Effect of Heat Process for Prebiotic Properties of Taro Starch

(Colocasia Esculenta L. Schott)

R. Haryo Bimo Setiarto

1,2

, Harsi Dewantari Kusumaningrum

2

, Betty Sri Laksmi Jenie

2

,

Tatik Khusniati

1

, Nunuk Widhyastuti

1

and Sulistiani

1

1

Microbiology Division, Research Center for Biology, Indonesian Institute of Sciences (LIPI) Jalan Raya Jakarta,

Bogor Km 46, Cibinong Science Center, Cibinong, Bogor, 16911 West Java, Indonesia

2

Department of Food Science and Technology, Faculty of Agricultural Technology, Bogor Agricultural University,

Bogor 16680, West Java, Indonesia

Keywords: Heat Process, Prebiotic Properties, Taro Starch.

Abstract: This study investigates the effects of a variety of heat processes on the prebiotic properties of taro starch. The

taro starch is treated by the annealing process (24 hours, 50

o

C), the heat moisture treatment (HMT, moisture

25%, 3 hours, 110

o

C), and the autoclaving (15 minutes, 121

o

C) - cooling (24 hours, 4

o

C) cycles with 1, 2, and

3 cycles. The results show that all treatments improve the prebiotic properties of taro starch. The modified

taro starches (MTS) significantly increases their slow digestibility starch (SDS) and resistant starch (RS)

content, while the in-vitro digestibility, very rapid digestible starch (VRDS), rapid digestible starch (RDS)

are relatively decreased. However, the autoclaving-cooling two cycles (AC-2C) results in the MTS with the

best prebiotic properties as shown by its high RS content, low digestibility, high prebiotic effect, high prebiotic

index as well as prebiotics activity towards pathogenic bacteria. The AC-2C modified taro starch is very

prospective to be used as a prebiotic candidate.

1 INTRODUCTION

Colocasia esculenta L. schott known as taro was one

of the tubers from the Araceae family that is rich in

consumable starch (Aboubakar et al., 2009; Kaushal

et al., 2012; Zhu et al., 2015). The most common

consumed parts of taro were corm and cormel, the

thickening root which grows in the soil (Deka & Sit,

2016; Yu et al., 2018a). Taro was one of the most

cultivated tubers in the tropics and the subtropics,

including Southeast Asia, the Caribbean and the

North Atlantic Ocean, South and West Africa, Pacific

Islands and Polynesia (Aboubakar et al., 2009). The

utilization of Taro in Southeast Asia was still minimal

(Kaushal et al., 2012; Zhu et al., 2015; Deka & Sit,

2016). In the last few years, however, taro cultivation

had been increased due to its potential as the

functional food which contains up to 70 – 80 gram /

100 gram of starch content, 2 – 6 gram / 100 gram of

protein, 0.6 – 0.8 gram / 100 gram of fiber, vitamin,

phosphorus, magnesium, and calcium (Kaushal et al.,

2012; Zhu et al., 2015, Li et al., 2018a). Taro could

be widely applied in the food industry and processed

into consumable products such as pasta, starch, flour,

cereal bar, canned product, chips and beverage

powder (Li et al., 2018a; Muñoz-Cuervo et al., 2016).

The digestibility rate of taro starch was very high and

it had been applied to various food products because

of its unique structure and small particle of taro starch

granules (Kaushal et al., 2012; Muñoz-Cuervo et al.,

2016). The utilization of native taro starch was still

limited as it is high in retrogradation, thermal

decomposition, poor in process tolerance, narrow

peak viscosity range and resistant towards low shear

stress (Demirkesen-Bicak et al., 2018; Yu et al.,

2018b). These weaknesses increase the interest of

many researchers to modify starch so its functional

properties could be improved (Sullivan et al., 2017;

Sharlina et al., 2017; Oyeyinka et al., 2018). Starch

modification techniques could be carried out by its

physical, chemical or enzymatic properties (Hazarika

& Sit, 2016). Some physical modification techniques

could improve the functional properties of taro starch

including the cycle of cooling, autoclaving, HMT and

annealing.

Generally, the modification of taro starch was

conducted to enhance its functional properties as well

Setiarto, R., Kusumaningrum, H., Jenie, B., Khusniati, T., Widhyastuti, N. and Sulistiani, .

Effect of Heat Process for Prebiotic Properties of Taro Starch (Colocasia Esculenta L. Schott).

DOI: 10.5220/0009978900002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 77-83

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

77

as its physicochemical characteristics. Setiarto et al.

(2018) modified the taro flour to improve its prebiotic

properties, using the fermentation technique and the

autoclaving-cooling cycling. Two cycles of the

autoclaving-cooling technique successfully increased

the RS content by 2.7-fold (from 4.13% to 11.15%)

compared to the control treatment. The modified taro

flour resulted shows a better prebiotic effect, index,

and activity than the control (the one without

fermentation and autoclaving-cooling). This study

aims to determine the physicochemical

characteristics and prebiotic properties of modified

taro starch by implementing annealing, HMT and

autoclaving-cooling treatments. The prebiotic

properties were assessed during this study to provide

the additional information on functional properties

for food industry application.

2 MATERIALS AND METHODS

2.1 Materials

The main raw material used in this study was the

Bogor Taro of Pandan (Colocasia esculenta) with

eight months harvest age, from Cijeruk Bogor West

Java, Indonesia. Lactobacillus plantarum SU-LS 36

and EPEC (Entero Pathogenic Escherichia coli) was

provided from The Laboratory of Food Microbiology,

Research Center for Biology, Indonesian Institute of

Science (LIPI).

2.2 Taro (Colocasia Esculanta) Starch

Extraction Process

Taro starch extraction was performed by applying the

technique from Airul et al. (2014) with a few

modifications. Taro tuber (Colocasia esculanta) was

peeled, washed, and soaked in the mixture of 1%

NaCl (3: 4) for an hour to remove oxalate crystals.

It was then shredded and mixed with distilled water

(3: 1) for one minute using a blender (Phillips,

Netherland). Double fold cotton cloth was utilized to

filter the taro pulp. The obtained taro pulp filtrate was

settled overnight to let the starch sink at the base of

the beaker glass. Taro pulp was centrifuged with High

Speed Centrifuge (Kubota, Japan) at 5000 rpm for 10

minutes to obtain taro starch. Distilled water was used

to clean the taro starch three times to remove the

supernatant. After that, it was oven dried in at 50oC

up to the constant weight. Finally, the dry taro starch

was ground using the disk mill (China).

2.3 Modification of Taro Starch

2.3.1 Annealing Treatment

The annealing treatment of taro starch was conducted

by the technique from Wang et al. (2018). Twelve

grams of taro starch was added to 60 ml of distilled

water with the ratio of taro starch: water (1: 5) (b / v)

was placed in a polyethylene bag. The annealing

treatment was carried out at 50

o

C for 24 hours by

inserting a polyethylene bag which had been tightly

closed into a water bath (Hitachi, Japan). Afterward,

the taro starch was freeze dried, crushed and filtered

using the 100-mesh sieve. The resulting taro starch

from the annealing process was then chilled at 4

o

C

prior to further analysis.

2.3.2 Heat-Moisture Treatment

The taro starch modification using HMT was

obtained following Deka & Sit (2016). Forty-five

grams of taro starch (dry-based) was placed into a

glass container, and distilled water was added to it

while stirring until the water content reached 25%.

Then, the glass container was sealed, balanced for 48

hours at room temperature then heated at 120°C in an

electric oven (Shimizu, Japan) for three hours. The

heated modified taro starch was then dried at 40°C for

overnight, milled and sieved with a 100-mesh sieve.

2.3.3 Autoclaving-Cooling Treatment

The autoclaving-cooling method of taro starch

followed the procedure by Setiarto et al. (2018). The

taro starch was added with aquadest at the ratio of 1:

2, heated in an autoclave (Hitachi, Japan) at 121°C for

15 minutes, then chilled in refrigerator at 4°C for 24

hours. Thereafter, the treated taro starch was dried

(70°C, 16 hours) in an oven (Shimidzu, Japan) until

the moisture content reached 12%, and milled using a

pin disk mill (Shimidzu, Japan). The starch was

sieved to obtain the 100-mesh taro starch. The

autoclaving-cooling treatment was also completed

with two cycles and three cycles.

2.4 In-vitro Digestibility and Digestible

Starch Composition Analysis

In-vitro starch digestibility was analyzed by

measuring the level of maltose as the product of

hydrolysis taro starch by using α-amylase enzyme

(Sigma) compared to starch solution. This analysis

was performed by referring to a method from

Anderson et al., (2002). The absorbance of sample

2nd SIS 2019 - SEAFAST International Seminar

78

and blank solutions was determined by

Spectrophotometer UV-Vis (Shimadzu UV-1800,

Japan) at 520 nm. In this study, the calculation of the

starch digestibility (%) is shown in the following

formula:

Starch digestibility (%) =

x

100%

(1)

The digestible starch composition analysis was

conducted in this study by following Englyst et al.,

(1992) method. There are four types of starch

compositions based on their digestibility times. The

first type is called very rapid digestible starch

(VRDS), which is expressed as the amount of

digested starch in the first minute by porcine

pancreatin and amyloglucosidase 210 U as explained

in the Sigma Cat. No. P7545 and No. A7095,

respectively. The second type is called the rapid

digestible starch (RDS) which is the amount of

digested starch expelled between 1 minute and 20

minutes. The third type is the slow digestible starch

(SDS) which is expressed as the amount of digested

starch between 20 and 120 minutes. Finally, the

resistant starch (RS) is described as non-digestible

starch after 120 minutes of analysis.

2.4.1 Analysis of Prebiotic Effect and

Prebiotic Index of MTS

The analysis of prebiotic effect and index was

conducted by observing the change in the number of

L. plantarum SU-LS 36 colonies on m-MSRB

medium and m-MSRB medium with 2.5% taro starch

(native, AC-1C, AC-2C, AC-3C, annealing and

HMT). They were determined using the methods by

Roberfroid (2007). After incubation process for 24

hours at 37°C, the probiotic cell cultures were

enumerated in the MRSA medium. The same

procedures were conducted using a commercial

prebiotic FOS (fructooligosaccharide) as positive

control. The calculations were finished using these

following equations:

Prebiotic Effect = Log (cfu/mL) 2.5% taro starch

–

Log (cfu/mL) m-MRSB

(2)

Prebiotic Index =

2.5%ℎ−

ℎ ℎ

(3)

2.4.2 Prebiotic Activity Examination of

MTS to Diarrhea-Causal-Bacteria

The examination of prebiotic activity was conducted

by adding 2% (v/v) of L. plantarum SU-LS 36 culture

into m-MSRB with 2.5% (w/v) of glucose or 2.5%

(w/v) of taro starch (native, AC-1C, AC-2C, AC-3C,

annealing and HMT). It was analyzed by referring the

method from Huebner et al. (2007). After 0 hour and

24 hours of incubation times, the samples were

enumerated in the MRSA medium. The examination

was also conducted towards diarrhea-causal-bacteria,

Entero Pathogenic Escherichia coli (EPEC). The

EPEC culture of 2% (v/v) was added into different

Erlenmeyer containing m-TSB 2.5% (w/v) of glucose

or 2.5% (w/v) taro starch (native, AC-1C, AC-2C,

AC-3C, annealing and HMT). The culture was

incubated at 37°C, and enumerated in the TSA

medium after 0 hour and 24 hours of incubation

times. Prebiotic activity value was calculated using

this equation:

Prebiotic Activity Value =

{

(/)

}-

{

(/)

}

(4)

Note

N = number of L. plantarum SU-LS 36 (log cfu/mL)

t

0

= start of incubation time (0 hour)

E = number of Entero Pathogenic Escherichia coli

(log cfu/mL)

t

1

= end of incubation time (24 hour)

2.5 Statistical Data Analysis

There were three replications in this experiment,

where the statistical analyses were implemented

to process the research data. The Duncan statistical

test was implied to examine the considerable

differences at the level of p <0.05 utilizing the SPSS

18.0 statistical software (SPSS, Inc., Chicago,

IL, USA).

Effect of Heat Process for Prebiotic Properties of Taro Starch (Colocasia Esculenta L. Schott)

79

Table 1: In vitro digestibility and starch digestibility profile.

Treatment

In-vitro

digestibility (%)

VRDS

(% dry weight)

RDS

(% dry weight)

SDS

(% dry weight)

RS

(% dry weight)

Native taro

starch

80.17±0.63

c

37.30±0.42

d

32.07±0.25

d

23.15±0.63

a

7.48±0.94

a

AC-1C

70.77±0.52

b

31.95±0.81

c

27.13±0.48

c

25.60±0.74

b

15.32±0.86

b

AC-2C

64.41±0.76

a

29.29±0.46

b

22.20±0.59

b

27.17±0.38

c

21.34±078

c

AC-3C

62.83±0.82

a

27.42±0.35

a

21.20±0.72

b

28.67±0.55

c

22.71±0.21

c

Annealing

67.24±0.26

b

33.27 ±0.87

c

24.02±0.29

b

25.27±0.88

b

17.44±0.69

b

HMT

65.66±0.31

a

30.58±0.93

b

18.54±0.46

a

27.26±0.61

c

23.62±0.49

c

Note: In-vitro digestibility, VRDS, RDS, SDS and RS content with the different superscript letters within a row were

significantly different at p<0.05 level

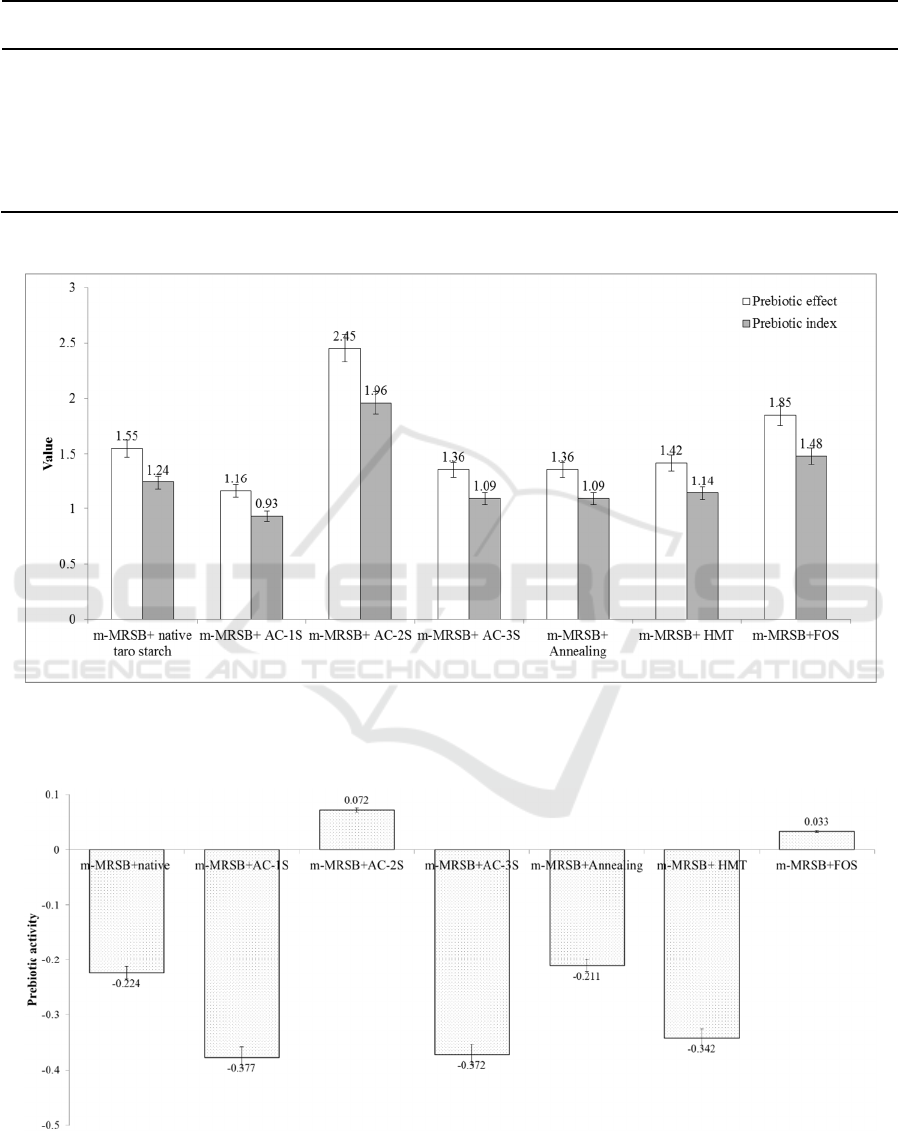

Figure 1: Prebiotic effect and index of native taro starch, modified taro starch by AC-1C, AC-2C, AC-3C, Annealing, and

HMT.

Note: Prebiotic effect and index are expressed in the different typescript letters of the bar chart, where the noticeable different

occurs at the p<0.05 level.

Figure 2: Prebiotic activity of native taro starch, modified taro starch by AC-1C, AC-2C, AC-3C, annealing, and HMT to

diarrhea-causal-bacteria.

Note: Prebiotic activity is expressed in the different typescript letters of the bar chart, where the noticeable different occurs

at the p<0.05 level.

a

b

b

b

c

d

e

a

b

b

b

c

d

e

2nd SIS 2019 - SEAFAST International Seminar

80

3 RESULTS AND DISCUSSION

3.1 In Vitro and Starch Digestibility

Profiles

The analysis identifies that the native taro starch had

the highest in-vitro digestibility up to 80.17%

compared to modified taro starches (Table 1). The

improvement of RS content might reduce the

digestibility of taro starch consistently. Starch

digestibility had a negative correlation with RS

content. This result was similar to analysis by Cheng

et al. (2019), Ashwar et al. (2016), Shi & Gao (2011),

and Zheng et al. (2018) showed that the HMT

treatment can reduce the vitro digestibility of rice

starch. Annealing, HMT, and autoclaving-cooling

cycles significantly reduced in-vitro digestion of taro

starch (p <0.05) (Table 1). HMT and autoclaving-

cooling cycle resulted the formation of double helix

structures, the increase of chain bonding between

amylose-amylose, amylopectin-amylopectin and

amylose-amylopectin, consequently taro starch was

more difficult to digest by α-amylase enzymes

(Cheng et al., 2019; Zheng et al., 2018).

The increasing number of autoclaving-cooling

cycles decreased the in-vitro digestibly of taro starch.

The AC-3C treatment showed the lowest digestibility

of taro starch (62.83%) compared to other treatments

(Table 1). The annealing treatment, autoclaving

cooling cycle and HMT also reduced the in-vitro

digestibility of starch due to the retrogradation

process, hence increased RS and SDS levels (Shah et

al., 2016; Chen et al., 2018; Lovera & Perez, 2017).

MTS with high RS content had low in-vitro starch

digestibility (Perera et al., 2010). The in-vitro

digestibility reduction due to the retrogradation

treatment (e.g. HMT and autoclaving-cooling cycle)

was also reported previously by Cheng et al. (2019),

Shah et al. (2016), Ashwar et al. (2016), Shi & Gao

(2011), Zheng et al. (2018), and Chen et al. (2018).

Annealing, HMT and autoclaving-cooling cycles

reduced the levels of VRDS and RDS significantly

(p<0.05) compared to the native taro starch (Table 1).

The more autoclaving-cooling cycles were applied,

the lower VRDS and RDS became. Taro starch with

autoclaving-cooling of 3 cycles (AC-3C) treatment

showed the lowest result of VRDS level (27.42%),

followed by AC-2C (29.29%), HMT (30.58%), AC-

1C (31.95%) and annealing (33.27%) (Table 1).

Moreover, taro starch with HMT showed the lowest

value of RDS level (18.54%). The VRDS and RDS

from annealing, HMT and autoclaving-cooling cycle

treatments showed significant decrease as their

internal structures were changed into the SDS and RS.

This is proved by the significant increase (p<0.05) of

SDS and RS levels in taro starch after annealing,

autoclaving-cooling cycles, and HMT (Table 1). The

more autoclaving-cooling cycles were applied, the

higher SDS and RS become. AC-3C treatment

showed the highest SDS levels (28.67%) while HMT

resulted the highest RS levels (23.62%) (Table 1).

These results were relatively higher than the research

from Cheng

et al. (2019) in which the HMT was

applied at 120

o

C condition (2 hours, 30% moisture

content) in corn, pea, and lentil starch. HMT

treatment led to the increase of resistant starches of

corn, pea, and lentil up to 7.7, 11.2, and 10.4%

respectively (Cheng et al., 2019).

3.2 Prebiotic Effect and Prebiotic

Index

The prebiotic effect is the increasing number of the

absolute probiotic bacteria without considering the

prebiotic concentration (Roberfroid, 2007; Huebner

et al., 2007). Meanwhile, the prebiotic index is the

increasing of probiotic bacteria population correlated

with the prebiotic concentration (Roberfroid, 2007;

Huebner et al., 2007). The highest prebiotic effect and

index were noticeable in L. plantarum SU-LS 36 in

the AC-2C treatment (Figure 1). The RS in AC-2C

taro starch accommodated the growth of probiotic

bacteria. The examination on prebiotic effect and

index were conducted directly to the taro starch

sample to explain its prebiotic properties. Huebner et

al. (2007) reported that a diet was a good prebiotic

source if it had more than 1.5 prebiotic effect and

index (Figure 1).

The AC-2C taro starch was a good prebiotic

candidate if it had more than 1.5 prebiotic effect and

index. This value was higher than the

fructooligosaccharide (FOS), as commercial

prebiotic. The resistant starch content in AC-2C taro

starch increased the probiotic growth of L. plantarum

SU-LS 36 (Figure 1). To increase the prebiotic effect

index could be achieved by isolating the RS from taro

starch or consuming the AC-2C taro starch in the

larger quantities (20 gram/day) as a functional diet.

The RS with 20 – 30 degree polymerization played an

important role as a prebiotic source, therefore it could

be fermented to form the short chains fatty acids

(especially the butyric acid) in the colon, using

probiotic bacteria assistance (Danneskiold-Samsøe et

al., 2019). The increase of butyric acid caused the

decrease of pH inside the colon. Therefore this

condition inhibited the pathogenic bacteria growth

and prevented the proliferation of cancer cells in the

colon (Sullivan et al., 2017; Luo et al., 2017).

Effect of Heat Process for Prebiotic Properties of Taro Starch (Colocasia Esculenta L. Schott)

81

3.3 Prebiotic Activity to

Diarrhea-Causal-Bacteria

The prebiotic activity is the prebiotic capability to

grow probiotic bacteria, which is related to its

selectivity towards pathogenic bacteria over glucose

(Vrese & Marteau, 2007). A diet had positive

prebiotic activity (over 0.25) if it was selectively

metabolized by probiotic bacteria’s such as

Bifidobacterium sp., L. acidophilus and L. plantarum,

and not metabolized by pathogenic bacteria such as

EPEC (Vrese & Marteau, 2007). Native taro starch,

AC-1C, AC-3C, annealing and HMT had negative

prebiotic activity values. These mean that they were

not potential as prebiotic candidates (Figure 2). The

AC-2C treatment was capable to produce a resistant

starch with a degree of polymerization (DP) of around

20-30. Resistant starch was a selective and specific

prebiotic source for probiotics L. plantarum SU-LS

36.

Furthermore, L. plantarum SU-LS 36 probiotics

utilized the resistant starch from the AC-2C MTS as

a carbon source for its growth. Meanwhile, EPEC

could not use it as a source of nutrition for its growth.

The AC-2C MTS had the highest prebiotic activity

and it was a positive growth medium for L.

plantarum- EPEC (0.072) (Figure 2). Positive

prebiotic activity was also produced by

fructooligosaccharide (FOS) as a commercial

prebiotic growth medium for L. plantarum-EPEC

(0.033) (Figure 2). Finally, the AC-2C MTC was the

best prebiotic candidate as it had the higher values of

prebiotic effect, index, and activity than any other

treatments.

4 CONCLUSIONS

Annealing, autoclaving-cooling cycle, HMT

decreased in-vitro starch digestibility, VRDS, RDS

significantly. On the other hand, all treatments

significantly increased SDS and RS levels from taro

starch. MTS with AC-2C had the potential as a

prebiotic candidate as it had the highest prebiotic

effect, index and activity against EPEC.

ACKNOWLEDGEMENTS

The authors would like to express their deepest

gratitude to the Research Center for Biology

(Indonesian Institute of Sciences) LIPI and the

Science & Technology Postgraduate Scholarship

from Ministry of Technology and Higher Education

in Republic of Indonesia which had funded this

research.

REFERENCES

Aboubakar, Njintang, N.Y., Scher, J., Mbofung, C.M.F.,

2009. Texture, microstructure and physicochemical

characteristics of taro (Colocasia esculenta) as

influenced by cooking conditions. Journal of Food

Engineering, 91, 373-379.

Airul, A., Yusof, M. S. M., Jamil, M. S., Abdullah, A.,

Yusoff, S. F. M., Arip, M. N. M., Lazim, A. M., 2014.

Physicochemical characterization of starch extracted

from Malaysian wild yam (Dioscorea hispida Dennst.).

Emirates Journal Food Agriculture, 26(8), 652–658.

Anderson, A.K., Guraya, H.S., James, C., Salvaggio, L.,

2002. Digestibility and pasting properties of rice starch

heat-moisture treated at the melting temperature.

Starch/Stärke, 54, 401–409.

Ashwar, B.A., Gani, A., Wani, I.A., Shah, A., Masoodi,

F.A., Saxena, D.C., 2016. Production of resistant starch

from rice by dual autoclaving retrogradation treatment:

In-vitro digestibility, thermal and structural

characterization. Food Hydrocolloids, 56, 108-117.

Chen, Y.F., Singh, J., Archer, R., 2018. Potato starch

retrogradation in tuber: Structural changes and gastro-

small intestinal digestion in vitro. Food Hydrocolloids,

84, 552-560.

Cheng, K., Chen, S., Yeh, A., 2019. Physicochemical

properties and in vitro digestibility of rice after

parboiling with heat moisture treatment. Journal of

Cereal Science, 85, 98-104.

Danneskiold-Samsøe, N.B., de Freitas Queiroz Barros,

H.D., Santos R., Bicas, J.L., Cazarin, C.B.R., Madsen

L., Kristiansen, K., Pastore, G.M., Brix, S. Junir,

M.B.M., 2019. Interplay between food and gut

microbiota in health and disease. Food Research

International, 115, 23–31.

Deka, D., Sit, N., 2016. Dual modification of taro starch by

microwave and other heat moisture treatments.

International Journal of Biological Macromolecules,

92, 416-422.

Demirkesen-Bicak, H., Tacer-Caba, Z., Nilufer-Erdil, D.,

2018. Pullulanase treatments to increase resistant starch

content of black chickpea (Cicer arietinum L.) starch

and the effects on starch properties. International

Journal of Biological Macromolecules, 111, 505-513.

Englyst, H.N., Kingman, S.M., Cummings, J.H., 1992.

Classification and Measurement of Nutritionally

Important Starch Fractions. European Journal of

Clinical Nutrition, 46, 533–550. H.N.

Hazarika, B.J., Sit, N., 2016. Effect of dual modification

with hydroxypropylation and cross-linking on

physicochemical properties of taro starch.

Carbohydrate Polymers, 140, 269-278.

Huebner, J., Wehling, R.L., Hutkins, R.W., 2007.

Functional activity of commercial prebiotics. Journal

2nd SIS 2019 - SEAFAST International Seminar

82

International Dairy, 17, 770-775.

Kaushal, P., Kumar, V., Sharma, H.K., 2012. Comparative

study of physicochemical, functional, antinutritional

and pasting properties of taro (Colocasia esculenta),

rice (Oryza sativa) flour, pigeonpea (Cajanus cajan)

flour and their blends. LWT - Food Science and

Technology, 48, 59-68.

Li, H., Dong, Z., Liu, X., Chen, H., Lai, F., Zhang, M.,

2018a. Structure characterization of two novel

polysaccharides from Colocasia esculenta (taro) and a

comparative study of their immunomodulatory

activities. Journal of Functional Foods, 42, 47-57.

Lovera, M., Pérez, E., Laurentin, A., 2017. Digestibility of

starches isolated from stem and root tubers of

arracacha, cassava, cush–cush yam, potato and taro.

Carbohydrate Polymers, 176, 50-55.

Luo, D., Li, Y., Xu, B., Ren, G., Li, P., Li, X., Han, S., Liu,

J., 2017. Effects of inulin with different degree of

polymerization on gelatinization and retrogradation of

wheat starch. Food Chemistry, 229, 35-43.

Muñoz-Cuervo, I., Malapa, R., Michaleta, S., Lebot, V.,

Legendrea, L., 2016. Secondary metabolite diversity in

taro, Colocasia esculenta (L.) Schott, corms. Journal of

Food Composition and Analysis, 52, 24-32.

Oyeyinka, S.A., Adeleke, O.F., Dauda, A.O., Abiodun,

O.A., Kayodea, R.M.O., Adejuyitan, J.A., 2018. Flour

composition and physicochemical properties of white

and yellow bitter yam (Dioscorea dumetorum) starches.

Industrial Crops & Products, 120,135-139.

Perera, A., Meda, V., Tyler, R.T., 2010. Resistant starch: A

review of analytical protocols for determining resistant

starch and of factors affecting the resistant starch

content of foods. Food Research International, 43,

1959–1974.

Roberfroid, M. 2007. Prebiotics: The Concept Revisited.

The Journal of Nutrition Effect of Probiotics and

Prebiotics, 137, 830-837.

Setiarto, R.H.B., Jenie, B.S.L., Faridah, D.N., Saskiawan,

I., Sulistiani., 2018. Effect of lactic acid bacteria

fermentation and autoclaving-cooling for resistant

starch and prebiotic properties of modified taro flour.

International Food Research Journal, 25(4), 1691-

1697.

Shah, A., Masoodi, F.A., Gani, A., Ashwar, B.A., 2016. In-

vitro digestibility, rheology, structure, and functionality

of RS3 from oat starch. Food Chemistry, 212,749-758.

Sharlina, M.S.E., Yaacob, W.A., Lazim, A.M., Fazry, S.,

Lim, S.J., Abdullah, S., Noordin, A., Kumaran, M.,

2017. Physicochemical Properties of Starch from

Dioscorea pyrifolia tubers.

Food Chemistry, 220, 225-

232.

Shi, M., Gao, Q., 2011. Physicochemical properties,

structure and in vitro digestion of resistant starch from

waxy rice starch. Carbohydrate Polymers, 84, 1151-

1157.

Sullivan, W.R., Hughes, J.G., Cockman, R.W., & Small,

D.M., 2017. The effects of temperature on the

crystalline properties and resistant starch during storage

of white bread. Food Chemistry, 228, 57-61.

Vrese, M.D., Marteau, P.R., 2007. Probiotics and

Prebiotics: Effects on Diarrhea. The Journal of

Nutrition, 22, 803-811.

Wang, X., Reddy, C.K., Xu, B., 2018. A systematic

comparative study on morphological, crystallinity,

pasting, thermal and functional characteristics of

starches resources utilized in China. Food Chemistry,

259, 81-88.

Yu, Z.Y., Jiang, S.W., Cai, J., Cao, X.M., Zheng, Z., Jiang,

S.T., Wang, H.L., Pan, L.J., 2018a. Effect of high

pressure homogenization (HPH) on the rheological

properties of taro (Colocasia esculenta (L). Schott)

pulp. Innovative Food Science and Emerging

Technologies, 50, 160-168.

Yu, Z., Wang, Y.S., Chen, H.H., Li, Q.Q., Wang, Q., 2018b.

The gelatinization and retrogradation properties of

wheat starch with the addition of stearic acid and

sodium alginate. Food Hydrocolloids, 81, 77-86.

Zheng, B., Wang, H., Shang, W., Xie, F., Li, X., Chen, L.,

Zhou, Z., 2018. Understanding the digestibility and

nutritional functions of rice starch subjected to heat-

moisture treatment. Journal of Functional Foods, 45,

165-172.

Zhu, G., Xiao, Z., Zhou, R., Lei, D., 2015. Preparation and

simulation of a taro flavor. Chinese Journal of

Chemical Engineering, 23, 1733-1735.

Effect of Heat Process for Prebiotic Properties of Taro Starch (Colocasia Esculenta L. Schott)

83