Mono-Diglyceride Fractions in Indonesian Infant Formula Products

Didah Nur Faridah

1,2

, Nadirah Farid Baktir

1

, Ria Noviar Triana

1,2

and Nuri Andarwulan

1,2

1

Department of Food Science and Technology, IPB University, Indonesia

2

Southeast Asian Food and Agricultural Science and Technology Center (SEAFAST), IPB University, Indonesia

Keyword: Diglycerides, Infant Formula Products, Triglycerides.

Abstract: Infant formula contains fat derived from a mixture of vegetable oils, which act as external source of fat. Oil

or fat is an ester of fatty acid glycerol. This work aimed at quantifying the content of triglycerides (TAG),

diglycerides (DAG) and monoglycerides (MAG) in Indonesian infant formula products. We observed infant

formula in BPOM depository (year 2018), then stratified random sampling was applied to determine samples

used. Fat content in all samples (50 products) was determined, as well as profile of acylglycerols. All 50

samples were then classified according to food category No. 13.1 (Standard of BPOM), resulting in 4 main

groups: infant formula (FB, n = 11.21%), advanced formula (FL, n = 16.32%), growth formula (FP, n =

15.30%) and special formula (FK, n = 8.17%). As the results, some samples possessed a high content of MAG

and DAG, in which they might be added as emulsifiers. In addition, correlation coefficient between DAG

content and proportion of palm oil in samples was recorded at R

2

0.4 to 0.7, suggesting that higher level of

palm oil would increase DAG content. PCA analysis clearly separated the distribution of DAG and TAG into

6 groups that exerted different characteristics of each group.

1 INTRODUCTION

Infant formula is included in the food category

number 13.0, namely food products for special

purposes, which mean that it needs a particular

processing or formulation to preserve nutritions

available for treatment of diseases or disorders

(Republic of Indonesia Food and Drug Supervisory

Agency, 2015). Based on the food category (Republic

of Indonesia Food and Drug Supervisory Agency,

2015), Formula milk is divided into several types

including infant formula, advanced formula and

special medical formula.

Infant formula contains protein, carbohydrates,

fats, vitamins and minerals. Generally, infant formula

is made from cow's milk which is modified and

fortified with other nutrients. An additional source of

fat used in infant formula particularly includes a

variety of vegetable oils, such as palm oil, coconut

oil, soybean oil, sunflower seed oil and corn oil

(Delplanque et al., 2015). However, detail

information on food label related to this fat additive

is often unclear. Oil or fat constitutes an ester of

glycerol and fatty acids, composed of a mixture of

most triglycerides (TAG) and a small number of other

compounds, including diglycerides (DAG) and

monoglycerides (MAG), free fatty acids, pigments,

sterols, hydrocarbons, phospholipids, lipoproteins.

The physical, chemical and functional properties

of oil or fat are determined by the profile of

triglycerides and their fatty acid composition (Da

Silva et al., 2010). MAG and DAG can be one of the

factors that affect oil quality standards. MAG and

DAG are minor components in oil that can be formed

not only through lipase hydrolysis by TAG during the

ripening, harvesting and transportation of fruit or

seeds, but also through the pyrolysis of TAG at high

temperatures, including conventional heating and

deodorization (Shimizu et al., 2012). High level of

MAG and DAG in vegetable oil represent a reduced

quality. Regardless source of oils, distribution of

MAG and TAG may differ, but commonly, the

proportion of MAG is lower than that of DAG

(Pacheco et al., 2014). In addition, the presence of

DAG in infant formula could cause the formation of

3-MCPDE compounds (Hamelet et al., 2014). This

compounds can cause a damage to the kidneys and

testicles in experimental animals (Abraham et al.,

2013; Liu et al., 2012).

Faridah, D., Baktir, N., Triana, R. and Andarwulan, N.

Mono-Diglyceride Fractions in Indonesian Infant Formula Products.

DOI: 10.5220/0009977800002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 31-37

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

2 MATERIALS AND METHODS

Chemicals for analysis included standard monolaurin,

a mixture of chloroform methanol (2:1) (Merck),

heptane (Merck), acetone (Merck), NaCl (Merck)

0.88%, N-methyl-N-

trimethylsilytrifluorocoacetamide, technical N

2

gas

andtetrahydrofuran (Merck).

The main instrument used was Gas

Chromatrography (Hawlett Packard) with DB-5HT

column type (15 m × 320 nm), thickness = 0.1 µm and

Flame Ionization Detector type detector.

2.1 Methods

2.1.1 Sample Identification and Sampling

The infant formula database was online-accessed in

www.pom.go.id, finding 361 registered products.

They were then categorized according to BPOM, in

which formula milk belonged to Food Category No.

13 (Regulation No. 1/2015), known as food products

for special nutritional needs. Specifically, it was

included in No. 13.1. The formula product in this

category is generally divided into 3 classes, namely

infant formula (13.1.1), advanced formula (13.1.2),

and infat formula for special medical use (13.1.3).

The sample size was determined from Slovin method

or the √N + 1 method as in Eq. 1.

n

(Eq. 1)

where N is total population; d is confidence level

(10%); and n is number of sample.

In this work, stratified random sampling method

was applied, enabling to divide the population into

smaller groups. These groups were classified

according to particular attributes or characteristics

within population. Subsequently, proportional

amount of sample was selected between groups.

Samples were taken randomly and proportionally at

each layer (category). The number of samples taken

in this study amounted to 50 samples. The Microsoft

Excel 2010 application was employed for random

sampling from each category using the formula "=

RANDBETWEEN (lower limit; upper limit)". Every

selected registered formula milk brand was taken 2

batches (different production codes) as a test, and

each test was analyzed 2 times. Products are

purchased from markets in Bogor, West Java,

Indonesia.

2.1.2 Fat Extraction

Extraction was carried out according to (Abraham et

al., 2013). Sample (24 g) was macerated in 60 mL of

chloroform and methanol solution (2:1) for 120 min

while stirring using a magnetic stirrer. The

maceration mixture was filtered using Whatman filter

paper with the help of a vacuum pump, then the

filtrate solution was added with 32 mL of 0.88% Cl

and shaken to produce two layers. The lower layer

(oil phase) was collected using filtration with a filter

paper, then evaporated using rotary vacuum

evaporator at 40°C to remove solvent residue.

Afterwards, the extraction product was concentrated

by blowing N

2

gas to eliminate the remaining solvent.

The oil was stored in a dark bottle, tightly closed with

parafilm coated and stored at 4°C until subsequent

analysis. Fat content was calculated as in Eq. 2.

Fatcontent

%

100% (Eq. 2)

where Wt is mass of extracted oil (g) and W0 is

sample mass (g)

2.1.3 Determination of Acylglycerol

Composition

Composition of acylglycerol was determined using

Gas Chromatography (Hawlett Packard Series 6890)

with Flame Ionization Detector, operated according

to AOCS Official Method Cd 11b-91 2003 (Liu et al.,

2012). The column used was DB-5HT (15 m × 320

nm) with thickness of 0.1 µm. The carrier gas used

was helium, while the make up gas was N

2

. Gas

chromatography apparatus was equipped with split

injection or injection column and FID, and run at

following conditions: initial column temperature of

50°C increased to 180°C at rate of 15°C·min

-1

, then

subsequently increased to 230°C at rate of 7°C·min

-1

,

and increased again to 380°C, the temperature for

detector and injector was set at 390°C with velocity

of carrier gas 0.7 mL N

2

·min

-1

, while the air flow

velocity was 450 mL·min

-1

with injection

volume of 1 µ.

Briefly, sample (0.0250-0.0255 g) was transferred

in vial, then added with 10 μL of tetrahydrofuran and

50 µL of N-methyl-N-trimethylsilyl-

trifluoroacetamide. After that, the tube was closed,

mixed using vortex at 2400 rpm for 90 sec. The

mixture was incubated in a dark room for 10 min,

added with 2 mL of heptane, then mixed at 2000 rpm

for 30 sec. The sample tube was covered with

parafilm, then incubated at room temperature for

approximately 30 min prior to injection at volume of

1 µL.

2nd SIS 2019 - SEAFAST International Seminar

32

DAG in product =

100(g)

(Eq. 3)

DAG + MAG (g/100mL) = DAG + MAG

(Serving size) (Eq. 4)

2.1.4 Data Analysis

The resulting data were statistically evaluated using

Analysis of Variance (ANOVA) in SPSS software.

Significance among means was verified using DMRT

(Duncan Multiple Range Test) at p<0.05. Proportion

of palm oil, diglycerides and triglycerides was

determined by multivariate using Pricipal Component

Analysis (PCA) in XLSTAT 2018 application.

3 RESULTS

3.1 Sample Identification and

Sampling

Among 361 infant formula products listed in BPOM,

we observed that advanced formula became the most

abundant product, i.e. 223 items (62%), while infant

formula and formula for special medical use was 77

(21%) and 61 (17%) items, respectively. The category

“advanced formula” is divided into two categories,

i.e. formula for ages 6-12 months (advanced formula)

and formula for 1-3 years (growth formula).

Previously, have been also reported categories of

formula products by the age: 0-6 months, 6-12

months, and 1-3 years (Liu et al., 2012). In this study,

we investigated 50 samples of milk formula.

3.2 Fat Content

Content of fat showed a noticeable difference

between samples, in which the highest one was

attributed to infant formula (FB10), reaching up to

25.86%, then advanced formula (FL9), i.e. 23.61%,

growth formula (FP4), i.e. 20.10%, and then special

formula (FK3), i.e. 25.64% (Table 1).

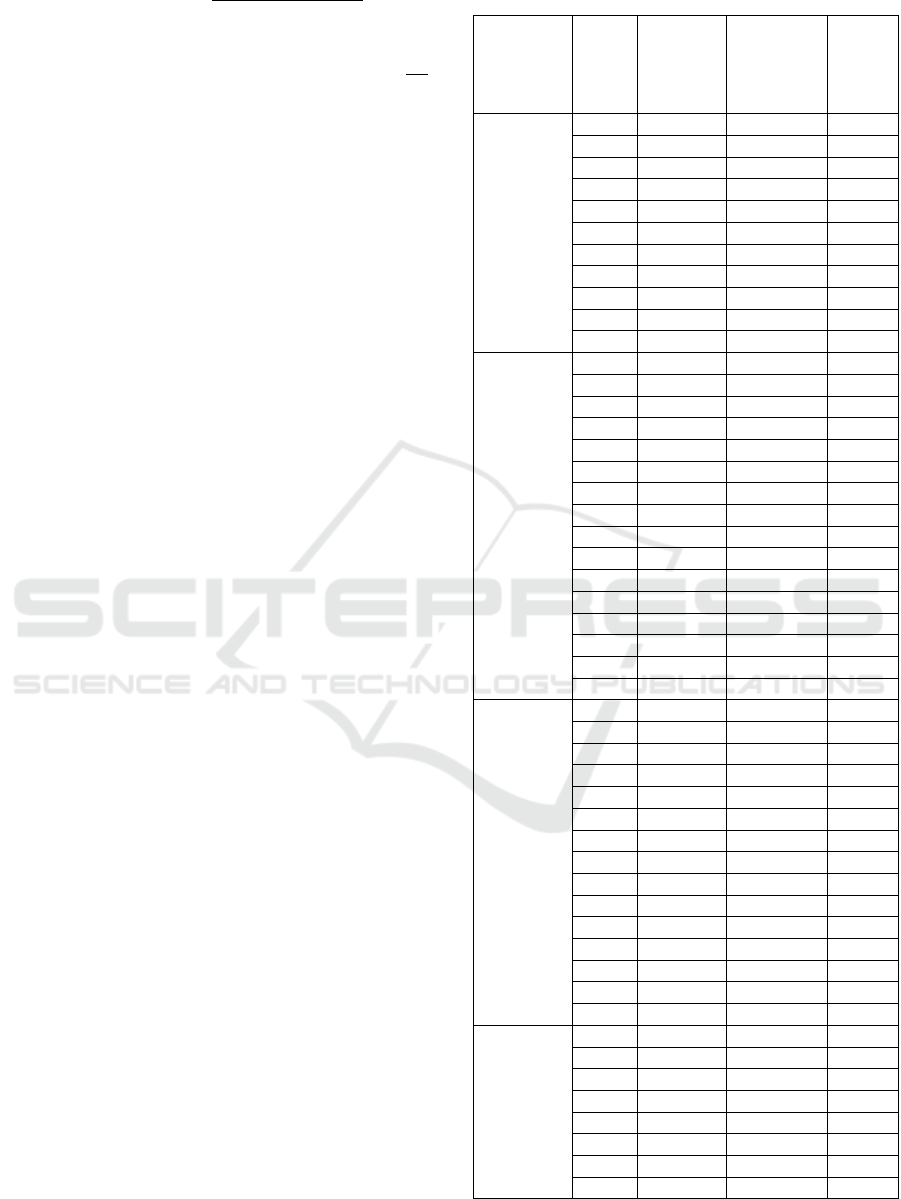

Table 1: Fat content of formula milk samples.

Categories Code

Weight of

sample [g]

Weight of

sample

extract

[g]

Fat

content

[%db]

Infant

Formula

FB1 24.03 4.24 18.01

FB2 24.02 5.26 22.10

FB3 24.02 5.08 21.56

FB4 24.12 4.52 19.09

FB5 24.06 5.11 21.61

FB6 24.11 5.26 22.16

FB7 24.03 5.56 23.54

FB8 48.02 4.91 10.40

FB9 24.02 5.52 23.44

FB10 24.05 6.13 25.86

FB11 24.00 5.36 22.73

Advanced

formula

FL1 24.04 4.40 18.60

FL2 24.00 4.74 20.12

FL3 24.03 5.19 21.77

FL4 24.09 4.34 18.18

FL5 24.02 5.40 22.95

FL6 24.04 4.14 17.61

FL7 42.06 2.79 6.82

FL8 24.05 3.97 16.94

FL9 24.05 5.58 23.61

FL10 24.10 3.59 15.20

FL11 24.01 5.26 22.35

FL12 24.02 4.22 17.99

FL13 24.01 4.48 18.84

FL14 42.05 3.20 7.76

FL15 24.01 4.44 18.77

FL16 24.02 4.41 18.75

Growth

Formula

FP1 42.03 2.15 5.24

FP2 45.04 2.32 5.26

FP3 24.01 4.11 17.33

FP4 24.18 4.82 20.10

FP5 24.03 3.19 13.58

FP6 24.03 3.72 15.80

FP7 24.03 2.99 12.72

FP8 45.78 3.41 7.62

FP9 24.02 3.38 14.38

FP10 30.01 1.56 5.33

FP11 24.06 2.85 12.10

FP12 45.02 2.91 6.58

FP13 30.02 3.99 13.57

FP14 30.03 5.62 19.09

FP15 30.59 3.68 12.25

Special

Formula

FK1 42.06 5.29 12.9

FK2 45.02 2.79 6.30

FK3 24.00 6.06 25.64

FK4 30.35 2.29 7.68

FK5 42.03 1.70 4.11

FK6 42.06 2.45 5.96

FK7 48.47 2.10 4.44

FK8 42.02 9.38 22.68

Mono-Diglyceride Fractions in Indonesian Infant Formula Products

33

3.3 Composition of Acylglycerol

Fraction

The results demonstrated that MAG was only found

in FB11, reaching up to 0.13% (Table 2). This

compound is intentionally incorporated by

manufacture as it occurs on the label. Furthermore,

DAG ranged from 0.3 to 1.8%, with an average of

1.67%. meanwhile, TAG was found at range of 83-

97%, with an average of 92.32%.

The distribution of MAG, DAG and TAG in

advanced formula samples is presented in Table 3.

The results exhibited that FL15 and Fl16 became two

samples that contained MAG, i.e. 0.35% and 0.26%,

respectively. In fact, both products confirmed

presence of MAG, as written on the label.

Furthermore, DAG in advanced formula samples

ranged from 0.4 to 4.3%, with an average of 1.17%.

The DAG content is greater than 4%, while the 3-

MCPD ester level is generally greater than 5 ppm.

The TAG content in the sample of the advanced

formula category occured between 78-100%, with an

average of 94.09%.

Table 4 presents the content of MAG, DAG, and

TAG in growth formula category. Our data revealed

that two samples (FP13 and FP15) were evidenced to

contain MAG at 0.16% and 0.81%, respectively.

Additionally, producers of both samples did not

provide information on the label related to addition of

MAG. DAG was found at range of 0.1-1.8%, with an

average of 0.69%. The highest DAG content was

detected in FP5, no information was given on the

label. Afterwards, TAG ranged from 86 to 100%,

with an average of 94.3%. In terms of special formula

category, one sample was evidenced to contain MAG,

i.e. FK7 (3.78%). However, manufacture has declared

the addition of was found at 91-100%, with an

average of 96.27%. We also detected percentage of

TAG reaching up to 100%, found in FK3, FK6 and

FK8. This presumably represents administration of

Medium Chain Triglyceride (MCT) in the sample

(AOCS Official Method Cd 11b-91, 2003). MAG

since it occurred on the label. For DAG, it ranged

from 0.1 to 0.4%, with an average of 0.34%, while

proportion of TAG

.

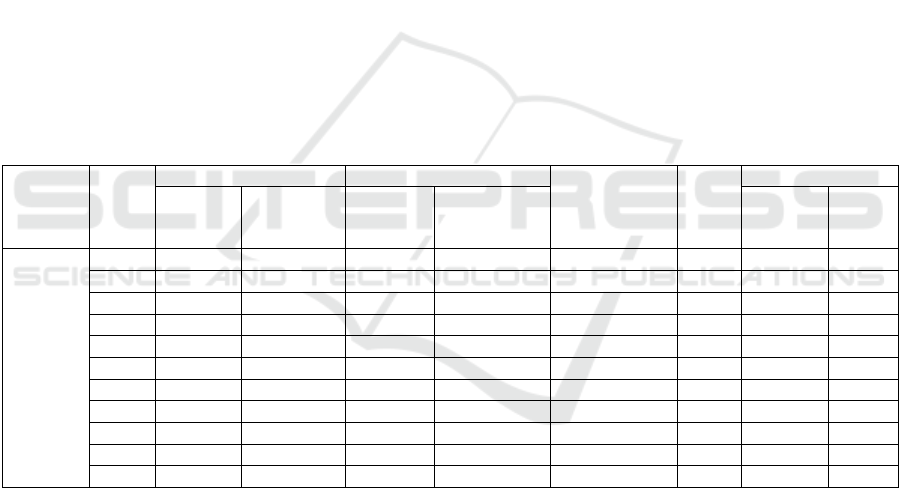

Table 2 : The content of MAG, DAG, TAG and label composition in samples of infant formula categories.

Category Sample

MAG DAG DAG+MAG

(g/100mL

ready to eat

product)

TAG

% in

fat/oil

Label composition

% in oil % in product % in oil % in product MAG MCT

Infant

Formula

FB1 - - 5.57 1.00 0.15 94.43 - -

FB2 - - 5.52 1.22 0.18 94.48 - -

FB3 - - 2.70 0.58 0.08 97.30 - -

FB4 - - 5.70 1.09 0.16 94.30 - -

FB5 - - 7.76 1.68 0.25 92.24 - -

FB6 - - 13.71 3.04 0.45 86.29 - -

FB7 - - 12.33 2.90 0.42 87.67 - -

FB8 - - 3.69 0.38 0.06 96.31 - -

FB9 - - 3.73 0.87 0.13 96.27 - -

FB10 - - 6.85 1.77 0.25 93.15 - -

FB11 0.55 0.13 16.95 3.85 0.57 83.05 √ -

2nd SIS 2019 - SEAFAST International Seminar

34

Table 3: The content of MAG, DAG, TAG and label composition in samples of advanced formula categories.

Categories Sample

MAG DAG

DAG+MAG

(g/100mL

ready to eat

product)

TAG

%in fat/

oil

Label

composition

% in oil % in product % in oil % in product MAG MCT

Advanced

Formula

FL1 - - 5.74 1.07 0.15 94.26 - -

FL2 - - 21.74 4.37 0.62 78.26 - -

FL3 - - 6.08 1.32 0.22 93.92 - -

FL4 - - 2.73 0.50 0.08 97.27 - -

FL5 - - 2.96 0.68 0.11 97.04 - -

FL6 - - - - - 100 - -

FL7 - - 6.17 0.42 0.06 93.83 - -

FL8 - - - - - 100 - -

FL9 - - 3.27 0.77 0.12 96.73 - -

FL10 - - 4.90 0.74 0.11 95.10 - -

FL11 - - 6.11 1.37 0.22 93.89 - -

FL12 - - 13.99 2.52 0.38 86.01 - -

FL13 - - 2.81 0.53 0.09 97.19 - -

FL14 - - 5.70 0.44 0.14 94.30 - -

FL15 1.84 0.35 3.12 0.59 0.13 95.05 √ -

FL16 1.40 0.26 6.00 1.13 0.20 92.60 √ -

Table 4: The content of MAG, DAG, TAG and label composition in samples of growth formula categories.

Categories Sample

MAG DAG

DAG+MAG

(g/100mL ready

to eat product)

TAG % in

fat/

oil

Label composition

% in oil

% in

product

% in oil

% in

product

MAG MCT

Growth

Formula

FP1 - - 5.93 0.31 0.06 94.07 - -

FP2 - - 3.11 0.16 0.03 96.89 - -

FP3 - - 3.56 0.62 0.08 96.44 - -

FP4 - - - - - 100 - -

FP5 - - 13.40 1.82 0.36 86.60 - -

FP6 - - 9.14 1.44 0.24 90.86 - -

FP7 - - 6.00 0.76 0.15 94.00 - -

FP8 - - 5.65 0.43 0.07 94.35 - -

FP9 - - 6.42 0.92 0.16 93.58 - -

FP10 - - 3.56 0.19 0.03 96.44 - -

FP11 - - 2.88 0.35 0.06 97.12 - -

FP12 - - 3.15 0.21 0.03 96.85 - -

FP13 1.17 0.16 2.90 0.39 0.10 95.93 √ -

FP14 - - 8.43 1.61 0.24 91.57 - -

FP15 6.59 0.81 3.61 0.44 0.23 89.80 - -

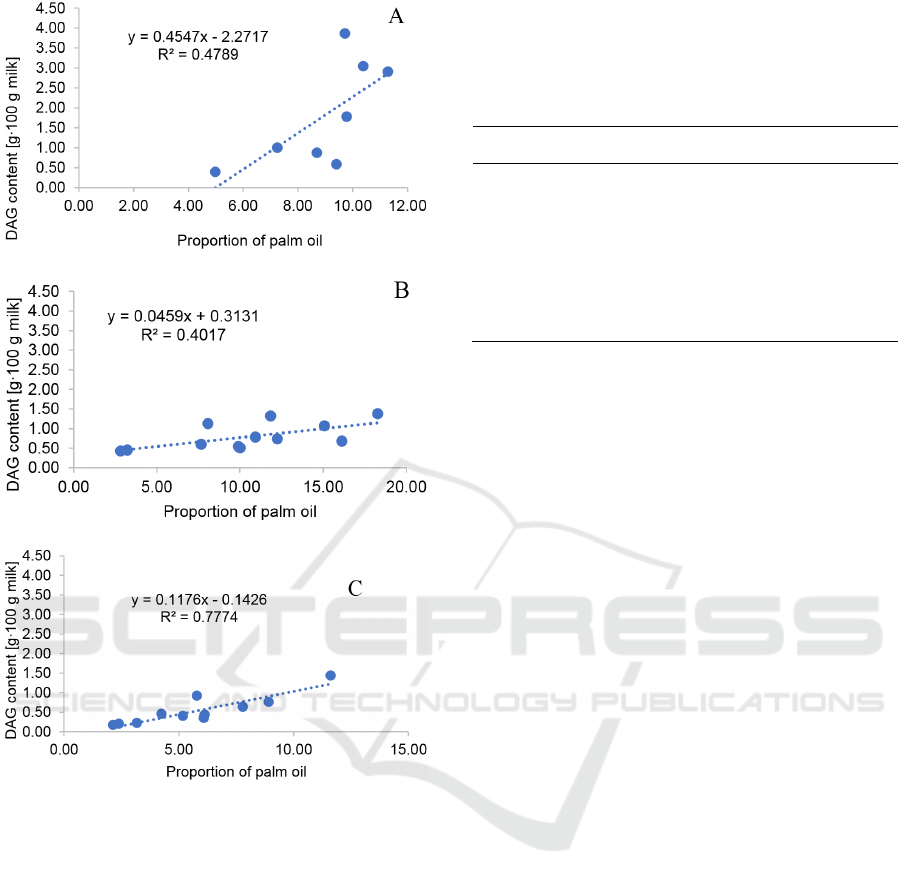

3.4 Coefficient Correlation between

Levels of Palm Oil and Diglyceride

The coefficient correlation between the proportion of

palm oil and DAG content in samples of infant

formula was depicted in Figure 1A. The test results

showed a linear curve with the equation y = 0.4547x

- 2.2717 with R

2

= 0.4789, suggesting that proportion

of palm oil positively correlates with level of DAG.

In case of advanced formula, the linear curve was

arranged with the equation y = 0.0459x + 0.3131, and

R

2

= 0.4017 (Figure 1B). Similarly, higher proportion

of palm oil also resulted in a higher level of DAG. For

growth formula category, the equation was y =

0.1176x - 0.1426, with R

2

= 0.7774 (Figure 1C),

indicating that content of DAG increases as more

palm oil is added.

Mono-Diglyceride Fractions in Indonesian Infant Formula Products

35

Figure 1: Plot of palm oil and DAG content in three groups

of samples: infant (A), advanced (B) and growth (C)

formula.

3.5 PCA Analysis

As depicted in Table 5, there is a significant

difference between content of DAG, TAG content

and proportion of palm oil for each groups. Group A

showed the lowest proportion of palm oil compared

to other groups; on the contrary, group B had the

highest level of DAG among groups. Meanwhile, the

highest proportion of palm oil was detected in group

C. The discrepancy between group D and E occured

in the gradient of group E closing to TAG gradient,

which means that TAG in group E is higher than in

group D. Furthermore, gradient of group D is also

close to DAG gradient, suggesting that DAG in group

D is higher than group E. Group F has the highest

TAG content, i.e. 100%. This links to the use of

medium chain triglycerides (MCT), while also

contains lower amount of palm oil compared to other

groups.

Table 5: Distribution of diglycerides and triglycerides.

Groups n DAG TAG

Palm Oil

Proportion

A 3 9.86 ± 3.08

d

90.14 ± 3.08

b

0.00 ± 0.00

a

B 7 13.81 ± 4.51

e

86.19 ± 4.51

a

46.57 ± 11.24

c

C 6 5.60 ± 0.40

c

94.40 ± 0.40

c

71.00 ± 1.10

d

D 12 5.77 ± 1.00

c

93.25 ± 1.28

c

42.17 ± 8.12

c

E 16 3.16 ± 0.33

b

96.66 ± 0.58

d

45.31 ± 6.64

c

F 6 0.00 ± 0.00

a

100.00 ± 0.00

e

28.67 ± 22.46

b

4 DISCUSSION

MAG is a common emulsifiers applied in milk-based

recombination products such as infant formula. In

short, presence of MAG in sample is associated with

its functionality as emulsifiying agent. Maximum

threshold of mono-diglycerides as emulsifier in infant

formula is 0.4g·100mL

-1

Sun et al., 2016). Our data

revealed that content of these chemicals in 27.27% of

samples was evidenced to be much higher than

standard, i.e. FB6, FB7 and FB11. The product does

not include an emulsifier in its composition. The high

content of MAG and DAG that exceeds the limit

possibly results from vegetable oil which does not fit

the requirements. The existence of MAG and DAG

depends on the process, storage and shelf life of the

oil Risma et al., 2019) or the condition of raw

materials that did not meet standard. Besides, they are

added intentionally by manufacturers to give

emulsifying properties, but not mentioned in list of

composition.

The high content of DAG needs to receive serious

concern related to its potentiality as precursor for the

formation of 3 MCPD esters (CODEX Alimentarius,

2017). MAG and DAG in samples studied are used as

emulsifiers. Compared to standard of Codex, we

found 16 samples (6.25%) did fit the criteria (>

0.4g·100mL

-1

), meanwhile FL2 showed no

compliance with regulations because the product did

not include the addition of emulsifiers. Based on

regulation issued by Codex Sun et al., 2016), we

concluded that all samples of growth formula

categories met the standard regarding to addition of

MAG and DAG. Compared to regulation of Codex

Sun et al., 2016), level of MAG and DAG present in

all samples of special formula is accordance with the

standard.

2nd SIS 2019 - SEAFAST International Seminar

36

5 CONCLUSION

Categorization of 50 samples based on food category

No. 13.1 resulted in 4 major classes: infant formula (n

= 11.21%), advanced formula (n = 16.32%), growth

formula (n = 15.30 %) and formula for special

medical purposes (n = 8.17%). The experiment

successfully detected presence of MAG and DAG in

samples, which might be linked to intentional

addition by manufacture considering their function as

emulsifiers. Besides, the results found 27.27% of

infant formula samples and 6.25% of advanced

formulas containing MAG and DAG that exceed the

maximum threshold of Codex. This presumably

relates to hydrolysis of vegetable oils used in the

samples, and may be intentionally added as

emulsifiers despite not mentioned on label. PCA

analysis successfully mapped proportion of palm oil,

MAG, DAG and TAG into 6 groups, having

distinctive feature for each group.

REFERENCES

Republic of Indonesia Food and Drug Supervisory Agency.

Food Cathegory. Jakarta (ID): Republic of Indonesia

Food and Drug Supervisory Agency, 2015.

Delplanque, B. ‒ Gibson, R. ‒ Koletzko, B. ‒ Lapillonne,

A. ‒ Strandvik, B.: Lipid quality in infant nutrition:

current knowledge and future opportunities. J Pediatr

Gastroenterol Nutr. 61(1), 2015, pp. 8‒17. DOI:

10.1097/MPG.0000000000000818.

Da Silva, R.C. ‒ Soares, D.F. ‒ Lourenço, M.B. ‒ Soares,

F.A.S.M. ‒ Da Silva, K.G. ‒ Gonçalves, M.I.A. ‒

Gioielli, L.A.: Structured lipids obtained by chemical

interesterification of olive oil and palm stearin. Food

Sci Technol LEB., 43, 2010, pp. 752–758. DOI:

10.1016/j.lwt.2009.12.010.

Shimizu, M. ‒ Vosmann, K. ‒ Matthaus, B.: Generation of

3-monochloro-1,2- propanediol and related materials

from tri-, di-, and monoolein at deodorization

temperature. Eur J Lipid Sci Technol, 114, 2012, pp.

73-1268. DOI: 10.1002/ejlt.201200078.

Pacheco, C. ‒ Palla, C. ‒ Crapiste, G.H. ‒ Carrin, M.E.:

Simultanous quantitation of FFA, MAG, DAG, and

TAG in enzymatically modified vegetable oils and fats.

Food Anal. Methods. 2014, pp. DOI: 10.1007/s12161-

014-9830-x.

Hamlet, C.G‒Asuncion, L. ‒Velbek, J. 2011. Formation

and occurance of esters 3- chloropropane-1,2-diol (3-

CPD) in foods : what we know and what we assume.

Eur J Lipid Sci Tech. 113: 374-379. DOI:

10.1002/ejlt.201000480.

Abraham, K. ‒Appel K,E. ‒Berger P,E. ‒Apel, E. ‒Gerling,

S‒Mielke, H. ‒2013. Relative oral bioavailability of 3-

MCPD from 3-MCPD fatty acid esters in rats. Arch

Toxicol. 87 (4). DOI: 10.1007/s00204-012-0970-8.

Liu, M. ‒Gao B,Y. ‒Wu P,P. ‒Shi, H, M. ‒Luo , W. 2012.

Acute oral toxicity of 3- MCPD mono- and di-palmitic

esters in Swiss mice and their cytotoxicity in NRK-52E

rat kidney cells. Food Chem Toxicol. 50(10): 785-3791.

DOI: 10.1016/j.fct.2012.07.038.

AOCS Official Method Cd 11b-91. Official Methods and

Recommended Practices of the AOCS. 5

th

edition.

Illinois (US): AOCS, 2003.

Sun, C. ‒ Zou, X. ‒ Yao, Y. ‒ Jin, J. ‒ Xia, Y. ‒ Huang, J.

‒ Jin, Q. ‒ Wang, X.: Evaluation of fatty acid

composition in commercial infant formulas on the

Chinese market: a comparative study based on fat

source and stage. Int Dairy J., 63, 2016, pp. 42‒51.

DOI: 10.1016/j.idairyj.2016.07.015.

Risma, R.Y.: Triacylglycerol profile of infant formulas in

Indonesia. Minithesis. Bogor (ID): Department of Food

Science and Technology. IPB University, 2019.

CODEX Alimentarius. Standard ForFollow-Up Formula.

Rome (IT): Codex Alimentarius, 2017.

Mono-Diglyceride Fractions in Indonesian Infant Formula Products

37