Chromatic Characteristics Edible Coating of Aloe Gel

L. Suriati

1

, I. M. S. Utama

2

, B. A. Harjosuwono

2

and I. B. W. Gunam

2

1

Department of Food Science and Technology, Warmadewa University, Denpasar, Indonesia

2

Department of Agricultural Engineering, Faculty of Agricultural Technology, Udayana University, Denpasar, Indonesia

Keywords: Edible Coating, Aloe Gel, Safe Fruit, Fruit Quality.

Abstract: Edible coating is biodegradable and eco-friendly packaging that current developments. Constituent

components of edible coatings in the form of hydrocolloid (polysaccharides, proteins), lipids and composite.

The edible coating serves as a protective material which is packed from outside influences also functions as

a matrix of antimicrobial agents. Synthetic preservatives that many outstanding raises concerns of the

community to use it, because of the high risk on health. One of the potential natural ingredients as an edible

coating and also as a natural preservative is aloe vera gel. Edible coating of aloe vera (ECOGEL). Consists

of polysaccharide that contains many components of bioactive, but the disadvantage easily becomes diluted.

Aloe Vera gel should be kept on the proper environmental conditions. The purpose of this study was to

determine the effect of incorporation of various types of additives (citric acid, ascorbic acid, potassium

sorbate) on the chromatic characteristics of Aloe gel as an edible coating for 15-day storage. This study used

a completely randomized design. The results showed that the best chromatic attributes of Aloe gel were the

incorporation with citric acid, ascorbic acid, and potassium sorbate.

1 INTRODUCTION

The use of edible coating is one of the most popular

alternatives to maintain fruits in recent years. Edible

coating is a thin layer that is made from materials

that can be eaten. This layer serves as a chemical,

physical and biological barrier. Edible coating also

serves as a carrier of additives, barrier of mass

transfer, water vapor, O

2

and CO

2

gas exchange

(Bourtoom, 2008). The main components of the

compiler of edible coatings are hydrocolloid, lipid

and composite. Hydrocolloid used in the

manufacture of edible coatings in the form of a

protein or polysaccharide. One great advantage of

using edible coatings are some active ingredient can

be incorporated into polymer matrices and

consumed with food, so that it can maintain nutrition

and sensorial attributes (Dhall, 2008).

Edible coating is an environmentally friendly

packaging, easily parsed nature, and shaped thin layer

(Dhall, 2008). The phenomenon of edible coating is

the formation of structural protection to prevent

physical, chemical and biological deterioration of

fruit coated. Edible coating serves as an additive

carrier and active ingredient, gas displacement

barrier, moisture, dissolved and lipid materials

(Bourtoom, 2008). The constituent components of

edible coatings are hydrocolloids (proteins,

polysaccharides), Lipids and composites (Sanchez-

Machando et al., 2017). The edible coating

formulation greatly affects the ability of the adhesion

on the surface of the hydrophilic fruit. The advantage

of using edible coatings are some additive materials

can be incorporation on a polymer matrix (Ahmed et

al., 2009).

Synthetic preservatives often raise public

concern. One of the natural ingredients that can be

used as a preservative and edible coating is aloe gel,

because it consists of polysaccharides containing 75

functional components (Rahman et al., 2017). Aloe

Gel can form a coating, does not affect the flavour,

is safe for the environment, inexpensive and easy to

obtain, and easy to apply (Hamman, 2008). But its

weakness is the fast changing color, easy dilute, high

enzyme activity and oxidation process (Suriati,

2018). The discoloration of the aloe gel affects its

effectiveness as an edible coating and is often not

acceptable on some products (Hamman, 2008).

Therefore, simple processing techniques need to be

developed. The incorporation of citric acid additives,

ascorbic acid, potassium sorbate, calcium chloride

and sorbitol can be done to maintain the stability of

Suriati, L., Utama, I., Harjosuwono, B. and Gunam, I.

Chromatic Characteristics Edible Coating of Aloe Gel.

DOI: 10.5220/0009980600002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 11-14

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

11

aloe gel as edible coating (Vargas, 2008; Siddiqui et

al., 2011). The study aims to determine the

characteristic chromatic edible coating of aloe gel

that is incorporated additive material.

2 MATERIALS AND METHODS

This study used two-factor complete random draft

and three repeats. Factor 1 is the stabilization of the

gel with the addition of additive material: citric acid,

ascorbic acid, potassium sorbate, calcium chloride,

sorbitol. Factor 2 is the storage time treatment of

aloe gel in cold temperatures (7 ± 1

C): 0, 3, 6, 9, 12

and 15 days. Variable observations of aloe gel include

composition, moisture content, viscosity, pH, color

visually, color with the Colorimeter tool. The Data

obtained in this study tested statistics with the

Analysis of Variance. When the data obtained shows

a noticeable effect, then proceed with the Duncan

Test.

3 RESULT AND DISCUSSION

Aloe Vera Gel is a biopolymer material rich in

functional and potential components as an edible

coating material. The content of the carbohydrate gel

aloe 1.08%, mostly a polysaccharide (Rahman,

2017). Aloe Gel has a pH of 4.8 which is precisely

used as an edible coating of fruits that has a degree

of high acidity. The composition of aloe gel before

adding additives as shown in table 1.

Table 1: The composition of aloe gel.

Composition

Amount

Water content

98.46 %

Carbohydrate 1.08 %

Protein 0.036 %

Lipid 0.29 %

Ash 0.21 %

pH 4.8

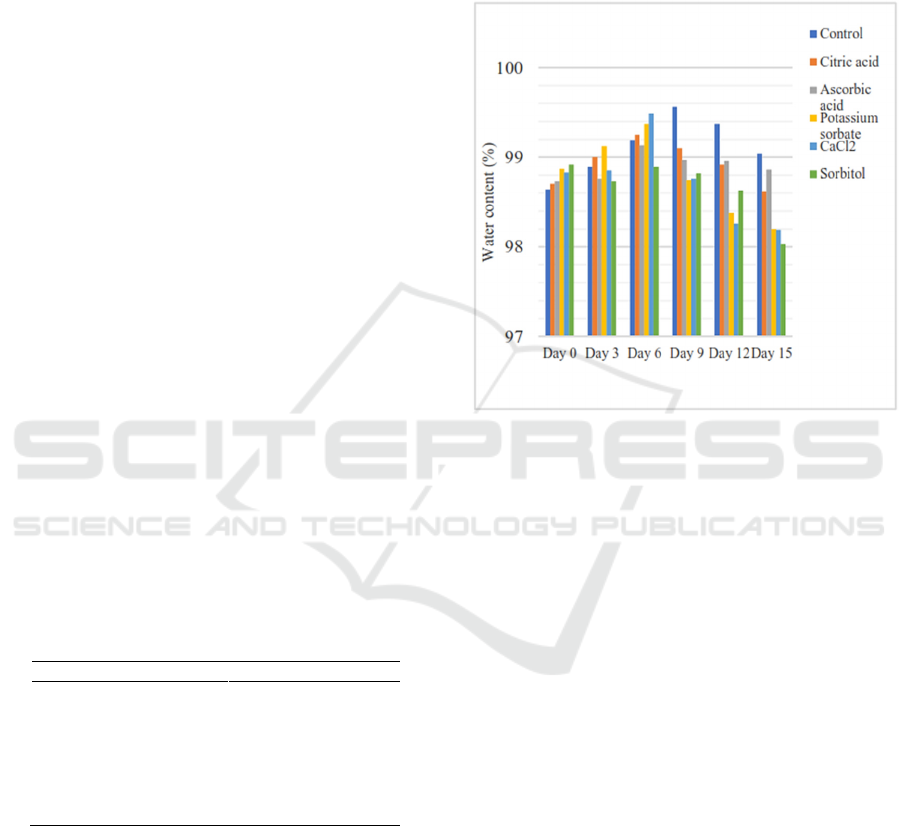

3.1 Water Content

The observation of the water content variable shows

that aloe gel contains water of 98.20-99.56%. The

average value of the moisture content of the aloe gel

has increased in all the treatment of additive material

until Day 9, after which it decreases back. This is

because aloe gel is undergoing hydrolysis due to

enzyme activity.

The stability of aloe gel is strongly influenced by

air, light, heat and enzyme activity (Hamman, 2008).

Aloe Gel with the added treatment of citric acid and

ascorbic acid has a relatively more stable water

content during storage compared to other treatments.

The water content of aloe gel with additives during

storage can be seen in and Figure 1.

Figure 1: Water content (%) Aloe gel with additives during

storage.

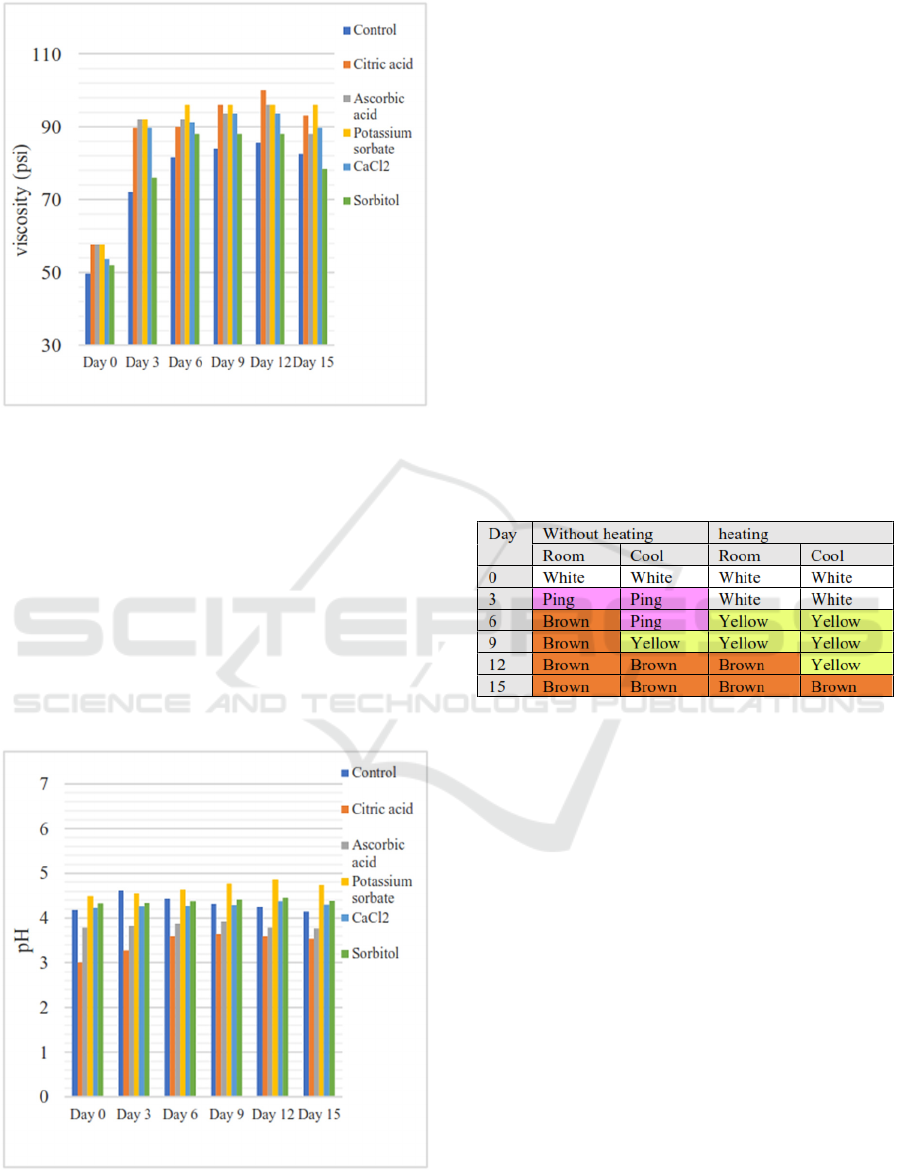

3.2 Viscosity

The observation of the viscosity variable indicates

that all additive addition treatments result in an

increase in the viscosity of aloe gel. Viscosity is

influenced by the number and size of particles

(Vargas, 2008). The increased viscosity began on the

3rd day and declined again after the 12th day. This is

due to the addition of additives able to strengthen the

bond cross linking polymer on aloe gel so that the

viscosity is increased.

The viscosity of aloe gel without additives

decreases drastically near the viscosity of water at

room temperature after 24-36 hours (Ergun and

Satici, 2012). The viscosity of aloe gel with additives

during storage can be seen Figure 2.

16th AFC 2019 - ASEAN Food Conference

12

Figure 2: Viscosity (psi) of aloe gel with additive

during

storage.

3.3 pH

From the results of various analyses was shown that

the pH of Aloe Vera gel without additives ranged

from pH 4.14-4.62. While the pH of gels with

additive treatment varies from 3.00-4.86. The Gel

with citric acid additives and ascorbic is lower

compared to sorbate treatment, CaCl2 and sorbitol.

This is due to citric acid and ascorbic acid is an

acidulants compound that is able to lower the pH

(Apelblat, 2014). Aloe Gel is stable at low pH.

Figure 3: pH of aloe gel with additives during storage.

The longer the storage of gel pH with additives

tends to stabilize. This is due to the addition of

additives capable of activation of enzymes so that

the reshuffle of polysaccharide into acids can be

prevented (Dhall, 2008). The pH of Aloe Gel with

additives during storage can be seen on Figure 3.

3.4 Color (Visual Observation)

Based on the results of color observations are visually

seen that the aloe gel without heating on the 0 day is

transparent white color. On the 3rd day of the ping

is coloured and the 12th day is brown. The Gel with

a coloured heating treatment ping on day 6, then

yellow Day 12 and Brown Day 15th. The color of the

aloe gel relates to its effectiveness and stability as an

edible coating. Discoloration of aloe Gel is caused by

high enzyme activity (Ramachandra and Rao, 2008).

The color of the aloe gel with additives during

storage can be seen in Table 2.

Table 2: Color of aloe gel without additive during storage.

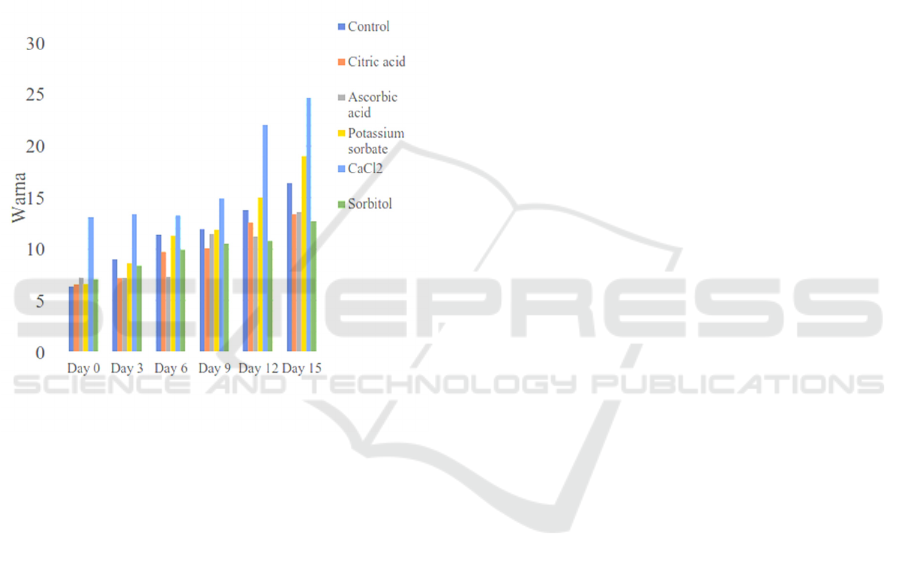

3.5 Color (Coordinate L*A*b*)

Based on the results of color observations with the

coordinates L * A * b * obtained that aloe gel with

additive citric acid and ascorbic acid has the lowest

value of ∆ E or close to control until day 15 while

the highest is a gel with CaCl2. This suggests that

citric acid and ascorbic acid are able to suppress

changes in the color of the aloe gel so it remains

stable and effective as an edible coating. The higher

the value of ∆ E then the aloe gel looks cloudier.

The longer the storage value ∆ E the higher. This

is due to the longer the storage the greater the chances

of hydrolysis of the aloe gel polymer. Hydrolysis

occurs due to an enzymatic reaction, Causes turbidity

components. Besides, there is a browning reaction.

The physicochemical properties of aloe gel are also

highly influenced by air, light, and heat. If direct

contact gel with air and light color to pink until

brown, and smell bad (Hamman, 2008; Ahmed et al.,

2009). The color of the aloe gel with additives can be

seen in Figure 5.

Chromatic Characteristics Edible Coating of Aloe Gel

13

4 CONCLUSIONS

Characteristic chromatic edible coating of aloe gel

is influenced by the activity of enzyme, air, light and

heat. The color of a good aloe gel is a transparent

white that shows its stability and its potency as an

edible coating. No additive Aloe Vera Gel on the 3rd

day of the color has changed. While the aloe gel with

additive citric acid and ascorbic acid is still stable

approaching control until day 15. The most

appropriate additive used to produce the best

chromatic characteristics of aloe gel as edible coating

is citric acid.

Figure 4: Color aloe gel with additives during storage.

ACKNOWLEDGMENTS

This research was supported by the competitive grant

in the scheme of Strategic Research of National

Excellency, Directorate General of Higher Education,

Republic of Indonesia. The authors are grateful to the

Rector and the Head of Research Institute of

Warmadewa University in facilitating to get the grant.

REFERENCES

Ahmed, M.J, Singh, Z., Khan, A.S., 2009. Postharvest Aloe

Vera Gelcoating Modulates Fruit Ripening and

Quality of ‘Arctic Snow’ Nectarine Kept in Ambient

and Cold Storage, International Journal of Food

Science and Technology. 44:1024–1033.

Apelblat, A., 2014. Citric Acid. Springer International

Publishing Switzerland. 357.

Bourtoom, T., 2008. Edible Films and Coatings:

Characteristics and Properties. International Food

Research Journal. 15(3): 237-248.

Dhall, R. K., 2013. Advances in Edible Coatings for Fresh

Fruits and Vegetables: a Review. Journal: Critical

Review Food Science Nutrition 53(5): 435-450.

doi:10.1080/10408398.2010.541568.

Ergun, M., Satici, E. F., 2012. Use of Aloe vera Gel as Bio

preservative for ‘Granny Smith’ and ‘Red Chief’

Apples M., J. Anim.Plant Sci. 22(2): 363.

Hamman, J. H., 2008. Composition and Applications of

Aloe Vera Leaf Gel. Molecules 13(8): 1599-1616.

doi:10.3390/molecules13081599.

Rahman, S., Carter, P., Bhattarai, N., 2017. Aloe Vera for

Tissue Engineering Applications. Department of

Chemical, Biological and Bioengineering, North

Carolina A&T State University, Greensboro, NC

27411, USA.

Ramachandra, C.T., Rao, P.S., 2008. Processing of Aloe

vera Leaf Gel: A Review. American Journal of

Agricultural and Biological Sciences. 3(2): 502-510.

Sanchez-Machado, D.I., Lopez-Carvantes, J., Raquel-

Sendon, Ana-Sanches-Silva. 2016. Aloe Vera: Ancient

Knowledge with New Frontiers. Trends in Food

Science & Technology. DOI:

10.1016/j.tifs.2016.12.005.

Siddiqui W., Chakraborty I., Ayala-Zavala J.F., Dhua R.S.,

2011. Advances in Minimal Processing of Fruit and

Vagetables: A Review. Journal Scientific & Industrial

Research. 70: 823-834

Suriati, L., Mangku, IG.P., Rudianta, I.N., 2018. The

Characteristics of Aloe Vera Gel as An Edible Coating.

IOP Conf. Ser.: Earth Environ. Sci. 207 012051.

doi:10.1088/17551315/207/1/012051.

Vargas, M., Pastor, C., Chiralt, A., McClements, D.J., Inez,

C.G., 2008. Recent Advances in Edible Coatings for

Fresh and Minimally Processed Fruits. Critical Reviews

in Food Science and Nutrition. Taylor and Francis Inc.

doi.org/10.1080/ 10408390701537344.

16th AFC 2019 - ASEAN Food Conference

14