Study of Antioxidant Liquid Smoke Cacao Fruit Peel Waste at

Different Water Content and Pyrolysis Temperatures

I. Ketut Budaraga and D. P. Putra

Lecturer Staff of the Faculty of Agriculture, Ekasakti University,

Veteran Dalam Street No. 26 B Padang, West Sumatra Province, 25113, Indonesia

Keywords: Cocoa Pods, Liquid Smoke, Antioxidants, IC

50

.

Abstract: Cocoa pod husks are agricultural waste whose management has not been done much. This waste is only used

as animal feed and many are left alone. This research uses cocoa waste as raw material for making liquid

smoke. This study aims to determine the antioxidant activity of liquid smoke of cocoa pod skin with

differences in raw material water content and pyrolysis temperature. The moisture content of the raw material

for cocoa pods is around 10-25% and the pyrolysis temperature is 200 - 400

o

C. Antioxidant analysis using

the DPPH method by calculating the IC

50

value of the liquid smoke of cocoa pods. The results showed that

liquid smoke with low moisture content of raw materials and high pyrolysis temperatures produced high

antioxidant activity values. IC

50

value of liquid smoke of cocoa pods ranged from 107.33 - 268.97 ppm and

AAI values ranged from 0.186 to 0.466. Treatment of 10% water content and pyrolysis temperature of 400

o

C

is the best treatment.

1 INTRODUCTION

Cocoa is an agricultural product from the plantation

sector which is a leading commodity in the

Indonesian state. The results of processing cocoa

from plantation land produce biomass waste in the

form of cocoa pods, cocoa leaves and cocoa wood.

One of the waste originating from plantation products

is the cocoa pods which have only been thrown away

and burned (Wijaya, Wiharto and Anwar, 2017). At

the time of harvest also produced fruit skins with

volumes almost the same as seeds (Mulyatni, Budiani

and Taniwiryono, 2012).

Cocoa pod waste produced in large quantities will

be a problem if not handled properly because the

production of solid waste reaches more than 60% of

the total fruit production, this will be a great potential

to pollute the surrounding environment (Harsini and

Susilowati, 2010).

Cocoa pods contain phenolic compounds and

flavonoids (Jusmiati, Rusli and Rijai, 2016). The

polyphenol content includes cinnamic acid, tannin,

pyrogalol, quercetin, resorcinol and epikatekin-3-

galat (Fapohunda and Afolayan, 2012). This

compound is a natural antioxidant found in the skin

of cocoa fruit.

Seeing the potential of the cocoa pod skin, this

study utilizes the cocoa pod skin to produce liquid

smoke. Liquid smoke is the result of condensation

process or condensation of steam from combustion

directly or indirectly using materials that contain

lignin, cellulose, hemicellulose, and hydrocarbon

compounds (Kondo, Gunawan and Rizke, 2017). The

purpose of this study is to utilize the cocoa pods as

raw material for making liquid smoke and to know

the antioxidant activity of liquid smoke produced.

Based on the description above, it has been tested

the antioxidant activity and liquid smoke of cocoa

pod skin using DPPH method (2,2-diphenyl-1-

pikrihidrazil) by calculating the value of inhibition

concentration of 50% (IC

50

).

2 MATERIALS AND METHODS

The research has been carried out at the Agricultural

Product Technology Laboratory of the Ekasakti

University and the Agricultural Microbiology and

Biotechnology Laboratory of the Andalas University

in April - May 2019. This research is an explorative

study with differences in the level of water content of

Budaraga, I. and Putra, D.

Study of Antioxidant Liquid Smoke Cacao Fruit Peel Waste at Different Water Content and Pyrolysis Temperatures.

DOI: 10.5220/0009978400002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 63-66

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

63

raw materials and the temperature of liquid smoke

pyrolysis.

Liquid smoke can be obtained by using a pyrolysis

tool. The material used in this study is the cocoa shells

that have been regulated according to the water

content and the process of pyrolysis is carried out to

obtain liquid smoke of cocoa pods, methanol p.a,

distilled water, DPPH.

The equipment used is a series of pyrolysis

apparatus, oven, UV-Vis spectrophotometer, 250 ml

erlenmeyer, 500 ml cup glass, test tube, test tube rack,

1 ml micro pipette, 0.1 ml micro pipette tissue and

spray bottles.

2.1 Research Procedure

2.1.1 Sample Preparation

The raw materials in this study are the cocoa pods

obtained from Padang Pariaman and Lubuk Minturun

Regencies, Padang City. The procedure for making

liquid cocoa pod smoke includes: Washing cocoa

shells, reducing cocoa shells with a diameter of 5-

9cm. Then the cocoa skin is dried by being dried in

the sun until the water content reaches 25%, 20%,

15%, and 10%.

2.1.2 Pyrolysis (Budaraga et al., 2016)

Each sample of cocoa shell was weighed as much as

1000 g based on treatment starting from water content

(10%, 15%, 20%, and 25%) and then put into a

pyrolysis reactor equipped with a series of

condensing equipment and condenser coolers. The

reactor is equipped with a temperature gauge. Electric

heating in the form of a reactor envelope with a

current of 10 amperes. Pyrolysis runs at temperatures

of 200-400 ° C. Pyrolysis is stopped after no liquid

smoke has dripped into the shade. The results of

pyrolysis in the form of liquid smoke are collected in

dark bottles and then left standing, then filtered using

filter paper and activated carbon and gauze to

separate tar and liquid smoke. After being stored for

1 (one) week, an analysis of antioxidant activity was

carried out.

2.1.3 Determine the Antioxidant Activity of

the DPPH Method (Tristantini et al.,

2016)

Prepare 1 ml of liquid smoke of the cocoa pod skin

and make each parent solution. Furthermore, dilution

using PA methanol solvent by making variations in

the concentration of 50 ppm, 100 ppm, 150 ppm, 200

ppm and 250 ppm in each sample. Prepare a stock

solution of DPPH 50 ppm. The DPPH stock solution

is prepared by dissolving 5 mg of DPPH solid into

100 ml of methanol PA. Then a comparison solution

is prepared, a control solution containing 2 ml of

methanol PA and 1 ml of a 50 ppm DPPH solution.

For the test sample, 2 ml of each sample solution is

prepared and 2 ml of DPPH solution is prepared

respectively. Then, it was incubated for 30 minutes at

27 ℃ until the discoloration of DPPH activity

occurred. All samples, ie incubated liquid cocoa

smoke smoke samples were tested for their

absorbance values using a UV-Vis spectrophotometer

at a wavelength of 517 nm.

Analysis of DPPH method antioxidant testing is

done by looking at the color changes of each sample

after incubation with DPPH. If all DPPH electrons are

paired with electrons in the extract sample, the sample

color changes from dark purple to bright yellow. Then

the absorbance value was measured using a UV-Vis

spectrophotometer at a wavelength of 517 nm.

3 RESULTS AND DISCUSSION

The DPPH method is an effective and fast

colorimetric method for estimating antiradical /

antioxidant activity. This chemical test is widely used

in natural product research to isolate antioxidant

phytochemicals and to test the capacity of extracts

and pure compounds to absorb free radicals. The

DPPH method is used to measure a single electron as

a hydrogen transfer activity as well as to measure the

inhibitory activity of free radicals (Prakash, Rigelhof

and Miller, 2001).

Antioxidant activity by DPPH method is

expressed by 50% inhibition concentration or IC50,

which is a sample concentration that can inhibit

DPPH activity by 50%, so the value of 50 is

substituted for the value of y. After substituting the

value of 50 on the value of y, we will get the value x

as the value of IC50.

The results showed that the moisture content of

raw materials in making liquid smoke affects the

IC50 value of the resulting liquid smoke. Low water

content results in lower IC50 values, which means

high antioxidant activity values. Similarly, the

pyrolysis temperature used, the higher the pyrolysis

temperature, the lower the IC50 value obtained. A

compound is said to be a very strong antioxidant if the

IC50 value is less than 50, strong (50-100), moderate

(100-150), and weak (151-200). The smaller the IC50

value the higher the antioxidant activity (Badarinath

et al., 2010). IC50 values of liquid smoke of cocoa

pod peels are listed in Table 1.

2nd SIS 2019 - SEAFAST International Seminar

64

Table 1: IC

50

values of liquid smoke of cocoa pod husks.

Treatment Temp

Antioxidant

IC

50

(ppm)

AAI

Water level 10%

200

o

C

156,04 0,32

Water level 15% 189,33 0,26

Water level 20% 218,56 0,23

Water level 25% 268,99 0,19

Water level 10%

300

o

C

148,54 0,34

Water level 15% 162,27 0,31

Water level 20% 170,67 0,29

Water level 25% 191,92 0,26

Water level 10%

400

o

C

107,33 0,47

Water level 15% 109,85 0,46

Water level 20% 114,87 0,44

Water level 25% 165,29 0,30

Based on Table 1, it can be seen that the IC50

value of liquid smoke of cocoa pod skins ranges from

107.33 - 268.97 ppm. This value is included in the

moderate to weak group. From the results of the study

it was found that liquid smoke with pyrolysis

temperature of 200 OC at 10-25% raw material

moisture content obtained IC50 values ranged from

156.04 - 268.97 ppm and included in the weak

category. At pyrolysis temperature 300 OC, IC50

values ranged from 148.54-191.92 ppm. At the

moisture content of raw materials 10% included in the

medium category, while at the moisture content of

raw materials 15-25% included in the category of

weak. At pyrolysis temperature of 400 OC, IC50

values ranged from 107.33-165.29 ppm. In the

moisture content of raw materials 10-20% included in

the medium category, while the moisture content in

raw materials 25% included in the category of weak.

According to (Chen, 2014), the results of lignin

pyrolysis will determine the stability of samples of

the phenolic compounds making up liquid smoke.

The compounds in liquid smoke vary, depending on

the type of material, water content and temperature

used during the pyrolysis process. Antioxidant testing

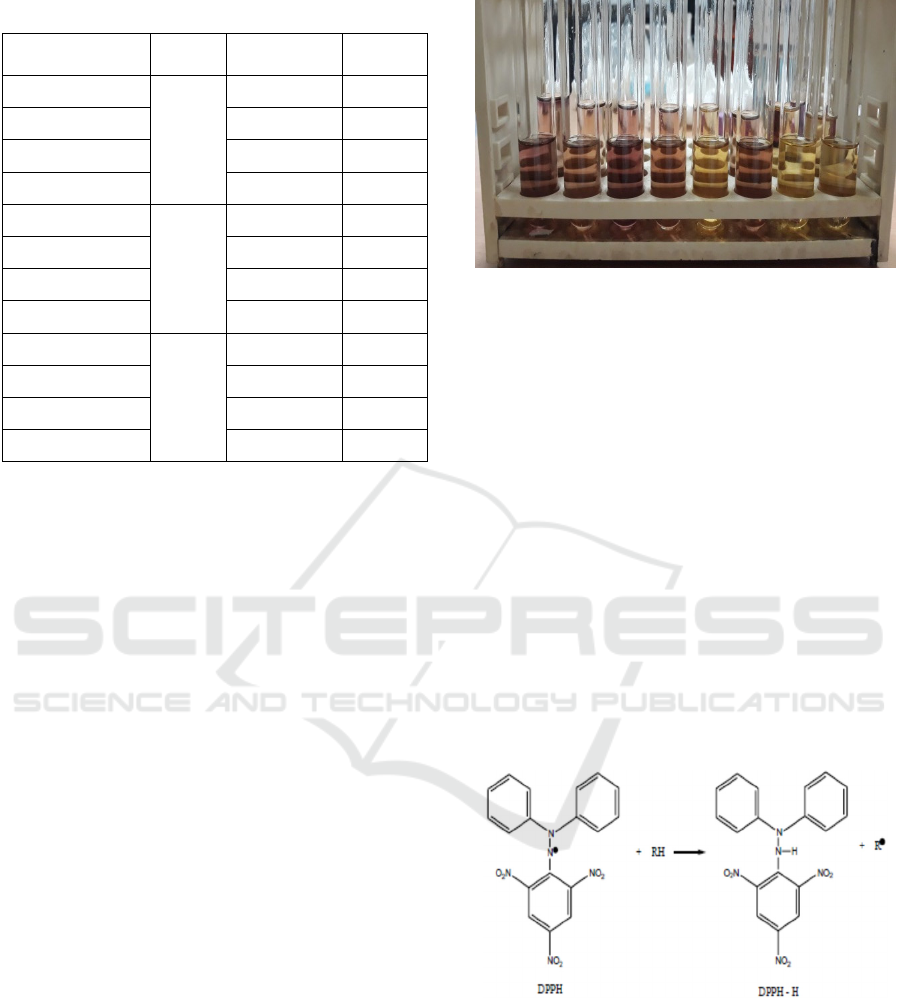

is in Figure 1.

In this study also observed the value of

Antioxidant Activity Index (AAI) which aims to

determine the antioxidant activity index of liquid

smoke of cocoa pods. From the research results

obtained AAI values ranged from 0.186 to 0.466. This

value is included in the weak category. This is

consistent with the statement (Scherer and Godoy,

2009); (Faustino et al., 2010) which stated antioxidant

Figure 1: Testing the antioxidant activity of liquid smoke of

cocoa pod skin DPPH method.

activity based on AAI values was said to be weak as

antioxidants if the AAI value <0.5. Moderate

antioxidant activity if the AAI value is 0.5 - 1. Strong

antioxidant activity if the AAI value is 1.0 - 2.0.

Antioxidant activity is very strong if the AAI value>

2.0.

When the purple DPPH solution meets the

electron donor material, the DPPH will be reduced,

causing the purple color to fade and replaced by the

yellow color from the picril group. A decrease in

absorbance and color change in the test sample

indicates the presence of electrons or hydrogen atoms

donated by the test solution as an antioxidant to

DPPH. The higher concentration of the test solution

means that more electrons or hydrogen atoms will be

donated to DPPH free radicals (Sumpono, Putri and

Sari, 2017). The DPPH radical reduction reaction by

antioxidants is shown in Figure 2.

Figure 2: DPPH radical reduction reaction by antioxidants.

Cocoa pods are known to have secondary

metabolites which act as antioxidants. According to

(Loppies and Yumas, 2014), cocoa pods contain a

number of compounds from the polyphenol and

flavonoid classes. The presence of phenol groups

with hydroxyl groups from polyphenols and

flavonoids allows this compound to be a preservative.

In addition (Burhanuddin, 2004), reported cocoa skin

Study of Antioxidant Liquid Smoke Cacao Fruit Peel Waste at Different Water Content and Pyrolysis Temperatures

65

contains tannins, polyphenols, flavonoids, alkaloids

and steroids which are active components that are

very beneficial for health.

Cocoa pods contain phenolic compounds and

flavonoids (Jusmiati, Rusli and Rijai, 2016). The

polyphenol content includes cinnamic acid, tannin,

pyrogalol, quercetin, resorcinol and epikatekin-3-

galat (Fapohunda and Afolayan, 2012). This

compound is a natural antioxidant found in the skin

of cocoa fruit.

4 CONCLUSION

The results showed that liquid smoke with low

moisture content of raw materials and high pyrolysis

temperatures produced high antioxidant activity

values. IC50 value of liquid smoke of cocoa pods

ranged from 107.33 - 268.97 ppm and AAI values

ranged from 0.186 to 0.466. Treatment of 10% water

content and pyrolysis temperature of 400OC is the

best treatment.

ACKNOWLEDGEMENT

We would like to thank the Director General of

strengthening research and development of the

Ministry of Research, Technology and higher

education for the funding provided pursuant to

Decree No. 7/E/KPT/2019 dated 19 February 2019

concerning Recipient of research in higher education

in 2019. Chairman LL Dikti Region X According to

contract research year 2019 budget number

012/K10/KM/Contract-Research-J/2019 dated 28

March 2019. Mr. Rector of the University of

Ekasakti, chairman of LPPM based on a research

contract with LPPM number 005/LPPM-

UNES/contract-Study-J/2019. Dean of the

agricultural Faculty of Ekasakti University, and the

team that helped the research.

REFERENCES

Badarinath, A. V. et al. (2010) ‘A review on In-vitro

antioxidant methods: Comparisions, correlations and

considerations’, International Journal of PharmTech

Research, 2(2), pp. 1276–1285.

Budaraga, I. K. et al. (2016) ‘Liquid Smoke Production

Quality from Raw Materials Variation and Different

Pyrolysis Temperature’, International Journal on

Advanced Science Engineering Information

Technology, 6(3), pp. 306–315.

Burhanuddin (2004) ‘Upaya diversifikasi manfaat limbah

buah kakao sebagai komponen aktif pasta gigi’, pp. 59–

67.

Chen, H. (2014) Biotechnology of Lignocellulose: Theory

and Practice. Springer Netherlands (SpringerLink :

Bücher). Available at: https://books.google.co.id/

books?id=0tcsBAAAQBAJ.

Fapohunda, S. and Afolayan, A. (2012) ‘Fermentation of

Cocoa Beans and Antimicrobial Potentials of the pod

Husk Phytochemicals’, Journal of Physiology and

Pharmacology Advances.

Faustino, H. et al. (2010) ‘Antioxidant activity of lignin

phenolic compounds extracted from kraft and sulphite

black liquors’, Molecules, 15, pp. 9308–9322. doi:

10.3390/molecules15129308.

Harsini, T. and Susilowati (2010) ‘Pemanfaatan kulit buah

kakao dari limbah perkebunan kakao sebagai bahan

baku pulp denga proses organosolv’, Jurnal Ilmiah

Teknik Lingkungan, 2(2), pp. 80–89.

Jusmiati, A., Rusli, R. and Rijai, L. (2016) ‘Aktivitas

antioksidan kulit buah kakao masak dan kulit buah kako

muda’, Jurnal Sains dan Kesehatan, 1(2), pp. 34–39.

doi: 10.25026/jsk.v1i1.7.

Kondo, S. A., Gunawan, W. and Rizke, C. (2017)

‘Pengaruh pemberian asap cair pada berbagai

konsentrasi terhadap pertumbuhan streptococcus

sanguis penyebab gingivitis’, JKD, 6(1), pp. 106–113.

Loppies, J. E. and Yumas, M. (2014) ‘Ekstraksi Komponen

Aktif Kulit Buah Kakao dan Pemanfaatannya Sebagai

Bahan Pengawet Alami Pada Produk Makanan’, Jurnal

Industri Hasil Perkebunan, 9(1), pp. 59–68.

Mulyatni, A. S., Budiani, A. and Taniwiryono, D. (2012)

‘Aktivitas antibakteri ekstrak kulit buah kakao (

Theobroma cacao L .) terhadap Escherichia coli ,

Bacillus subtilis , dan Staphylococcus aureus’, Menara

Perkebunan, 80(2), pp. 77–84.

Prakash, A., Rigelhof, F. and Miller, E. (2001) ‘Antioxidant

Activity’, Medallion Laboratories Analitycal Progress,

19(2), pp. 46–55.

Scherer, R. and Godoy, H. T. (2009) ‘Antioxidant activity

index (AAI) by the 2,2-diphenyl-1-picrylhydrazyl

method’, Food Chemistry, 112(3), pp. 654–658. doi:

10.1016/j.foodchem.2008.06.026.

Sumpono, Putri, H. D. and Sari, L. R. (2017) ‘Uji Aktivitas

Antibakterial dan Antioksidan Asap cair Cangkang

Buah Karet (Hevea brassiliensis) serta

Implementasinya Sebagai Pengawet dan Penghambat

Ketengikan Daging’, Prosiding Seminar Nasional

Kimia UNY, pp. 215–228.

Tristantini, D. et al. (2016) ‘Pengujian Aktivitas

Antioksidan Menggunakan Metode DPPH pada Daun

Tanjung (Mimusops elengi L)’, Prosiding Seminar

Nasional Teknik Kimia Kejuangan, pp. 1–7.

Wijaya, M. M., Wiharto, M. and Anwar, M. (2017)

‘Kandungan kimia asap cair kulit kakao dengan metode

GC-MS’, Jurnal Kimia dan Pendidikan Kimia, 2(3), pp.

191–197. doi: 10.20961/jkpk.v2i3.11974.

2nd SIS 2019 - SEAFAST International Seminar

66