Improving ICC Profiles Color Management System Performance by

Testing CIELAB of Duplex Paper in Color Reproduction

Wiwi Prastiwinarti

1

, Saeful Imam

2

1,2

Politeknik Negeri Jakarta, Prof. Siwabessy Street.

Kampus Baru Universitas Indonesia, Depok, Indonesia

Keywords: ICC Profile, CIELAB, Duplex Paper, Color Difference

Abstract: Accurate color control is very important in order to have a predictable quality of final product. A Technique

is proposed for improving the color quality of digital color proof. This method investigates ICC Profile’s

performance by testing CIELAB (Commission Internationale de l’Eclairage L*, a* and b*) value of Duplex

paper. Firstly, ICC profile with color target ECI2002CMYK is sent to offset machine, and the corresponding

CIELAB and the E color difference are obtained by spectrophotometer with color sensor. Secondly, the

CIELAB of duplex paper are measured, and a new color target is developed to create ICC profile based on

CIELAB of duplex paper. At last. For the purpose of testing the accuracy of the obtained ICC profile, these

color target is sent to offset machine, and the color eror E is calculated. In the experiment the average color

difference of ICC profile ECI2002 CMYK is 4.78E and the average color difference of ICC profile‘s duplex

paper color is 3.15E which is below the printing error threshold and 2D- color gamut visualization of ICC

profile ECI2002 CMYK and duplex paper color describe that creating ICC profile with approach of CIELAB

duplex paper closely follow the data of ICC profile’s color ECI2002CMYK.

1 INTRODUCTION

Color consistency is very important in printing

quality. The problems in color reproduction is the

difference between input device and output device

color model and color gamut. However, the color

devices used in the workflow have different color-

mixing models and color gamuts, which makes the

goal of color reproduction hard to accomplished (Liu

et.al, 2007). The repeatable quality of colour

reproduction is a growing challenge for producers of

digital printing devices as well as for paper producers.

The properties of the printing substrate such as

whiteness, brightness, gloss, opacity, porosity, surface

roughness, etc., the colourants and the printing

technology in different combinations together are all

factors that influence the overall print quality. Paper

properties are one of the most important factors

affecting the completeness of the image transfer and

image appearance (Ivana et.al, 2013)

Digital color proof on PrePress is a color reference

before sending it to the offset or digital machine. The

color management on PrePress uses a Color

Management System (CMS) for input and output

verification. CMS relationship regarding the CIE

LAB color model standards. The ICC (International

Color Consortium) profile is the key to achieving the

CMS workflow. ICC profile color transformation

begins by transforming the input device color on the

CIELAB color standard model, then mapping the

color gamut (collection of colors) from the input

device to the output device on the CIELAB model,

then transforming the color from CIELAB to the

output device (Zhen Liu et.al, 2009; Jure Ahtik,

2017). The fact shows that the color of CMS

application’s was not consistance between original

and the reproduced product, even though the printing

process is in accordance with the machine calibration

requirements in making color standards.

From the side of paper, making color standards

uses only one type of paper, while the color standard

is used to print several types of paper, such as duplex

and ivory paper with different color characteristics. It

is predicted that this paper color difference is one of

the factors causing the difficulty of achieving print

colors that match the color proofing, even though

CMS has been applied. This paper proposes the

design of the ICC Profile with a paper color approach

that is through testing the color of printed paper LAB,

using duplex paper. The Plate is printed with

Prastiwinarti, W. and Imam, S.

Improving ICC Profiles Color Management System Performance by Testing CIELAB of Duplex Paper in Color Reproduction.

DOI: 10.5220/0009969400002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 149-152

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

149

ECI2002 color target, and send it to offset machine

using duplex paper; the former target is employed to

get sample data; the CIELAB and density of sample

data are measured. A New color target is developed

to modify the ICC profile digital color proof based on

CIELAB value of duplex paper. For the purpose of

testing the accuracy of the obtained digital color

proof, the color difference are calculated.

2 METHODOLOGY

2.1 CIELAB Color Space

Color may be described using more color systems

such as XYZ, RGB, CMYK, CIELAB, which

quantify in different manners the three attributes of

color perception: hue, saturation and luminosity. The

present paper shows the data referring to the color

measurements in the CIELAB system to study the

color of ICC profiles transformations.

2.2 Color Difference

For the purpose of testing the accuracy of the obtained

ICC profile, color difference is used to measure the

accuracy of ICC profile based on ECI2002CMYK

and CIELAB duplex paper. The Color difference E

is calculated depends on the color model. Because the

color stimulus can be represented as a point in space,

the difference in color ∆E between two stimuli is

calculated as the distance between the points

representing these stimuli. The CIEL*a*b* and ΔEab

was introduced by the International Commission on

Illumination (CIE) in 1976. Given two colors in the

CIEL*a*b* color space, (L

1

, a

1

, b

1

) and (L

2

, a

2

, b

2

),

the ΔEab formula is defined as:

ΔE = (L

1

- L

2

)

2

+ (a

1

- a

2

)

2

+ (b

1

- b

2

)

2

Where L

1

– the CIE L* value of reference color

a

1

– the CIE a* value of reference color

b

1

– the CIE b* value of reference color

L

2

– the CIE L* value of sample color

a

2

– the CIE a* value of sample color

b

2

– the CIE b* value of sample color.

2.3 Color Gamut

In color reproduction systems, color gamut refers to

the subset of colors which can be accurately

represented in a given circumstance, such as within a

given color image or by a certain color device. While

the gamut boundary means the outer surface of the 3D

gamut, or the outer contour line of the 2D gamut.

Color gamut is often described in CIELAB space; this

is mainly because CIELAB color spaces are

independent of devices (Bangyong Sun, et al., 2014).

In this research, In order to determine the range of

the reproducible color, the 2D color gamut is used to

show that range color of ICC profile duplex and ICC

profile standar ECI2002 CMYK.

3 RESULTS AND DISCUSSIONS

In the experiment, firstly, the color target ECI2002

CMYK which has 1485 patches for ICC profile is

printed out on a 190 gsm semiglossy paper 44 inch by

Epson Stylus 9700 printer, a kind of digital color

proof printer, and then the spectrometer X-rite 530 is

used to measure CIELAB values. Within the

measured results for 216 CMY sample data, the

maximal CIEL* value is 93.99 and the minimal

CIEL* value is 88.81, the maximal CIEa* value is -

0.56 and the minimal CIEa* value is -4.55, the

maximal CIEb* value is 92.95 and the minimal

CIEb* value is 5.56. Then these color target is sent to

offset machine to find out the ΔE color difference, the

results shows the everage error is 4.78ΔE with

maximal error 6.45ΔE.

Secondly, the CIELAB value of duplex paper with

250, 270, 310, 350, 400 gsm are measured on solid

color and 100% raster, and then the corresponding

CIELAB value are obtained by spectrophotometer

with color sensor. Between these CIELAB value, the

range of colors and tones achievable by an imaging

system of duplex color (the optimal value) of CIEL*

is 91.30, the minimum CIEL* value is 89.10, and the

maximum CIEL* value is 93.50. At last, these CIEL*

values are used to modify the ICC Profile with oris

color tuner before the color target is printed out. In

this process, 320 patches were randomly selected and

the CIELAB of the optimal, maximal, and minimal

value of color target are measured used

spectrophotometer. For the purpose of testing the

accuracy of achievable the range color between the

optimal, maximal, and minimal value, CIELAB of

these value are measured. The former target is

employed to compare the CIELAB optimal value and

CIELAB maximal value, and CIELAB optimal value

with CIELAB minimal value. If ΔE color difference

more than 3.5 then back to previous process to get ΔE

color difference less than 3.5. At last, The CIELAB

of maximal and minimal value are used to determine

the limit of CIELAB duplex paper. In this

experiment, the ΔE color difference between

ASAIS 2019 - Annual Southeast Asian International Seminar

150

CIELAB optimal value and CIELAB maximal is

2.97, and CIELAB optimal value and CIELAB

minimal is 2.78, and the duplex paper’s color target

optimal is used to create ICC profile and the

comparison between CIELAB of ICC profile with

color target ECI2002 CMYK and ICC profile with

duplex color modified in yellow color are obtained in

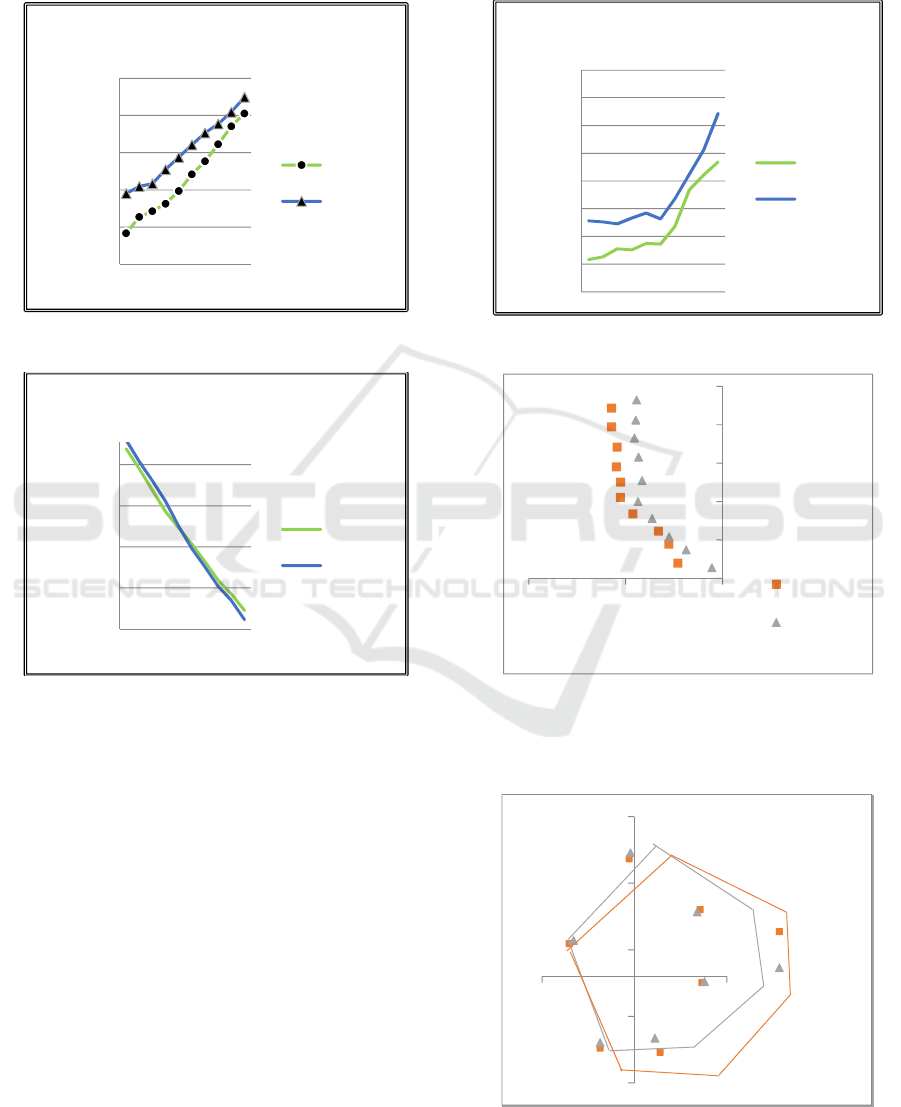

figure 1 to figure 3.

Figure 1: CIEL* of two ICC Profile

Figure 2: CIEa* of two ICC Profile

Figure 3: CIEa* of two ICC Profile

Figure 4: CIEa* and CIEb* ICC duplex and ICC standar

Figure 4 shows trend CIEa* and CIEb* of ICC profile

duplex and ICC profile with ECI2002 CMYK which

is duplex profile tend to a- (green) and b- (blue) and

ICC profile ECI2002CMYK tend to a- (green) dan b+

(yellow).

To test the accuracy of predictable color quality of

final product, ICC profile’s color reference of digital

color proof send to offset machine and compare the

ΔE color difference between the former data of ICC

profile with color target ECI2002 CMYK and ICC

profile based on the color of duplex paper. For all

testing color, the average error is 3.15 ΔE with the

maximal error 5.25 ΔE. Because for most of the

printing process, the average error threshold is 5 ΔE,

the experiment results is acceptable which indicate

the approach of color paper is suitable to create ICC

profile. In order to determine the range of the

reproducible color, the color gamut is obtained in

figure 5 below.

Figure 5: color gamut of ICC standar and ICC duplex

85

87

89

91

93

95

10

30

50

70

90

Lightness (L*)

Lightness (L*)yellow

Duplex

standar

‐7

‐6

‐5

‐4

‐3

‐2

‐1

0

1

10 30 50 70 90

chromatictya*

Kordinata*yellow

Duplex

standar

1

21

41

61

81

10

30

50

70

90

chromatictyb*

Kordinatb*yellow

Duplex

standar

0

20

40

60

80

100

‐10 ‐50

Kordinatb*

kordinata*

duplex

standar

‐80

‐30

20

70

120

‐100 0 100

duplex

standar

y

R

M

B

C

G

Improving ICC Profiles Color Management System Performance by Testing CIELAB of Duplex Paper in Color Reproduction

151

Figure 5 shows that range color of ICC profile duplex

and ICC profile standar ECI2002 CMYK are

different, Color gamut of duplex paper tend to a+

(red) and b- (blue), and it is follow the data of

CIELAB duplex paper.

4 CONCLUSIONS

A technic of create ICC profile by applying the

CIELAB of paper color has been proposed and the

approach of color paper is suitable to create ICC

profile. Results shows the accuracy is acceptable. To

achieve the visualization and parametric description

of color gamut is very significant for the accurate

evaluation of color gamut performance and

capabilities on color output device.

ACKNOWLEDGEMENTS

This works is supported Center for Research and

Community Service Politeknik Negeri Jakarta, and

Printing and Publishing Department of Politeknik

Negeri Jakarta.

REFERENCES

Ahtik, Jure. 2017. Comparison of ICC and DNG Colour

Profile Workflows Based on Colorimetric Accuracy.

Journal of Print and Media Technology

Research.6(2017)3.pp 115-121.

Bangyong Sun, Shisheng Zhou. 2012 Study on the 3D

Interpolation Models Used in Color Conversion.

ACSIT International Journal of Engineering and

Technology, Vol. 4, No. 1, February.

Bangyong Sun, et.al. 2014. Calculating Cyan-Magenta-

Yellow-Black (CMYK) Printer Gray Component Data

Based On Polynomial Modelling. Academic Journal.

Vol. 9 No. 9. Pp 352-356.

Bangyong Sun, et.al. 2014. A Color Gamut Description

Algorithm for Liquid Crystal Displays din CIELAB

Space.The Scientific World Journal Volume 2014,

article IC 671964.

Chuan, Zhi. Chuan, Shi Yi, and Sun Bangyong. 2016.

Research on Gamut Visualization Method of the Color

Output Device. Journal of Display Technology Vol. 12

No. 5

CIE. 2018. CIE 15:2018. Colorimetry. Vienna: CIE. DOI:

10.25039/TR.015.2018

Durmus, Dorukalp. 2019. Evaluation of Hue Shift Formula

in CIELAB and CAM02. Proceedings of the 29th CIE

SESSION Washington D.C., USA, June 14 – 22.

Juric Ivana, et. al. 2013. Optical paper properties and their

influence on colour reproduction and perceived print

quality. Nordic Pulp & Paper Research Journal Vol

28 no. 2.

Kamenov, 2018.Research on The Capabilities of Color

Toner Based Printer for Quality Printing Using Custom

Generated ICC Color Profiles. International Scientific

Journal Industry 4.0. ISSN 2534-997X. pp. 39-42.

Lin, Maohai. et.al. 2009. Quality Analysis in Digital

Printing Based on Color Management System.

Intenational Journal of Engineering and Technology

Vol 1 No.2.

Liu Zhen, et.al. 2009. The Research on Mechanism of Color

Management System based on iCAM Color Appearance

Model. Computer and Mathematics with Applications

57 (2009) pp 1829–1834.

Oulton, David. 2013, Technology for Colour Management.

Proceedings of the 1st International Conference on

Digital Technologies for the Textile Industries

Manchester, UK.

R H Liu, P Zeng, and Y F Wang. “A color calibration

method of printer using adaptive regression,”.Acta

Electronica Sinica, 2007, vol. 35, no.11, pp. 2201-

2204.

Sardjeva, Rossitza. 2014. Study of Color Quality

Uniformity in Digital Dry Toner Electro-photographic

Printing. International Journal of Modern

Communication Technologies & Research (IJMCTR)

ISSN: 2321-0850, Volume-2.

Singh, Nishan. et.al. 2017. Color Control in Sheet-Fed

Offset Printing Presses Using Mellow Colour

Management System. International Journal of

Enggineering Sciences & Research. ISSN: 2277-9655

Zhao, Lei. 2016. Study on the Gamut Mapping Method

Based on BP Neural Network. Journal of Computers

Vol. 27, No. 3, pp. 149-162.

ASAIS 2019 - Annual Southeast Asian International Seminar

152