Synthesis of Rhodinol Ester from Citronella Oil Reduction Product

Ali Nurdin*

1

and Retno Yunilawati

2

1

Pusat Teknologi Sumberdaya Energi dan Industri Kimia, Badan Pengkajian dan Penerapan Teknologi, Puspiptek Serpong,

Indonesia

2

Badan Penelitian dan Pengembangan Industri, Kementerian Perindustrian, Indonesia

Keywords: Rhodinol Ester, Reduction, Citronella Oil, Esterification

Abstract: Rhodinol is a mixture of citronellol and geraniol that can be esterified using organic acids into citronellol

esters and geraniol esters to generate a specific odour as fragrances. Rhodinol esters in this study were

synthesized from citronella oil by first reducing to convert the citronellal in citronella oil into citronellol.

Reduction was carried out using NaBH

4

in conditions with ethanol as a solvent and without a solvent and the

variation of mole ratio. Esterification of reduction product (rhodinol) was done to produce rhodinol ester.

Reduction citronellal in citronella oil was efficient without solvent in the mole ratio of citronellal and NaBH

4

1:1, and successfully converted citronellal to citronellol with the rhodinol total (citronellol and geraniol) was

65.85%. Esterification of rhodinol produced 69.69% rhodinol ester which contains 55.16 % citronellyl acetate

and 14.53% geranyl acetate.

1 INTRODUCTION

Citronella oil is one type of essential oil which widely

exported by Indonesia with a production of 700MT-

800MT (Dewan Atsiri Indonesia, 2017).Citronella oil

is an essential product to produce the basic

ingredients of perfume in perfumery, cosmetics,

soaps, and detergent. Citronella oil also has

characteristic as insect and mosquito repellent.

Citronella oil contains three main components

consisting of citronellal, citronellol, and geraniol

(Simic et al., 2008) (Wany et al., 2014) (Eden et al.,

2018). Citronellal (3,7-dimethyl-6-octenal) is a

monoterpene that with an aldehyde group and has an

important role in the synthesis of fine chemicals as

terpene derivatives (Lenardão et al., 2007).

Citronellol and geraniol are alcohol monoterpene and

the mixture of both is commonly named rhodinol.

Rhodinol was known to have a much finer and

flowery rose odour than citronellol.

Rhodinol can be converted into rhodinol ester to

generate a specific odour as the raw material in

fragrance. Geranyl acetate presents a sweet fruity

flavour and rose and lavender aroma (Murcia et al.,

2018). The synthesis of rhodinol ester was an effort

to derivatize citronella oil thus increase the added

value of citronella oil.

Synthesis of rhodinol ester in this experiment

was done in two steps. The first step was the reduction

of citronellal in citronella oil directly without

separation. The reduction reaction was done using

NaBH

4

. This step was converted citronellal into

citronellol with the aim of increase the rhodinol

(citronellol and geraniol) content. The second step

was esterification of rhodinol to produce rhodinol

ester (citronellyl acetate and geranyl acetate). This

experiment was interesting because of the reduction

reaction and the esterification reaction were done in

citronella oil directly. Some of the previous study was

done these process (Yu et al., 2000) (Yadav and

Lande, 2006).

2 MATERIALS AND METHODS

2.1 Materials

Citronella oil was used in this experiment obtained

from a small industry in Yogyakarta. The chemical

materials used in this experiment were natrium

borohydride (NaBH4) (Merck), ethanol technical

grade, hydrochloric acid (HCl) technical grade,

sodium hydroxide (NaOH) technical grade,

anhydrous acetic acid (Merck), and anhydrous

sodium sulphate (Na

2

SO

4

).

Nurdin, A. and Yunilawati, R.

Synthesis of Rhodinol Ester from Citronella Oil Reduction Product.

DOI: 10.5220/0009973101650169

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 165-169

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

165

2.2 Methods

2.2.1 Gas Chromatography Mass

Spectrometry Identification

The citronella oil and the product from the reaction

were identified by gas chromatography with a mass

spectrometer detector (GC-MS) Agilent 6890 series

with capillary column HP-5MS, 30 m x 0.25 mm id x

0.25 µm film thickness. Helium gas was used as the

carrier gas at a constant pressure of 65 kPa. The

sample was injected with a volume of 1 µL in a split

ratio of 1:25. The increasing of oven temperature was

programmed from 60-240°C with a step of 3°C per

minute until reaching 240°C.

2.2.2 Reduction of Citronella Oil

Reduction using Ethanol as the Solvent. The

reduction was carried out in round-bottomed flask

with reflux. The reaction contained NaBH

4

and

ethanol. NaBH

4

was dissolved with ethanol in flask

and the citronella oil was added with variation in the

mole ratio of the citronellal and NaBH

4

(1:1 and 1:3).

The reduction reaction was done at 78 °C for 3 hours.

The ethanol solvent was evaporated. The white solid

obtained from this reaction was diluted with water

and acidified with 20% HCl to pH reached 2, then

heated at 50°C for 1 hour. The reaction mixture was

extracted with ether, washed with water to neutral,

and dried with anhydrous Na2SO4. The product was

identified with GCMS.

Reduction without Solvent.

The reduction was

carried out in round-bottomed flask with reflux. The

citronella oil and NaBH

4

were added to the flask with

variation in a mole ratio of the citronellal and NaBH

4

(1:3; 1;1; 1: 0.5 and 1:0.025). The reduction reaction

was done for 3 hours at 150 °C. After completion, the

mixture was cooled, added H

2

O and stirred for half an

hour and added with the HCl 20% until pH reached 2.

The mixture was extracted with ether, washed with

water until neutral, and dried with anhydrous

Na2SO

4

. The product was identified with GCMS.

2.2.3 Esterification of Rhodinol

The optimum product reduction (rhodinol),

anhydrous acetic acid, and 5% of NaOH were

arranged in a round-bottomed flask with a mole ratio

of rhodinol and acetic acid was 1:3. The mixture was

stirred and heated at 180 °C for 3 hours. This was

followed by the neutralization with 1% of HCl

solution to separate it from the NaOH catalyst. The

rhodinol ester from this reaction was identified using

GCMS.

3 RESULTS AND DISCUSSION

3.1 Chemical Compounds Composition

of Citronella Oil

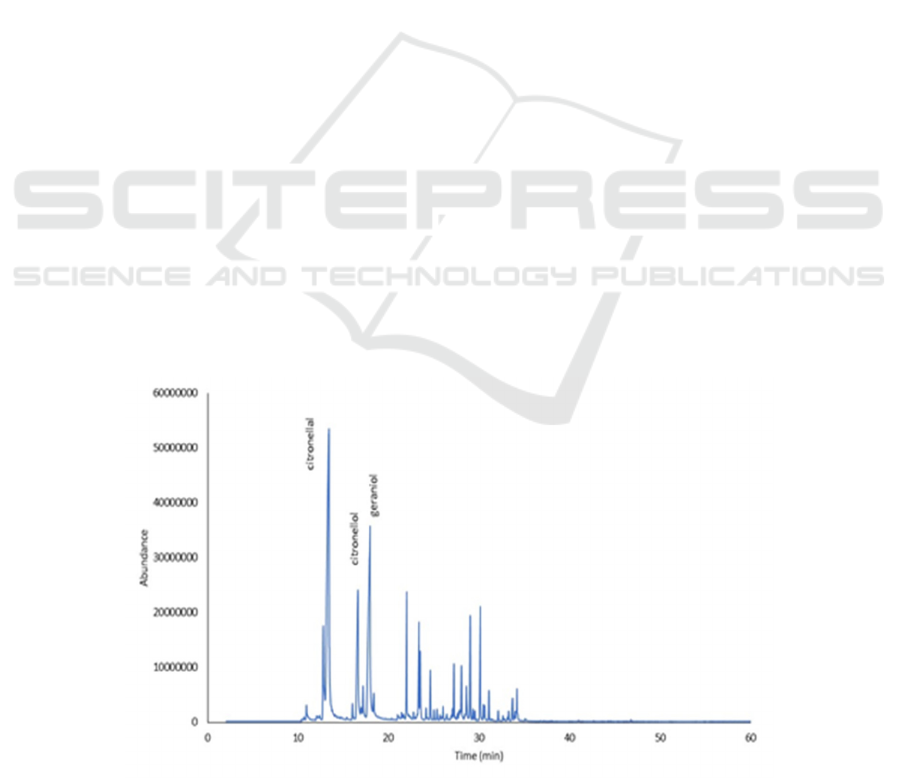

Characterization using GC-MS showed the

chromatogram profile detected several peaks in

citronella oil (Figure 1). The compounds identified

based on a comparison of the mass spectrum with

reference data from the database (Wiley 7) and the

results were presented in Table 1.

Figure 1: GCMS chromatogram of citronella oil.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

166

Table 1: Chemical compounds of citronella oil

No Retention time Identified compound Relative percentage area (%)

1 13.11 Citronellal

55.93

2 16.62 Citronellol

7.40

3 17.97 Geraniol

10.84

4 22.01 Citronellyl acetate

3.30

5 23.36 d-carene

2.27

6 23.51 β-elemene

2.59

7 24.61 Geranyl acetate

3.30

8 27.21 Germacrene

2.35

9 28.05 Methyl isoeugenol

2.28

10 29.04 d-cadinene

3.30

11 30.16 Elemol

4.29

The compounds were citronellal, citronellol,

geraniol, citronellyl acetate, d-carene, β-elemene,

geranyl acetate, d-cadinene, and elemol. The main

compounds in citronella were citronellal (55.93%),

geraniol (10.74%), and citronellol (7.40%. These

results appropriate with the previous finding in the

literature, citronellal, geraniol, and citronellol has

been described as the main compounds of citronella

oil (Simic et al., 2008) (Wany et al., 2014) (Eden et

al., 2018).

3.2 Reduction of Citronella Oil using

Ethanol as the Solvent

The reduction of citronellal to citronellol was carried

out using NaBH

4

with the reaction in Figure 2.

Borohydrides are very routinely used for selective

reduction in preparatory synthesis and also on a

commercial scale (Yadav and Lande, 2006). The

results of reducing citronellal to citronellol in

citronella oil was shown in Table 2.

Table 2. Reaction products of citronella oil reduction using

NaBH

4

with ethanol solvent.

Compounds Initial

Reduction product

in mole ratio citronellal

and NaBH

4

1:1 1:3

Citronellal 55.93 26.48 -

Citronellol 7.40 38.66 50,42

Based on Table 2, there was a change in the

amount of citronellal and citronellol at the end of the

reaction when compared to the initial amount, both at

a mole ratio of 1: 1 and 1: 3. This means that the

reaction under these conditions successfully reduced

citronellal to citronellol. In the 1: 3-mole ratio there

was no citronellal at the end of the reaction which

means that the citronellal has been converted

completely. However, in this condition, citronellal

was not completely converted into citronellol as

indicated by the amount of citronellol formed. The

imperfect citronellal reduction in this experiment was

predicted because of the ethanol solvent used.

Figure 2: Reduction of citronellal to citronellol

This experiment used technical ethanol which

still contains a lot of water thus there was NaBH

4

which reacted with water before reacting with

citronellal. The possibility of NaBH

4

reacting with

water was observed with the appearance of foam

when dissolving NaBH

4

in ethanol. So, the use of

solvents will require expensive costs because the

solvent must be free of water. For this reason, it is

necessary to try hydrogenation without ethanol as a

solvent.

3.3 Reduction without Solvent

Aldehyde reduction using NaBH

4

can be carried out

in the absence of a solvent (Zeynizadeh and Behyar,

2005). To improve the efficiency and effectiveness of

the reduction process, the citronella oil reduction

reaction was carried out with NaBH

4

without the use

of a solvent. The results of reducing citronellal to

citronellol without solvent were shown in Table 3 and

the GCMS chromatogram of reduction product were

described in Figure 3.

Synthesis of Rhodinol Ester from Citronella Oil Reduction Product

167

Figure 3: GCMS chromatogram of citronella oil reduction product

Figure 4. GCMS chromatogram of rhodinol ester

Table 3. Reaction products of citronella oil reduction using

NaBH

4

without solvent

Mole ratio of

citronellal

and NaBH

4

Citronellal Citronellol Geraniol

Initial 55.934 7.40 10.84

1 : 3 - 59.73 16.67

1 : 1 2,14 51.56 14.29

1 : 0,5 1,98 46.51 13.43

1 : 0,25 1,76 40.21 13.60

Table 3 showed that citronellal can be converted

into citronellol with NaBH

4

without the use of

solvents as indicated by decreasing levels of

citronellal and increasing levels of citronellol in

reaction products. In the variation of the mole ratio,

the higher the mole of NaBH

4

, the reduced citronellal

was higher. Citronellal was reduced completely at

1:3-mole ratios. The product contained 59.73%

citronellol and 16.67% geraniol so the amount of

rhodinol was 76.4%. Although optimal, this process

was inefficient because it required a large number of

moles of NaBH

4

. Therefore, for the next process used

rhodinol from the reduced mole ratio of 1: 1 because

need less NaBH4 and this was considered more

efficient. The rhodinol from this process contains

51.56% citronellol dan 14.29% geraniol with

rhodinol total was 65.85%.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

168

3.4 Esterification of Rhodinol

Esterification of rhodinol was conducted to obtained

rhodinol ester that has a specific smell. Geranyl

acetate presents a sweet fruity flavour and rose and

lavender aroma (Murcia et al., 2018). Rhodinol ester

(citronellyl acetate, geranyl acetate) can be isolated

by vacuum fractionation, but the availability of these

natural raw materials was limited. However, this

method was not suitable for large-scale industrial

production. For the alternative, these esters may be

produced by chemical synthesis and enzymatic

extraction or catalysis (bio catalysis) (Paroul et al.,

2012) (Wu et al., 2018) (Murcia et al., 2018).

Chemical synthesis was often performed using acetic

acid anhydride or direct acetic acid esterification (Jian

et al., 2014). This method was the traditional

chemical synthesis and commonly used in large-scale

industries. Rhodinol ester in this experiment was

synthesized using acetic acid.

Table 4. Rhodinol ester product from esterification

Compounds Rhodinol (%) Rhodinol ester

(%)

Citronellol 51.56 -

Geraniol 14.29 -

Citronellyl acetate 3.00 55.16

Geranyl acetate - 14.53

The GCMS analysis showed that all rhodinol

(citronellol and geraniol) have changed to rhodinol

acetate esters. This result was observed with the loss

of the rhodinol peak and the appearance of the

rhodinol acetate peak, as shown in Figure 4. The

complete data on the results of the experiment are

shown in Table 4.

4 CONCLUSIONS

Reduction citronellal in citronella oil was

successfully converted citronellal to citronellol with

the rhodinol total (citronellol and geraniol) was

65.85%. Esterification of rhodinol produced 69.69%

rhodinol ester which contains 55.16 % citronellyl

acetate and 14.53% geranyl acetate.

REFERENCES

Dewan Atsiri Indonesia (2017) ‘Indonesian Essential Oil

Output’.

Eden, W. T. et al. (2018) ‘Fractionation of Java Citronella

Oil and Citronellal Purification by Batch Vacuum

Fractional Distillation’, IOP Conference Series:

Materials Science and Engineering, 349(1). doi:

10.1088/1757-899X/349/1/012067.

Jian, X. et al. (2014) ‘Lipase-Catalyzed Transesterification

Synthesis of Geranyl Acetate in Organic Solvents and

Its Kinetics’, Food Science and Technology Research,

20(2), pp. 207–216. doi: 10.3136/fstr.20.207.

Lenardão, E. J. et al. (2007) ‘Citronellal as key compound

in organic synthesis’, Tetrahedron, 63(29), pp. 6671–

6712. doi: 10.1016/j.tet.2007.03.159.

Murcia, M. D. et al. (2018) ‘Kinetic modelling and kinetic

parameters calculation in the lipase-catalysed synthesis

of geranyl acetate’, Chemical Engineering Research

and Design. Institution of Chemical Engineers, 138, pp.

135–143. doi: 10.1016/j.cherd.2018.08.025.

Paroul, N. et al. (2012) ‘Solvent-free production of

bioflavors by enzymatic esterification of citronella

(Cymbopogon winterianus) essential oil’, Applied

Biochemistry and Biotechnology, 166(1), pp. 13–21.

doi: 10.1007/s12010-011-9399-4.

Simic, A. et al. (2008) ‘Essential oil composition of

Cymbopogon winterianus and Carum carvi and their

antimicrobial activities’, Pharmaceutical Biology,

46(6), pp. 437–441. doi: 10.1080/13880200802055917.

Wany, A. et al. (2014) ‘Extraction and characterization of

essential oil components based on geraniol and

citronellol from Java citronella (Cymbopogon

winterianus Jowitt)’, Plant Growth Regulation, 73(2),

pp. 133–145. doi: 10.1007/s10725-013-9875-7.

Wu, T. et al. (2018) ‘Engineering Saccharomyces

cerevisiae for the production of the valuable

monoterpene ester geranyl acetate’, Microbial Cell

Factories. BioMed Central, 17(1), pp. 1–11. doi:

10.1186/s12934-018-0930-y.

Yadav, G. D. and Lande, S. V (2006) ‘Novelties of kinetics

of chemoselective reduction of citronellal to citronellol

by sodium borohydride under liquid – liquid phase

transfer catalysis’, Journal of Molecular Catalysis A :

Chemical, 247, pp. 253–259. doi:

10.1016/j.molcata.2005.11.015.

Yu, W. et al. (2000) ‘Selective hydrogenation of citronellal

to citronellol over polymer-stabilized noble metal

colloids’, Reactive and Functional Polymers, 44(1), pp.

21–29. doi: 10.1016/S1381-5148(99)00073-5.

Zeynizadeh, B. and Behyar, T. (2005) ‘Fast and Efficient

Method for Reduction of Carbonyl Compounds with

NaBH 4 /Wet SiO 2 Under Solvent Free Condition’, J.

Braz.Chem.Soc., 16(6), pp. 1200–1209.

Synthesis of Rhodinol Ester from Citronella Oil Reduction Product

169