The Effect of Bean Size and Curing Process on Aroma Profile and

Vanillin/Glucovanillin Content of Indonesian Cured Vanilla Beans

Dede R. Adawiyah

1,2

, Petronela Yunia Dua Reri

1

and Hanifah Nuryani Lioe

1

1

Department of Food Science and Technology, Faculty of Agricultural Technology and Engineering, Bogor Agricultural

University, IPB Darmaga, Bogor 16680, Indonesia

2

Southeast Asian Food and Agricultural Science and Technology (SEAFAST) Center, Indonesia

Keywords: Aroma Profile, Glucovanillin, Curing, Killing Temperatures, Vanillin.

Abstract: A cured vanilla bean produced in Indonesia has lower quality than that produced in other countries, which

may be associated with improper maturity of vanilla bean and curing process. The quality of vanilla is

dependent on its aroma and vanillin content. The aim of this research was to evaluate the effects of fresh

vanilla bean size (weight and length) on aroma profile and vanillin/ glucovanillin of cured vanilla bean. Curing

condition was conducted under 90ºC killing temperatures and sun drying period (dried to 50% of initial beans

weight). Aroma profile was evaluated using sensory quantitative descriptive analysis and vanillin content

determined by high performance liquid chromatography. The results showed that different size of vanila beans

with same condition of curing process gave different aroma profile. Vanilla beans with size less than 8 grams

or 12.3 cm length of vanilla bean did not have good aroma vanilla characteristics. The highest vanillin content

was found in vanilla with size of bean more than 15 grams or 19.6 cm length of vanilla bean, and characterised

as vanillin aroma.

1 INTRODUCTION

Indonesia is one of the biggest vanilla producers in

the world beside Madagascar, Mexico, India and

Africa. However, the price of Indonesian vanilla

beans tends to be the lowest (US$12.592 per ton) over

vanilla beans produced from other countries (FAO,

2009). fruit maturity (indicated by bean size) and

curing condition seems to be a key stage affecting the

aroma compounds of the vanilla bean; thus, improper

harvesting time and curing process may contribute to

production of undesired aroma on the Indonesian

vanilla beans, such as dry smoky or woody aroma

(Adedeji et al., 1993).

Mature green vanilla beans contain precursors of

flavor and aroma compounds, and these compounds

are released during curing process. The curing

process induces the enzymatic reaction which

converts glucovanillin to vanillin. In green vanilla

beans, the concentration of glucovanillin was found

around 14% dry weight basis (Havkin-Frenkel and

Belanger, 2010). Many studies have investigated the

effects of various curing conditions on the hydrolytic

activity of glucovanillin (Dignum et al., 2002;

Havkin-Frenkel et al., 2004; Pérez Silva et al., 2011).

In a study, vanillin concentration was found to

increase during curing process from 8418 ppm to

22361 ppm (Pérez Silva et al., 2011). Vanillin content

in cured vanilla beans is an important analytical

parameter, which indicates a strong relationship

between curing condition and vanilla quality.

Numerous studies have identified hundred volatile

compounds present in vanilla bean, and their presence

is responsible for the aroma profile of vanilla

(Adedeji et al., 1993; Pérez-Silva et al., 2006;

Sostaric et al., 2000). However, vanillin is the major

volatile compound in vanilla bean (Sreedhar et al.,

2007; Pardio et al., 2009; Zhang and Mueller, 2012).

Many studies have been conducted to determine the

optimal conditions to obtain a good quality of cured

vanilla bean (Dignum et al., 2002; Van Dyk et al.,

2010).

Under ripe or immature green vanilla bean will

produce low quality of cured vanilla bean compare

with mature vanilla bean. Van Dyk et al. (2010)

reported that physiological age of vanilla bean during

harvesting is important factor affecting vanilla

quality. General indicators of fully mature vanilla

beans are green-yellow color, cylindrical shape and

length 10-25 cm and witdh of 1-1.5 cm (Rao dan

106

Adawiyah, D., Reri, P. and Lioe, H.

The Effect of Bean Size and Curing Process on Aroma Profile and Vanillin/Glucovanillin Content of Indonesian Cured Vanilla Beans.

DOI: 10.5220/0009977400002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 106-111

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Ravishankar 2000). Medina et al. (2009) mentioned

the importance of sorting and grading on the

harvested vanilla bean. The size and appearance

become very important because it is related with the

aroma produced from their Vanillin component

during curing process.

Based on information as mentioned above, vanilla

quality is heavily affected by maturity level based on

size parameter of vanilla bean or pod and curing

process. In this paper, we study on the effect of vanilla

bean size (weight and length) on the quality of cured

vanilla bean evaluated from aroma profile and

vanillin / glucovanillin contents.

2 MATERIAL AND METHODS

2.1 Materials

Green vanilla beans were obtained from vanilla

producers in Alor, Indonesia and commercial

Madagascar vanilla were supplied by Ogawa Co.,

Japan. Chemicals for HPLC analysis were of

analytical grade (Merck, Germany), while aroma

references (vanilin, asam asetat, guaiacol, eugenol,

cinnamaldehyde, 1-octen-3-ol, 2,4-decadienal,C-8

acid, furfural, etil asetat, etil propanoat, isoamil asetat,

fenil etil alkohol, alcohol C-10) for sensory analysis

were also provided by Ogawa Co. Japan.

2.2 Method

Fresh vanilla beans were graded into 4 classes based

on weight: (A) less than 8 gram, (B) 8-11 gram, (C)

12-15 gram and (D) more than 15 gram. Length of

vanilla beans were measure individually to determine

range of length of vanilla bean in each class.

The beans were killed by immersion in hot water

at 90ºC for 3 mins. After killing, all bean groups were

wrapped with three layers: black cotton cloth, black

flannel cloth and black plastic sheet (from inner to

outer). For sweating stage, the wrapped beans were

put in a separated box (using styrofoam box) and kept

for 24 hr. Next, the vanilla beans were sun-dried for

5 hr per day until reaching 50% weight reduction.

Prior to sun drying, the beans were wrapped with two

layers, e.g., black cotton cloth and black flannel cloth

and placed in separated styrofoam box for the next

day. After this stage, all bean samples were subjected

to subsequent slow drying. In this process, the beans

were placed on trays in a ventilated room to continue

the drying process until the bean weights reached 20-

22% of their initial weight. After slow drying, the

beans were bundled and then stored in a wooden box

at ambient temperature for 3 months for conditioning

process. It was noted that sweating, slow drying and

conditioning process were conducted at the same

condition for each group of vanilla beans.

2.2.1 Sensory Analysis

The method used for the sensory evaluation was

quantitative descriptive analysis (QDA). The aroma

quality of cured vanilla beans was evaluated by 13

trained panellists of Bogor Agricultural University (9

women and 4 men, aged from 21 to 28 years old),

previously selected from 41 candidates. The panellist

was trained for 1 month by rating test and focus group

discussion for vanilla aroma. Approximately 1 g of

samples (only seeds have taken) were served in dark

vial (5 mL capacity), coded and presented randomly

to panellists. They evaluated the aroma (sweet, sour,

phenol-like, spicy, hay-like, liquid/whisky-like, and

woody) in samples with reference odours (Table 1)

and scored aroma descriptor on an intensity scale of 0

– 10 indicating “none” to “strong”. All sensory

evaluations were performed in individual sensory

booths at room temperature (26-27ºC). The sensory

evaluation test was conducted in triplicate.

Table 1: Description of aroma references.

References Description

Vanilin Sweet

Asam asetat acid

Guaiacol, eugenol Phenol like

Cinnamaldehyde spice

1-octen-3-ol, 2,4-

decadienal, C-8 acid

Hay-like

Furfural, etil asetat, etil

propanoat

Liquid or whisky-like

Fenil etil alkohol,

alcohol C-10

woody

2.2.2 Determination Vanillin &

Glucovanillin

Sample Preparation. Cured vanilla beans

(approximately 200 mg) were suspended in 10 mL

distilled water, added with 0.5 mL of 18 M sulphuric

acid and thoroughly mixed. The mixture was then

incubated in a waterbath at 60ºC for 3 h to hydrolyze

the glycosides, cooled in room temperature and added

with 2 mL of 9 M KOH to neutralize the mixture

solution (pH adjusted to 6-7). Then, 10 mL of n-

hexane and dicloromethane (1:1, v/v) was added to

extract the vanillin and shaken. The upper organic

phase was recovered, while the remaining aqueous

layer was extracted three times more with 10 mL of

The Effect of Bean Size and Curing Process on Aroma Profile and Vanillin/Glucovanillin Content of Indonesian Cured Vanilla Beans

107

n-hexane and dichloromethane (1:1,v/v). The

combined organic phase was dried over anhydrous

Na

2

SO

4

and filtered. The filtrate was dried using N

2

gas. The dried analyte was adjusted to 2 mL by

mobile phase solvent and filtered using membrane

filter 0.45 μm. The filtrate obtained was subjected to

HPLC and the result was calculated as total vanillin

of the samples. Free vanillin was analyzed using the

above procedure but without acid hydrolysis and

neutralization.

HPLC Analysis. Vanillin concentrations in the

hydrolyzed extracts from cured vanilla beans were

determined using HPLC Shimadzu LC-6A

(Shimadzu, Japan). HPLC is operated at room

temperature with the condition of column C18 (15

cm, 4.6 mm i.d., 5 μm, Zorbak Eclipse XBD-C18,

Agilent, USA). The mobile phase consisted of 10%

H

2

O, 30% acetonitrile, 60% methanol. The separation

was performed under isocratic condition at a constant

flow rate of 0.5 mL/min. Detection was performed at

271 nm with a UV-Visible detector SPD-10AV

(Shimadzu, Japan). The injection volume was 20 μL

of sample. Vanillin standard solutions, 5-100 µg.mL

-

1

were prepared to obtain a linear calibration curve.

2.2.3 Statistical Data Analysis

Analysis of variance (ANOVA) was performed to

evaluate significant differences in aroma profile

among vanilla samples (p<0.05) using MINITAB

version 2016. Principal component Analysis was

performed using XLSTAT version 2014.

3 RESULT AND DISCUSSION

3.1 Vanilla Bean Size

Maturity level indicated by weight of individual

vanilla bean affected of aroma profile of cured vanilla

bean. Vanilla bean size was categorised by 4 groups

based on weight: A) less then 8 gram, (B) 8-11 gram,

(C) 12-15 gram dan (D) more than 15 gram. The

length of vanilla beans were ranging from 12.3 cm –

19.6 cm. Table 2 shows data of size (length and

weight) of vanilla bean used in this research. The

smallest size of vanilla bean was less than 8 gram

equivalent with 12.3 cm length (Table 2), while the

biggest size was more than 15 gram that equivalent to

19.6 cm length.

Table 2: Vanilla bean size.

Name

Group Range

Average

of weight

(g)

Average

of length

(cm)

A < 8 gram 5.16 12.3 ± 1.8

B 8-11 gram 9.52 15.5 ± 1.3

C 12-15

gram

13.55

17.6 ± 1.3

D >15 gram 19.09 19.6 ± 1.5

A < 8 gram 5.16 12.3 ± 1.8

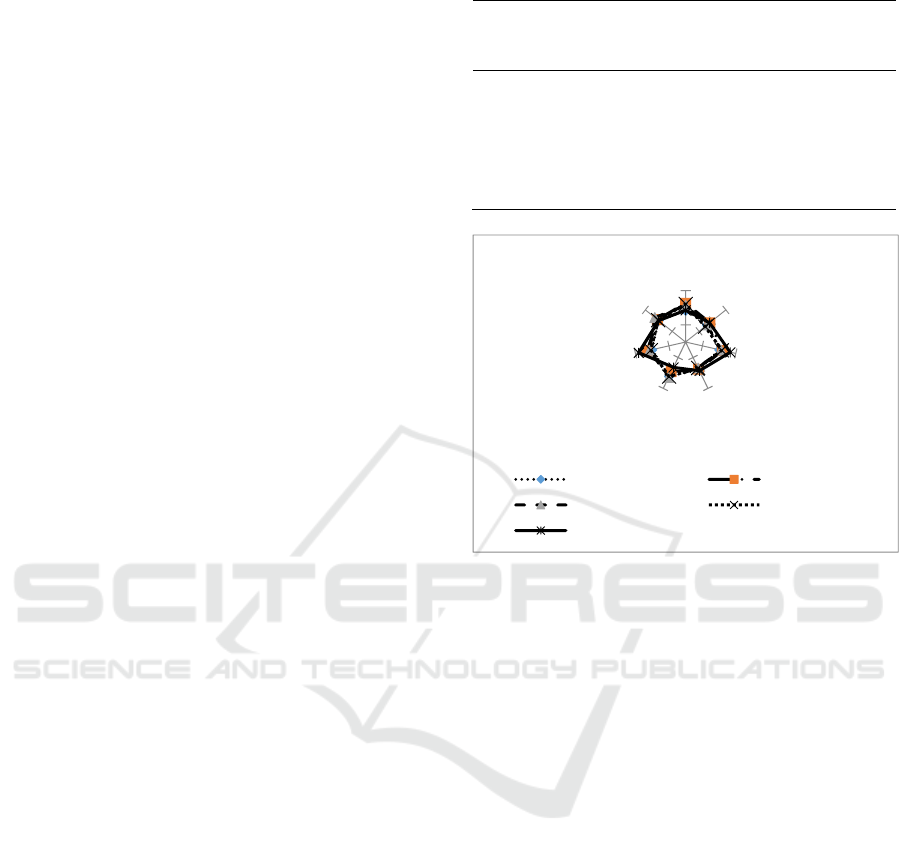

Figure 1: Aroma profile of 4 groups of cured vanilla bean.

Note: *significant different (p<0.05).

The results in figure 1 shows that bean size

(weight and length) significantly effect on aroma

profile of cured vanilla beans. Significant different

were found in phenol like, and hay like. Cured vanilla

bean from fresh vanilla bean weight less than 8 gram

had lower sweet aroma compare to the others. It

means that fresh vanilla bean weighs less than 8

grams or length less than 12.3 cm has not fully ripe or

optimum condition to produce sweet aroma because

flavour precursor for vanilla was not developed yet.

During this time, some of Indonesia's vanilla bean

farmers harvested the vanilla bean in under-ripe or

immature condition to avoid theft and to reduce the

production cost. They harvested vanilla bean at once,

mixed mature and immature vanilla bean. It resulted

in low quality of Indonesian vanilla bean compared to

vanilla from other countries such as the vanilla of

Madagascar. Immature fresh Vanilla bean has

incomplete flavor compound that responsible for

targeted flavors, such as sweet and vanillin flavor,

during the curing process (Ranadive 2006). The

vanilla bean more than 15 gram had sweet aroma

higher than the other size, although not significantly

different. Mature vanilla bean produce aroma profile

vanilla, sweet and creamy (Ranadive 2006).

0.00

2.00

4.00

6.00

sweet

sourness

Phenol‐like*

SpicyHay‐like*

Liquid/wisky…

Woody

A(<8gram) B(8‐11gram)

C(12‐15gram) D(>15gram)

Madagascar

2nd SIS 2019 - SEAFAST International Seminar

108

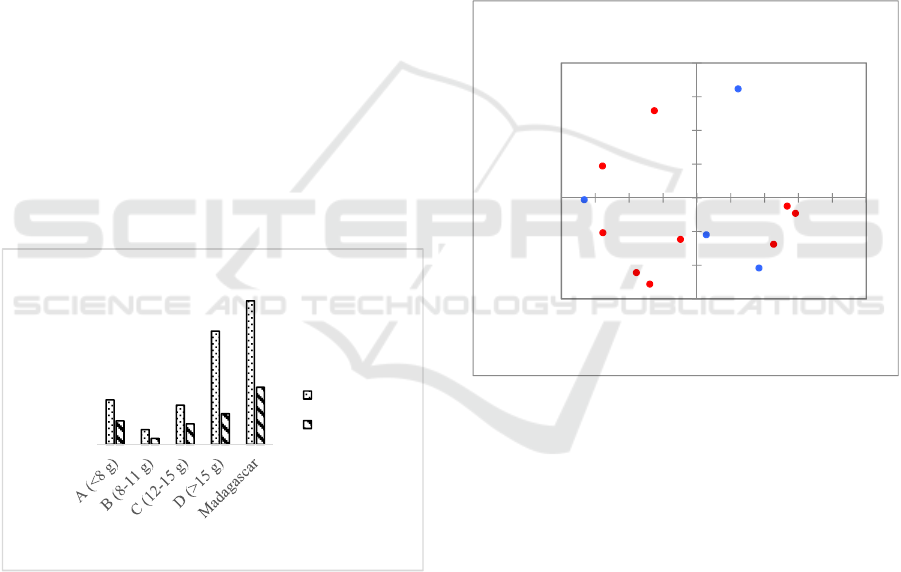

3.2 Vanilin/Glukovanilin Contents

Vanilin is an important flavour compound quality

parameter of cured vanilla bean as the result of

hydrolysis of glucovanilin by β-glukosidase. In

general, the vanillin concentration in cured vanilla

bean on average is 1.4-3.0% (Gassenmeier et al.

2008; Cicchetti dan Chaintreau 2009). Cured Vanilla

bean with a high concentration of Vanilin (2.0-3.0%)

is a high-quality of vanilla. Concentration levels of

vanillin in cured vanilla bean depend on several

factors, one of which is the level of maturity of the

fresh green vanilla bean during harvesting. This

relates to the concentration of glucovanillin in the

fresh vanilla bean as a precursor to the flavor

compounds of vanillin. Tokoro et al. (1990) reported

that the highest content of Glucovanillin is in mature

vanilla fruit. In this research the vanillin compound

was analyzed using HPLC UV-Vis and detected at the

3

rd

minute. The results showed that vanilla bean

weight more than 15 grams had a higher

concentration of vanillin compared to three others

size of vanilla bean (Figure 2). The content of vanillin

in this study was still relatively low in the range of

200-4000 ppm compared to the vanillin content of

Mexican vanilla, Madagascar (Pérez-Silva et al.

2011; Pardio et al. 2009).

Figure 2.

The results showed that vanilla bean with size

less than 15 grams on average had a lower vanillin

content than the size of more than 15 grams and

Madagascar vanilla. It is because Glucovanillin

content has not formed maximum level due to low

maturity level (immature). Glucovanillin is a

dominant flavor precursor found in cured vanilla

bean. Van Dyk et al. (2014) mentioned that

Glucovanillin began to increase in the 20th week after

pollination and achieved maximum concentration

after 40 weeks after pollination. The physical

condition as bean size became critical criteria in

determining the optimum harvest time of vanilla bean

for further processing of curing. Generally,

Indonesian vanilla farmers do not pay attention to the

size of vanilla fruit at the harvest time because

usually, farmers harvest the vanilla bean at once

without the selection of fruit one by one. It causes the

low quality of vanilla beans from Indonesia compared

to the other countries. Another factor that affected

vanillin/glucovanillin content is the curing process,

such as killing and drying methods.

3.3 Mapping of Cured Vanilla Beans

Characteristics by Principal

Component Analysis

Figure 3: PCA of cured vanilla bean with different size.

Mapping and correlation between cured vanilla bean

based on different size (weight) with aroma profile

and vanillin/glucovanillin content was described

using biplot graph from principle component analysis

(PCA) as can be seen in Figure 3. Figure 3 shows

mapping of characteristics cured vanilla bean from 4

different size of green vanilla bean as raw material.

The result of PCA explained 84.63% of the total

variance (F1=54.54% and F2=30.09%). The PCA

shows that fresh vanilla bean with different size

produce different characteristics of cured vanilla

bean. Vanilla A (weight less than 8 grams) does not

shows any dominant characteristics in sensory or

aroma profile and vanillin/glucovanillin content.

Vanilla B (weight 8-11 grams) has dominant

characteristics of liquid/whisky-like, phenol-like dan

woody, while cured vanilla C (12-15 grams) and D

(more than 15 grams) were noted by

0

1000

2000

3000

4000

5000

6000

7000

concentration (ug/g)

Weight

Vanillin

Glucovanillin

A (<8 g)

B (8-11 g)

C (12-15

g)

D (>15 g)

Sweet

Sour

Phenol-like

Spicy

Hay-like

Liquid/wisky

-like

Woody

Vanillin

Glucovanillin

-1.5

-1

-0.5

0

0.5

1

1.5

2

-2 -1.5 -1 -0.5 0 0.5 1 1.5 2 2.5

F2 (30,09 %)

F1 (54,54 %)

Biplot (axes F1 and F2: 84,63 %)

The Effect of Bean Size and Curing Process on Aroma Profile and Vanillin/Glucovanillin Content of Indonesian Cured Vanilla Beans

109

vanilin/glucovanilin content, and hay-like aroma.

This result research clearly clarify that the immature

vanilla bean indicated by small size less than 8 grams

or length less than 12.3 cm would produce low quality

of cured vanilla bean with less or no aroma identity.

Many factors are involved in providing good quality

of cured vanilla bean, including the level of fruit

maturity, environmental condition, curing process,

and others. In this study, the size of the vanilla bean

was a good indicator of the maturity level of vanilla

bean.

PCA also can be used to analyse correlation

between tested parameters. PCA also can be used to

analyse the correlation between tested parameters. A

Positive correlation can be seen from adjacent criteria

or parameters, while a negative correlation from the

data or parameter position in the opposite side or

diagonal quadrant. Based matrix correlation (data do

not shown), there was positive correlation between

glucovanillin with vanillin (r = 0.872), hay like aroma

(r = 0.846). Negative correlations were found

between vanillin with sour (r = -0.918); glucovanillin

with sour (r = -0.986); glucovanillin with

liquid/whisky-like (r = -0.869).

A positive correlation between glucovanillin with

vanillin (r = 0.873) means that higher glucovanillin

caused the higher vanillin concentration. High or low

concentration of vanillin in cured vanilla bean

depends on the concentration of Glukovanilin in fresh

vanilla bean. Vanillin obtained from hydrolysis of

glucovanillin by enzyme of β-glukosidase during

curing process. According to Van Dyk et al. (2014),

the concentration of Glucovanillin in vanilla bean

highly depends on the level of maturity. Some result

researches suggested that the maximum

concentration of glucovanillin in fresh vanilla bean

occurs at week 40 after pollination. This research

result emphasizes that the level of maturity was

highly significant in vanillin concentration produced

during the curing process.

Glucovanillin also has a positive correlation with

hay-like aroma (r = 0.846). Hay like is an undesirable

aroma in the cured vanilla bean. High glucovanillin

concentration in cured vanilla bean caused by less

intense hydrolysis to convert glucovanillin into

vanillin during the curing process. Hydrolysis of

glucovanillin highly depends on enzyme β-

glucosidase activity and water availability in the

vanilla bean. The moisture content of cured vanilla

bean was 13-14% wb which was relatively lower than

the optimum moisture content of 25-30%

(Brunschwig et al. 2012). It means intense hay-like

aroma in cured vanilla bean found in this research was

due to the low moisture content of vanilla bean.

Takahashi et al. (2013) reported that cut split vanilla

bean with the low moisture content of 11% had a

higher hay-like aroma intensity than vanilla red whole

beans with a moisture content of 25%.

4 CONCLUSION

Fresh vanilla bean size has a significant effect on the

aroma profile and the vanillin content in the cured

vanilla bean. Vanilla bean size less than 8 grams or

length of less than 12.3 cm produces a low quality of

cured vanilla bean in terms of aroma profile as well

as the content of vanilin/glucovanilin. The size of the

vanilla bean more than 17 cm or weigh more than 15

grams is recommended to the Indonesian vanilla

farmer as the physical criteria of the fruit to harvest

the vanilla bean to produces good characteristics of

cured vanilla bean.

ACKNOWLEDGEMENTS

We acknowledge to PT Ogawa Japan and PT Ogawa

Indonesia for their support both financial and

provision of materials in this research.

REFERENCES

[FAO] Food and Agriculture Organization of the United

Nations. 2009. Vanilla Post harvest Operation. 2009-

06-16.

Adedeji J, Hartman TG, Ho C. 1993. Flavor

characterization of different varieties of vanilla beans.

Perfum Flavor. 18:115–133 Ranadive AS.2006. Inside

look: Chemistry and biochemistry of vanilla flavor.

Perfum Flavor. 31:38-44.

Brunschwig C, Rochard S, Pierrat A, Rouger A, Senger-

Emonnot P, George G, Raharivelomanana P. 2016.

Volatile composition and sensory properties of Vanilla

×tahitensis bring new insights for vanilla quality

control. J Sci Food Agric. 96(3):848-858.

Brunschwig C, Senger-Emonnot P, Aubanel M-L, Pierrat

A, George G, Rochard S, Raharivelomanana P. 2012.

Odor-active compounds of Tahitian vanilla flavor.

Food Res Int. 46:148-157.

Cicchetti E, Chaintreau A. 2009. Quantitation of the main

constituents of vanilla by reverse phase HPLC and

ultra-high-pressure-liquid-chromatography with UV

detection: Method validation and performance

comparison. J Sep Sci. 32(17):3043-52.

Dignum MJW, Kerler J, Verpoorte R. 2002. Vanilla curing

under laboratory conditions. Food Chem. 79(2):165-71.

Gassenmeier K, Riesen B, Magyar B. 2008. Commercial

quality and analytical parameters of cured vanilla beans

2nd SIS 2019 - SEAFAST International Seminar

110

(Vanilla planifolia) from different origins from the

2006–2007 crop. Flavour Fragr J. 23:194-201.

Havkin-Frenkel D, Belanger F. 2011. Handbook of vanilla

science and technology. Willey-Blackwell. hlm 142-

148.

Medina J, Rodríguez G, García H, Rosado T, García M,

Robles V. 2009. Vanilla: post-harvest operations. Food

Agric Organ United Nations Publ. 2009:1-50.

Pardio VT, Mariezcurrena MD, Waliszewski KN, Sánchez

V, Janczur MK. 2009. Effects of killing conditions of

vanilla (Vanilla planifolia, Andrews) pods during the

curing process on aroma composition of pod ethanol

extract. Int. J. Food Sci. Technol. 44(12):2417-2423.

Pérez Silva A, Gunata Z, Lepoutre JP, Odoux E. 2011. New

insight on the genesis and fate of odor-active

compounds in vanilla beans (Vanilla planifolia G.

Jackson) during traditional curing. Food Res Int.

44(9):2930-2937.

Rao SR, Ravishankar GA. 2000. Vanila flavour: production

by conventional and biotechnological routes. J Sci

Food Agric. 80(3):289-304.

Sreedhar RV, Roohie K, Venkatachalam L, Narayan MS,

Bhagyalakshmi N. 2007. Specific pretreatments reduce

curing period of vanilla (Vanilla planifolia) beans. J.

Agric. Food Chem. 55:2947-2955.

Sostaric, T., Boyce, M.C., and Spickett, E.E. 2000.

Analysis of the volatile components in vanilla extracts

and flavorings by solid-phase microextraction and gas

chromatography. Jornal of Agricultural and Food

Chemistry. 48:5802–5807.

Takahashi M, Inai Y, Miyazawa N, Kurobayashi Y, Fujita

A. 2013a. Key odorants in cured Madagascar vanilla

beans (Vanilla planiforia) of differing bean quality.

Biosci. Biotechnol. Biochem.77(3):606-611.

Takahashi M, Inay Y, Miyazawa N, Kurobayashi Y, Fujita

A. 2013b. Identification of the Key Odorants in

Tahitian Cured Vanilla Beans (Vanilla tahitensis) by

GC-MS and an Aroma Extract Dilution Analysis.

Biosci. Biotechnol. Biochem. 77(3)601-5.

Tokoro K, Kawahara S, Amano A, Kanisawa T, Indo M.

1990. Glucosides in vanilla beans and changes of their

contents during maturation. Flavour science and

Technology. Besseire Y, Thomas AF. John Wiley &

Sons, Chichester, UK, pp. 73-76.

Van Dyk S, Holford P, Subedi P, Walsh K, Williams M,

McGlasson WB. 2014. Determining the harvest

maturity of vanilla beans. Sci Hortic (Amsterdam).

168:249-257.

Van Dyk S, McGlasson WB, Williams M, Gair C.2010.

Influence of curing procedures on sensory quality of

vanilla beans. Fruits. 65(6):387-399.

Zhang S, Mueller C. 2012. Comparative analysis of

volatiles in traditional cured Bourbon and Ugandan

vanilla bean (Vanilla planifolia) extracts. J Agric Food

Chem. 60(42):10433-10444.

The Effect of Bean Size and Curing Process on Aroma Profile and Vanillin/Glucovanillin Content of Indonesian Cured Vanilla Beans

111