Variation of Soaking Time on Asphalt Concrete Properties using

Anti Stripping Materials

Anni Susilowati

1

, Eko Wiyono

1

, Pratikto

1

, Roihans M. I.

1

1

Department of Civil Engineering, State Polytechnic of Jakarta, Jln. Prof. Dr. G. A. Siwabessy, Depok , Indonesia

Keywords: Wetfixbe, Soaking time, Marshall property

Abstract: The purposes of this study were to obtain Marshall property values and determine the optimum submersion

time in AC-WC asphalt concrete mixture using anti-stripping added ingredients. Marshall specimens were

made with an optimum asphalt content of 6%, wetfixbe content of 0.3% to asphalt and each was made with

a variation of submersion time 3, 6, 9, 12, 15, 18, 21, 24, 36 and 48 hours. The method of implementation is

by mixing the wetfixBe first with asphalt, then aggregate according to the proportion of the ideal gradation

of the mixture. Marshall testing method based on SNI 06-2489-1991. The results of the study found that the

addition of submersion time can increase the percent value of Void Filled with Bitumen (VFB) and flow and

reduce the percent of Void in Mix (VIM), percent of Void in the Mineral Aggregate (VMA), Stability, and

Marshall Quotient. The submersion period that still meets Marshall property is at the soaking time of 3 to 45

hours. The Optimum Soaking Time for asphalt concrete mix is 24 hours, with VMA value 17,80%, VFB

74,04%, VIM 4,63%, Stability 1071.76 kg, flow 3.25 mm and MQ 360 kg / mm, asphalt concrete mixture

meets Bina Marga 2018 specifications.

1 INTRODUCTION

Water is one of the factors causing road damage,

both from rainwater and water from the road

drainage system. Submerging asphalt concrete mix

can cause the release of aggregate granules from

asphalt and peeling off asphalt from road pavement,

according to (Djalante, 2011) that one of the most

important aspects in highway planning is the effort

to protect roads from water. According to

(Nurhuduyah, 2009) that the effects of continuous

immersion damage are faster than ordinary

immersion. Soak the asphalt mixture Hot Rolled

Sheet-Wearing Course (HRS-WC) either

continuously or periodically in high tide has a

greater effect than the use of laboratory water. To

increase the bond between the aggregate and asphalt

by adding anti-peeling additives or more commonly

known as the anti-stripping agent.

Moisture susceptibility is the tendency towards

the peeling of asphalt mixtures. Exfoliation usually

starts at the bottom of the asphalt mixture layer and

usually moves upward. That situation is a gradual

loss of power over the years, which causes many to

arise on the surface such as grooves, folds, waves,

raveling, cracking, etc. (Krebs and Walker,1971). In

specification ( Bina Marga, 2018), stickiness and

anti-stripping agent must be added in liquid form to

the mixture.

Werfix BE is an anti-chemical stripping that

useful for improving bonding and stabilizing the

mixture between aggregate and asphalt, especially in

the rainy season as a result of research (Susilowati

and Wiyono, 2015).

The quality of asphalt concrete mixes in the field

is influenced by the process of making mixtures in

the laboratory or Asphalt Mixing Plant (AMP),

laying and compaction in the field. To get the

characteristics of asphalt concrete mixture and its

effect on water immersion, testing is done using a

device Marshall, by settling the specimen first

before removing it from the mold and then settling it

for approximately 24 hours at room temperature.

Then measure thickness, weight, and immerse

the test specimen in the water at room temperature

for 24 hours. According to (Amal, 2009) that

immersion variation of 2 to 72 hours is very

influential on the nature of the mixture Marshall and

the plastic melt value, it is necessary to add

materials that can be used as an asphalt concrete

mixture, so that the asphalt concrete mixture is

resistant or waterproof.

132

Susilowati, A., Wiyono, E., Pratikto, . and M. I., R.

Variation of Soaking Time on Asphalt Concrete Properties using Anti Stripping Materials.

DOI: 10.5220/0009967900002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 132-137

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Some previous studies that support this research

include research by (Nurhuduyah, 2009) This is

indicated by the durability value of the asphalt

mixture in the immersion with low tide compared to

the asphalt mixture immersed in laboratory standard

water. According to (Arifin et all, 2008), Decreased

mixed performance due to the influence of rainwater

content on the characteristics of the Marshall Laston

mixture. From the results of these experimental

studies, it has been concluded that in general the

characteristics of the Marshall Laston mix have

decreased with increasing rainwater content. This

research (Sanusi, 2012) used an experimental

method on a mixture of laston with optimum asphalt

content of 6% of the total weight of the aggregate

levels filler Replacement used vary from 4%, 5%,

6%, 7%, 7.91% to the total weight of aggregates

with immersion for durability testing: 30 minutes (0

days), 1 day, 7 days and 14 days. The results showed

the greatest stability was a mixture with a filler

cement then carbide waste with an immersion of 14

days. According to (Kosim, 2013), The results of all

the LASTON mixtures obtained showed that the use

of the addition of a proportion additive filler cement

of 4% to the concrete asphalt mixture would

increase the stability of the mixture, with long

immersion in water for 3 days. By using the

proportion of adding an additive filler cement of 4%

to the asphalt concrete mixture, a pavement material

will be obtained which can withstand heavy traffic

loads, during the service life of the road. (Fauziah

and Handaka, 2017), that the effect of rainwater on

characteristics Marshall and the durability of the

mixture Split Mastic Asphalt, using two types of

asphalt as binding material, namely Starbit E-55

asphalt, and AC 60/70 asphalt is that the longer the

rainwater immersion time the mixed stability value,

Marshall Quotient and the value of the index of

retained strength decreases and the value of melt

increases. SMA mixes that use Starbit E-55 asphalt

bonding materials can maintain performance

Marshall and durability due to better rainwater

compared to SMA mixes with AC 60/70 asphalt

binding materials. The stability of fly ash and stone

dust tends to decrease after 72 hours of soaking,

with an even more drastic decrease in fly ash.

Whereas Portland Cement shows the inverse.

Portland cement as aggregate filler showed

improvement along with the increase in immersion

time (Latifah, et all, 2012). According to (Pratama

and Fauziah, 2017) The Longer immersion in

Aspalht Porous Based Buton Granular Asphalt

(BGA) can increase the value of VIM, VFB, Flow

and reduce VMA, stability and Marshall Quetient.

The longer time immersion of seawater can decrease

the durability index values of asphalt concrete with

and without substitution EVA waste (Rahmi, et all,

2017). According to (Angga, 2016), That the

retained strength as well as tensile strength of

mixtures with Retona were obtained better in each

duration of seawater immersion than those with

asphalt pen 60/70. According to (Rizal, et all, 2017),

the influence of the LTOA process on the porous

asphalt with BGA and without BGA showed that the

performance of porous asphalt with 2.5% BGA

super passed the mixture without BGA.

This study aims to obtain the property values

Marshall of AC-WC asphalt concrete mixtures in

the variation of immersion time and determine the

optimum immersion time by using anti-added

ingredients stripping that meet the specifications

(Bina Marga, 2018).

2 RESEARCH METHOD

The research method is an experimental method by

making hot mix asphalt concrete specimens, with

0.6% asphalt content, Wetfixbe content 0.3% of the

weight of asphalt.

This research was conducted at the Civil

Engineering Test Material Laboratory, State

Polytechnic of Jakarta.

The materials used in this study are Esso asphalt,

the coarse aggregate of crushed stone, stone ash and

filler of portland cement and anti-Stripping Wetfix

Be. Hot asphalt concrete mixed specimens with

immersion time variation of 3, 6, 9, 12, 15, 18, 21,

24, 36 and 48 hours. Each variation was tested 3

(three) times. Then the test is performed Marshall to

get the VMA, VFB, VIM, Stability, Meltability, and

Marshall Quotient (MQ) values. The stages in this

study can be illustrated with the flow chart as

follows

3 RESULT AND DISCUSSION

The Results of Aggregate and Asphalt Tests of

physical aggregate, both for fine aggregates and

coarse aggregates all meet the Specifications [4].

Test results with a density greater than 2.5

indicate that aggregates can be used for roads with

high traffic volume. The results of the physical

properties of aggregate are presented in Table 1.

Variation of Soaking Time on Asphalt Concrete Properties using Anti Stripping Materials

133

Table 1. Fine and Coarse Aggregate Test Result

Tests Results ofTesting

Requirement

Bina Marga

2018

Fine Aggr

Coarse

Aggr

Min Max

-Bulk Specific Gravity 2.57 2.56 2.5 -

-SSD Specific Gravity 2.61 2.61 2.5 -

-Apparent Specific

Gravity

2.68 2.70 2.5

-Water Absorption(%) 1.59 2.15 - 3

As for the Physical Examination Results, of

Asphalt with WetfixBe all of them meet

Specifications [4]. According to the test results, that

asphalt is included in the group with Penetration of

60/70 and a minimum of 48

0

C softening points;

suitable for roads with high traffic volume. The

results of physical asphalt examinations in Table 2.

Table 2. Hard Asphalt Test Results

Testing

Results

of

Testing

Requirement

Bina Marga 2018

Min Max

Penetration(mm) 65 60 70

Specific Gravity 1.02 0.92 1.06

Softening Point

O

C

48.5 45 -

Ductility(mm) 101 100 -

3.1 Planning Mixed Marshall Test

Object

Calculation of proportion of mixture using rough

aggregate passes 19 mm size filter and retained on

the 4.75 mm filter and used as fine aggregate is

stone ash which passes the 4.75 mm filter size and

retained on the 0.075 mm filter size. The filler used

by cement passes 0.075 mm sieve more than 75%.

Figure 1. Combined Aggregate Gradation Graph

Determination of Asphalt Level Variation is

done by calculating the initial estimate of the asphalt

level of the plan (Pb). Estimated asphalt content is

obtained from the following result.

Pb=[0.035 (% CA) + 0.045 (% FA) + 0.18 (% F)] +k

= [0.035 (40.7%) + 0.045 (52.6%) + 0.18 (6.7%)] x

0.75 = 5.99% ≈ 6%

Estimated ideal asphalt levels obtained from

calculation 5, 99%, used for making test specimens

with added wetfixbe 0.3%.

3.2 Marshall Test Results

Marshall test results for the variation of immersion

time at KAO 6.0%, and Wetfix Be 0.3%,

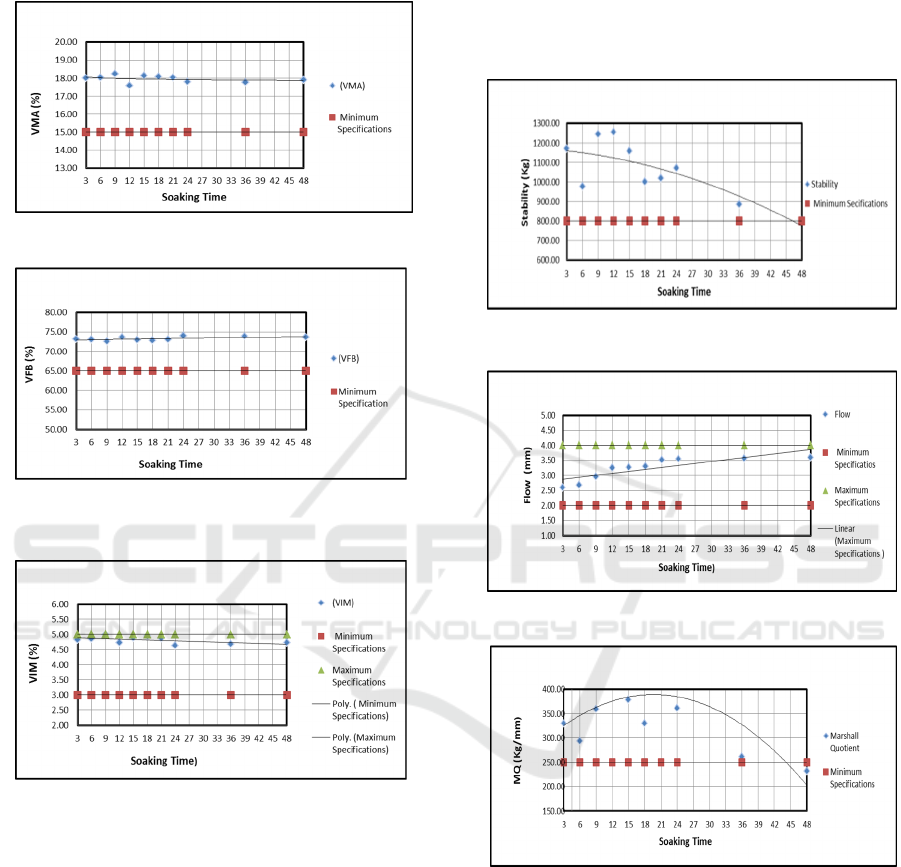

recapitulation is presented in Figure 3a to 3f.

a. Percentage of Voids in Mineral

Aggregate (VMA)

Based on the results of statistical tests it was found

that the immersion time had less effect on VMA.

This is indicated by the F value and the significant

value> 0.05 and the R-square value of 0.164, which

means that the variation of immersion time has an

effect of 16.4% on VMA. The result of the test also

shows that VMA value tends to decrease with

increasing immersion time, although the decrease is

small. The average VMA values obtained from the

test results are: 17.99%, 18.02%, 18.23%, 17.58%,

18.12%, 18.12%, 18.08%, 18.03%, 17.80%, 17.77%

and 17.90%. The specification of the VMA value

required by Bina Marga 2018 is at least 15% so that

the results of the overall VMA value test meet the

required specifications. (As in Figure 2a)

b. Percentage of Voids Filled with Bitumen

(VFB)

Based on the results of statistical tests it was found

that the immersion time did not affect VFB. This can

be seen from the R square value of 0.409 which

means that the variation of immersion time has an

effect of 40.9% on VFB. The test results also

showed that the VFB value increased according to

the addition of variations in the immersion time. all

results obtained from testing meet the 2018 Bina

Marga specifications of at least 65%. (As in Figure

2b).

c. Percentage of Voids in Mix (VIM)

Based on the results of statistical tests it was found

that immersion time affects VIM. This can be seen

from the R square value of 0.422 which means that

the variation of immersion time has an effect of

42.2% on VIM. The smaller the pore is left the more

water-resistant and the less air in the asphalt

concrete which results in a stronger asphalt film

oxidizes with air and becomes brittle. VIM value

still meets the requirements according to 2018 Bina

ASAIS 2019 - Annual Southeast Asian International Seminar

134

Marga specifications, namely 3.0 - 5.0% (As in

Figure 2c).

Figure 2a. VMA Graph

Figure 2b. VFB Graph

Figure 2c. VIM Graph

d. Stability

Based on the results of statistical tests indicate that

immersion time has a significant effect on stability.

This can be seen from the R-square value of 0.606

which means that the variation of immersion time

has an effect of 60.6% on stability. The test results

show that the value of stability obtained tends to

decrease. The average stability values obtained from

the test results on the variation of each immersion

time are: 1170.77; 975.23; 1245.03; 1254.93;

1158.39; 998.74; 1017,31; 1071.76; 884.88; 800.73

kg. The test results on the variation of immersion

time of 3 hours to 45 hours still meet specifications

(Bina Marga, 2018). The decrease in the value of

stability indicates a decrease in the ability of the

pavement layer (AC-WC) in receiving traffic loads.

The longer the layer of pavement (AC-WC) is

submerged in water, the less durable it is. (As in

Figure 2d)

Figure 2d. Stability Graph

Figure 2e. Flow Graph

Figure 2f. MQ Graph

e. Flow

Based on the results of statistical tests indicate that

the immersion time affects the melt. This can be

seen from the R square value of 0.523 which means

that the variation of the immersion time of 3 to 48

hours has an effect of 52.3% on the melt. the test

results show that the value flows with the addition of

soaking time up and down. The value flow still

meets the requirements according to the 2018 Bina

Marga specifications, namely 2-4 mm is at the time

Variation of Soaking Time on Asphalt Concrete Properties using Anti Stripping Materials

135

of immersion of 3 hours to 48 hours. (As in Figure

2e).

f. Marshall Quotient

Based on the results of statistical analysis showed

that the soaking time affects the Marshall Quotient.

This can be seen from the R square value of 0.586,

which means that the variation of immersion time

has an effect of 58.6% on Marshall Quotient. The

Marshall Quotient (MQ) value rises to a certain

extent then decreases with increasing immersion

time starting from 3 Hours to 48 Hours. The MQ

value that meets the requirements according to the

2018 Bina Marga specifications, namely a minimum

of 250 kg / mm, is at the time of immersion of 3 to

45 hours. (As in Figure 2f).

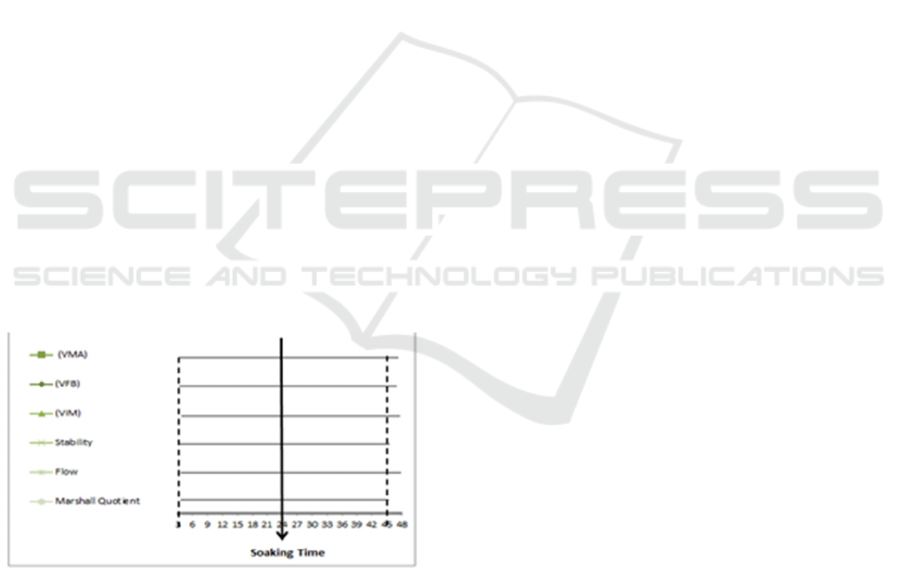

Determination of the Optimum Immersion Time,

after all Asphalt concrete properties have been

known, then the Optimum Immersion Time can be

determined from this Marshall test. To obtain the

Optimum Immersion Time a marshall chart is made

in Figure 3.

Mixed characteristic values generated in the test

Marshall in Figure 4. All parameters Marshall that

meet the requirements are in the Immersion Time

range 3 to 45 hours. From these results, it can be

concluded that:

Optimum Soaking Time = {(3 + 45}: 2 = 24;

Then Optimum Soaking Time is 24 Hours.

Table 3. Results of Mechanical Properties by Using

Optimum Soaking Time

Figure 3. Determining the Optimum Soaking

From the results of the Time Chart

4 CONCLUSION

Statistical test results show that:

Based on the research by making hot mix asphaltic

concrete specimens, with 0.6% asphalt content,

Wetfixbe content 0.3% of the weight of asphalt, with

the various of immersion time, it can be concluded.

Variation of immersion time from 3 hours to 48

hours affects significant to VFB, VIM, Stability,

Flow, and Marshall Quotient values but has less

effect on the VMA value because of the significant

value >0.05.

The addition of immersion time can increase the

% of Voids Filled with Bitumen (VFB) and Flow

and reduce the % of Voids in Mix (VIM), Voids in

Mineral Aggregate (VMA), Stability, and Marshall

Quotient.

The immersion time that still meets Marshall

property is the time of soaking 3 to 45 hours. The

Optimum Soaking Time for asphalt concrete mix is

24 hours, with VMA value 18.06%, VFB 72.29%,

VIM 5.03%, Stability 1071.76 kg, flow 3.25 mm and

MQ 360 kg / mm.

The variation of soaking time on Asphalt

concrete with 24 hours meets the specifications of

Bina Marga 2018.

ACKNOWLEDGMENTS

On this occasion the authors would like to express

their deepest gratitude to all those who have helped

this research, especially to the Head of PPPM State

Polytechnic of Jakarta, who has distributed funds

from the State Polytechnic of Jakarta DIPA.

REFERENCES

Amal, Andi S. 2009. Variations of Soaking in Asphalt

Concrete Mixes on Marshall Stability Values,

GAMMA, Volume IV, Number 2, March 2009: 81-85.

[Internet]. Available at: ejournal.umm.ac.id

Angga, Baskara K. M. at all.2016. Analysis Retained

Stablitty Index of Asphalt Porous Based Buton

Granular Asphalt (BGA). 2016.

http://repository.unhas.ac.id/bitstream/handle/1234567

89/21508/jurnal.docx?sequence=1

Arifin, Z., Jakfar, L., and Martina, G. 2008. Effect of

Rainwater Content on Marshall Characteristic Values

and Residual Strength Index (IKS) of Concrete

Asphalt Layers ( Laston). Journal of Civil

Engineering, 2 (1): 39-45. [Internet]. Available at:

http: //www.academia.edu/…Disses.

Djalante, S. 2011. Effect of Asphalt Concrete Resilience

(AC-BC) Using Asbuton Grain Type 5/20 on Sea

Water Judging from Mechanical Characteristics and

Durability. Journal of Transportation Engineering and

Management, I: (1): 57-68. [Internet]. Available at

http://jurnal.untad.ac.id/jurnal/index.php/JRMT/article

/view/713 Accessed March 29, 2018.

ASAIS 2019 - Annual Southeast Asian International Seminar

136

Fauziah M., Handaka A. 2017. of Starbit E-55 Asphalt to

Withstand Declining in Split Mastic Asphalt

Utilization Performance Due to Rainwater Immersion

Mixture of Transportation Journal Vol. 17 No. April 1,

2017: 11-20. [Internet]. Available at e-journal.

unpar.ac.id/index.php/journaltransportasi/article/

Accessed March 29, 2018.

General Specifications of Bina Marga Division 6, 2018,

Asphalt Pavement, Directorate General of Highways.

Kosim, Zainuddin. 2013. The Effect of Addition of

Cement Filler and Water Immersion Time on the

Durability of Concrete Asphalt Layer (Laston)

http://download.portalgaruda.org/article.php?article=1

55293&val=4006&title=PARUH%20PAMAMASI%2

0FILL. Accessed 2 April 2018.

Latifa, E.A. et all 2012. Performance of Hotmix Asphaltic

Concre with Various Filler Affected by Flood.

Proceeding of Annual SOUTH East Asian

International Seminar (ASAIS) 2012. I: (l): 51-57.

Nurhuduyah, N., Dato, AK, and Parung, H. 2009. Study of

Water Puddles on Road Damage in Gorontalo City.

Symposium XII FSTPT. Petra Christian University

Surabaya, 14 November 2009.

Pratama, B.A., Fauziah. 2017. Comparison of the

performance of a hot rolled asphalt (HRA) mixture

with 60/70 pen asphalt and retona blend 55 asphalt

with varying duration of sea water immersion.

Teknisia Journal.Vol XXII, No. Mei 1, 2017:324-333.

Rahmi Rizal, et all. 2017. Pengaruh Lama Rendaman AIR

Laut terhadap Durabilitas Campuran Aspal Beton

menggunakan Aspal Pen 50/70 yang disubstitusi

Limbah Ethylene Vinyl Acetate (EVA). Teknik Sipil

Journal University Syiah Kuala. Vol. 6. No. Mei 3,

2017: 271-282. http://journal.

Unsyah.ac.id/JTS/article/download/9843/7803.

Rizal, M. et all (2017). Performance Of Porous Asphalt

Affected By Aging Process. International Journal of

Civil Engineering and Technology (IJCIET) . Vol. 8.

Issue 6.June 2017,pp.1023-

1033.www.iaeme.com>IJCIET_08_06_111>

Robert D. Krebs and Richard D Walker. 1971. Highway

Materials. McGraw Hill Inc.

Sanusi, 2012. Durability of Concrete Asphalt Mixtures

using Portland Cement Filler, Carbide Waste and Coal

Waste, https://digilib.uns.ac.id/. .. = / Durability-mix-

asphalt-concrete-using-filler-se; Accessed March 29,

2018.http://journal.uii.teknisia/article/download/8290/

7971.

Susilowati, Anni and Wiyono, Eko (2015), Use of Anti-

Stripping Materials for Asphalt Concrete Mixtures,

Poly-Technology Journal, Vol 16, No 1 (2017).

[Internet]; Available at journal.

pnj.ac.id/index.php/politeknologi/article/viewFile/871/

562 Journal. Accessed 2 April 2018.

Variation of Soaking Time on Asphalt Concrete Properties using Anti Stripping Materials

137