Separation Process of Citronellal and Rhodinol from Citronella Oil

using Vacuum Fractionations at Pilot Plant Scale

Risna Silvianti

1

, Warsito

2

, and Chandrawati Cahyani

3

1

Department of Chemistry, Faculty of Mathematics and Science, Brawijaya University

2

Department of Chemical Engineering, Faculty of Engineering, Brawijaya University

2

Institut Atsiri, Brawijaya University

Keywords: Distillation Fractionation, Citronelal Oil, Citronellal, Limonene, Rhodinol, Temperatur, Vacuum pressure.

Abstract

: The aim of this work was to separate major components from citronella oil using vacuum distillation

fractionation method. Operating condition that used in this study is vacuum pressure 10-30 mmHg. This

process depends on the pressure and temperature of the system, as well the physical and chemical

characteristics of the components to be separated.Based on GC-MS analysis of Citronella Oil is known that

citronellal, citronellol, and geraniol has yielded 7,42%; 11,25%; and 31,68%, respectively. Fractional

distillation under reduced pressure can isolate major component like limonene,citronellal,citronellol and

rhodinol with higher purity

55.56%; 25.57%; and 46.19%, respectively.

1 INTRODUCTION

Essential oils are secondary metabolites that contain

a mixture of terpenes and other complex volatile

compounds produced from living organism. Essential

oils have widely used as raw material for medicine ,

cosmetics, perfume and flavor fragrance agent

(Almeida et al., 2018). The potential components of

essential oil which generally consist of oxygenated

compounds is very important to determine quality of

essential oil and widely used as starting materials for

flavor and fragrance industry.

Potential of essential oils in Indonesia is very

large, but to supply the demand of its downstream

industry, Indonesia should to import essential oils in

the form of pure oils which contain high purity

potential components.This fact show that the

separation of the potential compounds in essential oils

is a step that needs to be done to improve the purity

of potential components that are needed by many

industries.

Separation technique of potential components of

essential oils can be carried out through chemical or

physical processes.Separation of the components of

essential oils by chemical processes can be done by

adding chemical reagents that are selective to the

desired compound, while physical separation can be

done based on the physical properties of each

compounds that can be done by fractionation

distillation method. Fractionation distillation is a

physical separation process that uses the volatility of

different components in a mixture. The advantages of

the fractionation distillation method can be used to

separate components that have adjacent boiling points

(Budiman, 2016).

Process of separation in fractionation distillation

occurs due to contact and equilibrium between vapor

and liquid in the fractionation coloumn (Ibrahim,

2014). According to Kister (1992) the main factors

that influencing the effectiveness of the separation

occuring in the fractionation process are design of

fractionation coloumn and operating conditions.

Therefore, optimization of the separation process is

needed that can provide the most optimal operating

conditions like temperature operation, so that contact

between liquid and vapor takes longer to produce

high purity compounds. The fractional distillation is

one of unit operation that aims the separation of two

or more substances using vacuum state by the

volatility difference between them. This process

depends on the pressure and temperature of the

system, as well the physical and chemical

characteristics of the components to be separated

(Eden, 2018).

Citronella oil is the essential oil from citronella

grasses (Cymbopogon winterianus) from Java Island,

Indonesia. One part of Indonesia which is abundant

Silvianti, R., Warsito, . and Cahyani, C.

Separation Process of Citronellal and Rhodinol from Citronella Oil using Vacuum Fractionations at Pilot Plant Scale.

DOI: 10.5220/0009957300910095

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 91-95

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

91

of raw essential oil source especially citronella oil in

Central Java. Central Java has the potential

production of essential oils are quite large. The oil is

used extensively as a source of perfumery chemicals

such as citronellal, citronellol, and geraniol. These

compounds are used extensively in soap, candles and

incense, perfumery, cosmetic, and flavoring

industries throughout the world (Eden, 2018).

This research will focus on the isolation of

citronellal and rhodinol compounds using vacuum

fractionation distillation by studying its optimum

operating conditions in several parameters for the

pilot plant scale.

2 MATERIAL AND METHOD

2.1 Material

The main raw material in this research are citronella

oil from Institut Atsiri Brawijaya University. The

main equipment used is vacuum distillation

fractionation capacity 20kg that consists of reflux

column, mixer, condenser, tank product that all part

connected to a vacuum pump, and another equipment

are analytical balance, bottle glass, gas

chromatography mass spectrometry, refractometer.

2.2 Method

2.2.1 Characterization of Chemical

Compounds of Citronella Oil

The first stage of this research is characterization of

chemical compounds of citronella oil. The

composition of chemical compounds contained in the

raw material of citronella oil used as reference basis

for each compound that will taken.

2.2.2 Isolation Process of Citronellal and

Rhodinol Compounds using Vacuum

Fractionation

The process of isolation of citronellal and rhodinol

compounds is carried out under vacuum pressure of

10-30 mmhg. Temperature of the vessel is set

gradually appropriate to boiling point of each

compound that contained on citronella oil.

Temperature at the top of the fractionation column

(T.head) connected with a thermocouple instrument

to observe temperature change during isolation

process. Distilate that produced at different

temperatures are collected in different container. The

temperature at the top column (T.Head) and

temperature of raw material is recorded on each

distillate that collected.

2.2.3 Analysis of Isolation Product of

Citronella Oil

Distillate that obtained from each fraction produced

in the fractionation distillation process is then

analyzed to know purity level and refractive index of

the component to determine quality of the pure

compound that produced using Gas chromatography-

Mass Spectrometry (GC–MS) .

3 RESULT AND DISCUSSION

Essential oil consist highly volatile substance that

isolated by distillation from an odoriferous plant.

Citronellal or rhodinol is the major component of the

monoterpene fraction of citronella oil and gives the

essential oil of citronella its characteristic lemon odor

is also used in many chemical syntheses (Eden,2018).

In this study, citronella oil is separated by distillation

fractionation process to produce major compound of

citronella oil like citronellal and rhodinol.

3.1 Physical Properties of Citronella Oil

Citronella oil was obtained by using steam

distillation methods are pale yellow to yellow when

freshly distilled. The physical properties of Citronella

oil shown in Table 1.

Table 1. The Physical Properties Of Citronella Oil

Parameter Result

Appearance Oily Liquid

Color Pale Yellow

Odor Sweet,citrusy,woody

Refractive Index (20

o

C) 1.467

Specific Gravity (25

o

C) 0.88

3.2 Chemical Composition of

Citronella Oil

According to the data of Gas Chromatography Mass

Spectometry (GC-MS), citronella oil consist of

terpenoid compounds as major components that show

in table 2. The major components of Citronella Oil

that used as raw material in this study are

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

92

citronellal,citronellol, and geraniol that has yield

27,42%,11,25% and 31,68% respectively. The

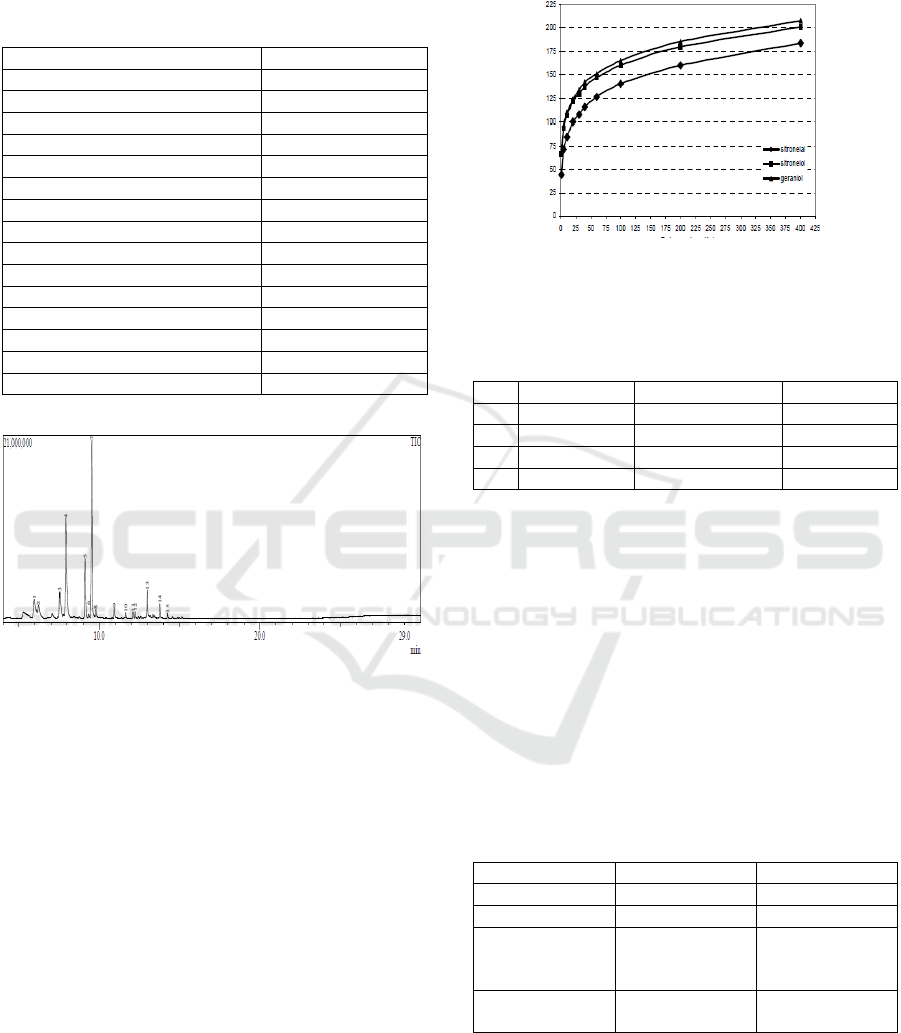

chromatogram of citronella oil shown in Figure 1.

Tabel 2. Chemical Composition of Citronella Oil

Composition Percent (%)

Limonene 7.23

Ocimen 4.08

Octatriene 6.90

Citronellal 27.42

Citronellol 11.25

Citral 0.62

Geraniol 31.68

Citronellyl Acetate 1.21

Cyclohexane 1.57

Germacrene 0.62

Benzene 1.10

Elemol 0.75

1,3-cyclopentadiene 3.24

Tricyclo hexane 1.74

Cyclopentadiene 0.58

Figure 1: Chromatogram of Citronella Oil

3.3 Isolation of Major Component

from Citronella Oil

Most terpenes such as citronellal, citronellol, and

geraniol are thermally unstable,decomposing or

oxidizing at high temperatures or the presence of light

or oxygen. Therefore, separation of component active

from citronella oil is needed a mode of vacuum

condition to decrease temperature operation (Eden,

2018). According to Egi (2005), correlation between

boiling point and pressure shown in Figure 2.

Theoritical approach of operating condition has

been done through correlation of pressure with

boiling point of the major components of citronella

oil. According to the theoritical, operating conditions

use pressure 10- 30 mmHg so the estimated boiling

point of citronellal 84,8 – 107,95

o

C, and rhodinol

107-133

o

C. Table 3 shows that theoritical boiling

point of each component of citronella oil in this study,

slightly different with theoritic data.

Figure 2: Correlation Between Presssure and Boiling Point

Table 3: Correlation of Temperature and Purity of Major

Components

No Components Temperature(

o

C) Percent (%)

1. Limonene 113-115 35.28

2. Citronellal 116-118 55,56

3. Citronellol 121-125 25,57

4. Geraniol 121-125 46,19

3.4 Physical Properties of Citronellal

and Rhodinol

Citronellal is responsible for the characteristic of odor

in citronella oil. It has flavor citrus-like odor but

seems to be less sweet and fruity than citral. Geraniol

and citronellol that called rhodinol are known as the

rose alcohols because of their occurrence in rose oils

and also because they are the key materials

responsible for the rose odor character in citronella

oil.

Each of active component has the characteristic

of physical properties that shown in Table 4.

Table 4: The Physical Properties of Citronellal and

Rhodinol from Citronella oil

Parameter Citronellal Rhodinol

Appearance Oily Liquid Oily Liquid

Color Pale yellow Colorless

Odor Citrus,slightly

sweet,green and

aldehyde, strong

Sweet, rosy

floral,citrus, soft

Refractive

Index

1.466 1.4734

3.5 Chemical Composition of Major

Component from Citronella Oil

Major components of Citronella Oil can obtained

Boiling Point (

o

C)

Pressure (mmhg)

Separation Process of Citronellal and Rhodinol from Citronella Oil using Vacuum Fractionations at Pilot Plant Scale

93

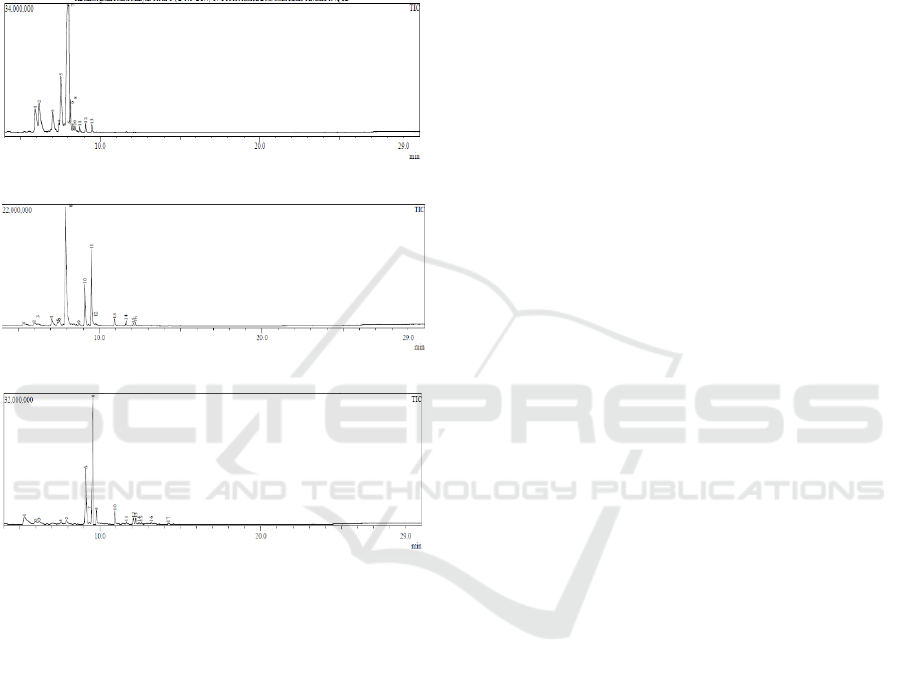

through fractional distillation process.Identification

of the major components fraction from citronella oil

was carried out by gas chromatography-mass

spectometry(GC-MS).In this study, we obtained

purity of limonene 35.28%, citronellal 55.56%,

citronellol 25.57% and geraniol 46.19%.The

chromatogram of limonene,citronellal,and rhodinol

shown in figure 3,4,5 respectively.

Figure 3: Chromatogram of Limonene

Figure 4: Chromatogram of Citronellal

Figure 5: Chromatogram of Rhodinol

4 CONCLUSIONS

Citronella oil is containt major component are

citronellal, citronellol, and geraniol with purity of

27.42%,11.25%,31.68% espectively.Vacuum

fractional distillation using operating condition with

pressure 10-30 mmhg that obtained increase purity of

major components citronellal, citronellol, and

geraniol are 55.56%; 25.57%; and 46.19%,

respectively.

ACKNOWLEDGEMENTS

Authors would say thank to Institut Atsiri Brawijaya

University for the support of this research.

REFERENCES

Agusta, A, 2000. Minyak Atsiri Tumbuhan Tropika

Indonesia, Institut Teknologi Bandung. Bandung.

Agustian., E., Sulaswatty, A., Tasrif, Laksmono, J.A., and

Adilina, I.B., 2005. Pemisahan Sitronelal Dari Minyak

Sereh Wangi Menggunakan Unit Fraksionasi Skala

Bench. J. Tek. Ind. Pert,17(2).

Almeida, R.N., Soares, R.P., and Cassel, E., 2018.

Fractionation Process Of Essential Oils By Batch

Distillation. Brazilian Journal of Chemical

Engineering, 35(3).

Atkin, P.W., 1986. Physical Chemistry, W.H. Freeman and

Company. New York.

Başer, K. H. C., and Buchbauer, G., 2010. Handbook of

Essential Oils: Science, Technology, and Applications,

CRC Press/Taylor & Francis. Boca Raton.

Beneti, S.C., Rosset, E., Corazza, M.L., 2011. Fractionation

of Citronella (Cymbopogon Winterianus) Essential Oil

and Concentrated Orange Oil Phase by Batch Vacuum

Distillation. Journal of Food Engineering, 102(4).

Budiman, A., 2016. Distilasi, Gadjah Mada University

Press. Yogyakarta.

Ferdayanti, 2014. Pemekatan Sitronelal Dalam Minyak

Sereh Wangi (Cymbopogon Nardus L.) Dengan

Fraksionasi Distilasi Dan Identifikasi Menggunakan

KG-SM. Indonesian Journal of Chemical Research,

2(1).

Geankoplis, C.J., 1993. Transport Processes and Unit

Operations, Prentice-Hall International, Inc. USA.

Górak, A., 2014. Distillation: Equipment and Processes,

Elsevier, Acad. Press. Amsterdam.

Guenther, E, 1987. The Essential Oil, Van Nostrand

Company Inc. New York.

Gunawan dan Mulyani, S., 2010. Ilmu Obat Alam

(Farmakognosi) Jilid I, Penebar Swadaya. Jakarta.

Hamzah, M.H., Man, H.C., Abidin, Z.Z., and Jamaludin,

H., 2013. Comparison of Citronella Oil Extraction

Methods from Cymbopogon Nardus Grass by Ohmic-

Heated Hydro-Distillation, Hydro-Distillation, and

Steam Distillation. BioResources, 9(1).

Hanson, J.R., 2010. Terpenoids and Steroids Volume 12,

The Royal Society of Chemistry. London.

Harris, R., 1989. Tumbuhan Minyak Atsiri, Penebar

Swadaya. Jakarta.

Heat, H.B., and Reineccius, G.,1986. Flavor Chemistry and

Technology, Van Nostrand Reinhold Company. New

York An AVI Book.

Ibrahim, H.A.H., 2014. MATLAB Applications for the

Practical Engineer. Licensee InTech.

Jalonszynski, K, A.F., and Wojdylo, A., 2008. Drying

Kinetics and Antioxydant Activity of Olegano,

Acta

Agrophysica.

Czaikoski, M.C.K., Mesomo, R.L.K., Queiroga, C.L., and

Corazza, M.L., 2015. Extraction of Campomanesia

Xanthocarpa Fruit Using Supercritical CO

2

and

Bioactivity Assessments. The Journal of Supercritical

Fluids, 98.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

94

Kister, H.Z., 1992. Distillation Design, McGraw-Hill. New

york USA.

Klemas, L., Bonilla, J.A., and City, E., 2000. Packed

Columns: Design and Performance.

Komariah, Nurul, L., Ramdja, A.F., and Leonard, N., 2009.

Tinjauan Teoritis Perancangan Kolom Distilasi Untuk

Pra-Rencana Pabrik Skala Industri. 16(4).

Wiwid, L., and Wijayanti., 2004. Isolasi Sitronelal,

Sitronelol dan Geraniol dari minyak sereh wangi

dengan distilasi fraksionasi pengurangan tekanan serta

sintesis Hidroksisitronelal. Universitas Gadjah Mada.

Tesis.

Muyassaroh., 2011. Sitronellal Dari Minyak Sereh Wangi

Dengan Variasi Kecepatan Pengadukan Dan

Penambahan Natrium Bisulfit. Jurusan Teknik Kimia,

Fakultas Teknologi Industri, Institut Teknologi

Nasional.

Pratika, S.D., 2014. Sintesis Hidroksi Sitronelal Dari

Sitronelal Yang Diisolasi Dari Minyak Sereh.

Universitas Gadjah Mada.

Rehman, R, Hanif, M.A., Mushtaq, Z., and Al-Sadi, A.M.,

2016. Biosynthesis of Essential Oils in Aromatic Plants

a Review. Food Reviews International, 32(2).

Santoso, H.B., 1992. Sereh Wangi Bertanam Dan

Penyulingan, Kanisius. Yogyakarta.

Setyadji, M., 2007. Pemilihan Bahan Isian Dan

Perbandingan Refluks Pada Distilasi Pemisahan

Metanol Dari Produk Samping Biodiesel.

Silvestre, W.P., Agostini, F., Muniz, L.A.R., and Pauletti,

G.F., 2016. Fractionating of Green Mandarin (Citrus

Deliciosa Tenore) Essential Oil by Vacuum Fractional

Distillation. Journal of Food Engineering, 178.

Smith, J.M, Ness, H.C.V., Abbott, M.M., and Swihart,

M.T., 2018. Introdustion to Chemical Engineering

Thermodynamics. 8th edition, McGraw-Hill. USA.

Speight, J., 1993. Gas Environmental and Processing.

Separation Process of Citronellal and Rhodinol from Citronella Oil using Vacuum Fractionations at Pilot Plant Scale

95