Effect of Soaking Formalin Solution on the Quality in Bean Sprout

Harirat Nimprasert and Varipat Areekul

Faculty of Agro-Industry, King Mongkut’s Institute of Technology Ladkrabang, Ladkrabang, Bangkok, Thailand

Keywords: Bean Sprout, Formaldehyde, Formalin.

Abstract: Formaldehyde is believed to preserve several agriculture produces not only seafood but also fruits and

vegetables. There are news spreading on the illegal adding this compound in bean sprout and other

vegetables but no scientific document has been investigated the effect of formaldehyde on it. Therefore, this

study was focused on the effect of formaldehyde on quality changes of bean sprout during chilled storage.

Bean sprout were soaked in three levels (10, 100 and 500 ppm) of formaldehyde solution for 15 min, rinsed

and stored at 8

o

C for 18 days, the samples were taken every 3 days to evaluate free and total formaldehyde

content, firmness, browning index (BI) and weight loss. It was found that the higher concentration of

soaking, the higher residues were significantly remained in free and total formaldehyde content (p≤0.05).

However, both residuals rapidly decreased and mostly was statistically indifference within 9 days (p>0.05).

After 9 days storage, the BI and weight loss were higher as increasing soaking concentration especially

soaking with 500 ppm formaldehyde solution (p≤0.05). For firmness, there were insignificantly among

untreated and treated samples (p>0.05). In conclusion, soaking with formaldehyde solution could not help

for preserving bean sprout but speedily deteriorate of this produces.

1 INTRODUCTION

Thailand cultivates vast variety of fruits and

vegetables. These nutrition produces contain high

amount in fiber, vitamins and minerals which are

benefits for health especially lower the risk of

intestinal cancer and other disease (Thai Health,

2017). In Southeast Asia, bean sprout is commonly

well-known in many varieties of soup, salad, stirred

fried vegetables and side dishes (Liu, 2008). It is

made either from soybean or mung bean by

germinating in the dark. It is rich in vitamins,

minerals, and phytochemicals (Guo et al., 2012).

Unfortunately, this sprout has a short period of shelf-

life which is about two weeks in a refrigerator

(Fresher Pantry, 2017). This produce is easily

infected by mold and bacteria and rapidly become

rotten because it is cultivated under conditions of

wetness and darkness (Hur & Koh, 2002).

Therefore, the agriculturists may use some

chemicals for extending shelf-life.

The rumor of using illegal chemicals in foods is

widely spread in the country. One of them is

formaldehyde (or methanol) or generally known as

formalin. This chemical is a precursor to produce the

resin for particle bonding or coating in several

industrial applications for example, textile and

furniture. Formaldehyde is a hazardous chemical for

human. At low volume of formaldehyde in food, it is

metabolized to formate and CO

2

and then excreted

from body but the metabolite may be toxic to liver,

kidneys, heart and nervous system. However, at high

volume of formaldehyde, it is collected in formic

acid form which can be toxic with cells, tissues,

digestive system and may result in death (Silpakorn

University, 2017; Changsap, 2015). The minimum

risk level (MRL) for oral exposure to formaldehyde

is 0.3 mg/kg/day which is derived for intermediate-

duration exposure and an MRL of 0.2 mg/kg/day is

derived for chronic-duration exposure (ATSDR,

1999). The United States Environmental Protection

Agency (US EPA) advises the recommended daily

intakes (RDI) for formaldehyde is 0.2 mg/kg/day

(Yeh et al., 2013). In addition, this chemical is also

recognized as biocide to fix animal organs and

bodies. Therefore, the agriculturists who lack of

knowledge may misuse to preserve meats, fruits and

vegetables. This chemical does not be legally

allowed to add into any agricultural produces and

foods. However, formaldehyde is naturally presented

in fruits and vegetables when plant cell wall

undergoes to de-methyl-esterified process. It produces

Nimprasert, H. and Areekul, V.

Effect of Soaking Formalin Solution on The Quality in Bean Sprout.

DOI: 10.5220/0009981700002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 227-231

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

227

methanol which convert to formaldehyde by the

catalase-H

2

O

2

system, cytochrome P450 (CYP2E1)-

mediated oxidation and the alcohol dehydrogenase 1

(ADH1) class of enzymes (Dorokhov et al., 2015).

The previous studies revealed various amounts of

formaldehyde in a variety of fruits and vegetables.

Formaldehyde content in cauliflower was reported at

5.94 ppm using HPLC procedure (Wahed et al.,

2016) and 26.9 ppm using colorimetric method

(CFS, 2009). Some fruits and vegetables were also

reported high formaldehyde content for example,

apple (17.3 ppm) (Tsuchiya et al., 1975). However,

the high amount of formaldehyde may contain in the

fresh produces and cause adverse effect for human

(Yuyong, 2016). In addition, there is controversial

on the effect of formaldehyde in fruits and

vegetables. The previous study revealed the

formaldehyde could extend shelf-life of mushrooms

while it presented negative effect on fruits and

vegetables (Antora et al., 2018). The objective of

this study was to investigate the effect of soaking

formaldehyde solution on the quality in bean sprout

during chilled storage.

2 MATERIALS AND METHODS

2.1 Chemicals

Formaldehyde solution (36-38%) was purchased

from GPO (Thailand). Trichloroacetic acid (TCA)

was bought from Fisher Scientific (England).

Phosphoric acid was obtained from MERCK

(Germany). Ammonium acetate was purchased from

LOBA Chemie (India). Acetic acid and Potassium

hydroxide (KOH) was bought from SIGMA-

ALDRICH (United States). Acetylacetone was

purchased from CARLO ERBA (New Zealand).

2.2 Sample Preparation

First, the Bean sprout was purchased from the

Amornphan village market, Bangkok, Thailand.

Next, four different concentrations of formaldehyde

solution (0, 10, 100 and 500 ppm) were prepared by

dilution with distilled water. Each sample about 200

g was soaked in 1L formaldehyde solution for 15

min. After that, the sample was rinsed with tap

water, drained and put in to HDPE bag. All samples

were kept in refrigerator at 8 °C and were sampling

every 3 days for analysis.

2.3 Methods

2.3.1 Determination of Weight Loss

Every sample was weighed before and after storage

by 2 digits analytical balance. The weight loss

percentage was calculated by using the following

formula:

%ℎ=

−

× 100

(1)

2.3.2 Determination of Browning Index

The sample of each treatment was tightly arranged

in area of 4 x 6 cm. After that, it was determined L

*

,

a

*

and b

*

by Hunter Lab (Color Quest XE, USA)

which, the reflectance specular excluded (RSEX)

mode, D65 of illuminant and 10° of observer was set

for this operation (Palou et al., 1999).

The browning index was calculated by using the

following formula:

=

[100 ×

(

− 0.31

)

]

0

.172

(2)

=

[

∗

+

(

1.75 ×

∗

)

]

[

(

5.645 ×

∗

)

+

[

∗

−(3.012 ×

∗

)

(3)

2.3.3 Determination of Firmness

The samples were investigated with a Texture

Analyzer (TA-XT Plus, UK) couple with needle

probe which, the compression mode, 10 g of contact

force and 2 mm/sec of test speed was set for this

operation (Paciulli et al., 2015).

2.3.4 Determination of Free and Total

Formaldehyde Contents

For free formaldehyde extraction, 5 g of minced

sample was mixed with 30 ml of 5% trichloroacetic

acid and homogenized at a speed of 11,000 rpm for

2 min. Next, the homogenate was filtered with the

Whatman No. 4 filter paper. Then, the filtrate was

adjusted to pH of 6.0-6.5 using 1 N KOH and was

made up to a final volume of 50 ml with distilled

water. This made-up volume filtrate was used for the

determination.

For total formaldehyde extraction, 20 g of

minced sample was mixed with 10 ml of 10%

phosphoric acid and 200 ml of distilled water. Next,

the mixture was homogenized with a homogenizer at

a speed of 11,000 rpm for 2 min. Then, the

homogenate was transferred to distillation flask and

the distillation was conducted for approximately 1

16th AFC 2019 - ASEAN Food Conference

228

hour or until the distillate of around 15 ml was

obtained. The distillate was used for the

determination.

For formaldehyde determination, 3 ml of filtrate

or distillate was mixed with 3 ml of Nash reagent

(0.2% Acetylacetone; 0.1 M Acetic acid; 3.89 M

Ammonium acetate). After that, the mixture was

reacted at 60 °C in the water bath for 15 min and

cooled with running water. Finally, the sample was

measured by Spectrophotometer (Evolution 201,

USA) at 412 nm of absorbance and the

formaldehyde content was calculated from the

standard curve prepared using standard

formaldehyde solution ranging 0-10 ppm (Sochaya

& Soottawat, 2013).

3 RESULTS AND DISCUSSIONS

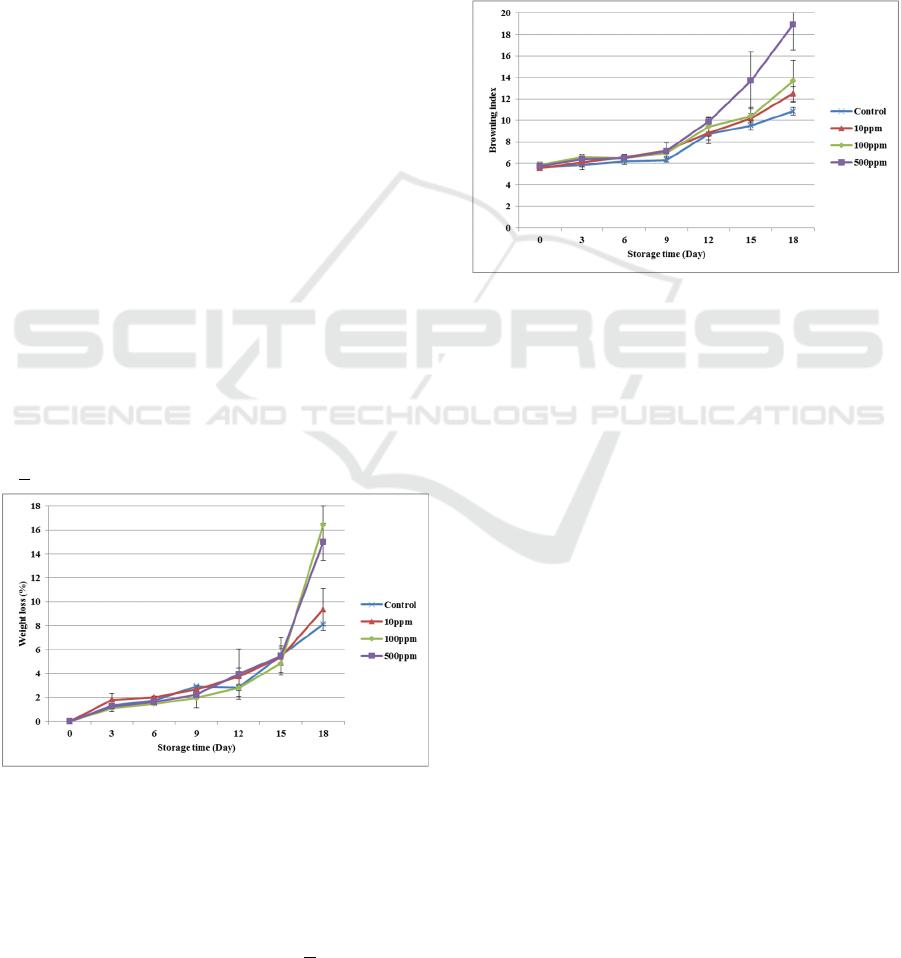

The weight loss of treated sample during chilled

storage is shown in Figure 1. During first 15 days of

storage, the weight loss in samples continuously

increased and were insignificantly among untreated

and treated samples (p>0.05). After that, during 15

to 18 days, the weight loss in sample soaked with

100 and 500 ppm formaldehyde solution was rapidly

increased and much higher than other samples

especially control. Weight loss occur when plant

transpire for heat transferring from respiration

(Siripanich, 2006). This result indicated that soaking

with formaldehyde could not extend the shelf-life

but it accelerated the deterioration of bean sprout

(p<0.05).

Figure 1: Change of weight loss percentage for

formaldehyde treated bean sprout graph.

The result of change in BI is presented in Figure

2. For the first 9 days of storage, BI slightly

increased after that, rapidly increased. The treated

sample at higher concentration were significantly

higher BI compared with control (p<0.05). During

storage, plant slightly produce ethylene which is

speedily respiration rate and browning reaction

(Siripanich, 2006). Soaking with formaldehyde

solution, the formaldehyde residues may be corroded

and oxidized to formic acid (Val Tech, 2014)

causing cell lysis. The enzyme such as polyphenol

oxidase will react with the substrate resulting in

formation of browning compounds and,

subsequently, increasing BI value. The result also

confirmed that soaking with formaldehyde is

speeding the deterioration of bean sprout. The final

sentence of a caption must end with a period.

Figure 2: Change of browning index for formaldehyde

treated bean sprout graph.

The firmness of all treated samples and control

were insignificantly different (p>0.05). However, all

samples were slowly decreased when the storage

time increased (p≤0.05). This phenomena is a

natural deterioration of plant caused by the change

of enzymatic pathways activation (Swieca & Dziki,

2015) and mechanism of cell wall will destroy

pectin that is structure of cell wall when plant cell

develop and grow (Dorokhov et al., 2015).

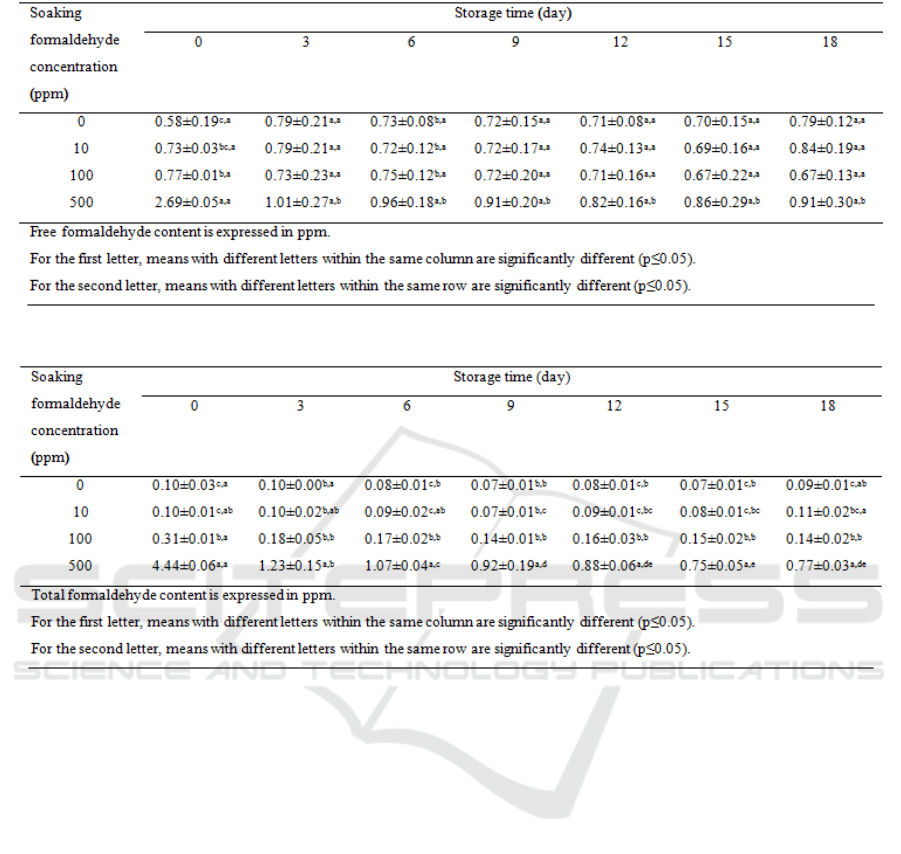

The free formaldehyde content in sample as

shown in Table 1. The soaked with water (Control)

was 0.58 ppm. After soaking in the formaldehyde

solution, the treated samples contained higher free

formaldehyde contents compared with control (0

ppm). As soaking the samples in higher

concentrations, the formaldehyde contents in the

samples were significantly higher (p≤0.05). This

result indicated that the compound can diffuse in the

plant tissue. It was noted that the intense of

formaldehyde smell was so strong after treating the

bean sprout at the concentration of 100 and 500 ppm

and could be noticed at the first sight. During the

chilled storage, the free formaldehyde content in

control slightly increased at the first 3 days of

storage from 0.58 to 0.79 ppm and after that, it

remained constant until the end of storage. For

Effect of Soaking Formalin Solution on The Quality in Bean Sprout

229

Table 1: Change of free formaldehyde content in treated bean sprout.

Table 2: Change of total formaldehyde content in treated bean sprout.

sample soaked with 10 and 100 ppm, the free

formaldehyde contents tended to be constant along

with the storage period. However, for the sample

soaked with 500 ppm, the free formaldehyde content

significantly decreased from 2.69 to 1.01 ppm at the

first 3 days storage which indicated that the

formaldehyde could be volatized at the chilled

temperature. However, the free formaldehyde

content seemed to remain constant (0.81-0.95 ppm)

for the rest of storage period same as other samples.

The final sentence of a caption must end with a

period.

For total formaldehyde content as shown in

Table 2. In control, we found that formaldehyde

contents were insignificantly changed during storage

ranged from 0.07 - 0.10 ppm. Surprisingly, the

amounts of total formaldehyde contents were lower

than those of free formaldehyde content. It indicated

that the condition of steam distillation may cause

loss of formaldehyde during extraction. After

soaking with formaldehyde solution, all samples

except soaked at 10 ppm had significantly higher

amount of total formaldehyde contents (p≤0.05).

These results agreed with the result obtained from

those of free formaldehyde content.

4 CONCLUSION

In conclusion, bean sprout soaked with

formaldehyde solution prior to storage could not

help for preservation. Moreover, it was speedily the

deterioration especially soaking at high

concentration. Therefore, this result was scientific

proof that the belief in its preservation benefit in

bean sprout was wrong.

ACKNOWLEDGEMENTS

The author would like to thank to faculty of Agro-

industry, KMITL for financial support this study and

Dr.Rachit Suwapanich for valuable guidance.

16th AFC 2019 - ASEAN Food Conference

230

REFERENCES

Agency for Toxic Substances and Disease Registry

(ATSDR). 1999. Toxicological Profile for

Formaldehyde. United States Department of Health

and Human Services.

Antora, R. A., Hossain, M. P., Monira, S. S. U., Aziz, M.

G. 2018. Effect of Formaldehyde on Some Post-

Harvest Quality and Shelf-Life of Selected Fruits and

Vegetables. Journal of Bangladesh Agricultural

University, Volume 16 (1), pp. 151-157.

Centre for Food Safety (CFS). 2009. Formaldehyde in

Food. [online]. Available at: http://www.cfs.gov.hk/

english/programme/programme_rafs/programme_rafs_

fa_02_09.html. [Accessed 27 August 2017].

Changsap, B. 2015. Formaldehyde/Formalin Nearly

Dangerous. Journal of Science and Technology of

Huachiew Chalermprakiet University, Volume 1 (1),

pp. 97-109.

Dorokhov, Y. L., Shindyapina, A. V., Sheshukova, E. V.,

Komarova, T. V. 2015. Metabolic Methanol:

Molecular Pathways and Physiological Roles.

Physiological Reviews, Volume 95 (2), pp. 603-644.

Fresher Pantry. 2017. Shelf-life of Bean Sprouts. [online].

Available at: https://fresherpantry.com/vegetables/

how-long-do-bean-sprouts-last/. [Accessed 28 August

2019].

Guo, X., Li, T., Tang, K., Liu, R. H. 2012. Effect of

Germination on Phytochemical Profiles and

Antioxidant Activity of Mung Bean Sprouts (Vigna

radiata). Journal of Agricultural and Food Chemistry,

Volume 60 (44), pp. 11050-11055.

Hur, J. S. & Koh, Y. 2002. Bactericidal Activity and

Water Purification of Immobilized TiO

2

Photocatalyst

in Bean sprout Cultivation. Biotechnology Letters,

Volume 24, pp. 23-25.

Liu, K. S. 2008. Food Use of Whole Soybeans. [online].

Available at: https://www.sciencedirect.com/topics/

agricultural-and-biological-sciences/bean-sprouts.

[Accessed 28 August 2019].

Paciulli, M., Ganino, T., Pellegrini, N., Rinaldi, M.,

Zaupa, M., Fabbri, A., Chiavaro, E. 2015. Impact of

the Industrial Freezing Process on Selected

Vegetables-Part I. Structure, Texture and Antioxidant

Capacity. Food Research International, Volume 74,

pp. 329-337.

Palou, E., Malo, A. L., Canovas, G. V. B., Chanes, J. W.,

Swanson, B. G. 1999. Polyphenoloxidase Activity and

Color of Blanched and High Hydrostatic Pressure

Treated Banana Puree. Journal of Food Science,

Volume 64 (1), pp. 42-45.

Silpakorn University. 2017. Formalin: Chemical

Contamination in Food. [online]. Available at:

http://oldweb.pharm.su.ac.th/chemistry-in-

life/d023.html. [Accessed 1 December 2017].

Siripanich, J. 2006. Physiology and Postharvest

Technology of Vegetables and Fruits. Nakhon Pathom:

Delectable Publications.

Sochaya, C. & Soottawat, B. 2013. Effect of

Formaldehyde on Protein Cross-Linking and Gel

Forming Ability of Surimi from Lizardfish Induced by

Microbial Transglutaminase. Food Hydrocolloids,

Volume 30, pp. 704-711.

Swieca, M. & Dziki, U. G. 2015. Effects of Sprouting and

Postharvest Storage Under Cool Temperature

Conditions on Starch Content and Antioxidant

Capacity of Green Pea, Lentil and Young Mung Bean

Sprouts. Food Chemistry, Volume 185, pp. 99-105.

Thai Health. 2017. 6 management of eat fruits and

vegetables for safety. [online]. Available at:

http://www.thaihealth.or.th/Content/38872-รุก%206%

20มาตรการขับเคลื่อนก

ิ

น%20"ผักผักผล%"20ปลอดภัย%20400%20ก

รัม.html. [Accessed 20 December 2017].

Tsuchiya, K., Hayashi, Y., Onodera, M., Hasegawa, T.

1975. Toxicity of Formaldehyde in Experimental

Animals-Concentrations of the Chemical in the

Elution from Dishes of Formaldehyde Resin in Some

Vegetables. Keio Journal of Medicine, Volume 24 (1),

pp. 19-37.

Val Tech. 2014. Formaldehyde, 37% w/w Safety Data

Sheet. Federal Register, Volume 77 (58).

Wahed, P., Razzaq, M. A., Dharmapuri, S., Corrales, M.

2016. Determination of Formaldehyde in Food and

Feed by an In-House Validated HPLC Method. Food

Chemistry, Volume 202, pp. 476-483.

Yeh, T. S., Lin, T. C., Chen, C. C., Wen, H. M. 2013.

Analysis of Free and Bound Formaldehyde in Squid

and Squid Products by Gas Chromatography-Mass

Spectrometry. Journal of Food and Drug Analysis,

Volume 21, pp. 190-197.

Yuyong, S. 2016. Formalin-Formaldehyde. [online].

Available at: http://www.pharmacy.mahidol.ac.th/th/

knowledge/article/322/ฟอร์มาลิน-ฟอร์มัลดีไฮด์/. [Accessed 1

December 2017].

Effect of Soaking Formalin Solution on The Quality in Bean Sprout

231