Eugenol Production from Clove Oil in Pilot Plant Scale for Small and

Medium Enterprises (SME)

Ali Nurdin

1

1

Pusat Teknologi Sumberdaya Energi dan Industri Kimia, Badan Pengkajian dan Penerapan Teknologi, Puspiptek Serpong,

Indonesia

Keywords: Eugenol, Saponification, Distillation, Pilot Plant Scale

Abstract: Clove oil was the largest essential oil commodity in Indonesia and production at Small and Medium

Enterprises (SME) was still below the standard quality due to low eugenol levels (70-80%). The eugenol level

can be increased by isolation which generally can be carried out by saponification and neutralization methods.

This method was the most widely used, inexpensive, and easy to scale-up from the laboratory scale to the

pilot plant scale. In this research, the production of eugenol from clove oil has been carried out in a pilot plant

scale with stages of saponification reaction using sodium hydroxide and neutralization using sulfuric acid

followed by vacuum distillation. All stages of this process produce eugenol with a yield of 50.25%, and an

increase in eugenol levels from 75% to 98%. The eugenol production technology that has been carried out

was expected to provide a solution for the small clove oil industry to improve its quality.

1 INTRODUCTION

Indonesia is one of the major Asian producers of

clove besides India, Malaysia and Sri Lanka

(Kamatou, et al., 2012). Clove oil production in

Indonesia reached 2500 MT – 3000 MT (Dewan

Atsiri Indonesia, 2017). Most of the clove oil is

produced in some small industries (Industri Kecil dan

Menengah/IKM). There are several types of clove oil,

namely clove bud oil, clove stem oil, and clove leaf

oil (Anonim, 2013), but the most is clove leaf oil.

Clove oil consists of a mixture of a different

compounds, with the main compound being eugenol,

eugenyl acetate, and caryophyllene. The quality of

clove oil is determined by eugenol. Eugenol is a

phenolic compound, which is weakly acidic, slightly

soluble in water and soluble in organic solvents

(Kamatou, et al., 2012). Eugenol has many roles both

in flavor, fragrance, and pharmacology. Standar

Nasional Indonesia (SNI) requires minimum eugenol

content in clove oil is 78% (v/v) (Badan Standardisasi

Nasional, 2006). Clove leaf oil from the distillation of

farmers (small industries) generally has not been able

to fulfill this requirement, and this is still become the

problem for small clove oil industries (Widayat and

Hardiyanto, 2016). The eugenol content in clove leaf

oil is influenced by various factors such as soil type,

distillation time, type of plant, and equipment of

distillation. Therefore further processes are needed to

improve eugenol content (Sastrohamidjojo and

Fariyatun, 2016)

There are some methods can be used on the

isolation of eugenol in order to increase eugenol

contents. The most common method for eugenol

isolation is saponification-distillation. Several

methods have been modified to get more efficient as

compared to the traditional method, like microwave-

assisted extraction (Kapadiya, et al., 2018),

supercritical carbon dioxide extraction (Cassiana et

al., 2019), ultra-sound assisted extraction (Khalil et

al., 2017), and polymeric membrane technology

(Kusworo, 2018)

The eugenol isolation method that can be applied

to small industries (IKM) by considering the

availability of equipment, a simple production

method and energy-efficient is the saponification-

distillation method. In this research, eugenol isolation

from clove leaf oil using saponification-distillation

method was studied in the pilot plant scale. Clove leaf

oil was saponified with sodium hydroxide and

neutralized with sulfuric acid followed by separation

using distillation. The result obtained from this

research would be beneficial for the IKM

applicability to give simple method on eugenol

production.

Nurdin, A.

Eugenol Production from Clove Oil in Pilot Plant Scale for Small and Medium Enterprises (SME).

DOI: 10.5220/0009957501010105

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 101-105

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

101

2 MATERIALS AND METHODS

2.1 Materials

The clove leaf oil (CLO) from small industry in Jawa

Timur, sodium hydroxide (NaOH) technical grade,

and sulfuric acid (H

2

SO

4

) technical grade.

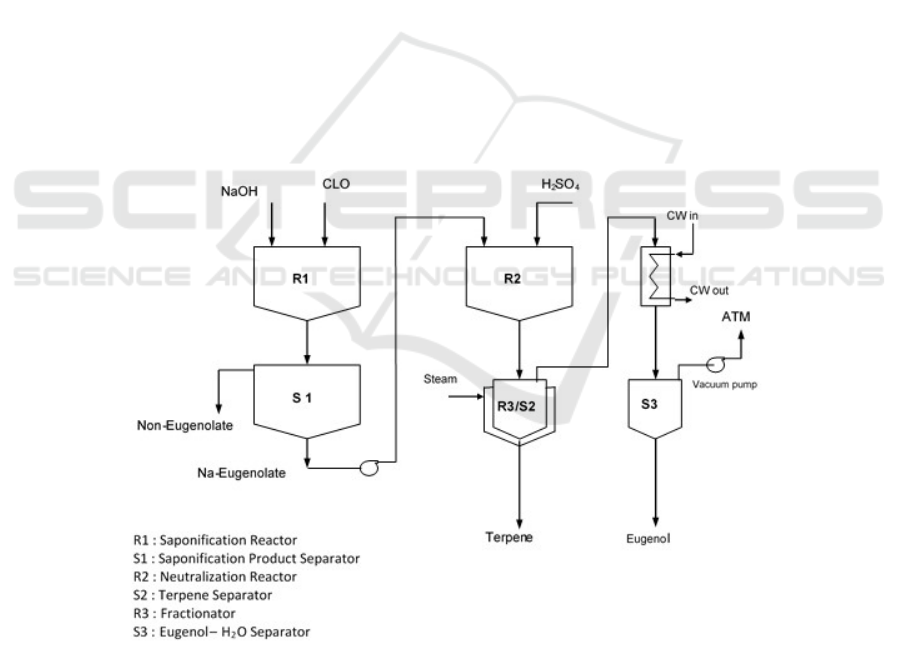

The equipment for isolation eugenol in the pilot

plant scale was described in Figure 1. Chemical

composition was determined by Gas

Chromatography-Mass Spectrometer (GCMS)

Agilent 6890.

2.2 Methods

2.2.1 Clove Leaf Oil Characterization

The characterization was carried out on clove leaf oil

includes specific gravity, refractive index, solubility

in alcohol and chemical component using GCMS.

2.2.2 Determination of Sodium Hydroxide

Concentration Excess for

Saponification

This experiment was done in laboratory scale, to

observe the effect of sodium hydroxide excess on the

saponification process. CLO was mixed with NaOH

in varying excess concentrations (3%, 5%, and 10%).

The mixture was stirred with a magnetic stirrer for 30

minutes and then allowed to stand 24 hours, there will

be two layers, the top layer is an organic layer and the

bottom layer contains sodium eugenolate layer. The

separation was observed to determine NaOH

concentration optimum.

2.3.3 Eugenol Isolation in the Pilot Plant

Scale

Eugenol isolation was being carried out in three-

stages. The first stage was saponification using

NaOH, followed by neutralizing with sulfuric acid

98% and vacuum distillation. This experiment was

done in a pilot plant scale using equipment was

described in Figure 1. CLO was mixed with NaOH

(the concentration NaOH was obtained from the

previous experiment) for 30 minutes and decanted for

12 hours.

Figure 1: Scheme of eugenol production equipment

Na-eugenolate was neutralized with H

2

SO

4

98% until

pH 5-7 and continued with decantation. The eugenol

product was distilled in atmospheric on 120

o

C to

separate water and other component in crude eugenol

and continued with vacuum distillation on 140

o

C-

150

o

C. The results were analyzed by GCMS.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

102

3 RESULTS AND DISCUSSION

3.1 Characterization of Clove Leaf Oil

The results of clove leaf oil characterization of which

includes physical and chemical properties can be seen

in Table 1. The characteristics of clove leaf oil in

general, include relative density, refractive index, and

miscibility in ethanol appropriated with the

requirements in SNI 06-2387-2006 Clove leaf oil.

Table 1: Clove oil characterization

Specification

Unit Result Requirements in

SNI 06-2387-

2006

Relative density

at 20

o

C

- 1.024 1.025 – .,049

Refractive

index (

n

D

20

)

- 1.53 1.528 – 1.535

Miscibility in

ethanol 70%,

20

o

C

- 1:2

clear

1 : 2 clear

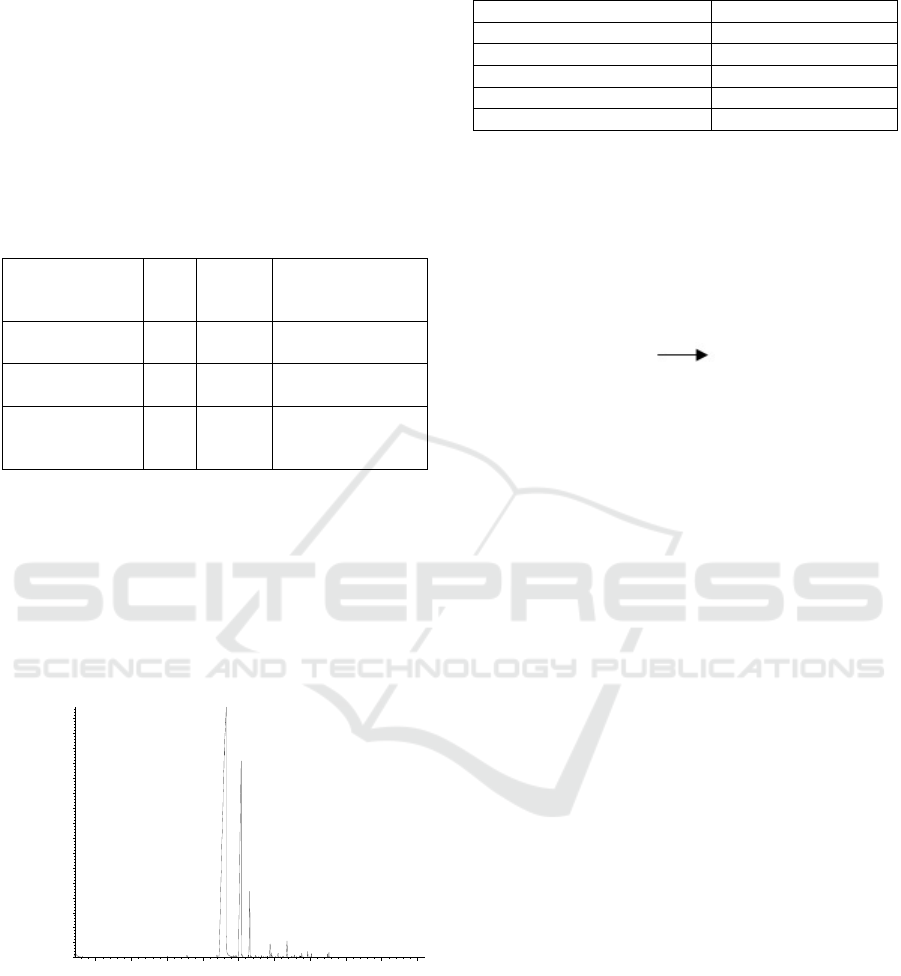

Figure 2 shows the analysis of clove leaf oil using

GCMS. The chromatogram has 5 peaks on retention

time 23.007 min to 31.147 min, with two major

components are eugenol (75.22%) and beta-

caryophyllene (15.40%), and the others small

quantities components such as alpha humulene, delta

cadinene and caryophyllene oxide (Table 2).

Figure 2: GCMS chromatogram of clove leaf oil

Standard quality for clove leaf oil (SNI 06-2387-2006

Clove leaf oil) requirements minimum eugenol

content was 78%. Eugenol contents in clove leaf oil

from small industry in Jawa Timur is 75.22%, so it is

below standard trade and needs to improve.

Table 2: Chemical compound composition in clove leaf oil

Chemical compound Abundance (%)

Eugenol 75.22

beta-Caryophyllene 15.40

Alpha-humulene 3.51

Delta-cadinene 1.60

Caryophyllene oxide 3.22

3.2 The Optimization of NaOH Excess

on Saponification

Saponification is a reaction in which an ester is mixed

with an alkali, such as sodium hydroxide producing a

carboxylate salt. Eugenol as an ester reacted with

sodium hydroxide to form sodium eugenolate salt:

Eug-OH + NaOH Eug-ONa+ H

2

O

Clove leaf oil which was originally blackish

brown when it was added with NaOH became Na-

eugenolate (turbid yellow). NaOH excess

concentration was added in this experiment are

different (3%, 5%, and 10%). 15 minutes after

stopped the mixing, the two layers were formed,

yellow liquid in the bottom layer (Na-eugenolate) and

brown liquid in the top of the layer (organic layer).

The Na-eugenolate forming was not perfect in

NaOH excess 3%, the separation between organic

layer (terpene) and aqueous layer (Na-eugenolate)

have not be seen yet. It indicated that all of eugenol

has not converted to Na-eugenolate on NaOH excess

3% so the NaOH concentration must be increased.

NaOH excess 5% gave the good separation between

terpene and Na-eugenolate, therefore the separation

was quick and more obvious with NaOH excess 10%.

However, the NaOH excess 5% was selected for the

saponification process in this experiment because the

eugenol conversion was complete and the NaOH

amount was not too excess. Some previous studies

used NaOH excess concentration in 3% (Khalil et al.,

2017); 5% (Sastrohamidjojo and Fariyatun, 2016);

and 2 M (Just et al., 2016) which gave optimum alkali

concentration in saponification.

3.3 The Eugenol Isolation in the Pilot

Plant Scale

The eugenol isolation in the pilot plant scale can be

described in three main steps simultaneous

saponification and distillation. Briefly, the steps can

be described as follows: saponification using NaOH,

neutralization with H2SO4 and separation with

decantation. Clove leaf oil as raw material was used

about 200 litres (204.8 kg). The saponification

5.00 10.00 15.00 20.00 25.00 30. 00 35.00 40.00 45.00 50.

0

0

500000

1000000

1500000

2000000

2500000

3000000

3500000

4000000

4500000

5000000

5500000

6000000

6500000

7000000

7500000

8000000

Time-->

A

bundance

TI C: MIN YAK CENGKEH.D\ dat a. ms

Eugenol Production from Clove Oil in Pilot Plant Scale for Small and Medium Enterprises (SME)

103

process with NaOH 5% excess needs 39 kg of NaOH

(or 40 kg of NaOH flake with purity is 98%).

Saponification process carried out in R1 column

(Saponification Reactor). NaOH flake dissolved in

1296 litres of water while stirring to get concentration

3%-wt. After dissolving, clove leaf oil was poured to

R1. Saponification reaction in R1 fast. The result of

saponification was formed two layers, the upper layer

was an organic layer (terpene layer) and the bottom

layer was aqueous layer Na-eugenolate layer.

Eugenol was reacted with NaOH to form Na-

eugenolate which is soluble in water. The other

component of clove leaf oil except eugenol such as

caryophyllene was not reacted with NaOH and

insoluble in water. This mixture was flowed in S1 to

separate the layers with decantation. Na-eugenolate

was streamed to R2 (neutralization reactor) and the

terpene layer was collected. This process results in

52,3 litres of a terpene.

Na-eugenolate layer in R2 was added with 49 kg

of H

2

SO

4

98% to neutralization. The neutralization

reaction is:

NaO-Eug + H

2

SO

4

Na

2

SO

4

+ 2H

2

O + Eug

During the addition of acid, the solution was

stirred for 30 minutes and the pH was 4,0. The Na-

eugenolate was converted to eugenol and Na2SO4

salt was formed. The eugenol was on the bottom layer

and Na2SO4 salt was on the upper layer. The eugenol

content was 96%. This process results in 157.3 kg of

eugenol. The eugenol layer was streamed to R3

(distillation unit) to purification and the salt in R2 was

discarded.

The distillation unit (R3) is a distillation reactor

with a steam heater, agitator, condenser, storage tank,

vacuum pump, and sight glass. The distillation

process was carried out using steam distillation. In

R3, the process was continued with eugenol

purification step using atmospheric distillation and

vacuum distillation. The atmospheric distillation

intends to separate water and initial fraction that

might still be passed of crude eugenol. It has been

done at (±120

o

C). The heating was carried out until

the liquid in the tank are no turbulent when the stirrer

is stopped. After the water was separated, the

distillation was continued with vacuum distillation on

effective pressure 750 mmHg below zero (outside air

pressure was 1 atm) and the eugenol distillation

temperature was 140

o

C-150

o

C (in 1 atm, the boiling

point of eugenol is 225

o

C. because the R3 distillation

column only 100 litres, and for safety, carry out was

only filled about 90 litres, hence to process 157.3 kg

of crude eugenol was carried out with 4 steps. Each

step was 90 litres after the residue was only 45 litres

the distillate was taken and the residue was added

with new eugenol.

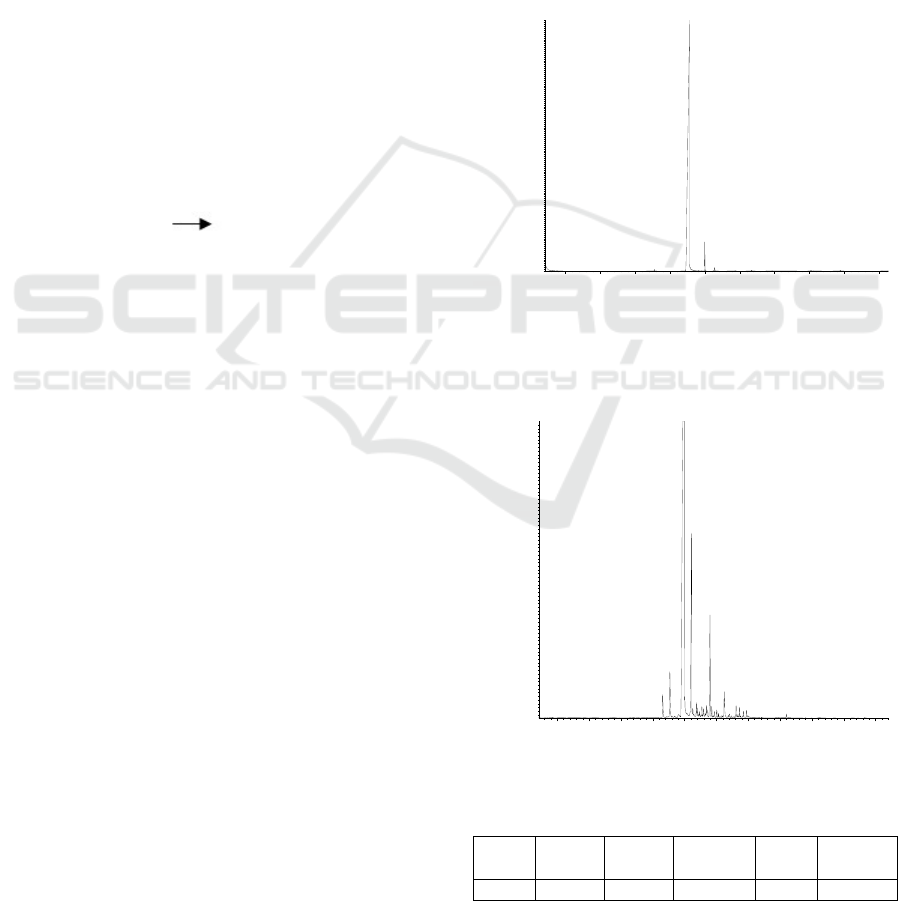

Figure 3 and 4 show the chromatogram of eugenol

and terpene that were analyzed by GCMS. The

GCMS chromatogram in Figure 3 showed the mayor

peak in retention time 23.007 which is the eugenol

peak with the abundance was 98%. The next peak was

beta-caryophyllene. The terpene fraction in Figure 4

showed some peaks with retention time from 22.733

to 31.337. The major component in terpene fraction

was beta-caryophyllene and alpha-caryophyllene

(Table 4).

Figure 3: GCMS chromatogram of eugenol

Figure 4: GCMS chromatogram of terpene

Table 3: The summarize of materials and product

CLO

(kg)

NaOH

(kg)

H

2

SO

4

(kg)

Eugenol

(kg)

Yield

(%)

Terpene

(L)

204.8 39 49 102.5 50.25 52.3

5.00 10.00 15.00 20. 00 25.00 30. 00 35.00 40. 00 45.00 50.0

0

0

200000

400000

600000

800000

1000000

1200000

1400000

1600000

1800000

2000000

2200000

2400000

2600000

2800000

3000000

3200000

3400000

3600000

3800000

4000000

4200000

4400000

4600000

4800000

5000000

5200000

Time-->

A

bundance

TIC: EUGENOL SINTESIS.D\ data.ms

5.00 10.00 15.00 20.00 25. 00 30.00 35. 00 40.00 45.00 50.00 55.00

5000000

1e+07

1.5e +07

2e+07

2.5e +07

3e+07

3.5e +07

4e+07

4.5e +07

5e+07

5.5e +07

6e+07

6.5e +07

7e+07

7.5e +07

Ti me-->

A

bund anc

e

TIC: 2608008. D\ dat a.ms

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

104

Terpene of clove leaf oil as the side product in

eugenol isolation has some benefit. Beta-

caryophyllene has been commonly used as a

fragrance and flavour. In recent years, beta-

caryophyllene has attracted to observe because it’s

biological activities, like antimicrobial and

antioxidant (Liu et al., 2013).

Table 4: Chemical compound in terpene

No

Retention

time

Compound

Abundance

(%)

1

22,733 α-copaene 3,37

2

24,857 β-caryophyllene 63,97

3

26,124 α- caryophyllene 14,28

4

28,972 δ- cadinene 4,27

5

31,337 caryophyllene oxide 4,48

4 CONCLUSIONS

Eugenol isolation from clove leaf oil using a

saponification-distillation method in the pilot plant

scale was successfully increase the eugenol content

from 75% to 98% with the yield was 50.25%. This

technology has beneficial in IKM applicability to

improve the clove oil quality.

REFERENCES

Anonim, 2013. The Complete Book on the Spices and

Condiments ( With cultivation, processing and uses).

Badan Standardisasi Nasional, 2006. Minyak daun cengkih.

Cassiana, P. et al., 2019. ‘Evaluation of the effects of

temperature and pressure on the extraction of eugenol

from clove ( Syzygium aromaticum ) leaves using

supercritical CO 2’, The Journal of Supercritical

Fluids. Elsevier, 143(July 2018), pp. 313–320. doi:

10.1016/j.supflu.2018.09.009.

Dewan Atsiri Indonesia, 2017. ‘Indonesian Essential Oil

Output’.

Just, J. et al., 2016 ‘Extraction of Eugenol from Cloves

Using an Unmodi fi ed Household Espresso Machine:

An Alternative to Traditional Steam-Distillation’, (iii).

doi: 10.1021/acs.jchemed.5b00476.

Kamatou, G. P., Vermaak, I. and Viljoen, A. M, 2012.

‘Eugenol—From the Remote Maluku Islands to the

International Market Place: A Review of a Remarkable

and Versatile Molecule’, pp. 6953–6981. doi:

10.3390/molecules17066953.

Kapadiya, S. M., Parikh, J. and Desai, M. A., 2018. ‘A

greener approach towards isolating clove oil from buds

of Syzygium aromaticum using microwave radiation’,

Industrial Crops & Products. Elsevier, 112(November

2017), pp. 626–632. doi:

10.1016/j.indcrop.2017.12.060.

Khalil, A. A. et al., 2017 ‘Essential oil eugenol: sources,

extraction techniques and nutraceutical perspectives’,

RSC Advances techniques and nutraceutical

perspectives, pp. 32669–32681. doi:

10.1039/c7ra04803c.

Kusworo, T. D., 2018 ‘Study of Polymeric Membranes

Potential for Eugenol Purification from Crude Clove

leaf Oil’, Asean Journal of Chemical Engineering,

18(2), pp. 81–92.

Liu, H. et al., 2013 ‘Physicochemical characterization and

pharmacokinetics evaluation of β-caryophyllene/β-

cyclodextrin inclusion complex’, International Journal

of Pharmaceutics. Elsevier B.V., pp. 1–7. doi:

10.1016/j.ijpharm.2013.04.013.

Sastrohamidjojo, H. and Fariyatun, E., 2016. ‘Synthesis of

Methyl Eugenol from Crude Cloves Leaf Oil Using

Acid and Based Chemicals Reactions’, 9(10), pp. 105–

112. doi: 10.9790/5736-091002105112.

Widayat, Hardiyanto, H. S., 2016. ‘Implementasi Proses

Adsorbsi Dalam Meningkatkan Kualitas Minyak

Cengkeh’, in Simposium Nasional RAPI XV - 2016 FT

UMS, pp. 1–7.

Eugenol Production from Clove Oil in Pilot Plant Scale for Small and Medium Enterprises (SME)

105