Extraction Optimization of Total Phenolic Content and

Antioxidant Activity from Teaw (Cratoxylum Formosum)

by Central Composite Design

Nuttakarn Somarrom and Varipat Areekul

Faculty of Agro-industry, King Mongkut's Institute of Technology Ladkrabang, Bangkok, Thailand

Keywords: Antioxidants, Central Composite Design, Extraction, Optimization, Teaw, Total Phenolic Content.

Abstract: The extraction of bioactive compounds from Teaw (Cratoxylum formosum (Jack) Dyer) was carried out based

on the central composite design and response surface methodology to optimize the three variables: solvent

polarity index (5.5-9.0), temperature (50-70°C) and extraction time (35-55 min). The optimization condition

was based on yield, total phenolic content (TPC), DPPH radical scavenging (DPPH), ABTS radical

scavenging (ABTS) and thiobarbituric acid reactive substances (TBARs) assay. From five variables, only two

responses (yield and TPC) were fitted to a quadratic equation with R-square of 0.8479 and 0.8891,

respectively. DPPH response was not quite fitted (R

2

= 0.4420) while ABTS and TBARs were insignificantly

fitted (p>0.05). The optimal extraction condition was obtained with a solvent polarity index of 8.64 at 70°C

for 55 min. The software predicted under these optimal conditions that yield was 28.58% whereas the TPC

and DPPH, were 289 and 402 mg/g dry sample, respectively. The desirability value was 0.933. The proposed

method proves to be simple, cheap and good for natural bioactive extraction from Teaw, being a potential

approach for natural antioxidants.

1 INTRODUCTION

Plants has recently been focused as good sources of

phytochemicals with strong antioxidant activity. The

major responsible compounds are phenolic

compounds which are abundantly contained in

vegetable, fruits, berries, tea leaves, and herbs

(Altermimi et al., 2017). A phenolic hydroxy group

in the phenolic structure can donate a hydrogen atom

to interrupt the propagation of free radical in

oxidation processes (Altermimi et al., 2017;

Kaur and

Kapool, 2002). Therefore, the antioxidant can inhibit

or delay the oxidation of molecules. From its activity,

it can reduce the oxidative damage in foods ultimately

increasing the shelf-life and quality of these foods

(Lattanzio, 2013). It is a role not only for food

preservation, but also for the defense of living

systems and environmental stresses such as high

light, low temperatures, pathogen infection,

herbivores, and nutrient deficiency. These stresses

can lead to increase production of free radicals and

other oxidative species in plants (Altermimi et al.,

2017).

Teaw (Cratoxylum formosum) is a native plant

mostly grown in the North and North-Easts of

Thailand and tolerates drought well. This plant is

typically consumed as fresh shoots and young leaves.

It tastes sour and slightly astringent due to phenolic

components (Nakahara et al., 2002). It also found that

plant have been reported as a medicinal plant. Fresh

shoot and young leaves are used as a laxative. Root

and leaves help a stomachache and skin disease

(Areekul et al., 2009). The extract of Teaw

(C.formosum) leaves showed strongly antioxidant

and antimutagenic properties when compared with

108 species of indigenous Thai plants (Nakahara et

al., 2002).The 80% methanol plant extract effectively

scavenged DPPH radicals and contained many total

polyphenol and flavonoids

(Maisuthisakul et al., 2007).

The different extraction conditions including

solvent, time and temperature affected on the yield of

total phenolic and antioxidant activity due to different

properties of each bioactive compound, a

biomolecule from plants are chosen based on the

polarity of the solute of interest. A solvent of similar

polarity to the solute will properly dissolve the solute

(Altermimi et al., 2017). In this situation, the many

Somarrom, N. and Areekul, V.

Extraction Optimization of Total Phenolic Content and Antioxidant Activity from Teaw (Cratoxylum formosum) by Central Composite Design.

DOI: 10.5220/0009980700002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 119-125

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

119

variables influenced the response. The response

surface methodology (RSM) based on the central

composite design (CCD) is an effective technique for

optimizing the extraction with the various factors and

the number of experiments are more useful for

modeling (Bas and Boyaci, 2007; Sebswree, 2009).

The aim of this study is to optimize the extraction

process from Teaw using central composite design.

Three variables were used in this study: solvent

polarity index (5.5-9.0), temperature (50-70°C) and

extraction time (35-55 min). The optimization

condition was based on yield, total phenolic content

(TPC), DPPH radical scavenging (DPPH), ABTS

radical scavenging (ABTS) and thiobarbituric acid

reactive substances (TBARs) assay.

2 MATERIALS AND METHODS

2.1 Materials

Ethyl acetate was purchased from Honeywell

(USA).2, 2- diphenyl- 1- picrylhydrazyl(DPPH), Gallic

acid (C

7

H

6

O

5

), 2,2-Azinobis (3-ethylbenzothiazoline-

6-sulfonic acid) (ABTS) and Linoleic acid were

purchased from Sigma-Aldrich (USA).6-hydroxy-

2,5,7,8tetramethylchroman-carboxylic acid (Trolox)

was purchased from BBL (USA). Folin–Ciocalteu

reagent was purchased from VWR- Prolabo. Sodium

Carbonate (Na

2

CO

3

) was purchased from Ajax-

Finechem (Australia). Thiobarbituric acid (TBA),

1,1,3,3-Tetraethoxypropane (MDA) and Tween 40

were purchased from Merck (USA), Trichloroacetic

acid (TCA) and Ethanol were purchased from RCI-

Labscan (Iceland).

Teaw (C. formosum) was collected from Ubol

Ratchathani province, Thailand. The sample was

cleaned and selected fresh leaves and dried at 40°C in

hot air oven for 24 hours. The dried Teaw was ground

and passed through a sieve with mesh number 40 and

frozen at -20°C.

2.2 Extraction Procedure

In this study, three variables, polarity index of solvent

(5.5-9.0), temperature (50-70°C) and extraction time

(35-55 min) were designed by using the Central

Composite Design. The extraction conditions are

shown in Table 1. The solvent preparation was

calculated by using equation 1 (Poole, 1998).

P

'

= ∑

i

P

'

i

Ø

i

(1)

Where, P

'

i

is the polarity index of solvent i

Ø

i

is the quantity of solvent i

The polarity index of ethyl acetate, ethanol and

water are 4.4, 5.2 and 10.2, respectively (Katz, 1998;

Harris, 2015). These solvents were used for preparing

the polarity index as calculated from the formula

above. From this, it has five varying solvent including

ethyl acetate, 95%ethanol, 60% ethanol, 25% ethanol

and water (Table1). For extraction, 200 ml of solvent

was placed in the waterbath to obtain the targeted

temperature and then mixed with 10 g of plant

powder. The sample was set for certain extraction

time, cooled with the tap water and filtered through

Whatman No. 4. The filtrate was concentrated by

rotary evaporator at 35±1 °C, vacuum pressure 50

mbar. After that, the concentrated extract was

dehydrated by using freeze-dryer at -80°C for 50

hours and extract powder was kept at -20°C. The

moisture content was determined by AOAC method

966.02 (2000).

2.3 Analytics Method

2.3.1 Yield (%)

The percentage ration of total solid of Teaw extract

and plant was calculated by using the equation 2.

% Yield =

()

()

× 100

(2)

2.3.2 Total Phenolic Content (TPC)

The total phenolic content was determined by the

Folin–Ciocalteu method (Shaghaghi et al., 2008).

The 40 µl extract was mixed with 100 µl deionized

water, 20 µl Folin–Ciocalteau reagent and 40 µl

sodium carbonate (10% Na

2

CO

3

). Then, it was kept

at room temperature for 30 minutes in the dark.

Absorbance was measured at 765 nm. Results were

expressed as mg of gallic acid per gram dry sample.

2.3.3 DPPH Radical Scavenging (DPPH)

The radical-scavenging activity was determined by

the DPPH method (Murakami et al., 2004). Aliquot

of 50 µl of extract was mixed with 150 µl of 0.22 M

DPPH (in 95% ethanol) and incubated at room

temperature in the dark for 30 minutes. The

Absorbance was measured at 517 nm using Trolox as

a standard. Results were expressed as mg of Trolox

per gram dry sample.

16th AFC 2019 - ASEAN Food Conference

120

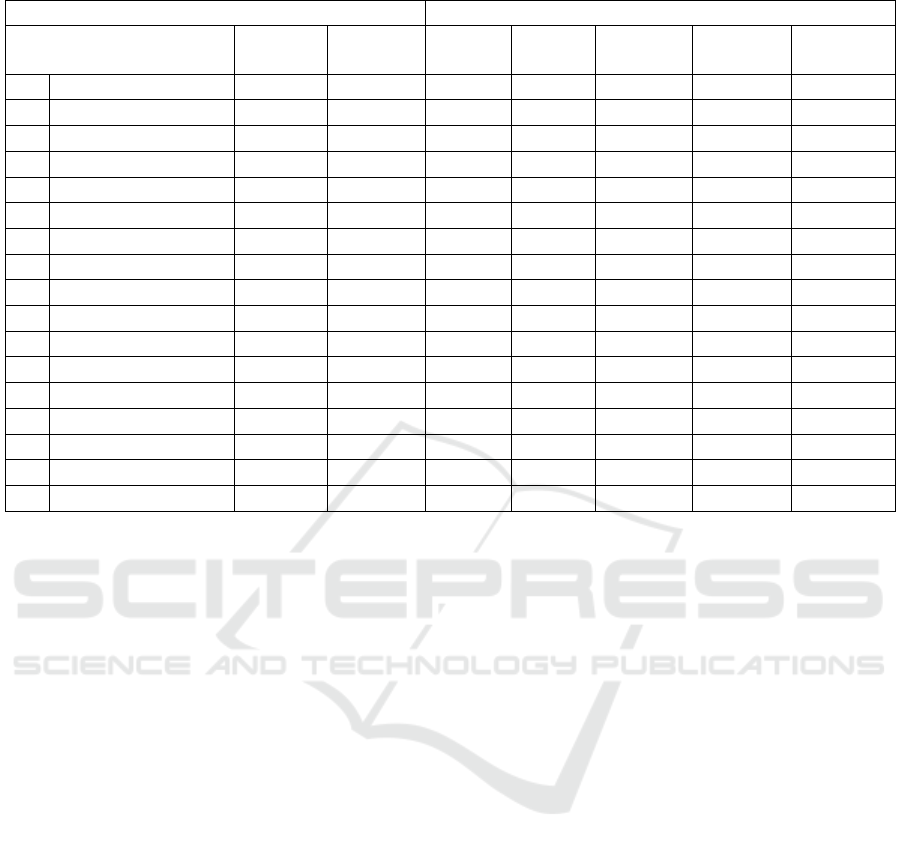

Table 1: Experimental designs using central composite designs (CCD) and results of the response variables studied.

Independent Variables Response Variables

Polarity:X

1

(Solvent)

Time:X

2

(min)

Temp:X

3

(°C)

Yield

(%)

TPC

(mg/g)

DPPH

(mg/g)

ABTS

(mg/g)

TBARs

(mg/g)

1 4.4(Ethyl acetate) 45.0 60 13.30 195.34 297.10 123.49 348.29

2 5.45(25% Ethanol) 35.0 50 19.33 207.49 271.46 227.29 272.40

3 5.45(95% Ethanol) 35.0 70 16.23 227.83 262.88 144.73 278.76

4 5.45(95% Ethanol) 55.0 50 19.04 208.41 267.42 141.55 423.49

5 5.45(95% Ethanol) 55.0 70 19.27 275.15 349.12 196.98 302.71

6 7.2(60% Ethanol) 28.2 60 23.96 264.37 379.55 233.10 285.50

7 7.2(60% Ethanol) 45.0 43 24.63 272.71 372.98 276.43 294.57

8 7.2(60% Ethanol) 45.0 60 19.27 275.15 349.12 196.98 302.71

9 7.2(60% Ethanol) 45.0 60 25.22 280.66 388.76 177.44 289.07

10 7.2(60% Ethanol) 45.0 60 27.16 288.23 390.15 172.95 324.42

11 7.2(60% Ethanol) 45.0 77 28.65 273.55 394.32 180.00 311.47

12 7.2(60% Ethanol) 61.8 60 28.90 283.49 372.10 288.91 317.60

13 8.95(25% Ethanol) 35.0 50 25.04 282.49 382.32 203.57 315.74

14 8.95(25% Ethanol) 35.0 70 29.77 297.63 402.40 213.33 296.74

15 8.95(25% Ethanol) 55.0 50 25.70 297.63 406.44 224.88 297.75

16 8.95(25% Ethanol) 55.0 70 27.03 289.98 409.47 203.49 295.89

17 10.2 (water) 45.0 60 21.81 244.72 335.48 177.60 322.17

2.3.4 ABTS Radical Scavenging (ABTS)

The ABTS was determined by ABTS method (Zhou

and Yu, 2004). Aliquots of 50 µl extract and 100 µl

of 5 mM ABTS solution was mixed and kept in the

dark for 5 minutes. The Absorbance was measured at

734 nm and compared with Trolox standard. Results

were reported as mg of Trolox per gram dry sample

2.3.5 Thiobarbituric Acid Reactive

Substances (TBARs) Assay

The Oxidation resistance was determined by the Ant-

TBARs method (McDonald and Hultin, 1987).

Briefly, aliquots of 0.2 ml samples and 0.8 ml

linolenic acid (1%) was mixed and placed in a water

bath at a temperature of 50 ± 1 °C for 18 hours. After

that, 2 mL of TCA-TBA-HCl solution was added and

boiled in the boiling water for 15 minutes. The sample

was cooled with the tap water and centrifuged at a

speed of 5,500 rpm for 5 minutes. The supernatant

was measured the absorbance at 520 nm and

compared to Butylated Hydroxy Toluene (BHT)

standard.

2.4 Experimental Designs and

Statistical Analysis

A Central composite (CCD) experimental design was

used to investigate the effects of three independent

variables, namely polarity index of solvent (X

1

)

extraction time (min; X

2

), and temperature (°C; X

3

).

A total of 17 experimental runs are listed in Table 1

The influence of extraction factors was optimized

using Response Surface Methodology (RSM) using

by design expert software (Design Expert 7.0 trial).

3 RESULTS AND DISCUSSION

3.1 The Yield, TPC, DPPH, ABTS and

TBARs

The response variables of Teaw extract obtained from

17 experiments from extraction factors values were

yield (13.30 - 29.77%), TPC (195-297 mg GAE/g dry

sample), DPPH (263-409 mg Trolox/g dry sample ),

ABTS (123-289 mg Trolox/g dry sample) and

TBARs (272-424 mg BHT/g dry sample). The data of

experiment were statistically tested for analysis of

variance (ANOVA) for regression model which are

shown in Table 2.

Extraction Optimization of Total Phenolic Content and Antioxidant Activity from Teaw (Cratoxylum formosum) by Central Composite

Design

121

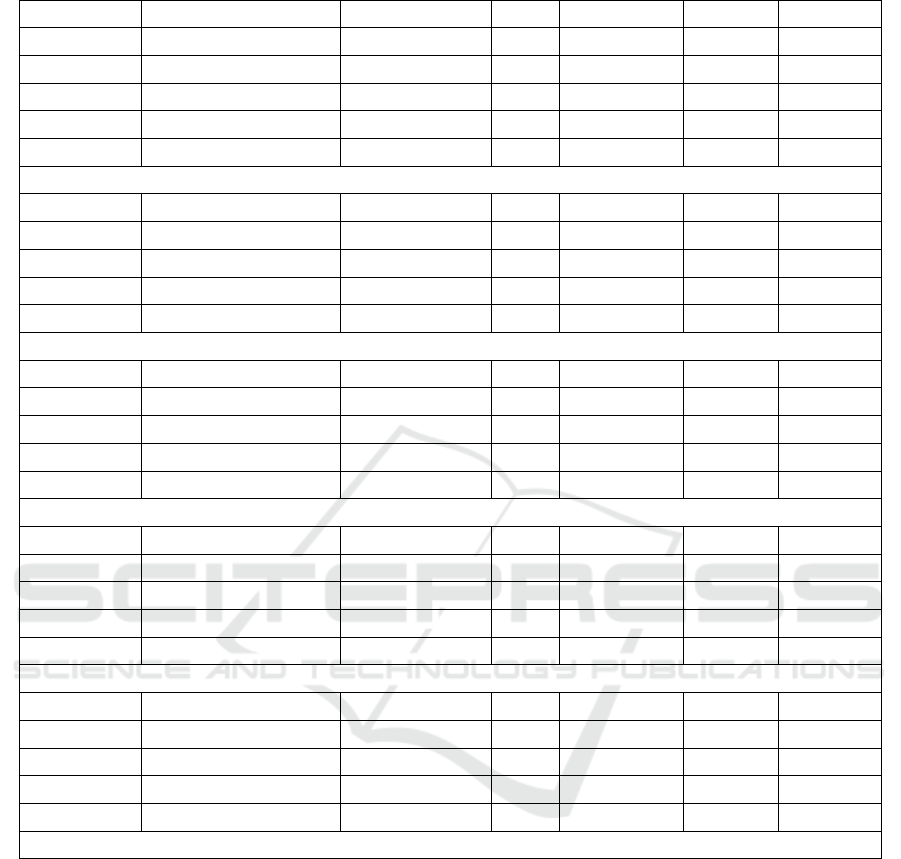

Table 2: Analysis of variance (ANOVA) for regression model.

Response Source of variation Sum of squares df Mean square F-value p- value

Yield Model 308.45 9 34.27 4.33 0.0331

Residual 55.35 7 7.91

Lack of fit 21.50 5 4.30 0.25 0.9060

Pure error 33.85 7 7.91

Corr total 363.80 16

R

2

= 0.8479 Adj.R

2

= 0.6522

TPC Model 15635.64 9 1737.29 6.24 0.0124

Residual 1949.85 7 278.55

Lack of fit 1863.68 7 287.55

Pure error 86.17 2 43.08

Corr total 17585.49 16

R

2

= 0.8891 Adj.R

2

= 0.7466

DPPH Model 21209.40 3 7069.80 4.72 0.0193

Residual 19472.50 13 1497.88

Lack of fit 18368.61 11 1671.51 3.08 0.2706

Pure error 1084.89 2 542.95

Corr total 40681.90 16

R

2

= 0.5213 Adj.R

2

= 0.4109

ABTS Model 22651.62 9 2516.85 2.14 0.639

Residual 8227.19 7 1175.31

Lack of fit 7900.75 5 1580.15 9.68 0.0963

Pure error 326.44 2 163.22

Corr total 30878.80 16

R

2

= 0.7336 Adj.R

2

= 0.3910

TBARs Model 13866.30 9 1540.70 2.07 0.1755

Residual 5220.07 7 745.72

Lack of fit 4584.47 5 916.89 2.89 0.2772

Pure error 635.60 2 317.80

Corr total 19086.37 16

R

2

= 0.7265 Adj.R

2

= 0.3749

The result showed that 3 of 5 response variables

including yield, TPC and DPPH were significant

difference (p≤0.05). This indicated that 3 extraction

factors; polarity index of solvent, extraction time and

temperature affected on their values. On the other

hand, ABTS and TBARs showed insignificant

difference (p>0.05).

For extraction yield, response model was fitted to

a quadratic equation with correlation coefficient (R

2

)

of 0.8479 (p=0.0331). In addition, the lack of fit value

was insignificantly (p-lack of fit = 0.9060)

indicating

that model was suitable and no other model could

explain this response. The yield regression equation

is shown in equation (3).

Yield = 17.528 + 11.968X

1

- 0.343X

2

-

1.337X

3

-0.0351X

1

X

2

+ 0.0639X

1

X

3

-

0.0000962X

2

X

3

- 0.844X

1

2

+ 0.00736X

2

2

+

0.00795X

3

2

(3)

The correlation coefficient of this equation was

0.8891. The TPC value was good fitted to a quadratic

model with R

2

of 0.8891 that mean a model was

effective to explain 88.91% of this result. Moreover,

the lack of fit value was insignificantly (p-lack of fit

> 0.05) representing a suitable model for TPC. The

TPC regression equation is presented in equation (4).

16th AFC 2019 - ASEAN Food Conference

122

TPC = -586.204 + 162.768X

1

+ 1.892X

2

+

5.042X

3

+ 0.291X

1

X

2

- 0.568X

1

X

3

+ 0.0295X

2

X

3

- 7.014X

1

2

– 0.0102X

2

2

– 0.0131X

3

2

(4)

The DPPH response was not quite fitted to linear

equation due to R

2

of 0.5231 which means that linear

model was able to explain only 52.31% of this result.

Despite, the lack of fit this model was insignificantly

(p-lack of fit > 0.05) which means no other models

fit. Therefore, this linear model was proper. The TPC

regression equation is presented in equation (5).

DPPH = 108.461 + 21.546X

1

+ 0.738X

2

+ 0.961

X

3

(5)

For the ABTS regression model, the ABTS data is

a quadratic model has a R

2

of 0.7336 and lack of fit

was insignificantly (p-lack of fit > 0.05).

Additionally, the ABTS data was insignificantly (p >

0.05) with any model. This means that the polarity

index of solvent, extraction time and temperature had

no influence on the ABTS. Similar result was

observed in TBARs. The TBARs response was

insignificantly fitted in any

model (p > 0.05).

Although, in a quadratic model the TBARs result

performed R

2

of 0.7265 with lack of fit of 0.2772 The

ABTS and TBARs regression equation was are

shown in Equation 6 and 7 respectively.

ABTS = 1303.183 + 66.614X

1

- 30.881X

2

-

22.271X

3

+ 0.321X

1

X

2

+ 0.110X

1

X

3

+ 0.133X

2

X

3

- 5.396X

1

2

+ 0.234X

2

2

– 0.1162X

3

2

(6)

TBARs = - 143.818 - 30.549X

1

+ 21.749X

2

+

2.568X

3

- 1.384X

1

X

2

+ 0.668X

1

X

3

- 0.137X

2

X

3

+ 3.309X

1

2

-0.22X

2

2

– 0.016X

3

2

(7)

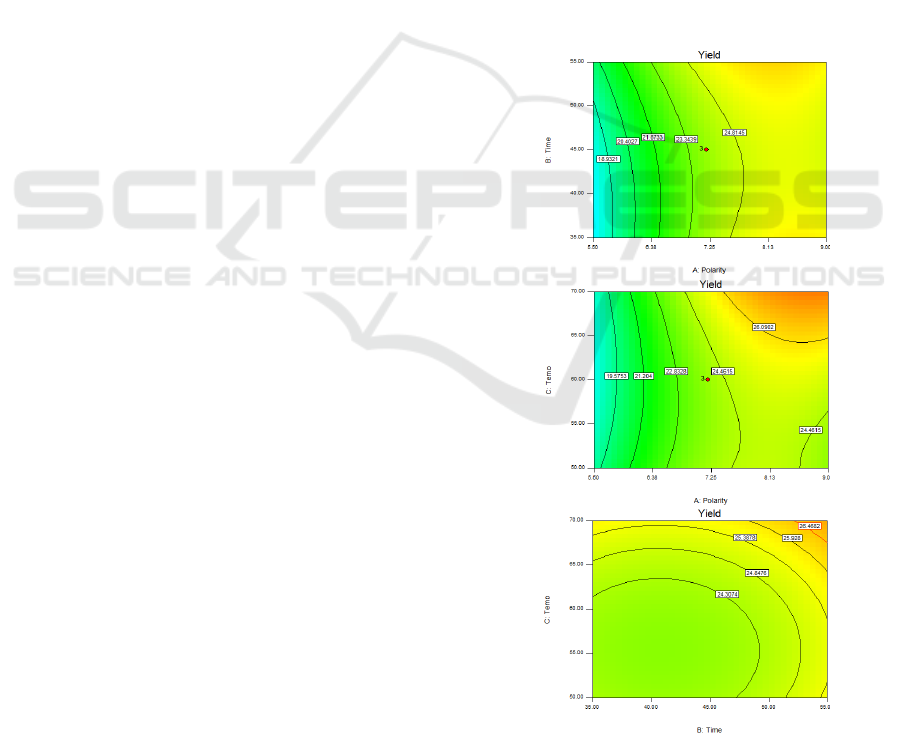

3.2 Analysis of Response Surface

Equations from mathematical models of three response

variables were plotted to a contour plot. The contour

plot present two factors between a response and

another one factor specifying at central value. Yield,

TPC and DPPH were response variables (Y) and a

polarity index of solvent (X

1

), extraction time (X

2

) and

temperature (X

3

) where independent variables.

Figure 1 shows a contour plot of yield of

extraction depending on the solvent polarity, time and

heating treatment. It is known as that polarity of

solvent is the most important factors under the same

extraction time and temperature (Ju et al., 2014).

Considering, the effect of polarity index of solvent

and extraction time in Figure 1a, yield increased by

increasing the polarity solvent and time. Yield for

24.81% was the highest yield by increasing 7.5-9 for

polarity index of solvent with time in range 35-55

minutes. These results suggested that increasing

polarity or water concentration in the solvent raised a

yield which may cause of the higher solubility of

proteins and carbohydrate in water (10.2 for polarity

index) than a low polarity index of solvent (Zielinski

and Kozlowska, 2000). That why a yield was

increased by increasing polarity solvent. Figure 1b

show the effect of polarity index of solvent and

temperature. Yield was increased by increasing

polarity solvent. The highest value was 26.09%

among 7.5-9 for polarity index of solvent with

temperature 63-70°C, but it decreased at low

temperature (< 63 °C). Thus, yield of Teaw extract

affected by temperature. The higher temperature may

improve the solubility of antioxidant compounds

(Liang et al., 2017). The effect of extraction time and

temperature with 7.25 for polarity index of solvent

was shown in contour plot Figure 1c. Yield of extract

was increased by increasing extraction time and

temperature. This result confirmed that extraction

time and temperature influenced the yield.

Figure 1: Contour plot for yield (%) as a function of (a)

polarity index of solvent and extraction time, (b) polarity

index of solvent and temperature, (c) extraction time and

temperature of Teaw extract.

(a)

(b)

(c)

Extraction Optimization of Total Phenolic Content and Antioxidant Activity from Teaw (Cratoxylum formosum) by Central Composite

Design

123

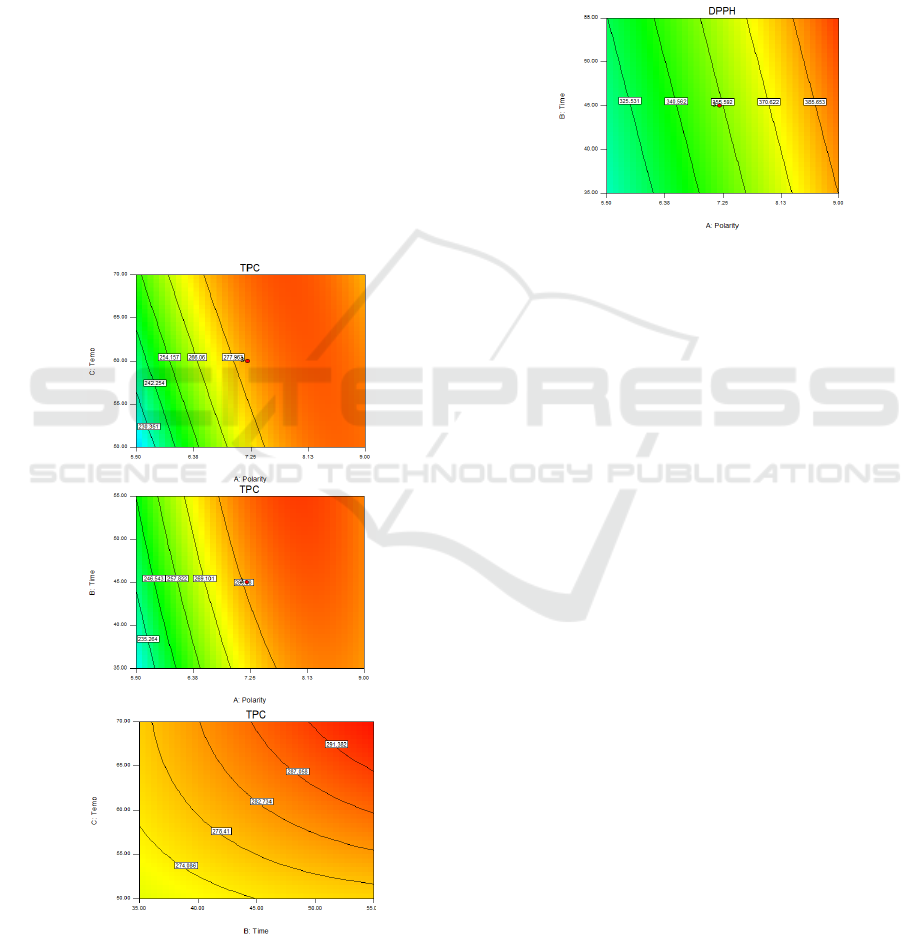

Influence of extraction factors on a TPC is

presented in contour plot (Figure.2). The TPC value

increased by increasing a polarity index of solvent

from 7.25 until almost 9 after that slightly decreased

(Figure.2a). TPC increased by increasing a polarity

index of solvent at higher 7.25 and the highest TPC

value was inspected at 8.13 to 9 for polarity index.

These results confirmed the polarity of solvent greatly

influence on the TPC value. On the other hand, when

temperature increasing the TPC value had a slightly

decrease as a result of high temperature. The

temperature was an important factor affecting of the

extract due to thermal degradation or loss of the

antioxidant compounds. It suggests molecular change

inside the antioxidant compounds structure (Sahin,

2018). In addition, the TPC increased by increasing

time and temperature (Figure.2c). High temperature

and time might soften the plant tissue and waken the

phenol-polysaccharide and phenol-protein inter-

actions in plant therefore, the polyphenol would

migrate into solvent (Youseff and Adawi, 2006).

Figure 2: Contour plot for TPC (mgTrolox/g dry sample) as

a function of (a) polarity index of solvent and extraction

time, (b) polarity index of solvent and temperature, (c)

extraction time and temperature of Teaw extract.

Figure 3 shows the contour plot of Teaw extract

on DPPH. The DPPH values were fitted to linear

model. This meant factors had not interaction term on

this result (Equation 5). However, each factor was

effective to DPPH value. It increased by increasing

the polarity index of solvent, extraction time and

temperature. Polarity of solvent was vastly influent

factor. When polarity index increased at 8.95, DPPH

was highest value. Then, polarity index at 10.2 DPPH

was slightly decreased.

Figure 3: Contour plot for DPPH (mgTrolox/g dry sample)

of Teaw extract.

3.3 The Optimum Extraction

Using the design expert software 7.0 trial, the

computer program calculated the optimal conditions

which was solvent polarity index of 8.64 at 70°C for

55 min. The yield, TPC and DPPH were predicted to

be 28.58%, 289 mg/g dry sample and 402 mg/g dry

sample, respectively with the desirability value of

0.933. The desirability represents the correlation of

independent and response. In this experiment, it was

correlation of 93.3% which a “very good” correlation

level (Lazic, 2004).

4 CONCLUSIONS

Three extraction factors including polarity index of

solvent and extraction condition (temperature and

time) significantly pronounced the effect on yield and

TPC while the other three variables were

insignificant. The central composite design as an

experimental design using by design expert program

could be used for optimizing the Teaw extraction. The

optimum condition was a solvent polarity index of

8.42 at 70°C for 55 min with desirability of 0.933.

This technique is simple, cheap and good for natural

bioactive extraction from Teaw being a potential

approach for natural antioxidants.

(a)

(b)

(c)

16th AFC 2019 - ASEAN Food Conference

124

REFERENCES

Altermimi, A., Lakhssassi, N., Baharlouei, A., Watson,

D.G., Lightfoot, D. A., 2017. Phytochemicals:

Extraction, Isolation, and Identification of Bioactive

Compounds from Plant Extracts. Plants. Volume 6(4),

pp. 2-23.

Areekul, S., Inthorn, J., Thakaew, S., Nunthakeaw, 2009. A.

Knowledge about wild plants and utilized in northern

Thailand volume 1. Bankok: Amarin printing

plublising.

Bas, D., Boyaci, I.H.,2007. Modeling and optimization I:

Usability of response surface methodology. Journal of

Food Engineering. Volume. 78, pp. 836-845.

Harris, D., 2015. Quantitative Chemical Analysis. 9th

edition. United States of America: W. H. Freeman and

Company.

Ju, Y., Do, Q.D., 2014. Angkawijaya A.E., Tran-Nguyen

P.L., Huynh L.H., Soetaredjo F.E., Ismadji S. Effect of

extraction solvent on total phenol content, total

flavonoid content, and antioxidant activity of

Limnophila aromatica. Journal of food and drug

analysis. Volume 22, pp. 296-302.

Katz, E., 1998. Handbook of HPLC. New York: Marcel

Dekker.

Kaur, C., Kapoor, H.C., 2002. Antioxidants in fruits and

vegetables-the millennium's health. International

Journal of Food Science and Technology. Volume 36,

pp. 703-725.

Lattanzio, V., 2013. Phenolic Compounds: Introduction In:

Ramawat K.G., Me´rillo J.M. Natural products .Sprin-

ger-Verlag Berlin Heidelberg https://www.resear-

chgate.net/publication/249970213_qPhenolic_Compo

unds_Introduction.

Lazic, Z.R., 2004. Design of experiment in chemical

engineering. Mörlenbach: Wiley-VCH.

Liang, H., Wang, W., Xu, J., Zhang, Q., Shen, Z., Zeng, Z.,

Li. Q., 2017. Optimization of ionic liquid-based

microwave-assisted extraction technique for curcumi

noids from Curcuma longa L. Food and Bioproducts

Processing. Volume 104, pp. 57-65.

Maisuthisakul, P., Pongsawatmanit, R., Gordon, M.H.,

2007. Characterization of the phytochemicals and

antioxidant properties of extracts from Teaw

(Cratoxylum formosum Dyer). Food Chemistry.

Volume 100, pp. 1620-1629.

McDonald, R. E., Hultin, H.O., 1987. Some Characteristics

of the Enzymic lipid peroxidation system in the

microsomal fraction of flounder skeletal muscle.

Journal of Food Science. Volume 52, pp. 15–21.

Murakami, M., Shukla, Y.N., Jain, S.P., Kumar, S., 2004.

Effect of thermal treatment on radical-scavenging

activity of single and mixed polyphenolic compounds.

Journal of Food Science. Volume 69, pp. 7-10.

Nakahara, K., Trakoontivakorn, G., Alzoreky, N.S., Ono,

H., Kameyama, M.O., Yoshida, M., 2002.

Antimutagenicity of Some Edible Thai Plants, and a

Bioactive Carbazole Alkaloid, Mahanine, Isolated from

Micromelum minutum. Journal of Agricultural and

Food Chemistry. Volume 50, pp 4796-4802.

Poole, C.F., Poole, S.K., 1999. Chromatography Today.

Amsterdam: Elsevier Science Publishers.

Sahin, S., 2018. Optimization of ultrasonic-assisted

extraction parameters for antioxidants from Curcuma

longa L. Trakya University Journal of Natural

Sciences. Volume 19(2), pp.121-128.

Sebswree, J., 2009. DOE chapter: Central composite

design. Production quality. Volume.145, pp. 72-74.

Shaghaghi, M., Manzoori, J.L., 2008. Jouyban, A.,

Determination of total phenols in tea infusions tomato

and apple juice by terbium sensitized fluorescence

method as an alternative approach to the Folin-

Ciocalteu spectrophotometric method. Food Chemistry.

Volume 108, pp. 695-701.

Youseff, D., Adawi, H. E., 2006. Study on grap seeds

extraction and optimization: An approach. Journal of

Applied Sciences. Volume 6(14), pp. 2944-2947.

Zhou, K., Yu, L., 2004. Antioxidant properties of bran

extracts from Trego wheat grown at different location.

Journal of Agricultural and Food Chemistry. Volume

52, pp. 1112-1117.

Zielinski, H., Kozlowska, H., 2000. Antioxidant activity

and total phenolics in selected cereal grains and their

different morphological fractions. Journal of

Agricultural and food Chemistry. Volume 48(6), pp.

2008-2016.

Extraction Optimization of Total Phenolic Content and Antioxidant Activity from Teaw (Cratoxylum formosum) by Central Composite

Design

125