Optimum Condition for the Production of N-acetylglucosamine from

Tiger Shrimp Shells using Semi Pure Extracellular Chitinase Enzyme

Produced by Mucor circinelloides

Yuniwaty Halim

1

, Hardoko

1,2

, Nicholas Candra

1

and Ratna Handayani

1

1

Food Technology Department, Universitas Pelita Harapan, Jl. M.H Thamrin Boulevard, Tangerang, Indonesia

2

Faculty of Fisheries and Marine Sciences, Brawijaya University, Jl. Veteran, Malang, Indonesia

Keywords: Chitin, Chitinase Enzyme, Glucosamine, Mucor circinelloides, Tiger Shrimp Shells.

Abstract: Chitin is a biodegradable polysaccharide, commonly found in shrimp shells and further processed into its

derivatives, such as glucosamine that is extensively used in dietary supplements for the treatment

of osteoarthritis, knee pain and back pain. This research was conducted to determine the optimum pH,

temperature, substrate concentration and fermentation time for semi pure extracellular chitinase enzyme from

Mucor circinelloides to be used in N-acetylglucosamine production. The optimum pH was determined at

different pH of 3, 4, 5, 6, 7, 8 and 9 and optimum temperature was determined at 30, 40, 50, 60, 70 and 80°C

by measuring chitinase activity. Substrate concentration varies from 0.5, 1.0, 1.5 and 2.0% and fermentation

time varies from 2, 4, 6 and 24 hours were used to determine the optimum condition for N-acetylglucosamine

production. Results showed that optimum pH of extracellular chitinase enzyme produced by Mucor

circinelloides with colloidal chitin as a substrate was 8 with chitinase activity of 5.76 ± 0.17 U/ml and

optimum temperature was 50°C with chitinase activity of 6.78 ± 0.13 U/ml. The optimum substrate

concentration of extracellular chitinase enzyme with chitin as substrate was 1.5% chitin with concentration

of N-acetylglucosamine produced of 1285.73 ± 66.19 ppm and the optimum fermentation time was 2 hours

with concentration of N-acetylglucosamine produced of 1322.71 ± 45.43 ppm.

1 INTRODUCTION

Chitin is a non-toxic biodegradable polysaccharide

that is commonly found in shrimp shells. Chitin is

hard to be absorbed by human body because chitin

has low solubility and large molecular size.

Therefore, it is commonly further processed into its

derivatives, such as glucosamine and chitosan (Haliza

and Suhartono, 2012). Glucosamine is a derived

chitin monomer and an important precursor in the

biosynthesis of glycolipids, glycoproteins and

proteoglycans proven to be involved in maintaining

joint health (Kardiman, 2013). Glucosamine can be

found naturally in the human body and is a precursor

for the biochemical synthesis of glycosaminoglycans

found in cartilage. Glucosamine is extensively used

in dietary supplements for the treatment of

osteoarthritis, knee pain and back pain (Benavente et

al., 2015). The conventional production of

glucosamine using chemical treatment has many

disadvantages as it is not environment friendly due to

acidic wastes, the yield is low and hard to control

(Sashiwa et al., 2002). Enzymatic hydrolysis method

as an alternative treatment using chitin directly from

crab or shrimp shells is faster, simpler and more

environmentally friendly compared to chemical

treatment (Krokeide et al., 2007). Glucosamine

produced by enzymatic hydrolysis is in the form of

N-acetylglucosamine.

Mucor circinelloides is one of the filamentous

fungi that produce chitinase enzyme to degrade chitin

into glucosamine (Shubakov and Kucheryavykh,

2004). In this research, chitin degradation into

glucosamine is done using semi pure extracellular

chitinase enzyme produced and collected from

Mucorcircinelloides because of the ability of Mucor

circinelloides to secrete chitinase enzyme

extracellularly (Luong et al., 2010) and higher purity

of chitinase enzyme increases the chitinase enzyme

activity (Suryadi

a

et al., 2013). The aim of this

research was to utilize Tiger shrimp (Penaeus

monodon) shells to produce N-acetylglucosamine

enzymatically using extracellular semi pure chitinase

Halim, Y., Hardoko, ., Candra, N. and Handayani, R.

Optimum Condition for the Production of N-acetylglucosamine from Tiger Shrimp Shells using Semi Pure Extracellular Chitinase Enzyme Produced by Mucor circinelloides.

DOI: 10.5220/0009980500002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 185-191

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

185

enzyme from Mucor circinelloides. Several

parameters that contribute to enzymatic reaction, such

as pH, temperature, substrate concentration and

fermentation time were also determined.

2 MATERIALS AND METHODS

The materials used in this research were chitin

isolated from Tiger shrimp shells (Penaeus monodon)

obtained from PT. Lola Mina, Muara Baru, Jakarta,

Mucor circinelloides culture isolated from Tiger

shrimp shells, Potato Dextrose Agar (PDA)

“MERCK” and Potato Dextrose Broth (PDB) “DB

Filco”, N-acetylglucosamine standard “SIGMA

ALDRICH”, 3-5 dinitro salicylic acid “MERCK”,

bovine serum albumin (BSA), dipotassium phosphate

(K2HPO4), potassium dihydrogen phosphate

(KH2PO4), magnesium sulphate heptahydrate

(MgSO4.7H2O), ammonium sulphate ((NH4)2SO4),

disodium hydrogen phosphate (Na2HPO4),

potassium sodium tartrate (Na-K-tartrate),

phosphoric acid (H3PO4), distilled water, NaOH

solution (3.5%, 10 N), HCl solution (37%, 1 M),

tartaric acid 10% and ethanol 96%. The equipment

used in this research were incubator shaker

“HEIDOLPH 22UNIMAX 1010”, analytical balance

“OHAUS U-1800 AR 2140”, oven “MEMMERT”,

centrifuge “MPW-223e”, microcentrifuge

“HETTICH ZENTRIFUGE EBA 20”, microscopic

camera “OLYMPUS DP21”, UV-VIS

spectrophotometer “THERMO SCIENTIFIC

GENESYS 10S”, pH meter “METROHM 913”,

quartz cuvette “HELLMA Analytics”, micropipette

and glassware.

2.1 Colloidal Chitin Preparation (Setia

and Suharjono, 2015)

Colloidal chitin was prepared as substrate in optimum

pH and optimum temperature determination and

added in culture media to induce the chitinase

production. Ten grams of isolated chitin was added

with 140 ml of 37% HCl and stirred with magnetic

stirrer for 2 hours to dissolve the chitin. The mixture

was added with 500 ml of absolute ethanol and

filtered with Buchner funnel. The residue obtained

was added with 5 N of NaOH until the pH reached

neutral and centrifuged with speed 4000 rpm for 5

minutes. The precipitate obtained was collected as the

colloidal chitin.

2.2 Production of Semi Pure Chitinase

(Jenifer et al., 2014)

About 5 ml of Mucor circinelloides spore culture was

added into 250 ml Potato Dextrose Broth (PDB)

media containing 0.5% colloidal chitin, 0.5%

Na2HPO4 and 0.5% MgSO4.7H2O. The mixture was

incubated for 2 days in incubator shaker at room

temperature. The grown culture suspension was

centrifuged at 3300 rpm for 10 min at 4°C and the

supernatant obtained was the extracellular crude

chitinase. The extracellular crude chitinase was

precipitated with 90% ammonium sulphate while

stirred at 4°C. This suspension left for 24 hours at 4°C

then centrifuged at 3300 rpm for 10 minutes. The

precipitate was taken and dissolved in 8 ml of 0.05 M

phosphate buffer solution (pH 8) per 150 ml of grown

culture suspension (Lawati, 2013). The precipitate

taken was the extracellular semi pure chitinase

enzyme and was stored at 4°C prior to usage in

fermentation.

2.3 Determination of Optimum pH and

Temperature (Jenifer et al., 2014)

1 ml of 0.5% colloidal chitin in each pH buffers (pH

3-9) were added by 1 ml of semi pure chitinase

enzyme then incubated in room temperature for 1

hour. The optimum pH was determined from highest

chitinase activity. Furthermore, 1 ml of 0.5%

colloidal chitin in the optimum pH buffer were added

by 1 ml of semi pure chitinase enzyme then incubated

in temperature of 30, 40, 50, 60, 70 and 80°C for 1

hour. The optimum fermentation temperature was

determined from highest chitinase activity.

2.4 Determination of Optimum

Substrate Concentration and

Fermentation Time (Herdyastuti et

al., 2009)

Different levels of chitin concentration of 0.5, 1, 1.5

and 2% chitin were added to the optimum pH buffer.

1 ml of different concentration of chitin in the

optimum pH buffer were added by 1 ml of semi pure

chitinase enzyme then incubated in the optimum

temperature for 2, 4, 6 and 24 h. The optimum

substrate concentration and fermentation time were

determined by the highest N-acetylglucosamine

concentration.

16th AFC 2019 - ASEAN Food Conference

186

2.5 Analysis of Chitinase Enzyme

Activity (Rahmansyah and

Sudiana, 2003)

Chitinase activity was measured using DNS

(dinitrosalicylic) colorimetric method. The

determination of chitinase activity used colloidal

chitin as the substrate. 1 gram of 3,5-dinitrosalicylic

acid (DNS) was dissolved in 20 ml distilled water

then added with 1 gram of NaOH, 0.2 gram of phenol

and 0.05 gram of sodium sulphite. The mixture was

then transferred and diluted into 100 ml volumetric

flask. The mixture was then centrifuged at 3300 rpm

for 5 minutes. 1 ml of supernatant was taken and

added with 2 ml of modified DNS and 1 ml of 4%

potassium sodium tartrate. The mixture then heated

for 15 minutes at boiling temperature. The mixture

then was observed using spectrophotometer at 540

nm. Chitinase activity were calculated using the

formula:

Chitinase Activity (U/ml) =

Nace

t

ylglucosamineconcen

t

ra

t

ion

x1000x

enzy

m

e

Nace

t

ylglucosaminemolecularweigh

t

x

incuba

t

ionperiod

h

(1)

2.6 N-acetylglucosamine Concentration

Quantification (Rahmansyah and

Sudiana, 2003)

Glucosamine standard curve was prepared for

quantification of N-acetylglucosamine concentration.

Blank was first prepared by adding 2 ml of modified

DNS and 1 ml of 4% potassium sodium tartrate into

1 ml of distilled water then heated for 15 minutes in

boiling temperature. N-acetylglucosamine standard

was prepared in concentration of 200, 400, 600, 800

and 1000 ppm. 1 ml from each concentration was

added with 2 ml of modified DNS and 1 ml of 4%

potassium sodium tartrate. The mixture heated for 15

minutes in boiling temperature. The heated mixture

of blank and each concentration of glucosamine

standard were observed by spectrophotometer at 540

nm. N-acetylglucosamine content calculated by using

the linear equation of glucosamine standard. 1 ml of

N-acetylglucosamine from the fermentation was

added with 2 ml of modified DNS and 1 ml of 4%

potassium sodium tartrate. The mixture was heated at

boiling temperature for 15 minutes and the

absorbance observed using spectrophotometer at 540

nm.

2.7 Data Analysis

The experimental design used was Completely

Randomized Factorial Design with 1 factor for

optimum pH or temperature determination and 2

factors for optimum substrate concentration and

fermentation time determination. All data obtained

were analyzed using SPSS version 22.

3 RESULT AND DISCUSSION

3.1 Characteristics of Isolated Chitin

Chitin used in this research was isolated from Tiger

shrimp shells through demineralization and

deproteination processes and then analysed for its

yield, moisture content, protein content, ash content

and degree of deacetylation. The results can be

observed on Table 1.

Table 1: Characteristics of isolated chitin.

Parameter Content

Yield (% db) 8.85 ± 0.33

Moisture content (% wb) 4.59 ± 0.32

Ash content (%) 0.46 ± 0.03

Protein content (%) 1.74 ± 0.07

Degree of Deacetylation (%) 28.07

Yield of isolated chitin obtained in this research

was lower compared to the previous study by Hossain

and Iqbal (2014) that showed the yield content of

chitin from shrimp shell is in range of 13.12-17.36%.

The moisture content of isolated chitin is comparable

to the previous studies (Arif et al., 2013; Isa et al.,

2014; Liu et al., 2013; Sanusi, 2004) that showed the

moisture content of chitin is fewer than 10%, i.e.

about 8.70%, 7.64% and 5.22%, respectively. The ash

content of chitin is lower compared to the previous

studies by Arif et al. (2013), Isa et al. (2014) and Liu

et al. (2013) that was about 2%, 5.60% and 1.59%,

respectively. This shows that the demineralization

process in this research was more effective to remove

the minerals from shrimp shells. Furthermore, protein

content of isolated chitin was lower compared to by

Arif et al. (2013) that showed that the protein content

of isolated chitin was 4.16%. This result also shows

that the deproteination process in this research was

more effective. Degree of deacetylation is an

indicator of chitin purity (Sanusi, 2004). The degree

of deacetylation (DD) of isolated chitin obtained was

28.07%, in accordance with previous researches (Arif

et al., 2013; Younes and Rinaudo, 2015) that

mentioned degree of deacetylation of chitin was 15 -

70% and less than 50%, respectively.

Optimum Condition for the Production of N-acetylglucosamine from Tiger Shrimp Shells using Semi Pure Extracellular Chitinase Enzyme

Produced by Mucor circinelloides

187

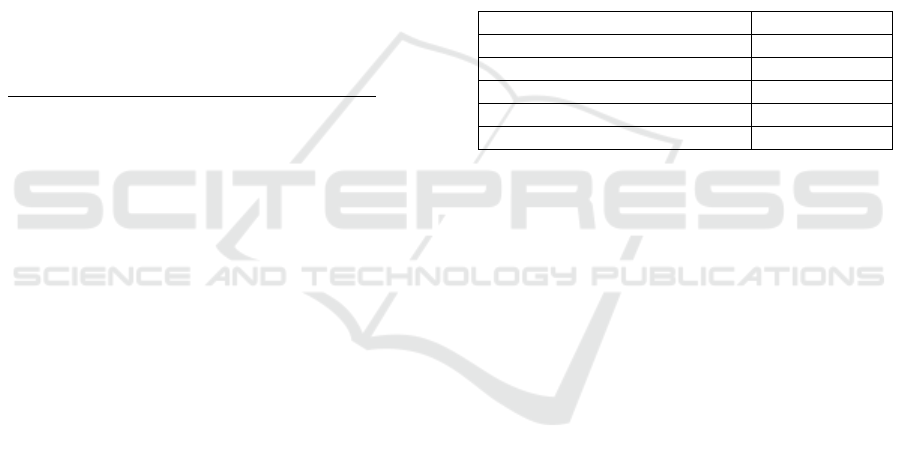

3.2 Effect of pH on Semi Pure

Extracellular Chitinase Activity

Statistical analysis using ANOVA shows that pH

gave significant effect on enzyme activity of chitinase

produced by Mucor circinelloides. Results also show

that the optimum pH for semi pure extracellular

chitinase activity is at pH 8, with enzyme activity of

5.76 ± 0.17 U/ml. The results can be observed on

Figure 1.

Figure 1: The effect of pH on chitinase enzyme activity

(Note: Different letter notations indicates a significant

difference at p≤0.05).

This result is in accordance with a previous study

who stated that the chitinase activity may increase

and decrease because of the difference in pH as a

factor (Purkan et al., 2014). Chitinase enzyme

produced by M. circinelloides that is optimum at pH

8, is similar to chitinase enzyme produced by

Moniliophthora perniciosa (Galante et al., 2012),

Aeromonas sp. (Haliza and Suhartono, 2012) and

Bacillus cereus (Suryadib et al., 2013) that were also

optimum at pH 8.

3.3 Effect of Temperature on Semi

Pure Extracellular Chitinase

Activity

Statistical analysis using ANOVA shows that

temperature of reaction gave significant effect on

enzyme activity of chitinase produced by Mucor

circinelloides. Results also show that the optimum

temperature for semi pure extracellular chitinase

activity is at 50

o

C, with enzyme activity of 6.78 ±

0.13 U/ml. The results can be observed on Figure 2.

Temperature affects the kinetic energy of

molecule which can accelerate enzyme hydrolysis

reaction with substrate when the temperature is raised

(Murray et al., 2005). However, after optimum

temperature is reached, the chitinase enzyme activity

decrease as the temperature is raised because enzyme

can be denatured in high temperature (Lehninger et

al., 2004). The optimum temperature of 50°C

obtained in this research is similar to chitinase

enzyme produced by Aspergillus tereus (Farag et al.,

2016) and Serratia marcescens (Zeki and Muslim,

2010). Chitinase enzyme produced by M.

circinelloides can be considered as thermostable.

Figure 2: The effect of temperature on chitinase enzyme

activity (Note: Different letter notations indicates a

significant difference at p≤0.05).

Temperature affects the kinetic energy of

molecule which can accelerate enzyme hydrolysis

reaction with substrate when the temperature is raised

(Murray et al., 2005). However, after optimum

temperature is reached, the chitinase enzyme activity

decreases as the temperature is raised because enzyme

can be denatured in high temperature (Lehninger et

al., 2004). The optimum temperature of 50°C

obtained in this research is similar to chitinase

enzyme produced by Aspergillus tereus (Farag et al.,

2016) and Serratia marcescens (Zeki and Muslim,

2010). Chitinase enzyme produced by M.

circinelloides can be considered as thermostable.

3.4 Effect of Substrate Concentration

and Fermentation Time on

N- acetylglucosamine Production

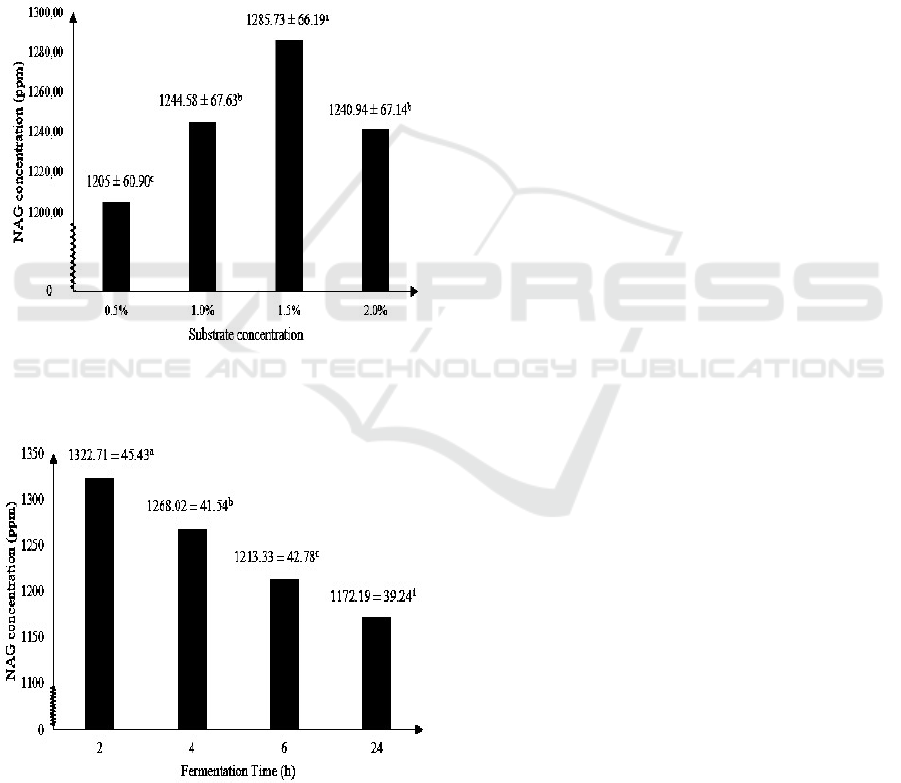

Statistical analysis using Univariate shows that

interaction between substrate concentration and

fermentation time did not affect the N-

acetylglucosamine (NAG) concentration produced by

chitinase enzyme. However, substrate concentration

and fermentation time affected the NAG

concentration produced by chitinase enzyme. These

results can be observed on Figure 3 and Figure 4.

16th AFC 2019 - ASEAN Food Conference

188

Figure 3 shows the highest NAG produced by

chitinase enzyme of M. circinelloides with isolated

chitin as substrate is at 1.5% substrate concentration,

i.e. about 1285.73 ± 66.19 ppm. The optimum

substrate concentration of 1.5% is according to a

previous study that stated chitinase activity reached

maximum activity at chitin concentration of 1.5%, in

which optimum chitinase activity maximizes the

production of NAG (Karthik et al., 2014). Optimum

substrate concentration for chitinase isolated from M.

circinelloides of 1.5% is also in accordance with

optimum substrate concentration of chitinase isolated

from Streptomyces viridificans (Gupta et al., 1995)

and Aeromonas sp. (Huang et al., 1996).

Figure 3: The effect of substrate concentration on NAG

concentration (Note: Different letter notations indicates a

significant difference at p≤0.05).

Figure 4: The effect of fermentation on NAG concentration

(Note: Different letter notations indicates a significant

difference at p≤0.05).

Figure 4 shows that the highest NAG

concentration produced by chitinase enzyme of M.

circinelloides is at 2 hours of fermentation, i.e. about

1322.71 ± 45.43 ppm. The ability of chitinase to

degrade chitin structure affected the time needed to

produce NAG (Wulandari, 2009). Chitinase activity

isolated from Aeromonas sp. reached maximum

chitinase activity of 8.7 U/ml at 72 hours of

incubation (Younes et al., 2013), Trichoderma

harzianum reached maximum chitinase activity of 5.4

U/ml after incubation of 72 hours (Sandhya et al.,

2005) and Streptomyces rubiginosus reached

maximum chitinase activity of 2.2 U/ml after 72 h of

incubation (Jha et al, 2016). This also means that

chitinase produced by Mucor circinelloides reaches

its maximum activity and NAG production much

faster compared to chitinase produced by Aeromonas

sp., Trichoderma harzianum and Streptomyces

rubiginosu.

4 CONCLUSIONS

This research confirmed the potency of extracellular

semi pure chitinase enzyme produced by Mucor

circinelloides as an alternative method to produce N-

acetylglucosamine. The optimum pH of extracellular

semi pure chitinase from Mucor circinelloides is 8

with chitinase activity of 5.76 ± 0.17 U/ml and the

optimum temperature is 50°C with chitinase activity

of 6.78 ± 0.13 U/ml. The optimum substrate

concentration to produce N-acetylglucosamine is

1.5% of chitin with 1285.73 ± 66.19 ppm of N-

acetylglucosamine produced and the optimum

fermentation time is 2 hours with concentration of N-

acetylglucosamine produced is about 1322.71 ± 45.43

ppm.

ACKNOWLEDGEMENTS

The authors would like to thank Center of Research

and Community Development, Universitas Pelita

Harapan, Tangerang, Indonesia for financially

supporting this research through Project no: P-

0004/FaST/I/2018.

REFERENCES

Arif, A.R., Ischaidar, N., Hasnah, Dali, S. 2013. Isolasi

Kitin dari Limbah Udang Putih (Penaeus merguiensis)

secara Enzimatis. Seminar Nasional Kimia, pp. 10-16.

Benavente, M., Arias, S., Moreno, L., Martinez, J. 2015.

Production of Glucosamine Hydrochloride from

Optimum Condition for the Production of N-acetylglucosamine from Tiger Shrimp Shells using Semi Pure Extracellular Chitinase Enzyme

Produced by Mucor circinelloides

189

Crustacean Shell. Journal of Pharmacy and

Pharmacology, volume 3, pp. 20-26.

Farag, A.M., Hanan, M.A., Hassan, A.H., Moustafa, E.

2016. Purification, Characterization and Antimicrobial

Activity of Chitinase from Marine-derived Aspergillus

terreus. The Egyptian Journal of Aquatic Research,

volume 42(2), pp. 185-192.

Galante, R.S., Taranto, A.G., Koblitz, M.G.B., Góes-Neto,

A., Pirovani, C.P., Cascardo, J.C.M., Cruz, S.H.,

Pereira, G.A.G., De Assis, S.A. 2012. Purification,

Characterization and Structural Determination of

Chitinases Produced by Moniliophthora perniciosa.

Anais Da Academia Brasileira De Ciências, volume

84(2), pp. 469-486.

Gupta, R., Saxena, R.K., Chaturvedi, P.I., Virdi, J.S. 1995.

Chitinase Production by Streptomyces viridificans: Its

Potential in Fungal Cell Wall Lysis. Journal of Applied

Bacteriology, volume 78, pp. 378–383.

Haliza, W., Suhartono, M.T. 2012. Karakteristik Kitinase

dari Mikroba. Balai Teknologi Pascapanen Pertanian,

volume 8(1), pp. 1-14.

Herdyastuti, N., Raharjo, T., Mudasir, M., Matsjeh, S.

2009. Chitinase and Chitinolytic Microorganism:

Isolation, Characterization and Potential. Indo J Chem.,

volume 9(1), pp. 37-47.

Hossain, M.S., Iqbal, A. 2014. Production and

Characterization of Chitosan from Shrimp Waste. J.

Bangladesh Agric. Univ., volume 12(1), pp. 153–160.

Huang, J.H., Chen, C.J., Su, Y.C. 1996. Production of

Chitinolytic Enzymes from a Novel Species of

Aeromonas. J Ind Microbiol., volume 17, pp. 89-95.

Isa, M.T., Ameh, O.A., Danlami, A., Abutu, D. 2014.

Kinetic Modelling of the Demineralization of Shrimp

Exoskeleton using Citric acid. Leonardo Electronic

Journal of Practices and Technologies, volume 13(25),

pp. 99-108.

Jenifer, S., Jesayree, J., Laveena, D.K., Manikandan, K.

2014. Purification and Characterization of Chitinase

from Trichoderma viride N9 and Its Antifungal Activity

Against Phytopathogenic Fungi. World Journal of

Pharmacy and Pharmaceutical Sciences, volume 3(12),

pp. 1604-1611.

Jha, S., Hasmukh, A.M., Jha, C.K. 2016. Characterization

of Extracellular Chitinase Produced from Streptomyces

rubiginosus Isolated from Rhizosphere of Gossypium

sp. Cogent Food and Agriculture, volume 2(1), pp. 1-

12.

Kardiman, C. 2013. Manfaat Glukosamin, Kondroitin, dan

Metilsulfonilmetana pada Osteoartritis. Cermin Dunia

Kedokteran, volume 40(12), pp. 936-939.

Karthik, N., Akanksha, K., Binod, P., Pandey, A. 2014.

Production, Purification and Properties of Fungal

Chitinases. Indian Journal of Experimental Biology,

volume 52, pp. 1025-1035.

Krokeide, I.M., Synstad, B., Gaseidnes, S., Horn, S.J.,

Eijsink, V.G., Sorlie, M. 2007. Natural Substrate Assay

for Chitinases Using High Performance Liquid

Chromatography: a Comparison with Existing Assays.

Anal Biochem. volume 363, pp. 128-134.

Lawati, N. 2013. Pemurnian Parsial dan Karakterisasi

Enzim Kitinase dari Beauveria bassiana. Thesis. Institut

Pertanian Bogor, Bogor.

Lehninger, A.L., Nelson, D.L., Cox, M.M. 2014. Principles

of Biochemistry. Worth Press, New York, 4th edition.

Liu, L., Liu, Y., Shin, H., Chen, R., Li, J., Du, G., Chen, J.

2013. Microbial Production of Glucosamine and N-

acetylglucosamine: Advances and Perspectives. Appl

Microbiol Biotechnol., volume 97, pp. 6149–6158.

Luong, D.T., Tuan, N.A., Van, N.T., Yen, L.T.H., Versali,

M.F.J., Dommes, J., Duong, V.H. 2010. Study in an

Actinomycetes Producing Chitinase and Chitin

Deacetylase. AnnuRep, pp. 439-448.

Murray, R.K., Granner, D.K., Mayes, P. W., Rodwell, V.

W. 2005. Harper’s Illustrated 13 Biochemistry.

McGraw-Hill, New York, Twenty-sixth edition.

Purkan, Badiatul A., Baktir, A., Sumarsih, S. 2014.

Eksplorasi Bakteri Kitinolitik dari Sampah Organik:

Isolasi dan Karakterisasi Enzim Kitinase. Molekul,

volume 9(2), pp. 128-135.

Rahmansyah, M., Sudiana, I.M. 2003. Optimasi Analisis

Amilase dan Glukanase yang Diesktrak dari Miselium

Pleurotus ostreatus dengan Asam 3,5 Dinitrosalisilat.

Ber Penel Hayati. volume 9, pp. 7-12.

Sandhya, C., Binod, P., Nampoothiri, K.M, Szakacs, G.,

Pandey, A. 2005. Microbial Synthesis of Chitinase in

Solid Cultures and Its Potential as a Biocontrol Agent

against Phytopathogenic Fungus Colletotrichum

gloeosporioides. Applied Biochem Biotechnol.,

volume 127, pp. 1-15.

Sanusi, M. 2004. Transformasi Kitin dari Hasil Isolasi

Limbah Industri Udang Beku menjadi Kitosan. Mar

Chim Acta., volume 5(2), pp. 28-32.

Sashiwa, H., Fugishima, S., Yamano, N., Nakayama, A.,

Muraki, E., Hiraga, K., Oda, K., Aiba, S. 2002.

Production of N-acetyl-D-glucosamine from α-chitin

by Crude Enzymes from Aeromonas hydrophila H-

2330. Carbohydrate Research, volume 337, pp. 761-

763.

Setia, I.N., Suharjono. 2015. Chinolytic Assay and

Identification of Bacteria Isolated from Shrimp Waste

Based on 16S rDNA Sequences. Advances in

Microbiology, volume 5, pp. 541-548.

Shubakov, A.A., Kucheryavykh, P.S. 2004. Chitinolytic

Activity of Filamentous Fungi. Applied Biochemistry

and Microbiology, volume 40(5), pp. 445-447.

Suryadi, Y., Priyatno, T.P., Samudra, I.M., Susilowati,

D.N., Lawati, N., Kustaman, E. 2013a. Pemurnian

Parsial dan Karakterisasi Kitinase Asal Jamur

Entomopatogen Beauveria bassiana Isolat BB200109.

Jurnal AgroBiogen, volume 9(2), pp. 77-84.

Suryadi, Y., Priyono, T.P., Susilowati, D.N., Samudra,

I.M., Yudhistira, N., Purwakusumah, E.D. 2013b.

Isolasi dan Karakterisasi Kitinase Asal Bacillus cereus

11 UJ. Jurnal Biologi Indonesia, volume 9, pp. 51-62.

Wulandari, F. 2009. Optimasi Produksi N-asetilglukosamin

dari Kitin melalui Fermentasi oleh Aspergillus

rugulosus 501. Thesis. Institut Pertanian Bogor, Bogor.

Younes, I., Rinaudo, M. 2015. Chitin and Chitosan

Preparation from Marine Sources. Structure, Properties

16th AFC 2019 - ASEAN Food Conference

190

and Applications. Mar Drugs., volume 13(3), pp. 1133-

1174.

Younes, G., Zahra, D., Mohkam, M., Kargar, M. 2013.

Isolation and Optimization of Cultivation Conditions

for Production of Chitinase by Aeromonas sp. ZD_05

from the Persian Gulf. Journal of Pure and Applied

Microbiology, volume 7(2), pp. 913-918.

Zeki, N.H., Muslim, S.N. 2010. Purification,

Characterization and Antifungal Activity of Chitinase

from Serratia marcescens Isolated from Fresh

Vegetables. Ibn Al-Haitham J Pure Appl Sci., volume

23(1), pp. 13-25.

Optimum Condition for the Production of N-acetylglucosamine from Tiger Shrimp Shells using Semi Pure Extracellular Chitinase Enzyme

Produced by Mucor circinelloides

191