Physicochemical Characterization of Crude Palm Oil (CPO) in

Sumatra and Non Sumatra Region

Azis Boing Sitanggang

1,2

,

Febrian Isharyadi

1

, Didah Nur Faridah

1,2

and Nuri Andarwulan

1,2

1

Department of Food Science and Technology, IPB University, Indonesia

2

Southeast Asian Food Science and Agricultural Science and Technology (SEAFAST) Center, IPB University, Indonesia

Keywords: CPO, Contaminants, Diacylglycerol, Physicochemical Characterization.

Abstract: Crude palm oil (CPO) is a strategic commodity for Indonesia. The locations of palm oil plantation and mill

in Indonesia are almost spread evenly in almost all regions of Indonesia. This condition leads to variations in

CPO processing which may yield in varied physicochemical characteristics of CPO. Physicochemical

characteristics of CPO will determine the final quality of CPO for trade. This study was aimed to investigate

the physicochemical characterizations of CPO (i.e., acylglycerol fraction, free fatty acid, moisture content,

deterioration of bleachability index (DOBI), and total carotene) especially those produced in Sumatra and non

Sumatra region (Kalimantan and Sulawesi). These locations were selected based on the productivity value of

CPO. The results showed that physicochemical characteristics of CPO in Sumatra and non Sumatra were very

varied in terms of those parameters. Most of the free fatty acid, moisture content, DOBI, and total carotene

from those regions met the requirements of national and international standards. However, the

physicochemical characteristics of CPO were not found to be fulfilled by all the observed CPOs, so that the

preparation guidelines for production systems and management of CPO processing was needed. Furthermore,

diacylglycerol levels as part of acylglycerol fractions were considerably high with an average of 6.73% (3.18

– 13.64%). A higher portion of diacylglycerol in CPO must be mitigated as this compound is the precursor of

a processing contaminants, such as 3-MCPDE and GE. These compounds have the potential to cause cancer.

Therefore, it requires further mitigation regarding the potential formation of 3-MCPDE and GE in crude palm

oil.

1 INTRODUCTION

Utilization of crude palm oil (CPO) is currently very

broad, including as raw material for the production of

various types of food and non-food products

(Ayustaningwarno 2012). The need of CPO in this

world increasing every year (Abdullah 2011) and

Indonesia is one of the largest CPO producer

countries in the world (Nasution et al. 2015) with

production value in 2017 reaching 34.47 million tons

produced in almost all regions of Indonesia,

especially in The regions of Sumatra, Kalimantan and

Sulawesi are the largest CPO production areas (BPS

2018). The exports of Indonesia's CPO is quite high,

in 2017 reaching 29.07 million tons (84.33% of total

production). Asian and European are the biggest

export destinations (BPS 2018). This shows that CPO

is one of the strategic trading commodities for

Indonesia besides oil and gas (Widyaningtyas and

Widodo 2016).

However, Indonesia's CPO exports still have

obstacles, especially to European countries, several

factors including environmental issues and

contaminants in palm oil (GAPKI 2017). Today

concern of contaminants in palm oil are 3-

monochloropropane-1,2-diol ester (3-MCPDE) and

glycidyl ester (GE) (Lanovia et al. 2014). 3-MCPDE

and GE compounds are potential carcinogenic

contaminants (Habermeyer et al. 2011). Matthäus and

Pudel (2013) reported that Indonesian palm oil

contains 3-MCPD and GE (calculated as free 3-

MCPD) between 8 - 10 mg/kg. This value is quite

high because European countries have set a tolerable

daily intake limit (TDI) of 3-MCPD is 2 µg/kg body

weight/day (Freudenstein et al. 2013). In regulation in

Europe, the maximum limit of GE content in palm oil

for consumption is set at 1,000 µg/kg and as raw

material for formula milk and baby food is 500 µg/kg

(EC 2018).

Sitanggang, A., Isharyadi, F., Faridah, D. and Andarwulan, N.

Physicochemical Characterization of Crude Palm Oil (CPO) in Sumatra and Non Sumatra Region.

DOI: 10.5220/0009978000002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 43-48

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

43

Several studies have shown that 3-MCPDE and

GE are produced in the oil refining process,

specifically in the deodorization process (Craft et al.

2012). The formation of 3-MCPDE and GE is also

supported by the precursors contained in CPO namely

monoacylglycerol (MAG) and diacylglycerol (DAG)

(Chai et al. 2018) as a result of hydrolysis of

triacylglycerol (TAG) (Ab Kadir et al. 2017) in palm

oil. However DAG has more potential to produce 3-

MCPDE and GE than MAG (Šmidrkal et al. 2016).

Handling of palm fruit is one of the crucial factors

triggering the formation of DAG. Differences in the

source of oil palm plantations and the production

process of each palm oil mill (PKS) will result in

different physicochemical characteristics in CPO

(Matthäus and Pudel 2014). Based on that

information this study aimed to identification

physicochemical characterization of CPO was carried

out in Sumatra, Kalimantan, and Sulawesi as the

largest CPO production area in Indonesia on several

characteristics including the acylglycerol fraction to

determine the DAG content in CPO which has the

potential to form 3-MCPDE and GE compounds. In

addition, the physicochemical characteristics of CPO

were made as a requirement in trade including

moisture content, free fatty acid (FFA) (Šmidrkal et

al. 2016), deterioration of bleachability index

(DOBI), total carotene (Sim et al. 2018; Zulkurnain et

al. 2012), and density (Wulandari et al. 2011).

2 MATERIALS AND METHODS

2.1 Materials

This study was conducted at the Seafast Center

Chemical Laboratory, IPB and palm oil mill (POM)

in Sumatra, Kalimantan and Sulawesi. The materials

used in this study were 62 CPO samples from 19

POM in Sumatra region, and 11 POM in non Sumatra

region including 10 POM in Kalimantan, and 1 POM

in Sulawesi.

Materials for analysis include distilled water,

NaOH 0.25 N, indicator phenolphthalein 1%, alcohol

95% (Mallinckrodt), hexane (Merck),

tetrahydrofuran (Merck), N-methyl-N-trimethylsilyl-

trifluoroacetamide (Sigma), heptane (Merck).

The apparatus for analysis include 250 mL high

density polyethylene (HDPE) plastic bottle, 50 mL

amber bottle, beaker glass, erlenmeyer, burette, hot

plate, analytical balance, oven (Memmert),

desiccator, porcelain crucible, waterbath (NAPCO

model 220 A), 25 mL volumetric flask, UV-Vis

spectrophotometer (Shimadzu), vial tube, vortex,

micropipet, gas chromatography instrument with

flame ionization detector (GC-FID) (Agilent 7820A).

2.2 Sampling and Sample Preparation

Sampling of CPO was carried out in Sumatra

(Nangroe Aceh Darussalam, North Sumatra, West

Sumatra, Jambi, South Sumatra, Bengkulu, Riau,

Lampung and Bangka Belitung), Kalimantan (West

Kalimantan, East Kalimantan, Central Kalimantan

and South Kalimantan), and Sulawesi (West

Sulawesi).

The number and location of POM being the target

of CPO sampling is determined by stratified

purposive sampling by taking into value of total

production, number of POM, location, and

availability of access to take samples at the POM.

Samples were taken in 2 different storage tanks in one

POM. Samples were taken randomly from the top,

middle and bottom of each storage tank and then

homogenized in a container. At each storage tank ±

500 mL sample was taken which was divided into 2

containers (as replications) and then taken to the

laboratory.

When arrived at the laboratory, the sample was

poured into a glass cup and then heated to a

temperature of ± 50

0

C and homogenized. After the

sample is homogeneous and a temperature of 50

0

C is

reached, the sample is put into a 50 mL amber bottle.

Before storing, nitrogen gas is blown on the

headspace for 1 minute. Samples are stored at 4

0

C.

2.3 Analysis of Moisture Content, Free

Fatty Acid, Total Carotene,

Density, and Acylgliserol Fraction

CPO samples that have been obtained are then

analyzed by physicochemical characterization,

namely moisture content with SNI 01-2901-2006 test

method, free fatty acid levels (FFA) with official Ca

5a-40 2009 AOCS test method, deterioration of

bleachability index (DOBI) with MPOB test method

(2004), total carotene with MPOB test method

(2004), and acylglyserol fraction using AOCS official

test method modification Cd 11b-91 2017.

3 RESULTS AND DISCUSSION

The physicochemical characteristics of CPO

including FFA, moisture content, DOBI, total

carotene, and the fraction of acylgliserol

(diacylglycerol (DAG) and triacylglycerol (TAG)) in

2nd SIS 2019 - SEAFAST International Seminar

44

the regions of Sumatra, and non Sumatra is vary

greatly. Some of physicochemical characterization

CPO have fullfiled of standard specification that

applies nationally and internationally, namely the

Indonesian National Standard (SNI), Malaysian

standard, and Codex (BSN 2006; Malaysian Standard

2007; Codex 2017). The standard is used as a control

of CPO production.

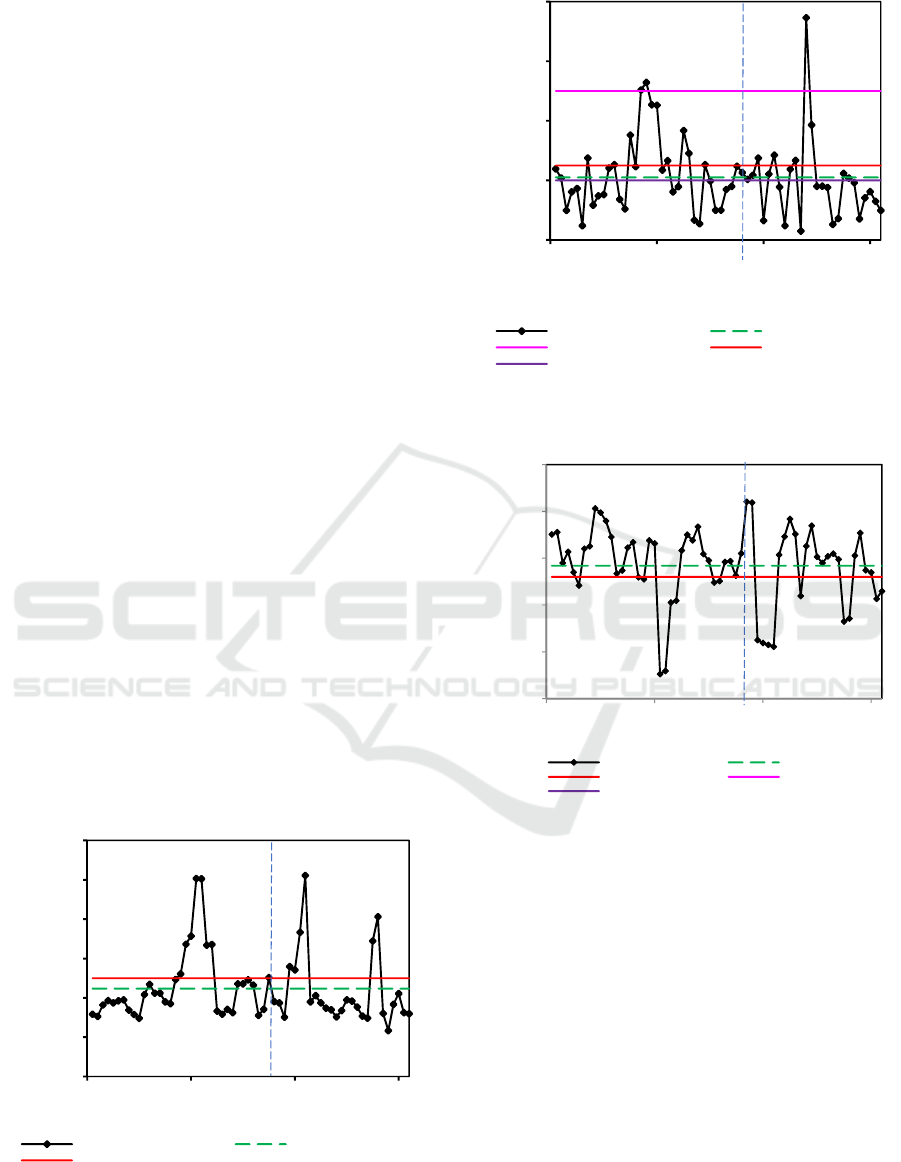

The physicochemical characterization of FFA,

moisture content, and DOBI are mostly below (FFA

and moisture content) and above (DOBI) of the

standards specifications (Figures 1, 2, and 3).

However, some CPOs have values that are outside the

specifications. High FFA indicates a decrease in

quality due to the hydrolysis of triglycerides in CPO

(Matthäus and Pudel 2013). This is due to the

condition of oil palm fruit that is not fresh and the

waiting time for oil palm fruit to be processed too

long (Hudori 2017). These conditions can be

controlled through good handling of oil palm fruit.

The high moisture content in CPO will also accelerate

the hydrolysis reaction (Ab Kadir et al. 2017). DOBI

values in CPO indicate an increase in secondary

oxidation product content. This is caused by several

factors in the processing of oil palm fruit, such as the

level of fruit maturity, the time and condition of the

processing, distribution process, and storage and

contamination that occurs in CPO (Hasibuan 2016).

The results showed that relatively much CPO

contained carotenoids under standard specifications

(Figure 4). The influencing factors are varieties and

fruit maturity level (Syahputra et al. 2008) as well as

the processing, due to excessive temperature, light,

pressure, and time which will cause the carotene

content in CPO to decrease (Hasibuan and Harjanto

2009).

Figure 1: Free fatty acid levels of CPO in Sumatra and non

Sumatra region.

Figure 2: Moisture content of CPO in Sumatra and non

Sumatra region.

Figure 3: DOBI of CPO in Sumatra and non Sumatra

region.

0.00

2.00

4.00

6.00

8.00

10.00

12.00

0 204060

Free fatty acid (FFA) (%)

Number of sample

FFA levels Average FFA levels

SNI dan Malaysia Standard

Sumatra

0.00

0.20

0.40

0.60

0.80

0 204060

Moisture content (%)

Number of sample

Moisture content Average moisture content

SNI Malaysia standard

Codex

Sumatra

1.00

1.50

2.00

2.50

3.00

3.50

0 204060

DOBI (-)

Number of sample

DOBI Average DOBI

Malaysia standard SNI

Codex

Sumatra

Non Sumatra

Non Sumatra

Non Sumatra

Physicochemical Characterization of Crude Palm Oil (CPO) in Sumatra and Non Sumatra Region

45

Figure 4: Total carotene of CPO in Sumatra and non

Sumatra region.

DAG fraction is a precursor that has the potential

to form 3-MCPDE and GE compounds (Šmidrkal et

al. 2016) during the process of refining palm oil,

especially the deodorization process, where the

process undergoes a heating process at a temperature

of 240

0

C for 2 hours (Matthäus et al. 2011).

According to Rahn and Yaylayan (2011) the

formation of 3-MCPDE is produced through the

reaction of chloride ions in lipid through the

formation of acyloxonium ions. Based on the research

results, the average DAG content in CPO in Sumatra,

and non Sumatra region is 6.73% (3.18 - 13.64 %)

(Figure 5). These results are relatively high,

according to Greyt (2012) if the DAG content in palm

Figure 5: Diacylglycerol content of CPO in Sumatra and

non Sumatra region.

oil is more than 4%, then the 3-MCPDE content in the

oil is greater than 5 ppm. A high enough DAG

component in CPO has the potential to form 3-

MCPDE contaminants in the presence of chloride

ions supported under suitable conditions. Franke et al.

(2009) have reported that chloride ion levels in CPO

are below 1 mg/kg and total chlorine is 2 mg/kg.

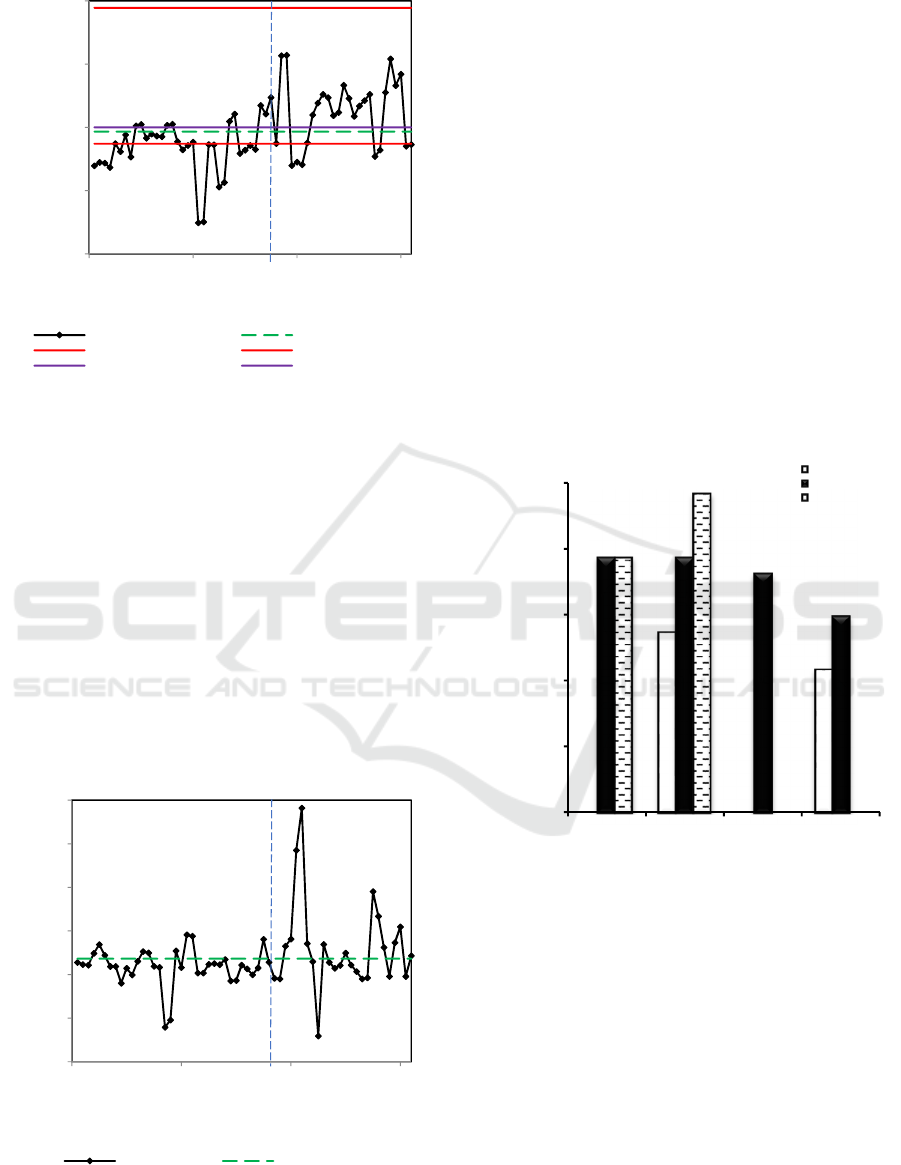

The conformity of the physicochemical

characterization of CPO (FFA, moisture content,

DOBI, and total carotene) in Sumatra and non

Sumatra region to SNI, Malaysia Standard, and

Codex standards is quite good (Figure 6). However,

the physicochemical characteristics of CPO were not

found to be fulfilled by all the observed CPOs, several

things need attention including some critical points in

the process of CPO processing such as the selection

and handling of oil palm which will result in a

decrease in the quality of CPO. Therefore preparation

of guidelines for production systems and

management of CPO processing was needed.

Figure 6: The conformity of the physicochemical

characterization of CPO in Sumatra and non Sumatra region

against several standards (SNI, Malaysia Standard, and

Codex).

Based on the ANOVA test, physicochemical

characterization CPO produced in Sumatra and non

Sumatra did not have significant differences in FFA

values, moisture content and DOBI, but there were

significant in total carotene and DAG content (Table

1). So that CPO originating from Sumatra and non

Sumatra tends to have different physicochemical

characteristics. Characteristics of land conditions,

soil physicochemistry, and climate are important

factors in palm oil production (Hasriyanti et al. 2017).

In addition, the CPO production process will also

300.00

400.00

500.00

600.00

700.00

0 204060

Total carotene (mg/Kg)

Number of sample

Total carotene Average total carotene

Malaysia standard (min) Malaysia standard (max)

Codex (min) Codex (max)

Sumatra

Non Sumatra

2.00

4.00

6.00

8.00

10.00

12.00

14.00

0 204060

Diacyglycerol (%)

Number of sample

Diacylglycerol Average diacylglycerol

Sumatra

Non Sumatra

54.84%

43.55%

77.42%

77.42%

72.58%

59.68%

77.42%

96.77%

0%

20%

40%

60%

80%

100%

FFA Moisture

content

DOBI Total

carotene

Conformity with standard

Codex

Malaysia Standard

SNI

2nd SIS 2019 - SEAFAST International Seminar

46

affect variations in the physicochemical

characteristics of CPO.

Table 1: Variation of physicochemical characterization

CPO in Sumatra and non Sumatra region.

Physicochemical

characterization CPO

Region

Sumatra Non Sumatra

Free fatty acid (%) 4.51 ± 1.72

a

4.40 ± 1.92

a

Moisture content (%) 0.22 ± 0.12

a

0.19 ± 0.15

a

DOBI (-) 2.50 ± 0.39

a

2.30 ± 0.43

a

Total carotene (mg/kg) 477.64 ± 52.61

a

518.09 ± 48.57

b

Diacylgliserol (%) 6.36 ± 0.83

a

7.31 ± 2.07

b

Note : (a,b) different letters above the value of physicochemical

characterization in each region showed significant difference (p <

0.05)

4 CONCLUSION

The physicochemical characterization of CPO in

Sumatra and non Sumatra region varies greatly in all

physicochemical characteristics studied (FFA,

moisture content, DOBI, total carotene, and

diacylglycerol) but for some physicochemical

characteristics some regions did not differ

significantly. Some of physicochemical

characteristics of CPO in Sumatra and non Sumatra

have met the requirements of SNI, Malaysia

standards, and Codex for FFA parameters, moisture

content, total carotene, DOBI, and density. However,

the physicochemical characteristics of CPO were not

found to be fulfilled by all the observed CPOs. The

DAG content of CPO in Sumatra, Kalimantan and

Sulawesi is relatively high so that further mitigation

is needed regarding the cause so that the potential

formation of 3-MCPDE and GE in the next process

can be minimized. The results of this study are

expected to be followed up as recommendations for

the authorities in the preparation of CPO production

management and management system guidelines in

order to obtain quality and competitive CPO. In

addition it is necessary to further mitigate the causes

of high DAG content and its potential in the formation

of 3-MCPDE and GE in the next process.

ACKNOWLEDGEMENT

The authors thanks to Palm Plantation Fund

Management Agency (BPDP), and the Southeast

Asian Food and Agricultural Science and Technology

(SEAFAST) Center of IPB for their support in this

research activity.

REFERENCES

Ab Kadir IA, Jurid LS, Zubairi SI. 2017. Physico-Chemical

properties of recycled refined, bleached and deodorized

(RBDPO) palm olein: Which cycle should the olein

considered spoilage?. J. Teknol. 79(4) :17-25.

Abdullah R. 2011. World palm oil supply, demand, price,

and prospects : focus on Malaysian and Indonesian

palm oil industries. Oil Palm Industry Economic

Journal. 11(2) :13-25.

[AOCS] American Oil Chemists Society. 2017. Official

Methods and Recommended Practices of the AOCS. Ed

ke-5. Champaign, Illinois (US): AOCS Press.

Ayustaningwarno F. 2012. Proses pengolahan dan aplikasi

minyak sawit merah pada industri

pangan. Vitasphere. 2(1) :1-11.

[BPS] Badan Pusat Statistik. 2018. Statistik kelapa sawit

Indonesia 2017. Jakarta (ID) : BPS.

[BSN] Badan Standardisasi Nasional. 2006. SNI 01-2901-

2006 tentang Minyak kelapa sawit mentah (crude palm

oil). Jakarta (ID) : BSN.

Chai Q, Hayat K, Karangwa E, Duhoranimana E, Zhang X,

Xia S, Yu J. 2018. Investigating the optimum

conditions for minimized 3-chloropropane-1, 2-diol

esters content and improved sensory attributes during

savory beef flavor preparation. Food chem. 243 : 96-

102.

[Codex] Codex Allimentarius. 2017. CODEX STAN 210-

1999 : Codex standard for named vegetable oils. Roma

(IT) : CODEX.

Craft BD, Nagy K, Sandoz L, Destaillats F. 2012. Factors

impacting the formation of monochloropropanediol

(MCPD) fatty acid diesters during palm (Elaeis

guineensis) oil production. Food Addit. Contam. Part

A. 29(3) : 354-361.

[EC] European Commission. 2018. Commission

Regulation (EUO) 2018/290 amending Regulation

(EC) No 1881/2006 of 26 February 2018 as regards

maximum levels of glycidyl fatty acid esters in

vegetable oils and fats, infant formula, follow-on

formula and foods for special medical purposes

intended for infants and young children. Brussels

(BEL) : EC.

Franke K, Strijowski U, Fleck G, Pudel F. 2009. Influence

of chemical refining process and oil type on bound 3-

chloro-1,2-propanediol contents in palm oil and

rapeseed oil. Food Sci. Tech. 42 :1751–1754.

Freudenstein A, Weking J, Matthäus B. 2013. Influence of

precursors on the formation of 3MCPD and glycidyl

esters in a model oil under simulated deodorization

conditions. Eur. J. of Lipid Sci. and Technol. 115(3) :

286-294.

[GAPKI] Gabungan Pengusaha Kelapa Sawit Indonesia.

2017. Refleksi Industri Kelapa Sawit 2016 dan Prospek

Physicochemical Characterization of Crude Palm Oil (CPO) in Sumatra and Non Sumatra Region

47

2017. [Internet]. Jakarta (IDN) : GAPKI. [diakses pada

tanggal 6 Juni 2019]. Tersedia pada

https://gapki.id/news/1848/refleksi-industri-kelapa-

sawit-2016-prospek-2017

Greyt WD. 2012. Review on 3-MCPD and glycidyl esters

in vegetable oils and fats. [internet]. Zaventem (BE) :

AOCS. [diakses pada tanggal 12 Juni 2018]. Tersedia

pada http://aocs.files.cms-

plus.com/ResourcesPDF/MCPD-GE-mitigation-

AOCS-2012(DGW)-final.pdf.

Habermeyer M, Guth S, Eisenbrand G. 2011. Identification

of gaps in knowledge concerning toxicology of 3-

MCPD and glycidol esters. Eur. J. of Lipid Sci. and

Technol. 113(3) : 314-318.

Hadi S, Perdana M. 2018. Pengaruh bahan komposit ramah

lingkungan terhadap sifat fisik dan sifat termal

komposit alam. JTM-ITP. 8 (1) : 33-38.

Hasibuan HA, Harjanto S. 2009. Kajian lanjutan kandungan

karoten pada crude palm oil Indonesia. Jurnal

Standardisasi. 11(3) : 220-225.

Hasibuan HA. 2016. Deterioration of bleachability index

pada crude palm oil: bahan review dan usulan untuk

SNI 01-2901-2006. Jurnal Standardisasi. 18(1) :25-34.

Hasriyanti H, Abbas I, Leo MNZ. 2017. Aplikasi peta jenis

tanah dalam mengidentifikasi lahan berpotensi untuk

perkebunan kelapa sawit di Kecamatan Cendana

Kabupaten Enrekang. Jurnal Pendidikan

Geografi. 21(1) :12-21.

Hudori M. 2017. Dampak kerugian dan usulan pemecahan

masalah kualitas crude palm oil (CPO) di pabrik kelapa

sawit. IEJ. 5(1) :35-40.

[ISO] International Organization of Standardization. 2017.

ISO 6883:2017 - Animal and vegetable fats and oils -

Determination of conventional mass per volume (litre

weight in air). Geneva (CH) : ISO.

Lanovia T, Andarwulan N, Hariyadi P. 2014. Validasi

Modifikasi Metode Weiẞhaar untuk Analisis 3-MCPD

Ester dalam Minyak Goreng Sawit. J.Teknol. dan

Industri Pangan. 25(2) : 200-208.

Matthäus B, Pudel F, Fehling P, Vosmann K, Freudenstein

A. 2011. Strategies for the reduction of 3-MCPD esters

and related compounds in vegetable oils. Eur. J. Lipid

Sci. Technol. 113 :380-386.

Matthäus B, Pudel F. 2013. Mitigation of 3MCPD and

glycidyl esters within the production chain of vegetable

oils especially palm oil. Lipid Technol. 25(7) : 151-155.

Matthäus B, Pudel F. 2014. Mitigation of MCPD and

glycidyl esters in edible oils. MacMahon S, editor. Di

dalam Processing Contaminants in Edible Oils. Illionis

(US) : AOCS.

[MPOB] Malaysia Palm Oil Board. 2004. MPOB test

method : a compendium of test on palm oil products,

palm kernel products, fatty acids, food related products

and others. Bandar Baru Bangi (MYS) : MPOB.

Nasution A, Fajri, Sofyan. 2015. Analisa pola produksi

kelapa sawit dan keseimbangannya terhadap pabrik

kelapa sawit di pantai barat Aceh. Agrisep. 16(2) :70–

76.

Rahn AKK, Yaylayan VA. 2011. Monitoring cyclic

acyloxonium ion formation in palmitin systems using

infrared spectroscopy and isotope labelling

technique. Eur. J. of Lipid Sci. and Technol. 113(3) :

330-334.

Sim BI, Muhamad H, Lai OM, Abas F, Yeoh CB, Nehdi

IA, Khor YP, Tan CP. 2018. New Insights on

Degumming and Bleaching Process Parameters on The

Formation of 3-Monochloropropane-1, 2-Diol Esters

and Glycidyl Esters in Refined, Bleached, Deodorized

Palm Oil. J. Oleo Sci. 67(4) : 397-406.

Šmidrkal J, Tesařová M, Hrádková I, Berčíková M,

Adamčíková A, Filip V. 2016. Mechanism of formation

of 3-chloropropan-1, 2-diol (3-MCPD) esters under

conditions of the vegetable oil refining. Food Chem.

211 : 124-129.

[Standards Malaysia] Department of Standards Malaysia.

2007. MS 814 : 2007 tentang palm oil specification

(second revision). Selangor (MY) : Standards Malaysia.

Syahputra MR, Karwur FF, Limantara L. 2008. Analisis

komposisi dan kandungan karotenoid total dan vitamin

A fraksi cair dan padat minyak sawit kasar (CPO)

menggunakan KCKT detektor PDA. Jurnal Natur

Indonesia. 10(2) : 89-97.

Widyaningtyas D, Widodo T. 2016. Analisis pangsa pasar

dan daya saing CPO Indonesia di Uni Eropa. J. Ekon.

Manaj. Sumber Daya. 18 (2) :138–145.

Wulandari N, Muchtadi TR, Budijanto S, Sugiyono. 2011.

Sifat fisik minyak sawit kasar dan korelasinya dengan

atribut mutu. J.Teknol. dan Industri Pangan. 22(2) :

177.

Zulkurnain M, Lai OM, Latip RA, Nehdi IA, Ling TC, Tan

CP. 2012. The effects of physical refining on the

formation of 3-monochloropropane-1, 2-diol esters in

relation to palm oil minor components. Food

Chem. 135(2) : 799-805.

2nd SIS 2019 - SEAFAST International Seminar

48