sugar

Content (Obrix) of Mead

Conversion of sugar into alcohol was an important

process in the fermentation of wine. During mead

fermentation process, alcohol content formed was

related to sugar content. The higher the alcohol

content formed, the lower the sugar content value in

the mead. Total sugar content (

o

Brix) during

16th AFC 2019 - ASEAN Food Conference

194

fermentation was an indicator of yeast’s activity in

fermenting solution (Kaur et al., 2014). When the

value of sugar content decreased, it was due to the

formation of alcohol.

The alcohol content achieved in this research

varied between 8,5-9,5%, where fermentation using

immobilized cells achieved higher alcohol content

and faster fermentation rate than control. This

proved that fermentation using immobilized cells

caused yeast cells to have higher alcohol tolerance

that control. Besides, this difference was due in

immobilized cells, yeast cells were protected from

inhibitors and other unfavourable fermentation

conditions that caused faster development of yeast

cells (Park & Chang, 2000). This result was in

accordance with the research conducted before (Yu

et al., 2007), where the productivity of alcohol in

fermentation was higher in immobilized system

compared to the free cells system because yeast cells

in the immobilized system consumed sugar faster

and efficiently.

4.2 Effect of Immobilized Cells on

Mead Fermentation Rates

Mead fermentation rate is associated with the value

of yeast assimilable nitrogen (YAN), where there

was an increase of fermentation rate associated with

a decrease in the amount of YAN (Pereira et al.,

2014). Fermentation rate depends in the

concentration of the inhibitors such as fatty acids

(hexanoic acid, octanoic acid, decanoic acid),

protein (enzymes), furfural, and

hydroxymethilfurfural (Sroka et al., 2013). High

concentration of inhibitors will inhibit the

fermentation rate. Inhibitors interact synergistically

with high osmotic pressure and an increase in

alcohol content during fermentation.

Thus in this research, mead fermentation using

immobilized cells resulted in a faster fermentation

rate and fermentation time than free cells system

because of the yeast cells were protected from

inhibitors and other unfavourable fermentation

conditions. This result was in accordance with the

research before (Navrátil et al., 2001), where the use

of immobilized cells can increase the rate of

fermentation because yeast cells were protected in

the matrix from adverse environmental conditions

such as pH, temperature, and inhibitors so their

growth were faster. In addition, the reduced

intracellular pH value in immobilized cells increases

the permeability of cytoplasmic membranes with

protons thereby increasing ATP consumption which

cause an increase in glucolytic activity and an

increase in glucose consumption in the medium

(Kourkoutas et al., 2004) thereby increasing the rate

of mead fermentation.

5 CONCLUSIONS

During mead fermentation, there were a decrease in

sugar content and YAN concentration, as well as an

increase in alcohol content. Fermentation using

immobilized cells achieved higher alcohol content

and faster fermentation rate and fermentation time

than control (free cells system).

REFERENCES

German, J. B., & Walzem, R. L. (2000). The Health

Benefits of Wine. Annual Review of Nutrition, 20(1),

561–593.

https://doi.org/10.1146/annurev.nutr.20.1.561

Joshi, V. K., Kumar, V., & Kumar, A. (2012). Physico-

chemical and sensory evaluation of wines from

different citrus fruits of Himachal Pradesh, 2(2), 145–

148.

Kaur, B., Kumar, B., Kaur, N., Sirhindi, G., Silakari, O.,

Garg, N., & Kaur, P. (2014). Role of lactobacillus

fermentum as a starter culture for malolactic

fermentation to improve quality of white wines. World

Journal of Pharmacy and Pharmaceutical Sciences,

3(3), 1687–1712.

Kourkoutas, Y., Bekatorou, A., Banat, I. M., Marchant, R.,

& Koutinas, A. A. (2004). Immobilization

technologies and support materials suitable in alcohol

beverages production: a review. Food Microbiology,

21, 377–397. https://doi.org/10.1016/j.fm.2003.10.005

Levenspiel, O. (1999). Chemical reaction engineering.

Wiley. Retrieved from https://www.wiley.com/en-

us/Chemical+Reaction+Engineering%2C+3rd+Edition

-p-9780471254249

Liouni, M., Drichoutis, P., & Nerantzis, E. T. (2008).

Studies of the mechanical properties and the

fermentation behavior of double layer alginate–

chitosan beads, using Saccharomyces cerevisiae

entrapped cells. World Journal of Microbiology and

Biotechnology, 24(2), 281–288.

https://doi.org/10.1007/s11274-007-9467-7

Mendes-Ferreira, A., Cosme, F., Barbosa, C., Falco, V.,

Inês, A., & Mendes-Faia, A. (2010). Optimization of

honey-must preparation and alcoholic fermentation by

Saccharomyces cerevisiae for mead production.

International Journal of Food Microbiology, 144(1),

193–198.

https://doi.org/10.1016/j.ijfoodmicro.2010.09.016

Navrátil, M., Šturdík, E., & Gemeiner, P. (2001). Batch

and continuous mead production with pectate

immobilised, ethanol-tolerant yeast. Biotechnology

The Role of Single Layer Immobilized Cells in Mead Fermentation Rate

195

Letters, 23(12), 977–982.

https://doi.org/10.1023/A:1010571208324

Park, J. K., & Chang, H. N. (2000). Microencapsulation of

microbial cells. Biotechnology Advances, 18(4), 303–

319. Retrieved from

http://www.ncbi.nlm.nih.gov/pubmed/14538106

Pereira, A. P., Mendes-Ferreira, A., Oliveira, J. M.,

Estevinho, L. M., & Mendes-Faia, A. (2013). High-

cell-density fermentation of Saccharomyces cerevisiae

for the optimisation of mead production. Food

Microbiology, 33(1), 114–123.

https://doi.org/10.1016/j.fm.2012.09.006

Pereira, A. P., Mendes-Ferreira, A., Oliveira, J. M.,

Estevinho, L. M., & Mendes-Faia, A. (2014). Effect of

Saccharomyces cerevisiae cells immobilisation on

mead production. LWT - Food Science and

Technology, 56, 21–30.

https://doi.org/10.1016/j.lwt.2013.11.005

Ramalhosa, E., Gomes, T., Pereira, A. P., Dias, T., &

Estevinho, L. M. (2011). Mead Production. In

Advances in food and nutrition research (Vol. 63, pp.

101–118). https://doi.org/10.1016/B978-0-12-384927-

4.00004-X

Reddy, L. V., Reddy, Y. H. K., Reddy, L. P. A., & Reddy,

O. V. S. (2008). Wine production by novel yeast

biocatalyst prepared by immobilization on watermelon

(Citrullus vulgaris) rind pieces and characterization of

volatile compounds. Process Biochemistry, 43(7),

748–752.

https://doi.org/10.1016/J.PROCBIO.2008.02.020

Roldán, A., van Muiswinkel, G. C. J., Lasanta, C.,

Palacios, V., & Caro, I. (2011). Influence of pollen

addition on mead elaboration: Physicochemical and

sensory characteristics. Food Chemistry, 126(2), 574–

582. https://doi.org/10.1016/j.foodchem.2010.11.045

Snopek, L., Mlcek, J., Sochorova, L., Baron, M.,

Hlavacova, I., Jurikova, T., … Sochor, J. (2018).

Contribution of Red Wine Consumption to Human

Health Protection. Molecules (Basel, Switzerland),

23(7). https://doi.org/10.3390/molecules23071684

Srimeena, N., Gunasekaran, S., & Murugesan, R. (2014).

Optimization of fermentation conditions for producing

Indian rock bee (Apis dorsata) mead using response

surface methodology. Journal of Applied and Natural

Science (Vol. 6). Retrieved from

www.ansfoundation.org

Sroka, P., Satora, P., Tarko, T., Duda-Chodak, A., &

Kepska, K. (2013). Immobilization Of Yeast on

Grapes for Mead Production. Retrieved from

https://www.semanticscholar.org/paper/IMMOBILIZ

ATION-OF-YEAST-ON-GRAPES-FOR-MEAD-

Sroka-

Satora/7d7a5ead42c344a72eac3ff1f70fff6a1bcddc57

Wintersteen, C. L., Andrae, L. M., & Engeseth, N. J.

(2005). Effect of Heat Treatment on Antioxidant

Capacity and Flavor Volatiles of Mead. Journal of

Food Science, 70(2), C119–C126.

https://doi.org/10.1111/j.1365-2621.2005.tb07071.x

Wurz, D. A. (2019). Wine and health: A review of its

benefits to human health. BIO Web of Conferences,

12, 04001. https://doi.org/10.1051/bioconf/

20191204001

Yu, J., Zhang, X., & Tan, T. (2007). An novel

immobilization method of Saccharomyces cerevisiae

to sorghum bagasse for ethanol production. Journal of

Biotechnology, 129(3), 415–420.

https://doi.org/10.1016/j.jbiotec.2007.01.039

16th AFC 2019 - ASEAN Food Conference

196