Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass

through Microfiltration Technique to Prevent Natural Infection

Agustine Susilowati, Aspiyanto, Hani Mulyani, Puspa D. Lotulung and Yati Maryati

Research Center for Chemistry, Indonesian Institute of Sciences (LIPI), 452 Building Kawasan PUSPIPTEK, Serpong,

South Tangerang, 15314, Banten, Indonesia

Keywords: Beetroot (Beta Vulgaris L.), Betacyanin, Polyphenol, Microfiltration (MF), Antibacteria.

Abstract: Fermentation of beetroot (Beta vulgaris L.) by using Kombucha culture produces biomass as a source of

polyphenol, particularly betacyanins having potential use as prevention of natural infection. This experiment

activity aims to find out separation optimization of beetroot biomass through microfiltration (MF) technique

and characteristic of retentate and permeate as a result of MF on composition, monomer domination of

polyphenol and betacyanin compounds, particle size distribution, and ability of anti-bacteria to prevent natural

infection on Staphylococcus aureus Ina CC-B4 and Escherichia coli Ina CC-B5. Separation was conducted

at room temperature, strirrer rotation speed (SRS) 200, 300 and 400 rpm, and fixed transmembrane pressure

(TMP) 40 psia. Result of experiment work showed that based on betacyanin, the best treatment is achieved at

SRS 300 rpm yielding retentate and permeate with composition of betacyanin of 0.31 and 0.16 µg/mL, total

polyphenol of 0.55 and 0.37%, total acids 1.00 and 0.72%, reducing sugars 16.33 and 28.97 mg/mL, total

solids 10.05 and 9.38%, dissolved protein 18.50 and 24.35 mg/mL, particle size 3002.4 and 1962.0 nm,

particle index 0.468 and 0.370, respectively. Identificaion on betacyanin and gallic acid monomers as total

polyphenol at retentate is dominated by monomer with molecular weight (MW) 551.13, 551.53, and 171.02,

171.24 and 171.76 Dalton (Da.), meanwhile permeate is dominated by monomer with MW 551.16 and 171.23,

171.72 Da. and relative intensities 100%, respectively. Ability to inhibit the growth of bacteria of

Staphylococcus aureus Ina CC-B4 and Escherichia coli Ina CC-B5 is achieved by retentate with zone area of

inhibiting 11 and 10 mm, respectively. In this optimum condition, MF membrane technique was able to retain

betacyanin and total polyphenol as anti-bacteria compounds in retentate with 416% (4.16-folds) and 83.33%

and pass them in permeate 166% (1.67-folds) and 23.33% compared to prior to process (feed).

1 INTRODUCTION

Fermentation of beetroot (Beta vulgaris L.) by

Kombucha cultures generates biomass with

beneficial as source of polyphenol and natural organic

acids as functional food. Beetroot is the deep violet

tubers by betacyanin pigment (Sarkar et al, 2015).

being having potential uses as antioxidant, anti-

cholesterol, natural detoxification, and prevention of

hypertension. Betacyanin including in betalain

pigment can be categorized as phenolic compound

(Coultate, 2009). Betalain pigment is synthesized

from amino acid of tirosyne containing nitrogen

element (Pavoković & Krsnik-Rasol, 2011) as shown

in Fig. 1. Betacyanin has a property of exclusive-

mutual on anthocyanin pigment. In other words, both

these pigments are not found together with

anthocyanin (Cai et al, 2005; Grotewold, 2009).

Figure 1: Chemical structure of betacyanin.

Recovery of betacyanin as biomass of fermentation

by Kombucha culture is related to microbe activity in

degrading sucrose into glucuronic acid, acetic acid,

malic acid (Malbaša et al, 2008) and other

compounds, such as betacyanin being possibility has

beneficial to prevent infection of Stapylococcus

aureus Ina CC-B4 and Escherichia coli Ina CC-B5

through chemical reactions assimilative and

dissimulative during fermentation (0 –12 days). In its

function as natural detoxification, they have the

Susilowati, A., Aspiyanto, ., Mulyani, H., Lotulung, P. and Maryati, Y.

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection.

DOI: 10.5220/0009981000002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 301-311

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

301

ability to prevent infection-related to the role of

betacyanin as phenolic compounds.

Betacyanin in retentate (concentrate) and

permeate as a result of MF on fermented beetroot

suspensions have potential use as prevention of

natural infection being generated via separation by

means of MF membrane. MF membrane is able to

sieve particles with particles in the ranges larger than

0.1 to 10 μm at trans membrane pressure (TMP) 5 –

50 psia (0.3 – 3.3 bar), so that it retains fat particle (1

– 10 μm), protein (0.04 – 2 μm), polysaccharides (8 –

20 μm) on the membrane surface. Particles with size

in the ranges of smaller than 0.1 to 10 μm will pass

freely as permeate, particularly colour pigment, such

as anthocyanin, chlorophyll, β-carotene (0,001 – 0.1

μm), organic acids, amino acids, vitamin and mineral

(0.001 – 0.1 μm) (Raja et al 2003; Field et al 1993

and Mulder, 2012). The presence of fouling becomes

a possibility when compounds retained on the

membrane surface are affected by type of membrane,

characteristic of biomass, operation condition

(temperature, flow rate or stirrer rotation speed, trans

membrane pressure, TMP) (Field, 1993; Mulder

2012). MF membrane being made of fluoropolymer

has specification with pores size in the ranges of 0.15

µm to 0.65 µm and is able to operate at TMP in the

range of 1 bar to 10 bar (module scale) or TMP in the

ranges of 20 psia to 40 psia (dead-end stirred

ultrafiltration cell, DESUFC), flow rate in the ranges

of 3.5 L/minute to 15 L/minute (module scale) or

stirrer rotation speed (SRS) in the ranges of 200 rpm

to 400 rpm (DESUFC), temperature in the ranges of

0 to 60 °C and pH ranges of 1 to 11 (Millipore, 2008),

so that assessment on the effect of SRS at fixed TMP

enables to get optimization of betacyanin.

Characterization of betacyanin compounds in

fermented beetroot biomass is performed by

identifying betacyanin compounds using Liquid

Chromatography coupled with Mass Spectrometry

(LC-MS). By using LC-MS, MWs range of purified

polyphenol compound could be known and estimated

so that the functional property of betacyanin could be

declared. Chromatography separates mixtures of

molecular based on difference in migration speed and

molecules distribution in stagnant phase (adsorbent)

and moved phase (eluent), while mass spectrometry

ionizes analytes based on the principle of electrospray

ionization (ESI) to the gas phase (fine aerosol)

(Onggo et al, 2009). LC-MS will separate betacyanin

monomer and identify MW (Eichhorn, 2001),

whereas particle size and particle size distribution can

be known by means of Particle Size Analyzer (PSA)

(Dapkunas et al, 2001); Retsch-Technology GmbH,

2019). In progress, the ability of anti-bacteria activity

of Staphylococcus aureus Ina CC-B4 and Escherichia

coli Ina CC-B5 in permeate and concentrate as a

result of separation of target and desired compounds

from fermented beetroot biomass through MF

membrane was performed via analysis of

microbiology covering inhibition power to the growth

of both types of microbes. Staphylococcus aureus is

a Gram-positive, a facultative anaerobe, round-

shaped bacterium with diameter size (Ø) ranging 0.8

– 1.0 µm, and the optimum growth at 37 ºC. S. aureus

can become an opportunistic pathogen, being a

common cause of skin infections including abscesses,

respiratory infections associated with various

pathologies condition, such as sinusitis, pneumonia,

meningitis, arthritis, and food poisoning (Madigan et

al, 2008). Meanwhile, Escherichia coli known E. coli

is a non-spore-forming, Gram-negative, facultative

anaerobic, rod-shaped, and coliform bacterium of the

genus Escherichia which is harmless, but some

serotypes can cause serious food poisoning and

contamination in their hosts because it produces

exotoxin, which can stop synthesis of protein

(Levinson, 2008). Characteristic of biomass,

concentrate, and permeate on the domination of

betacyanin monomer, particle size, and particle size

distribution are enabled to affect on ability of their

materials in inhibiting the growth of Staphylococcus

aureus Ina CC-B4 and Escherichia coli Ina CC-B5.

This matter enables to get the functional property as

anti-bacteria being can prevent infections of both

microbes.

The aim of this experiment work was to find out

process optimization of MF based on difference in

SRS on composition, particularly total polyphenol

and betacyanin, monomer domination of polyphenol

and betacyanin, particle size, particle size

distribution, and ability to inhibit the growth of

bacteria of Staphylococcos aureus Ina CC-B4 and

Escherichia coli Ina CC-B5.

2 MATERIALS AND METHODS

2.1 Materials and Equipments

The materials used for this experiment activity were

fresh beetroot tuber procured from local market,

Kombucha culture (Research Center for Chemistry –

LIPI), sucrose, Staphylococcus aureus Ina CC–B4

and Eschericiae coli Ina CC-B5 bacteria (Research

Center for Biology – LIPI), commercial composite

fluoropolymer MF membrane with pore size of 0.15

µm (FSM-0.15-PP, Alfa Laval, Nakskov, Denmark)

(according to the manufacturer), and chemicals with

16th AFC 2019 - ASEAN Food Conference

302

analytical grade quality used for preparation and

analysis purposes, such as gallic acid.

Meanwhile, main equipments applied in this

experimental activity were digital balance (Fujitsu,

Japan), peeler (local product), autoclave (Cheng Yi,

LS-50 L, China), blender (National, local), sieve of

60 mesh (Retsch, Germany), incubator (local), series

of fermentation system in laboratory scale (local),

stopwatch (Hanhart Profil2, Germany), magnetic

stirrer (HI 303 N, HANNA Instrument, Japan),

pressure gauge of technical nitrogen (Fisher

Scientific Company, England), cylinder tank for

technical nitrogen (local), Dead-End Stirred

Ultrafiltration Cell (DESFC) (MILLIPORE Model

8200, U.S.A.), UV-vis Spectrophotometer (Model

RF-550, Shimadzu, Japan), Liquid Chromatography-

tandem Mass Spectrometry (Mariner

Biospectrometry) equipped with LC (Hitachi L 6200)

[2] and Particle Size Analyzer (PSA) with SZ 100-

nano Partica Dynamic Light Scattering (DLS) system

(Beckman Coulter LS 100 Q, U. S. A) (Dapkunas et

al, 2001).

2.2 Experimental Design

Experiment activity was conducted using beetroot

biomass fermented by Kombucha culture. Beetroot

biomass was concentrated through a MF membrane

fitted in DESUFC at room temperature, SRS 200, 300

and 400 rpm, and TMP 40 psia for 30 minutes.

Analysis was conducted on initial material of biomass

(feed), retentate, and permeate covers total solids

(Gravimetric method) (AOAC, 2019), total acids

(titratable acids method), total polyphenol (Folin-

Denis or Folin-Ciocalteu method) (Liu, 2006),

dissolved protein (Lowry method)(Lowry, 1951), and

betacyanin (Wong et al, 2015). Aliquot from the best

condition treatment was performed by identifying

betacyanin by means of LC-MS (Eichhorn, 2001)

and anti bacteria activity of Staphylococcos aureus

Ina CC-B4 and Escherichia coli Ina CC-B5 through

investigation of inhibition zone (Bell et al, 1984),

particle size distribution through PSA (Dapkunas et

al, 2001). Process and analysis were performed in

duplicate. Data were processed in this description

based on result of average analysis.

2.3 Procedure

A series of the process initiated by preparing

inoculum of fermented beetroot covers sorting,

cutting of beetroot, blanching at 80 ºC for 5 minutes,

pulverizing by adding clean water at ratio ranged

from 1 to 4, and filtering via 60 mesh in order to get

filtrate. Further, filtrate was autoclaved at 90 – 95 °C,

added sucrose 10% (w/v, filtrate), cooled, inoculated

with Kombucha culture 10% (v/v, filtrate), and

fermented in closed container in darkroom so that it

is produced inoculum of fermented beetroot.

Fermentation process was conducted with similar

initial step, however process of pulverizing beetroot

was carried out by adding clean water at ratio of

beetroot/water (1 : 8, w/w), sucrose 10% (w/v filtrate

of beetroot) and inoculum of fermented beetroot 10%

(v/v filtrate of beetroot), and fermentation of mixture

of pulverized beetroot, sucrose and inoculum of

fermented beetroot was performed in closed container

in darkroom at room temperature for 12 hours so that

it is generated biomass of fermented beetroot. This

recovery of biomass of fermented beetroot is used as

feed in purifying by means of MF membrane.

Separating and/or concentrating biomass of

fermented beetroot was conducted through fitted in

DESMFC mode with a capacity of 180 mL

(laboratory scale). Empty DESMFC was filled by

biomass of fermented beetroot, flown by nitrogen gas

at a pressure of 40 psia, and stirred at room

temperature, SRS of 200 rpm and TMP of 40 psia for

± 0 (initial process) and 30 minutes

(Millipore. 2008).

Both permeate passing across MF membrane and

remained retentate were collected in small beaker

glasses and analysed. After used, the membrane was

washed with distilled water. This procedure is

conducted according to experimental design.

3 RESULTS AND DISCUSSION

3.1 Characteristic of Materials

Composition of beetroot before and after

fermentation process was tabulated in Table 1, in

which it had been appeared that fermentation process

generates biomass with composition of dominant on

polyphenol in its function as prevention of natural

infections. The fermentation process increases

organic acids and reducing sugars, but decreases

almost the whole components. Increasing both these

components are caused by activity of Kombucha

culture degrading sucrose and produce ethanol

followed by oxidizing ethanol to acetaldehyde and

then generate acetic acid. Accumulation from each

metabolite will form organic acids, such as

glucorunic acid, acetic acid, malic acid, butyric acid,

and other components as antioxidant. Betacyanin is

able to bind sugars so that total acids is yielded higher

compared to prior to fermentation. Betacyanins are

able to bind several molecules of sugars (glucose,

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection

303

fructose, galactose, arabinose and several other

molecules of sugar, such as disaccharides and

polysaccharides, and flavonoid compound present in

polyphenol group (Welch et al, 2008) which have

possibility activity of anti bacteria. Declining total

solids, polyphenol, betacyanin, dissolved protein, and

pH are occurred by increasing total acids causing its

occurrence of dilution of the whole components by

chemical reaction on biomass.

Table 1: Materials composition as a result of purification of

biomass of fermented beetroot through MF membrane for

natural anti-bacteria.

Components

Kind of materials

Pulp of

beetroot*

Fermented

beetroot 0

day*

Fermented

beetroot

12 day*

Betacyanin

(µg/mL)

0.43 0.45 0.060

Polyphenol 0.45 0.43 0.30

Total acids

(%)

0.06 0.16 0. 50

Reducing

sugars

(mg/mL)

9.45 14.66 17.33

Total solids

(%)

10.07 10.22 10.02

Dissolved

protein

(mg/mL)

21.41 21.20 15.36

pH 6.38 4.32 3.64

Legend: *ratio of beetroot/water (1: 8, w/w),

**fermentation for 0 day, ***fermentation for 12 days.

3.2 Influence on Process Condition of

MF Membrane on Composition

3.2.1 Total Polyphenols (%), Total Acids

(%), Dissolved Protein (mg/mL) and

Reducing Sugars (mg/mL)

Separation process of biomass of beetroot at SRS 200,

300 and 400 rpm, and TMP 40 psia for 30 minutes

generates retentate (concentrate) and permeate

(extract) as clear liquid by degrading color from

magenta to clear red. Increasing SRS is able to retain

total polyphenols and total acids more much on the

membrane surface compared to them passing in

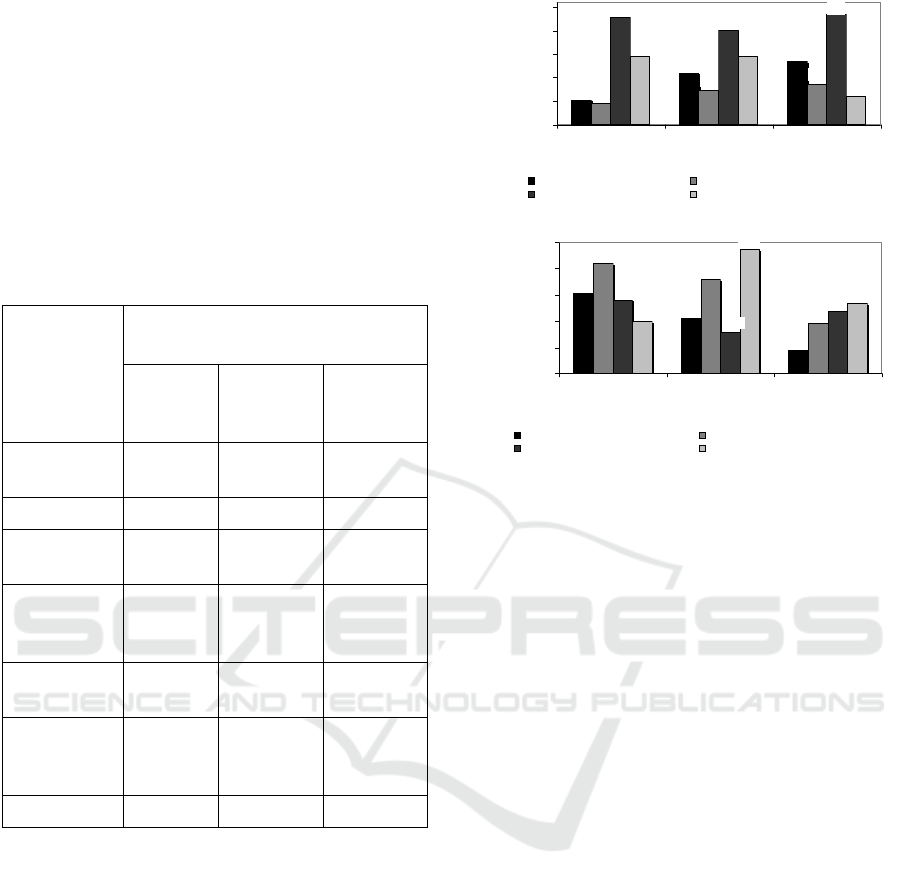

permeate, as shown in Fig 2a.

(a)

(b)

Figure 2: Effect of SRS at TMP 40 psia on (a) total

polyphenols and total acids, and (b) dissolved protein and

reducing sugars contents in retentate and permeate as a

result of MF of fermented beetroot suspensions.

SRS becoming more and higher will increase total

polyphenols in concentrate. This reason is possibily

caused by its formation of ‘cake’ due to decreasing

water mass passing through membrane so that it

inhibits total polyphenol to pass through membrane

(Mulder, 2012). Particle size of polyphenol

compounds (MW between 200 and 600 Da.) (Liu,

2006), has smaller particle size than that pores size of

MF membrane (0.15 µm), however, there is an

interaction between SRS (200, 300 and 400 rpm) and

fixed TMP 40 psia so that fouling phenomenon has

occurred. Fouling is defined as the process in which

microparticles, colloidal particles, solute molecules

or bacteria trapped or accumulated on the membrane

surface or into the membrane pores such that the

membrane pores are blocked or become smaller, and

formation of cake layer, in turn depletion of water

mass so that particles of polyphenol and organic acids

will be inhibited to pass across membrane.

Polyphenol is chemical component having activity of

anti-bacteria because of ability to increase membrane

permeability from microbial cell so that membrane

becomes unstabil causing cell hemolysis (Cushnie et

al, 2005) Similar pattern is occurred at total acids, in

which fouling is occurred in spite of particle size of

organic acids compound (MW 200 – 250 Da.) are

small (Liu, 2006). Organic acids is possibility have

ability due to hydrophilic property from membrane so

0.26

0.55

0.67

0.22

0.37

0.43

1.00

0.72 0.72

0.30

1.17

1.14

0.00

0.25

0.50

0.75

1.00

1.25

200 300 400

Stirrer rotary speed (rpm)

Total Polyphenol &

Total Acid (%)

Retentate-Total Polyphenol (%) Permeate-Total Polyphenol (%)

Retentate-Total Acid (%) Permeate-Total Acid (%)

26.75

24.35

28.98

13.54

18.50

22.17

17.70

19.53

16.33

21.22

20.68

17.94

10.0

14.0

18.0

22.0

26.0

30.0

200 300 400

Stirrer rotary speed (rpm)

Dissolved protein &

Reducing sugar (mg/mL)

Retentate-Dissolved Protein (mg/mL) Permeate-Dissolved Protein (mg/mL)

Retentate-Reducing sugar (mg/mL) Permeate-Reducing sugar (mg/mL)

16th AFC 2019 - ASEAN Food Conference

304

that it functionates as transport media of positive

charge ions. In other word, H+ diffuse to microbial

cell wall (Trivedi et al, 2010) so that microbial cell

wall will be more polar so that polyphenol

compounds, flavonoid, etc. ease to permeate. On

treatment combination at SRS 400 rpm and TMP 40

psia, optimization of total polyphenols and total

organic acids in concentrate were achieved at 0.67%

and 1.17% higher compared to passing in permeate

0.43% and 0.3%. In this condition, MF membrane

system is able to retain total polyphenols and total

acids in retentate 123.33% (1.23-folds) and 134%

(1.34-folds), however, it passes both them 43.3% and

40% compared to total polyphenols (0.30%) and total

acids (0.50%) in feed. SRS becoming higher, passes

dissolved protein and reducing sugars to get

optimization of MF membrane system followed by

decreasing its concentration. This matter showed that

MF membrane gives ability of separation

unsuccessfully for both types of components, as

indicated in Fig. 2b. Passing level of dissolved protein

and reducing sugars are related with particle size

calculated as amino acids and monosaccharides (0.01

– 0.1 µm) (PCI Membrane, 2005); Michael 1989)

being smaller compared to MF membrane (0.15 µm),

TMP (40 psia), and type of biomass. Interactions

amongs these factors, it is not possibility occurred

fouling so that they pass more much in permeate

compared with being retained in retentate. Dissolved

protein is the whole proteins from raw material of

beetroot tuber (1.61%), in which beetroot tuber is

degraded by microbe activity in Kombucha culture to

dissolved protein derivatives accoding to Lowry

(Lowry, 1951), whereas, reducing sugar is molecule

of sugar having property of reducing because reactive

hydroxyl ion (OH) according to Nelson-Somogyi

method (AOAC 2019). Reducing sugars and

dissolved protein become parameter in converting

carbohydrate and protein by activity of microbes in

Kombucha culture (Wong, 2015). Optimization of

dissolved protein (22.17 mg/mL) and reducing sugars

(21.22 mL) in concentrate is obtained at SRS 200

rpm, and passes dissolved protein (26.75 mg/mL) and

reducing sugars (17.94 mg/mL) in permeate. In this

optimum condition, MF membrane system is able to

retain dissolved protein (44.33%) and reducing sugars

(22.45%) in retentate, however, it passes dissolved

protein 74.15%) and reducing sugars (3.40%) in

permeate compared to dissolved protein (15.36

mg/mL) and reducing sugar (17.33 mg/mL) in feed.

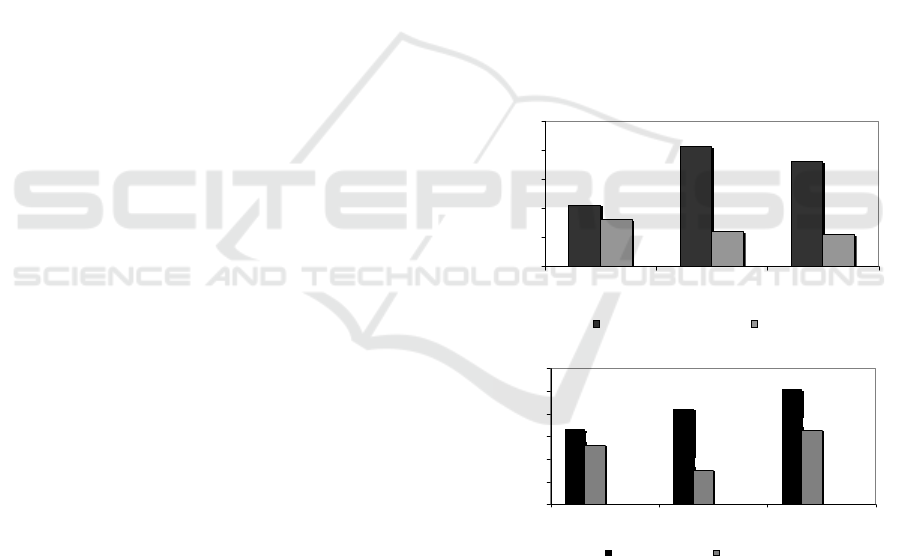

3.2.2 Betacyanin and Total Solid

Betacyanin in biomass of beetroot, retentate and

permeate as a result of MF process are possibility as

compound being have activity of anti bacteria in

phenolic compound group (Coultate, 2009).

Separation process of betacyanin and total solids from

biomass of beetroot showed that increasing SRS

generates increasing betacyanin until it is get the best

SRS followed by dropping betacyanin, however, on

total solids becomes more and more high to optimum

SRS. The best SRS on betacyanin was achieved at

300 rpm, which is able to separate betacyanin in

retentate 0.31 µg/mL and passes in permeate 0.16

µg/mL, as shown in Fig. 3a. In the optimum

condition, MF membrane separates betacyanin in

retentate 416.67% (4.17-folds) compared to

betacyanin in feed (0.06 µg/mL). It had been known

that fermentation process declines betacyanin by

effect of glucosidase enzyme of Kombucha culture

(Havlíková et al, 1983). With particle size ranging

from 0.001 – 0.01 µm, like flavonid compounds

passes freely in permeate, however, due to presence

of fouling causes betacyanin trapped in ‘cake’ layer

on the membrane surface. On total solids, MF

membrane showed increasing total solids in line with

incresing SRS, as showed in Fig. 3b.

(a)

(b)

Figure 3: Effect of SRS at TMP 40 psia on (a) betactanin

and (b) total solids contents in retentate and permeate as a

result of MF of fermented beetroot suspensions.

MF membrane process generates a separation

successfully, in which total solids retained on the

membrane surface in retentate much more than that

passing in permeate for the whole process treatment.

Increasing total solids is caused by deficit of water

mass passing across membrane as a consequence

0.21

0.31

0.28

0.18

0.16

0.16

0.10

0.15

0.20

0.25

0.30

0.3

5

200 300 400

Stirrer rotary speed (ug/mL)

Betacyanin (ug/mL)

Retentate Permeate

9.83

10.05

10.27

9.66

9.38

9.82

9.00

9.25

9.50

9.75

10.00

10.25

10.50

200 300 400

Stirrer rotary spee d (rpm )

Total solid (%) CH+)

Retentate Permeate

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection

305

from interaction between driven force and SRS to

solidify components on the membrane surface.

Optimization of total solids is achieved by retentate

(10.27%) higher compared to pass in permeate

(9.82%) at SRS 400 rpm. In this optimum condition,

MF membrane process is able to retain total solids in

retentate 2.49%, however, pass in permeate 1.99%

compared to total solids in feed (10.02%). Total

solids is an accumulation of the whole components of

beetroot biomass both soluble and insoluble in water

according to Gavimetric method (AOAC 2019) [17].

3.3 Optimum Condition Process of

Microfiltration

Based on the highest betacyanin concentration as

prevention of the best natural infection, separation

process of betacyanin from fermented beetroot was

achieved at SRS 300 rpm and TMP 40 psia. In this

condition is yielded concentrate and permeate of

fermented beetroot with composition of betacyanin

0.31 and 0.16 µg/mL, total polyphenols 0.55 and

0.37%, total acids 1.00 and 0.72%, reducing sugars

16.33 and 28.97 mg/mL, total solids 10.05 and

9.38%, and dissolved protein 18.50 and 24.35

mg/mL. In this condition, MF membrane process is

able to retain components in concentrate and pass

components in permeate on betacyanin 416% (4.16-

folds) and 166% (1.67-folds), total polyphenols

83.33% and 23.33%, total acids 100% (1-fold) and

44%, reducing sugars 6.31% and 88.61%, total solids

0.3% and 6.84%, and dissolved protein 20.44 and

58.53% compared to concentration of components in

feed. Fig. 4 shows feed (biomass of beetroot

fermented for 12 days), concentrate and permeate

yielded from MF membrane process at room

temperature, SRS 300 rpm and TMP 40 psia for 30

minutes.

(a)

(b) (c)

Figure 4: (a) feed, (b) retentate and (c) permeate as a result

of MF of fermented beetroot suspension at optimum

condition (300 rpm and 40 psia).

3.4 Activity of Anti Bacteria from

Fermented Beetroot

Fermented beetroot has possibility activity of natural

anti bacteria relating with presence of polyphenol

compounds, particularly betacyanin. Retentate from

MF membrane process on fermented beetroot at

optimum condition (SRS 300 rpm, TMP 40 psia)

indicates an ability in inhibiting the growth of

Staphylococcos aureus and Escherichia coli on Agar

Sodium with concentration 10 µmL incubated at 37

°C for 18 hours. Fig. 5a and 5b displays ability to

inhibit the growth of Staphylococcus aureus and

Escherichia coli in retentate of fermented beetroot

with diameter of the inhibition zone of 11 mm and 10

mm, respectively.

(a)

(b)

Legend: *Number 20 and 21 are code of samples.

Figure 5: The growth of inhibition ability of (a)

Staphylococcus aureus and (b) Escherichia coli from

retentate of fermented beetroot suspension at optimum

condition.

Feed and permeate does not demonstrate presence

of clear zone arounds colony of Staphylococcus aureus

and Escherichia coli or in other words it does not

display activity of anti bacteria. This matter showed

that MF membrane process tends to affect on ability to

inhibit the growth of Staphylococcus aureus and

Escherichia coli according to concentrations of total

polyphenol (0.55%) and betacyanin (0.31 µg/mL) at

higher concentrate compared to biomass without

through MF membrane process with total polyphenol

(0.30 µg/mL) and betacyanin (0.06 µg/mL). Similar

case is also occurred in permeate according to both

lower concentration of total polyphenol (0.37%) and

betacyanin (0.16 µg/mL) compared to retentate.

Bioactive compound concentration becoming more

and more high will increase its activity as anti- bacteria

(Brooks et al 2010). In general, S. aureus as a gram-

positive bacterium has cell wall composed from

peptidoglycan, in which polyphenol has property of

toxis so that it is able to inhibit bacterial adhesin,

Enzymes function and protein transport on cell cover

(Cowan, 1999). that has deleterious ability on bacteria

function causing lysis.

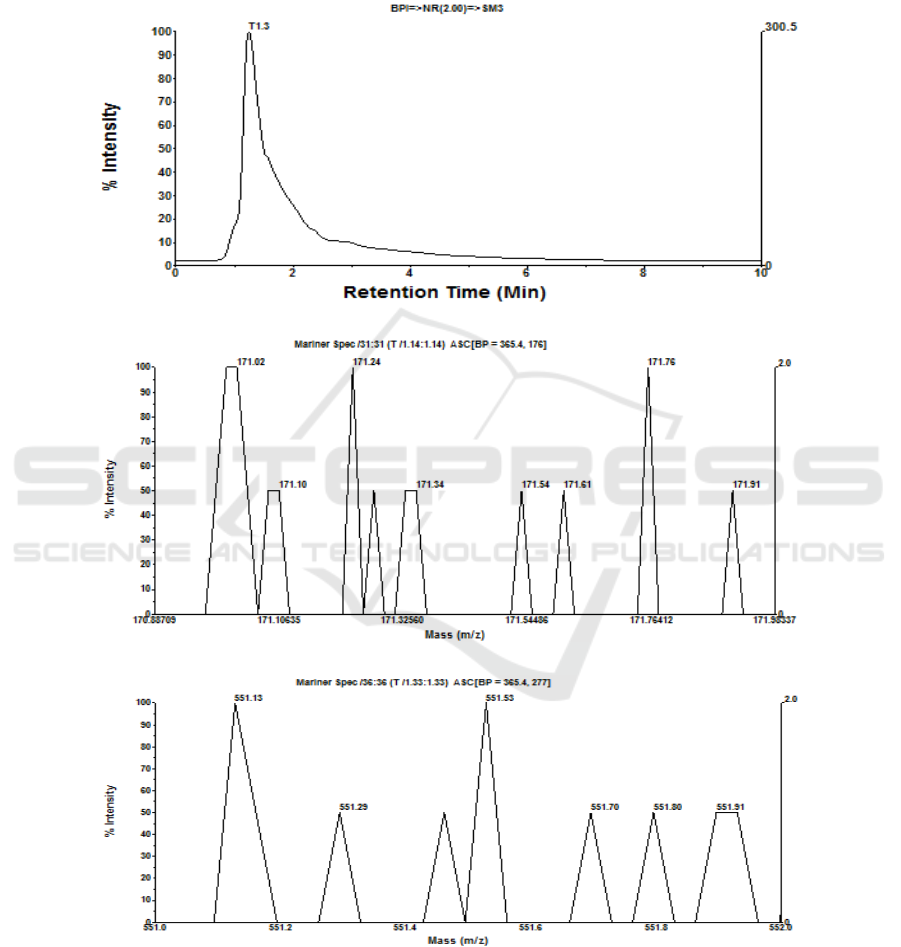

3.5 Identification of Monomer on

Polyphenol and Betacyanin

Compounds

Identification on polyphenol and betacyanin

monomers is performed on an aliquot of retentate and

16th AFC 2019 - ASEAN Food Conference

306

permeate from optimum condition treatment at SRS

300 rpm and TMP 40 psia by means of LC-MS based

on molecular weight (MW) of gallic acid (MW 170

Da.) and betacyanin (MW 550 Da.). By means of LC-

MS method had been known that a compound

indicated difference in MW, in which its possibility is

as M+, M+ Na+, 2M++ or 2M+, Na+ [12]. Operation

condition of LC-MS was adjusted in column of C-8

(15 mm x 2 mm), in which mobile phase (eluent) is

methanol solution at flow rate of 0.1 mL/minute and

injection volume of 5 μL, as displayed in Fig 6a-6f.

(a)

(b)

(c)

Figure 6: (a) Chromatogram of retentate, (b) mass spectra of retentate monomer as gallic acid, (c) mass spectra of retentate

monomer as betacyanin, (d) chromatogram of permeate, (e) mass spectra of permeate monomer as gallic acid, (f) mass spectra

of permeate monomer as betacyanin as a result of MF of fermented beetroot suspensions at room temperature, SRS 300 rpm,

and TMP 40 psia for 30 minutes.

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection

307

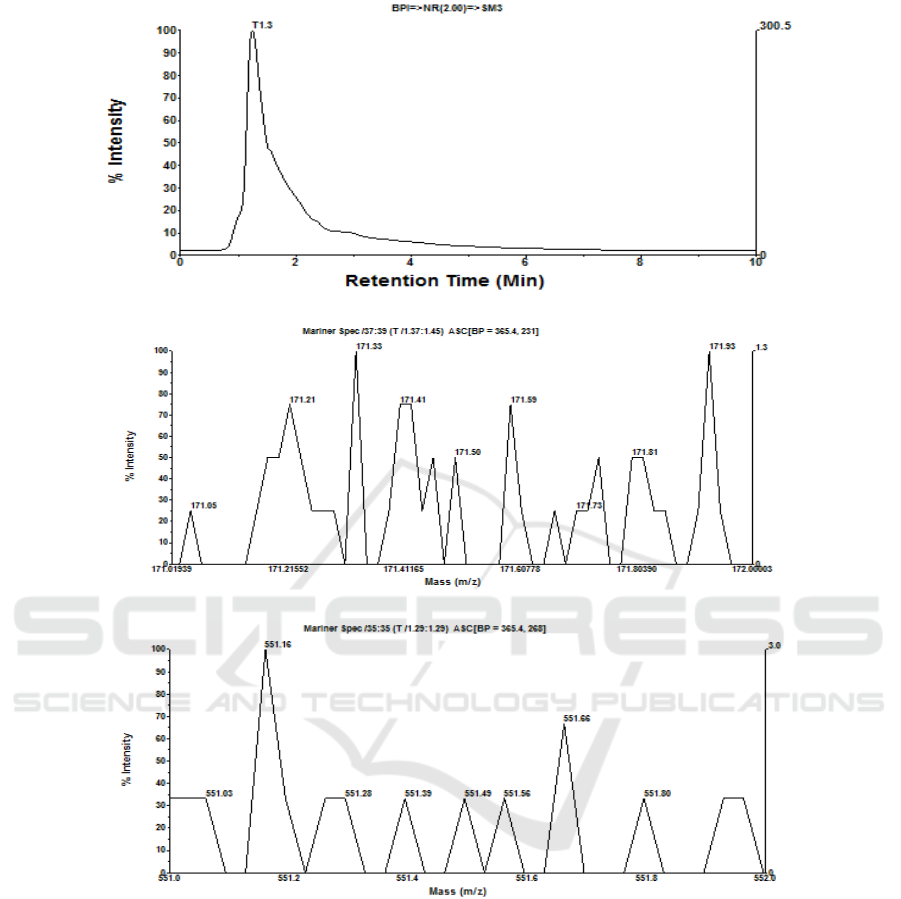

(d)

(e)

(f)

Figure 6: (a) Chromatogram of retentate, (b) mass spectra of retentate monomer as gallic acid, (c) mass spectra of retentate

monomer as betacyanin, (d) chromatogram of permeate, (e) mass spectra of permeate monomer as gallic acid, (f) mass spectra

of permeate monomer as betacyanin as a result of MF of fermented beetroot suspensions at room temperature, SRS 300 rpm,

and TMP 40 psia for 30 minutes (cont.).

On polyphenol monomer as gallic acid,

chromatogram on fermented beetroot concentrate

shows one (1) peak (T1.3), in which at mass spectra

T1.3 is get 8 monomer of gallic acid with MW

between 171.02 and 171.92 Da. dominated by 3

monomers of gallic acid with MW 171.0231, 171.24,

and 171.76 Da. (2M+) and relative intensity of 100%.

Meanwhile, on monomer of betacyanin is get 6

monomers of betacyanin with MW between 551.13

and 551.91 Da. dominated by 2 monomers of

betacyanin with MW 551.13 and 551.53 Da. and

relative intensity 100%, as shown in Fig 6a, 6b, and

6c. Permeate of fermented beetroot is get

chromatogram with one (1) peak with mass spectra

10 monomers of gallic acid dominated by monomer

with MW 171.23 and 171.72 Da. with relative

intensity 100%, whereas monomer of betacyanin is

get 9 monomers of betacyanin with MW between

16th AFC 2019 - ASEAN Food Conference

308

551.03 and 551.95 Da. dominated by monomer of

betacyanin with MW 551.16 Da. and relative

intensity 100%, as showed in Fig 6d, 6e and 6f.

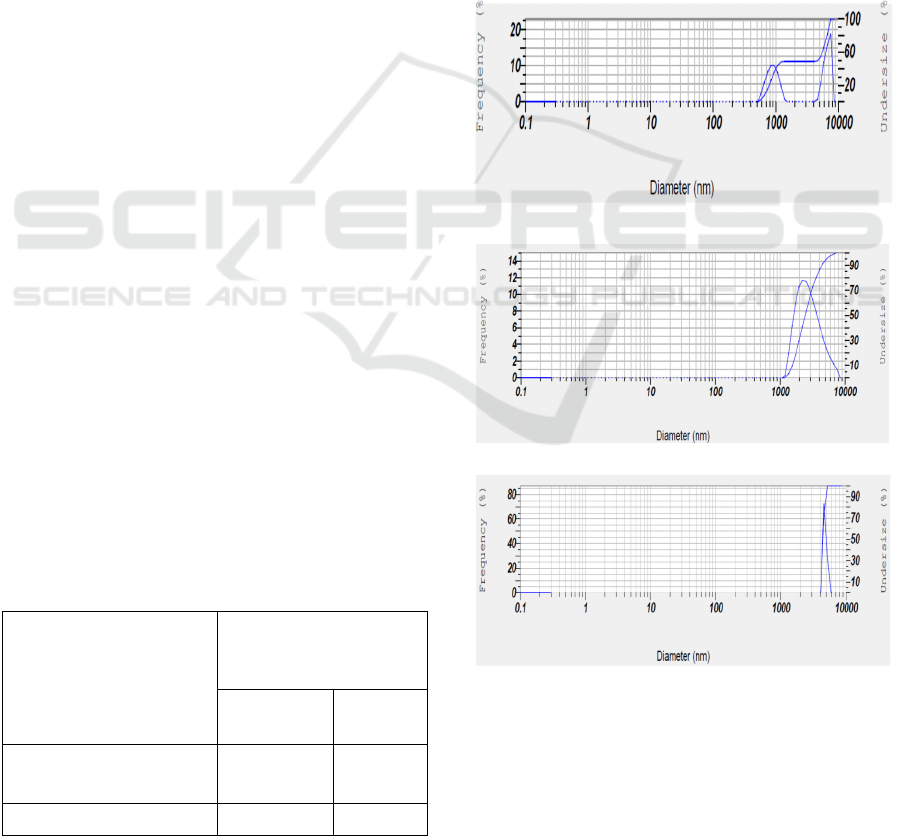

3.6 Distribution of Particle Size

Based on betacyanins, MF membrane process on

fermented beetroot with the best process condition is

resulted from concentrate with thick suspension and

permeate with clear liquid by degrading colour from

red to dark red. By using stirrer at SRS 300 rpm and

TMP 40 psia for 30 minutes affects possibility on

particle size and particle size distribution. Particle

size and particle size distribution are conducted to

know the characteristic of suspension relating with

adsorption aspect in the digestive system. Table 2.

demonstrates larger particle size of feed (5656.4 nm)

than particle size of retentate (3002.4 nm) and

permeate (1962.0 nm) with particle index of 0.370,

1.912 and 0.468, respectively. The difference in this

particle size is possibily caused by MF system being

separating suspension so that biomass feed without

MF system has the highest particle size. Meanwhile,

the concentrate is an accumulation from all

components with particle size larger than 0.15µm due

to fouling phenomenon and permeate has the smallest

particle size because components with particle size

smaller than 0.15µm passes freely in permeate.

Dispersion of particles are displayed as dispersed

particle index (PI), in which feed has the highest PI

(1.912) compared to PI of retentate (0.468) and PI of

permeate (0.370). Particle size becoming more and

more small will be small in PI or in other words

dispersion of particle is more uniform and homogen.

It had been appeared that retentate and permeate have

PI smaller than 1 expressed that particle size

distribution is more homogenous compared to feed

indicating particle size distribution is ununiform (PI

> 1) (Eichhorn, 2001).

Table 2: Characteristic of particles in feed, retentate and

permeate by MF membrane fitted in DESMFC at room

temperature, SRS of 300 rpm and TMP 40 psia for 30

minutes.

Kind of of fermented

beetroot*

Distribution of nano-

polyphenol particles

(nm)

Z-Average

(nm)**

PI***

Feed*

Retentate (concentrate)

5656.4

3002.4

1.912

0.468

Extract (permeate) 1962.0 0.370

Particle size distribution on feed showed that particles

have diameter size (Ø) of 500 – 1200 nm and 700 –

9000 nm (> 10000) at frequency between 0 and 10%,

and between 0 and 15% or the whole particles with Ø

between 500 and 10000 nm (> 10000 nm) at

frequency between 0 and 25%, respectively, as

indicated in Fig 7a. It had been appeared that particles

in retentate have Ø between 1000 and 9500 nm (>

10000 nm) at frequency between 0 and 13% or the

whole particles with Ø between 1000 and 9500 nm (>

10000 nm) at frequency between 0 and 15%, as

demonstrated in Fig. 7b. Meanwhile, on permeate

appears particles with Ø between 6000 and 8000 nm

at frequency between 0 and 65%, as shown in Fig. 7c.

Particle size distribution indicates a difference in the

whole materials, in which feed has particle size with

more variation compared to retentate and permeate.

(a)

(b)

(c)

Figure 7: Particle size distribution of (a) feed, (b) retentate,

and (c) permeate as a result of separation of fermented

beetroot by MF membrane fitted DESUFC at room

temperature, SRS of 300 rpm and TMP 40 psia for 30

minutes.

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection

309

4 CONCLUSIONS

Separation of total polyphenol and betacyanin

compounds from fermented beetroot through MF

membrane generates a separation successfully for

betacyanin, total solids, total acids, and

unsuccessfully for dissolved protein and reducing

sugars. SRS becoming more and higher will retain

total polyphenol, betacyanin, total acids, total solids

in retentate, however SRS pass freely dissolved

protein and reducing sugars in permeate. Based on

recovery of betacyanin, optimization on process

condition by means of MF technique was achieved at

SRS 300 rpm being resulting retentate and permeate

with composition betacyanin of 0.31 and 0.16 µg/mL,

total polyphenols of 0.55 and 0.37%, total acids of

1.00 and 0.72%, reducing sugars of 16.33 and 28.97

mg/mL, total solids of 10.05 and 9.38%, dissolved

protein of 18.50 and 24.35 mg/mL, particle size

3002.4 and 1962.0 nm, particle index 0.468 and

0.370, respectively. Identification on betacyanin and

galic acid monomers as total polyphenol at retentate

is dominated by monomer with molecular weight

(MW) 551.13, 551.53, and 171.02, 171.24 and 171.76

Dalton (Da.), meanwhile permeate is dominated by

monomer with MW 551.16 and 171.23, 171.72 Da.

and relative intensities 100%, respectively. Ability to

inhibit the growth of bacteria of Staphylococcus

aureus Ina CC-B4 and Escherichia coli Ina CC-B5 is

obtained by retentate with zone area of inhibiting 11

and 10 mm, respectively. In this optimum condition,

MF membrane technique was able to retain

betacyanins 416% (4.16-folds), total polyphenol

83.33%, total acids 100% (1-fold), reducing sugars

6.31%, total solids 0.3% and dissolved protein

20.44% in retentate, whereas it passes betacyanin

166% (1.67-folds), total polyphenol 23.33%, total

acids 44%, reducing sugars 88.61%, total solids

6.84% and dissolved protein 58.53% in permeate

compared to components prior to process (feed).

ACKNOWLEDGEMENT

The authors wish to thank the Kemenristekdikti

throughout Program Insentif Riset Sistem Inovasi

Nasional (INSINAS) Fiscal Year 2019 supporting

this research in Program INSINAS Riset Pratama

Individu on Research Field for developing functional

food–based local natural resources.

REFERENCES

Sarkar, T., Sen, M. K., and Nihar, S. 2015. Extraction of

natural pigment from beet root & proper packaging of

that red dye: a review. Journal of Agricultural

Engineering and Food Technology, (2): 116 – 118.

Coultate, Tom P. 2009. Food: the chemistry of its

components. Royal Society of Chemistry,

Pavoković, Dubravko; Krsnik-Rasol, Marijana. 2011.

Complex biochemistry and biotechnological

production of betalains. Food technology and

Biotechnology, 49.2: 145-155.

Cai, Yizhong; Sun, Mei; Corke, Harold, 2005. HPLC

characterization of betalains from plants in the

Amaranthaceae. Journal of chromatographic science, ,

43.9: 454-460.

Grotewold, Erich. 2006, The genetics and biochemistry of

floral pigments. Annu. Rev. Plant Biol., 57: 761-780.

Malbaša, R.; Lončar, E.; Djurić, M. 2008, Comparison of

the products of Kombucha fermentation on sucrose and

molasses. Food Chemistry, 106.3: 1039-1045.

Raja, Ghosh. 2003. Protein Bioseparation Using

Ultrafiltration: Theory, Applications And New

Developments. World Scientific.

Field, R. W. 1993. Transport processes in membrane

systems. In: Membranes in bioprocessing: theory and

applications. Springer, Dordrecht, p. 55-112.

Mulder, J. 2012) Basic principles of membrane technology.

Springer Science & Business Media.

MILLIPORE. 2008. Catalogue and Product Information of

Stirred Ultrafiltration Cell, Amicon Bioseparation,

MILLIPORE, Bedford, U. S. A. www.millipore.com.

Onggo, Djulia, 2009. General Principles in Electrospray

Mass Spectrometry: A New Technique in Mass

Spectral Analysis. Jurnal Matematika dan Sains, , 3.2:

115-131.

Eichhorn, Peter; Knepper, Thomas P. 2001. Electrospray

ionization mass spectrometric studies on the

amphoteric surfactant cocamidopropylbetaine. Journal

of mass spectrometry, 36.6: 677-684.

Dapkunas, Stanley J.; Jillavenkatesa, A.; Lum, L. H. 2001.

Particle Size Characterization. NIST, Gaithersburg,

MD.

Retsch-Technology GmbH. 2019. Nano Particle Analyzer

Horiba SZ-100.https://www.retsch-technology.com.

Accessed at February 3, 2019.

Madigan, M. T., Martinko, J. M., Dunlap, P. V., & Clark,

D. P. 2008. Brock biology of microorganisms 12th

edn. Int. Microbiol, 11, 65-73.

Levinson, W. 2008, Mycology. Review of medical

microbiology and immunology. 10th ed. USA, The

McGraw-Hill Company, 336-52.

AOAC. 2019. Official Methods of Analysis. Association of

Official Analytical Chemists International, 21st

Edition, 2275 Research Blvd, Ste 300, Rockville, MD

20850. http://www.aoac.org. Accessed at 3 September

2019.

Liu, Z. 2006. New techniques for tea catechins extraction.

In: International Training Workshop of Tea Science.

China: Hunan Agricultural University,.

16th AFC 2019 - ASEAN Food Conference

310

Lowry, Oliver H., 1951. Protein measurement with the

Folin phenol reagent. Journal of biological chemistry,

1951, 193: 265-275.

Wong, Yen-Ming; SIOW, Lee-Fong. 2015. Effects of heat,

pH, antioxidant, agitation and light on betacyanin

stability using red-fleshed dragon fruit (Hylocereus

polyrhizus) juice and concentrate as models. Journal of

food science and technology, 52.5: 3086-3092.

Bell, S. M. 1984. Antibiotic sensitivity testing by the CDS

Methods. Dalam Clinical Microbiology Up date

Program. Editor: Hartwig, N. The Prince of Wales

Hospital. New South Wales.

WELCH, Cara R.; WU, Qingli; SIMON, James E. 2008.

Recent advances in anthocyanin analysis and

characterization. Current analytical chemistry, 2008,

4.2: 75-101.

PCI Membrane and Filtration Group. Membrane

Technology For Process Industry, 2005. http.www.

pcims.com./images/ TP105.5us.pdf; PCI Membrane

System Inc., Milford, U.S.A. Accessed 1 September

2019.

Michael, A. S. 1989 Handbook of Industrial Membrane

Technology. Noyes Publications, Park Ridge, USA.

Cushnie, TP Tim; LAMB, Andrew J. 2005. Antimicrobial

activity of flavonoids. International journal of

antimicrobial agents, 26.5: 343-356.

Trivedi, P. C., Pandy, S., and Bhadauri, S.. Text Book of

Microbiology, 1st ed., Aavishakar Publisher, India,

2010 :82 – 83.

USDA, U. 2018. National nutrient database for standard

reference, Legacy Release.

Havlíková, Ludmila; Miková, Kamila; Kyzlink, Vladimír.

1983. Heat stability of betacyanins. Zeitschrift für

Lebensmittel-Untersuchung und Forschung, 177.4:

247-250.

Brooks, George F. Jawetz, Melnick, & Adelberg's 2010.

medical microbiology/Geo. F. Brooks...[et al.]. New

York; Chicago: McGraw Hill Medical.

COWAN, Marjorie Murphy. Plant products as

antimicrobial agents. Clinical microbiology reviews,

1999, 12.4: 564-582.

Difference in Characteristic of Beetroot (Beta Vulgaris L.) Biomass through Microfiltration Technique to Prevent Natural Infection

311