Effect of Temperature on Rheological Behavior of Liquid Milk and

Its Impact to Adequacy of Thermal Process

Eko Hari Purnomo

1,2

and Ni Putu Arriva Satyani

1

1

Department of Food Science and Technology, IPB University, Kampus IPB Darmaga, Bogor, Indonesia

2

Seafast Center, IPB University, Kampus IPB Darmaga, Bogor, Indonesia

Keywords: Milk Rheology, Temperature, Sterilization.

Abstract: Temperature is one of the factors affecting fluid flow characteristics and the thermal adequacy in milk

sterilization in an aseptic system. This research is aimed to study density and rheology of milk at temperature

of 20-80 0C and its effect to Reynold number and thermal sterility. Four different kinds of commercial milk

were used. The density and rheological properties were measured by using densitometer a Brookfield

Viscometer DV II, respectively. The results showed that the milks were Newtonian. Temperature affected the

density and viscosity of the liquid milk and consequently affected the Reynolds number. Increased

temperatures lead to decreased density and decreased viscosity which could be well described using an

Arrhenius model. Combined effect of increased temperature on decreased density and viscosity resulted in

increased Reynolds numbers. This indicated that Reynolds number is more affected by the value of viscosity

rather than density, as temperature increased. Under a full-scale production set up in one of the milk factories,

the four kinds of liquid milk exhibited turbulent fluid flow properties (Reynolds number more than 4000).

Therefore, decreased viscosity and density of milk at elevated temperature did not adversely affect adequacy

of aseptic thermal process at a constant flow rate.

1 INTRODUCTION

Milk is one of the good sources of protein, vitamin,

fat, and minerals with relatively short shelf life

(Miller 2007). Pasteurization and sterilization are

often used to extend its shelf life. Milk consumption

in Indonesia is relatively low as compared to other

countries. However, the growth of milk consumption

in Indonesia is increasing, which is believed to be

associated with the growing of middle-income

population (15% within 10 years) (USDA 2016). This

market growth drives the milk industry to increase the

production of safe and high-quality milk to be able to

compete in the market.

Sterilization is more favorable to preserve liquid

milk due to its longer shelf life and handling

convenience. Liquid milk is commonly sterilized

using an aseptic system in which the milk is held at a

temperature of around 140

o

C for few seconds in a

holding tube to achieve a minimum sterility level. The

Government of Republic of Indonesia requires that

thermally sterilized food should have F

o

of at least 3.0

minutes to ensure product safety (BPOM, 2016).

Thermal sterilization is determined by two main

factors i.e. time and temperature. Minimum residence

time of the milk in holding tube is strongly affected

by its rheological properties (viscosity (µ), flow

behavior index (n), and consistency index (K)) and

Reynold number (Re). Depending on its Re, flow of

milk in the holding tube can be either laminar

(Re<4000) or turbulent (Re>4000). For milk flowing

in a specific geometry and a constant volume rate, Re

is affected by both milk viscosity and density.

Rheological properties of milk and the effect of

temperature on milk’s rheology is well studied.

McCarty and Singh (2009) reported that milk with fat

content less than 40% (w/w) measured at temperature

above 40

o

C shows Newtonian behavior. Several

researchers studied the effect of temperature on milk

viscosity (Cheng, Barbano, and Drake, 2019 and

Deshpande & Walsh, 2017). Viscosity of milk

decreases as temperature increases. However, no

study has shown the effect of temperature on milk

viscosity and milk density. Therefore, it is important

to study the effect of temperature on milk viscosity

and density to be able to predict its effect on the

Reynold number and finally assess its possible effect

to the adequacy of a thermal process in a holding tube

during sterilization process.

38

Purnomo, E. and Satyani, N.

Effect of Temperature on Rheological Behavior of Liquid Milk and Its Impact to Adequacy of Thermal Process.

DOI: 10.5220/0009977900002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 38-42

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIAL AND METHOD

2.1 Material

Four types of UHT milk i.e. full cream, chocolate

milk 1, chocolate milk 2, and strawberry milk were

used in this study. The equipment used were density

meter Anton Paar DMA 35 and Brookfield

Viscometer RVDV-II Pro, water bath, and hotplate.

2.2 Method

2.2.1 Density Measurement

Milk density was measured using portable

densitometer Anton Paar model DMA 35. Milk

density at different temperatures (20, 30, 40, 50, 60,

70, dan 80

o

C) were measured.

2.2.2 Characterization of Rheological

Properties

Shear stress of the sample was measured using

Brookfield viscometer RVDV-II Pro at different

spindle speed i.e. 0.5, 1.0, 2.0, 2.5, 4.0, 5.0, 10.0,

20.0, 50.0, dan 100.0 rpm. Shear rate was calculated

from the spindle speed using the following formula:

=

2

(1)

where γ

w

is shear rate (s-1), R is radius of the

spindle (cm), N is rotational speed of the spindle

(RPM), δ is gap between spindle and container wall

(cm).

2.2.3 Thermal Process Adequacy Analysis

Thermal process adequacy expressed as F

o

value is

calculated using the following formula

=

t

min

10

121.1-T

ho

z

(2)

Where

t

min

=

L

V

maks

(3)

L is minimum length of holding tube, V

max

is

speed of fastest moving particles, T

ho

is product

temperature at the outlet of holding tube, z value is

10oC, and t

min

is minimum residence time of milk in

the holding tube. Vmax is obtained from average

velocity and their relation depends on Re. For a

Newtonian liquid, Re can be calculated using the

following formula:

Re =

ρDV

µ

(4)

Where r is density (kg/m

3

), D is diameter of the

holding tube (m), V is average speed of milk flowing

in holding tube (m/s), and m is viscosity (Pa.s).

3 RESULT AND DISCUSSION

3.1 Milk Density

Density of milk is the intrinsic physical parameter of

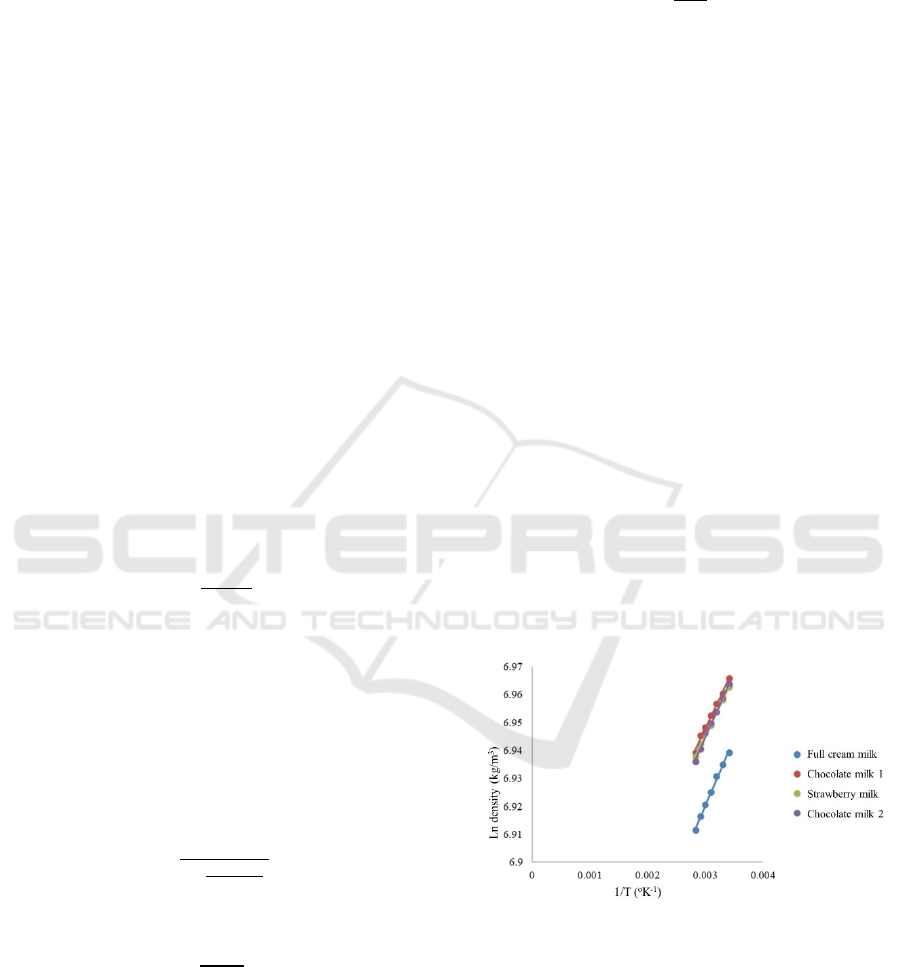

milk contributing to flow properties. Figure 1 shows

that effect of temperature on density of different milk.

Milk density decreased as function of time. At a

temperature of 20

o

C, milk density ranges from 1.0319

to 1.0596 g/ml. whereas at a temperature of 80

o

C, the

density ranged between 1.0037 g/ml and 1.0335 g/mL

Similar observation was reported by Minim,

Coimbra, and Minim (2002) and Munir et. al. (2016).

Kumbar, and Nedomova (2015) stated that density of

fresh and UHT milk at different fat contents (0.5, 1.5

dan 3.0 %) decreases at higher temperatures.

Moreover, density of full cream milk was markedly

lower compared to chocolate and strawberry milk. It

was believed to be associated with higher fat content

of full cream milk (McCarthy and Singh (2009),

Munir et. al. (2016) and Alcantara et. al. (2012)).

Figure 1: Effect of temperature on milk density. The lines

represent corresponding Arrhenius model of each sample.

The dependence of milk density to temperature was

well described using Arrhenius model in which natural

logarithmic of density is plotted against 1/T (

o

K). Table

1 shows the Arrhenius model of the four samples

including their activation energy. Full cream milk

exhibited higher activation energy compared to the

three other milks. It indicated that density of full cream

milk was more sensitive to temperature change.

Effect of Temperature on Rheological Behavior of Liquid Milk and Its Impact to Adequacy of Thermal Process

39

Table 1: Arrhenius model and activation energy for density

of four different milks.

3.2 Milk Rheology

Rheological properties of milk determine flow

characteristic of the milk flowing in holding tube

during sterilization process. One of the important

rheological parameters of milk is its viscosity. Under a

specific sterilization system, milk with higher viscosity

flows at lower velocity. For a non-Newtonian fluid,

viscosity can be strongly influenced by shear rate. The

milks used in this study showed Newtonian behavior

in which its viscosity was not influenced by shear rate.

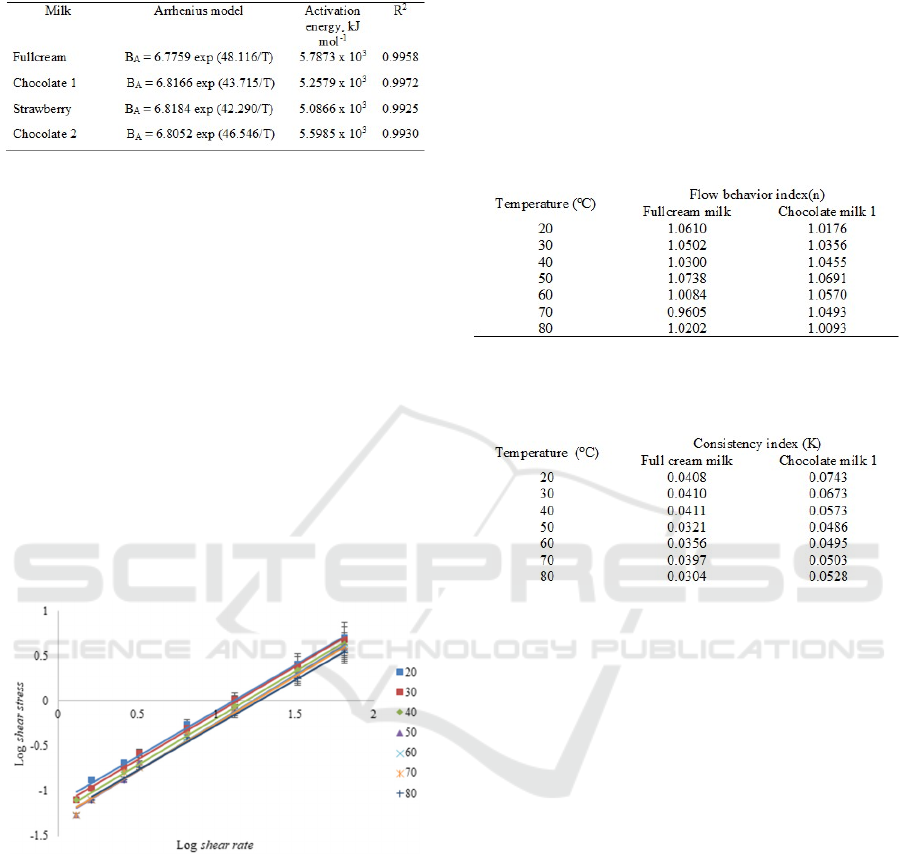

Figure 2 shows flow curves of the chocolate milk

1 measured at different temperatures. Shear stress

increased as function of shear rate. At a constant shear

rate, higher shear stress was observed for milk

measured at lower temperature. Relation between

shear rate (g) and shear stress (t) of the milk was well

explained using Power Law model (t=Kg

n

).

Figure 2: Flow curve of chocolate milk 1 at different

temperatures. The lines represent corresponding power law

model of each sample.

Two rheological parameters extracted from power

law model were flow behavior index (n) and

consistency index (K). Table 2 shows that flow

behavior index of milks was close to 1. It means that

the milks were Newtonian at temperature range of 20-

80

o

C (Toledo, 2012). Similar observation for milk

measured at 25, 35, 45, 55 dan 65

o

C (Roozi et. al.

(2007)), milk containing fat content less than 40%

(McCarthy and Singh, 2011), milk containing soluble

solid less than 20% (Morison, Phelan and Bloore,

2013). Rao (2007) stated that fluid containing low

molecular weight substances exhibited Newtonian

behavior (linear relation between shear stress and

shear rate). In addition, Table 3 shows the effect of

temperature on the consistency index (K) of milks.

Consistency index of full cream milk was lower than

chocolate milk 1. Index consistency of milks

decreased as function of temperatures.

Table 2: Flow behavior index (n) of full cream milk and

chocolate milk 1 measured at different temperatures.

Table 3: Consistency index (K) of full cream milk and

chocolate milk 1 measured at different temperatures.

Since the milks exhibited Newtonian behavior, its

viscosity was independent of shear rate. Figure 3

shows viscosity of the milks measured at temperature

of 20-80

o

C. Viscosity of the milks decreased as

temperature increased. Similar trends were also found

in other reports (Flauzino et. al., 2009, Bozikova and

Hlavac, 2013, and Kumbar and Nedomova, 2015).

The Arrhenius model used to describe the

temperature dependence of viscosity on temperature

fitted well to the experimental data. Fitting

parameters including the activation energy of the

Arrhenius model for temperature dependence of

viscosity is presented in Table 4. Activation energy

of chocolate milk 2 was the highest indicating that

viscosity of chocolate milk 2 was the most sensitive

to temperature change (Cuah et. al., 2008). Goat milk

was reported to have lower activation energy of

6.2736 kJ mol

-1

(Gabas et. al., 2012). Whereas Velez

Ruiz (1998) reported that activation energy of milk

concentrated ranged between 2.42 and 11.8 kcal g

mol

-1

. Activation energy of milk cream, fermented

milk, and whey protein were reported to be higher.

Activation energy of milk cream, fermented milk, and

whey protein were 20.5 kJ mol

-1

(Flauzino et. al.,

2009), 19.57 kJ mol

-1

(Goncalves et. al., 2017), and

19.92 kJ mol

-1

(Tello et. al., 2009), respectively.

2nd SIS 2019 - SEAFAST International Seminar

40

Figure 3: Effect of temperature on viscosity of different

milks measured at different temperatures. The lines

represent corresponding Arrhenius model of each sample.

Table 4: Arrhenius model and activation energy for

viscosity of four different milks.

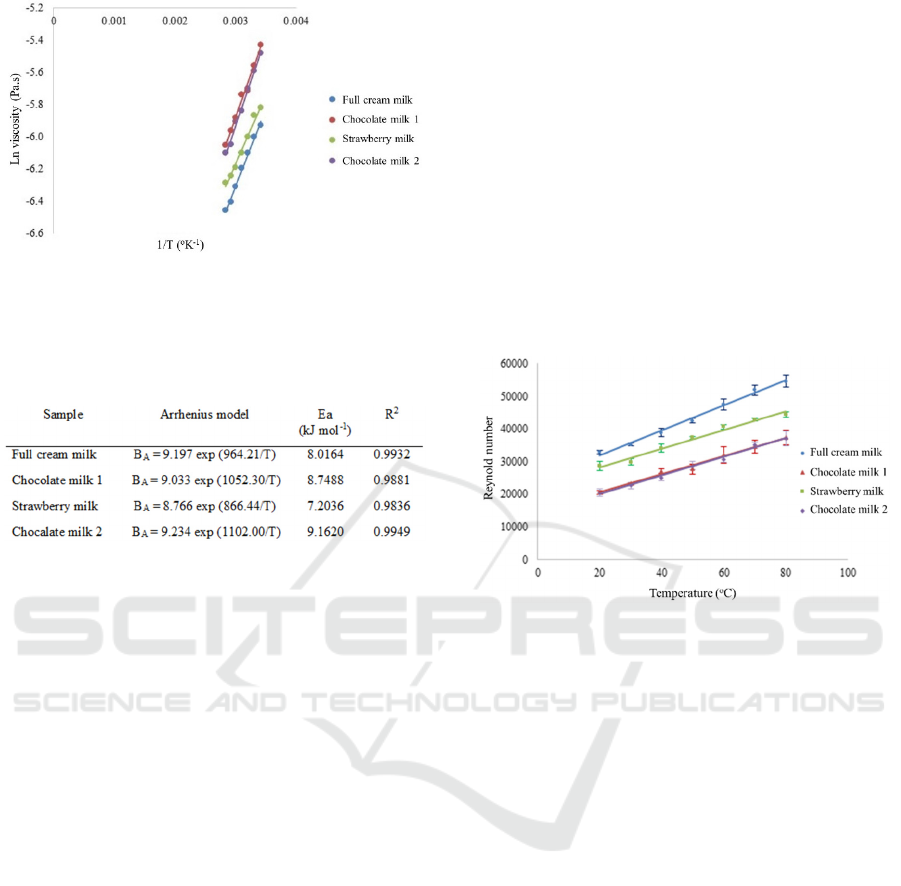

3.3 Reynold Number and Thermal

Process Adequacy

Milk is often processed using an aseptic system in

which thermal sterilization is carried out in a holding

tube for few second at temperature of around 140

o

C

(Varzakas & Labropoulos, 2007). Minimum

residence time of the milk in the holding tube is

controlled by fastest moving particles in the milk. It

is almost impossible and impractical to directly

measure velocity of fastest moving particles. Velocity

of fastest moving particle can be quantitively

predicted from its average velocity obtained from

flow rate of the milk. However, the relation between

maximum velocity and average velocity of milk

flowing in a holding tube depends on dimensionless

Reynold number defined as rDV/m. Milk flow is

under turbulent condition if the Reynold number is

higher than 4000. It has been shown that both density

(r) and viscosity (m) of milk decreased as temperature

increased. Combined effect of density and viscosity

of milk, flowing in a commercial holding tube, on

Reynold number as temperature increased is shown in

Figure 4. Reynold number increased as temperature

increased for all the samples.

Increased Reynold number along with increase in

temperature indicated that decreased viscosity had a

more dominant effect than decreased density. This

effect could also be observed from the activation

energy of viscosity change (Table 4) which were

higher than activation energy for density change

(Table 1). The higher the activation energy, the more

sensitive the parameter to temperature change.

Figure 4 shows that Reynold number of the milks

was higher than 4000 which mean that the flow of the

milk was turbulent. For turbulent flow, velocity of

fastest moving particle determining minimum

residence time is 1.23 x average velocity (Steffe,

1996). However, since increased temperature resulted

in higher Reynold number, the flow characteristic of

the milks in the holding tube remained turbulent.

Therefore, the effect of decreased density and

viscosity which resulted in increased Reynold

number did not adversely affect the safety of

sterilized milk.

Figure 4: Effect of temperature in Reynold number of

different milks.

4 CONCLUSIONS

Density and viscosity of milk are two intrinsic

properties of milk which may affect fluid dynamic

inside a holding tube. Density of four commercially

available milk i.e. full cream milk, chocolate milk 1,

strawberry milk, and chocolate milk 2 were lower

when measured at different temperature. The four

different kind of milk showed Newtonian behavior at

different measurement temperatures (20-80

o

C).

Viscosity the milks decreased as function of

temperature. Milk density and viscosity dependence

on temperature were well described using Arrhenius

model. Viscosity is found to be more temperature

dependent than density. Effect of density to Reynold

number was the opposite of viscosity effect to

Reynold number. However, combined effect of

increased temperature on density and viscosity

resulted in higher Reynold number. Therefore, under

a constant flow rate, milk sterilization in a holding

tube at higher temperature did not reduce minimum

residence time and consequently did not reduce

thermal process adequacy.

Effect of Temperature on Rheological Behavior of Liquid Milk and Its Impact to Adequacy of Thermal Process

41

REFERENCES

Alcantara L.A.P, Fontan, R.C.I., Bonomo, R.C.F., de

Souza, E.C., Sampaio, V.S. and Pereira, R.G. 2012.

Density and dynamic viscocity of bovine milk affect by

temperature and composition. International Journal of

Food Engineering. 8(1).

Bozikova M and Hlavac P. 2013. Temperature and storing

time influence on selected physical properties of milk

band acidophilus milk. Acta Univeritatis Agriculturae

et Silviculturae Mendelianae Brunensis. 6:1589-1595.

[BPOM] Badan Pengawas Obat dan Makanan. 2016.

Peraturan kepala badan Pengawas Obat dan makanan

Republik Indonesia Nomor 24 tahun 2016 tentang

Persyaratan Pangan Steril Komersial Jakarta(ID):

BPOM.

Cheng, N., Barbano, D.M., and Drake, M. A., 2019. Effect

of pasteurization and fat, protein, casein to serum

protein ratio, and milk temperature on milk beverage

color and viscosity. Journal of Dairy Science

102:2022–2043.

Cuah T.G, Ling H.L, Chin N.L, Choong T.S.Y, and

Fakhru’l-Razi A. 2008. Effect temperatures on

rheological behaviour of dragon fruit (hylocereus sp).

Journal of Food Engineering 4(7): 1-30.

Deshpande, V.K., and Walsh, M.K., 2017. Effect of

sonication on the viscosity of reconstituted skim milk

powder and milk protein concentrate as influenced by

solids concentration, temperature and sonication. Int

Dairy J. 78: 122-129.

Flauzino R.D.F, Wilhelms J.A, Tadini C.C., and Romero

J.T. 2009. Flow properties and tube friction factor of

milk cream: influence of temperature and fat content.

Journal of Food Processing. 33: 820-836.

Gabas, A. L., Cabral, R.A.F., Oliveira, C.A.F., Romero J.T.

2012. Density and rheological parameters of goat milk.

Cienc. Tecnol. Aliment. 32(2): 381-385.

Goncalves, B.J, Pereira, C.G, Lago, A.M.T, Goncalves,

C.S, Giarola T.M.O, Abreu, L.R dan Resende, J.V.

2017. Thermal conductivity as influenced by the

temperature and apparent viscocity of dairy products.

Journal of Dairy Science 100:1-13.

Kumbar, V and Nedomova S. 2015. Viscocity and

Analytical Dofferences between raw milk and UHT

milk of Czech cows. Scientia Agricultura Bohemica.

46(2): 78-83.

McCarthy, O.J. and Singh, H. 2009. Advanced Dairy

Chemistry: Lactose, Water, Salts and Minor

Constituents Volume 3. New Zealand (NZ): Springer.

McCarthy, O.J. and Singh H. 2011. Rheology of liquid and

semi solid milk product. New Zealand (NZ): Elsevier.

Miller, G.D., Jarvis, J.K., and McBean, L.D. 2007.

Handbook of Dairy Food and Nutrition 3rd edition.

Florida (US): CRC Press.

Minim, L.A., Coimbra, J.S.R, and Minim, V.P.R. 2002.

Influence of temperature and water and fat contents on

the thermophysical properties of milk. Journal of

Chemical Engineering Data. 47: 1488-1491.

Morison, K.R, Phelan, J.P., and Bloore, C.G. 2013.

Viscocity and non-newtonian behaviour of

concentrated milk and cream. International Journal of

Food Properties. 16: 882-894.

Munir, M.T., Zhang, Y, Yu, W., Wilson, D.I. and Young,

B.R. 2016. Virtual milk for modelling and simulation

of dairy processes. Journal of Dairy Science. 99:1-16.

Rao, M.A. 2007. Rheology of Fluid and Semifluid Foods:

Principles and Applications 2nd edition. New York

(US): Springer.

Roozi, S., Massini, R., Paciello, G., Pagliarini, G,, Rainieri,

S. and Trifiro, A. 2007. Heat treatment of fluid foods in

a shell and tube heat exchanger: Comparison between

smooth and helically corrugated wall tubes. Journal of

Food Engineering. 79:249-254.

Steffe, J.F.. 1996. Rheological Methods in Food

Engineering 2nd edition. Michigan (US): Freeman

Press.

Tello, P.G., Camacho, F., Guadix, E.M., Luzon, G., and

Gonzalez, P.A. 2009. Density, viscocity and surface

tension of whet protein concentrate solutions. Journal

of Food Process Engineering. 32: 235-247

Toledo, R.T. 2012. Fundamentals of Food Process

Engineering 2nd edition. New York (US): Chapman &

Hall.

[USDA] United States Departement of Agricultural. 2016.

Indonesia 2016 dairy and products annual report.

Washington(US): USDA.

Varzakas, T.H and Labropoulos, A.E. 2007. The effect of

mass flow rate in an indirect ultra-high temperature

processing system. Journal of Food Technology. 2(6):

490-501.

2nd SIS 2019 - SEAFAST International Seminar

42