Characterization of Seedlac Hydrolysis from Kesambi (Schleicera

oleosa Merr) as an Intermediate Compound for Fragrance Synthesis

Retno Yunilawati

1

, Dwinna Rahmi

1

, Chicha Nuraeni

1

, Arief Riyanto

1

, Novinci Muharyani

2

, Pujo

Sumantoro

2

, Murgunadi

2

, and Nur Hidayati

1

1

Badan Penelitian dan Pengembangan Industri, Kementerian Perindustrian, Indonesia

2

Pusat Penelitian dan Pengembangan Perum Perhutani, Indonesia

Keywords: Seedlac, Kesambi, Hydrolysis, Aleuritic Acid.

Abstract: Seedlac is the organic resin obtained from secretion of female insect Laccifer lacca Kerr on a selected plant,

one of them is Kesambi (Schleicera oleosa Merr). Seedlac contains almost 80% polyester which can be

hydrolysed to ester compounds such as aleuritic acid which is an intermediate compound for the fragrance

synthesis of the perfume industry. One of the problems in the seedlac hydrolysis is the presence of natural

dyes (laccaic acid) which interfered with the hydrolysis process and affect the purity of the hydrolysis

products. In this research, hydrolysis was carried out by first removing the natural dyes of shellac (decolorized

process). The hydrolysis results were characterized using Gas Chromatography-Mass Spectrometry to

determine the type of ester and its composition. The decolorized process of seedlac before hydrolysis in this

experiment could improve the percentage of aleuritic acid up to 56%. Therefore, seedlac hydrolysis by

decolorized process before hydrolysis can be considered for the production of esters from seedlac, especially

aleuritic acid.

1 INTRODUCTION

Lac is an organic resin secreted by the insect Laccifer

lacca Kerr on a selected plant (Sutherland and Río,

2014) (Nagappayya and Gaikar, 2010). In Indonesia,

Kesambi (Schleicera oleosa Merr) is a plant

prioritized for use as the host plant in the cultivation

of the insects (Taskirawati et al., 2017). Lac forms a

solid material on the branches of host plants attacked

by the insects, and when collected in this form it is

referred to as sticklac. The sticklac is crushed and

sieved to remove impurities to get seedlac. Further

processing in the refining of seedlac produced

shellac.

Lac in Indonesia is developed by Perhutani

(Probolinggo) and the insect’s cultivation has spread

evenly in Nusa Tenggara Barat and Nusa Tenggara

Timur (Taskirawati et al., 2017). Pehutani produced

lac in the form of seedlac to fulfil domestics and

foreign market and used mainly as varnish. So far

there was no diversification of other lac products

were done by Perhutani.

Shellac consists of 68% resin, 6% wax, and 1-2%

dyes (such as laccaic acid and erythrolaccin). The

resin of seedlac is a mixture of cross-linked polyester

or cyclic aliphatic polyhydroxy acid with

sesquiterpenic acid (Biswas, 2014) (Sutherland and

Río, 2014) (Nagappayya and Gaikar, 2010). The

composition varies depending on the insect species

and the host plant where seedlac is obtained (Farag

and Leopold, 2009). The main compositions of

polyester in shellac consists of aleuritic acid, butolic

acid, shellolic acid and jalaric acid (Farag, 2010).

Aleuritic acid (9,10,16-trihydroxyhexadecanoic

acid) was used as the starting material because of its

multi functionalities (Ravi, Padmanabhan and

Mamdapur, 2001). Aleuritic acid is mainly used in the

perfumery industry, as a starting material for

preparation isoambritolite is the main ingredient

fragrance compounds "musk" (Biswas, 2014).

Derivatization of shellac to aleuritic acid can increase

shellac added value up to 15 times (Prasad, 2014).

The most common method in the isolation of

aleuritic acid is alkaline hydrolysis of lac resin,

separation, and purification. Besides containing

polyester, seedlac also contains natural dyes which

the presence influences the isolation of aleuritic acid.

It is possible that polyester could be transferred into

the colorant matrix (Berbers et al., 2019) and so the

otherwise that colorant matrix could have been

86

Yunilawati, R., Rahmi, D., Nuraeni, C., Riyanto, A., Muharyani, N., Sumantoro, P., Murgunadi, . and Hidayati, N.

Characterization of Seedlac Hydrolysis from Kesambi (Schleicera oleosa Merr) as an Intermediate Compound for Fragrance Synthesis.

DOI: 10.5220/0009957200860090

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 86-90

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

transferred when attempting the separation, it can

prolong the purification process. In this experiment,

seedlac was hydrolysis after decolorized. The dyes

were obtained in the decolorized process ca be used

as natural dyes. Product hydrolysis was compared

with seedlac hydrolysis product without the

decolorized process.

2 MATERIALS AND METHOD

2.1 Materials

Seedlac was used in this experiment obtained from

Perhutani. The chemical materials used in this

experiment were methanol (Merck), potassium

hydroxide (Merck), ethyl acetate (Merck),

hydrochloric acid (Merck), n-hexane, and activated

charcoal.

2.2 Method

2.2.1 Seedlac Characterization

The characterization of seedlac includes moisture

contents, ash contents, and acid value. A Fourier

Transform Infrared (FTIR) spectra were collected for

seedlac to determine the functional group.

2.2.2 Extraction of Natural Dyes

(decolorized process)

Seedlac that have been crushed macerated using

water with a ratio of seedlac: water is 1:10.

Maceration is carried out for 3-4 hours at room

temperature while stirring (Yaqub et al., 2014),

2014). After maceration, filter the products, take the

filtrate as natural dyes and the pulp for hydrolysis.

2.2.3 Hydrolysis of Seedlac

There are 2 types of hydrolysed seedlac, one is

seedlac from the 2.3 process, namely decolorized

seedlac, and the second is pure seedlac. To a reflux

apparatus add 20 g of seedlac granules, 80 mL of

methanol and 11 g of potassium hydroxide dissolved

in 100 mL water, reflux for 15 minutes. Then the

methanol is distilled off completely and the solution

is then neutralized until pH 5 is reached. Then add 4

g of activated charcoal, filter while hot and let stand

for 3 days. Then the solution is filtered and the filtrate

is added to a beaker with boiling water. Add just

enough of ethyl acetate until all of the crude product

dissolves. 800 mg of activated charcoal and 2-4 g of

sodium sulphate is added and the solution is brought

to boil. The solution is filtered and few drops of n-

hexane are added, the solution is then allowed to

stand for 24 h and it is then filtered and dried.

2.2.4 Characterization of Seedlac Hydrolysis

A Fourier Transform Infrared (FTIR) spectra were

collected for seedlac hydrolysis to determine the

functional groups. Seedlac hydrolysis compounds

were identified by gas chromatography with a mass

spectrometer detector (GCMS) Agilent 6890 series

with capillary column HP-5MS, 30 m x 0.25 mm id x

0.25 µm film thickness. Helium gas was used as the

carrier gas at constant flow mode at 1.5 mL/min. The

sampel was injected with a volume of 2 µL in splitless

mode. The increasing of oven temperature was

programmed from 50-320°C with step of 10°C per

minute until reaching 320°C and hold 12 min.

3 RESULTS AND DISCUSSION

3.1 Characterization of Seedlac

Moisture content, ash content and acid value in this

experiment are presented in Table 1. The acid value

(AV) is a good indicator of the quality of seedlac

(Farag and Leopold, 2009). AV indicates the content

of acid available in the seedlac. AV was expressed as

the weight of KOH in mg needed to neutralize the

organic acids. Some studies reported seedlac has

various AV, ranging from 55 to 85 (Prasad, 2014).

During storage, polymerization induced by

esterification takes place, resulting in a decrease in

the AV (Farag and Leopold, 2009). AV in this study

is very low compared to AV in the literature already

mentioned.

The seedlac used in this experiment may have

been stored for a long time. Aldehydes are

susceptible to oxidation and the aldehyde groups in

seedlac are converted to carboxylic acid groups over

time (Shearer, 1989). The polymerization of

carboxylic acid can occur over time during storage.

There are also a large number of free hydroxyl groups

which are susceptible to further esterification during

storage. Therefore, AV has decreased.

Characterization of Seedlac Hydrolysis from Kesambi (Schleicera oleosa Merr) as an Intermediate Compound for Fragrance Synthesis

87

Tabel 1: Water content, ash content and acid value of

seedlac

Specification Unit Result

Water content % (wt) 3.60

Ash content % (wt) 6.60

Acid value mg KOH / g 13.14

4000 3500 3000 2500 2000 1500 1000 500

80

90

100

%T

Wavenumber (cm-1)

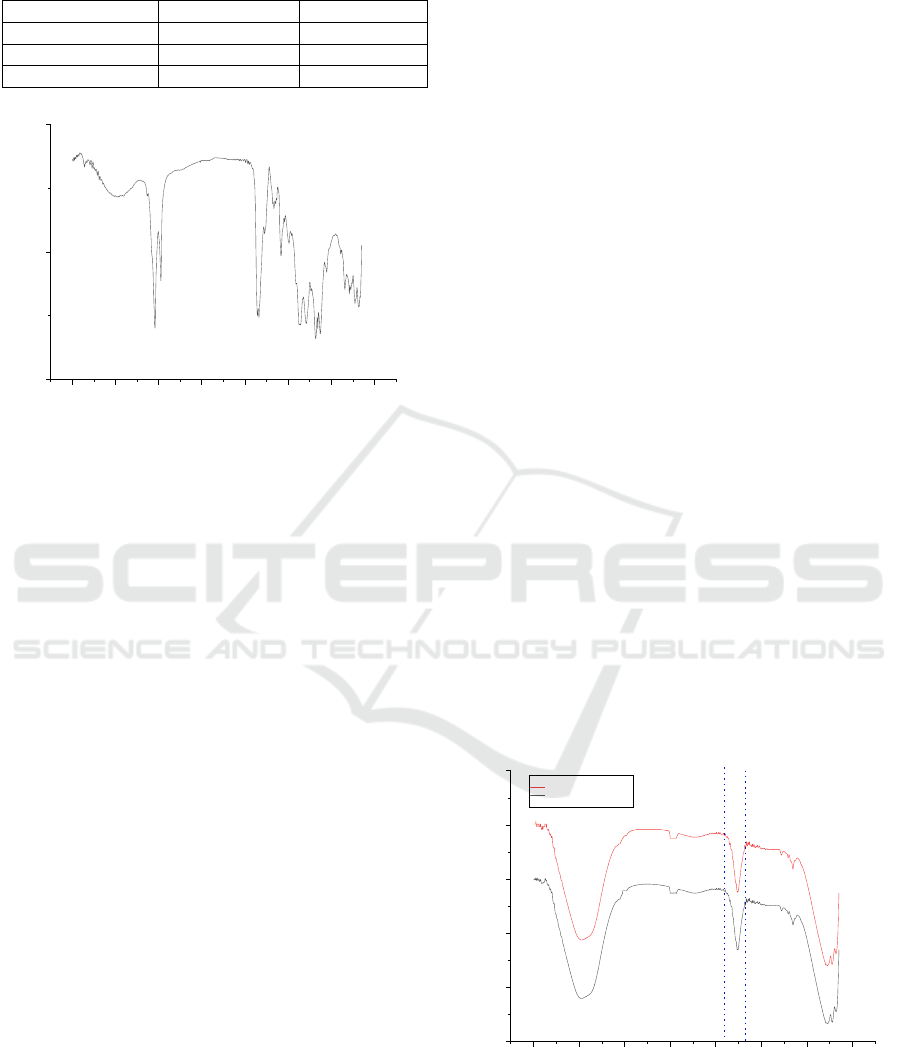

Figure 1: FTIR spectra of seedlac

FTIR spectroscopy was performed to determine

the functional groups in seedlac, the result was shown

in Figure 1. The carbonyl groups absorption of

seedlac has three shoulder in the region of 1640 cm

-1

,

1610 cm

-1

and 1550 cm

-1

. A broad peak in the range

between 3400 cm

-1

-3300 cm

-1

indicated the stretching

vibration of hydroxyl group (O-H), and bands at 2934

cm

-1

-2920 cm

-1

and 2857 cm

-1

was the C-H stretching.

The carbonyl band from ester formation was visible

at 1730 cm

-1

, and the band at 1715 cm

-1

corresponds

to acid groups. An olefinic band from C=C stretching

was present at 1630 cm

-1

, while C-O bands from ester,

acid and alcohol groups are present at 1240 cm

-1

,

1163 cm

-1

, and 1040 cm

-1

, respectively (Derry, 2012).

The region between 1500 cm

-1

and 900 cm

-1

was very

characteristic for shellac.

3.2 Seedlac Hydrolysis

Aleuritic acid (9,10,16-Trihydroxyhexa-decanoic

acid) was a major constituent acid of lac resin and

founded in the lac resin about 35% (Prasad, 2014).

The terminal hydroxyl and carboxyl functional

groups on aleuritic acid made it an excellent starting

material for the synthesis of perfumery chemicals like

macrocyclic lactones such as civetone, ambrettolide,

isoambrettolide (Nagappayya and Gaikar, 2010).

Aleuritic acid in the seedlac was in the form of

polyester.

Aleuritic acid was obtained from seedlac through

four steps. The first step was the hydrolysis of seedlac

by sodium or potassium hydroxide. The second step

involves the filtration of hydrolysate and washing of

the precipitates with saturated saltwater to yield

sodium aleuritate. The third step was acidified

sodium aleuritate using hydrochloric acid or

sulphuric acid to yield aleuritic acid. The last step was

the purification of aleuritic acid.

Lac contains natural dyes, namely erythrolaccin

and laccaic acid which are still present in seedlac.

Erythrolaccin forms a violet coloured salt when

reacted with alkali. This could interfere with the

purification process. In this experiment, seedlac was

decolorized to reduce interference. Decolorized of

seedlac was carried out by maceration at room

temperature and get natural dyes. The residue of

maceration was used in hydrolysis to yield aleuritic

acid. From this process, the natural colour was

obtained beside the aleuritic acid.

3.3 FTIR Spectrum of Product

Hydrolysis

Several analytical techniques have been applied to

study the resin of lac, and spectroscopic methods are

most widely used (Sutherland and Río, 2014). The

FTIR spectroscopy was used to investigate the

hydrolysis product of seedlac and decolorized seedlac

in this experiment. When they were compared, FTIR

spectrum of hydrolysis product from seedlac and

decolorized seedlac showed the same pattern, there

was no significant difference (Figure 2.). The main

band at 1702 cm

-1

corresponded to the C=O of

carboxylic acid groups (Heredia-Guerrero et al.,

2010). If the spectra were compared with seedlac

spectra, there were some differences.

4000 3500 3000 2500 2000 1500 1000 500

1702cm

‐1

%T

Wavenumber (cm-1)

seedlac hydrolysis

decolorized seedlac hydrolysis

Figure 2: FTIR spectra of hydrolysis product from seedlac

and decolorized seedlac

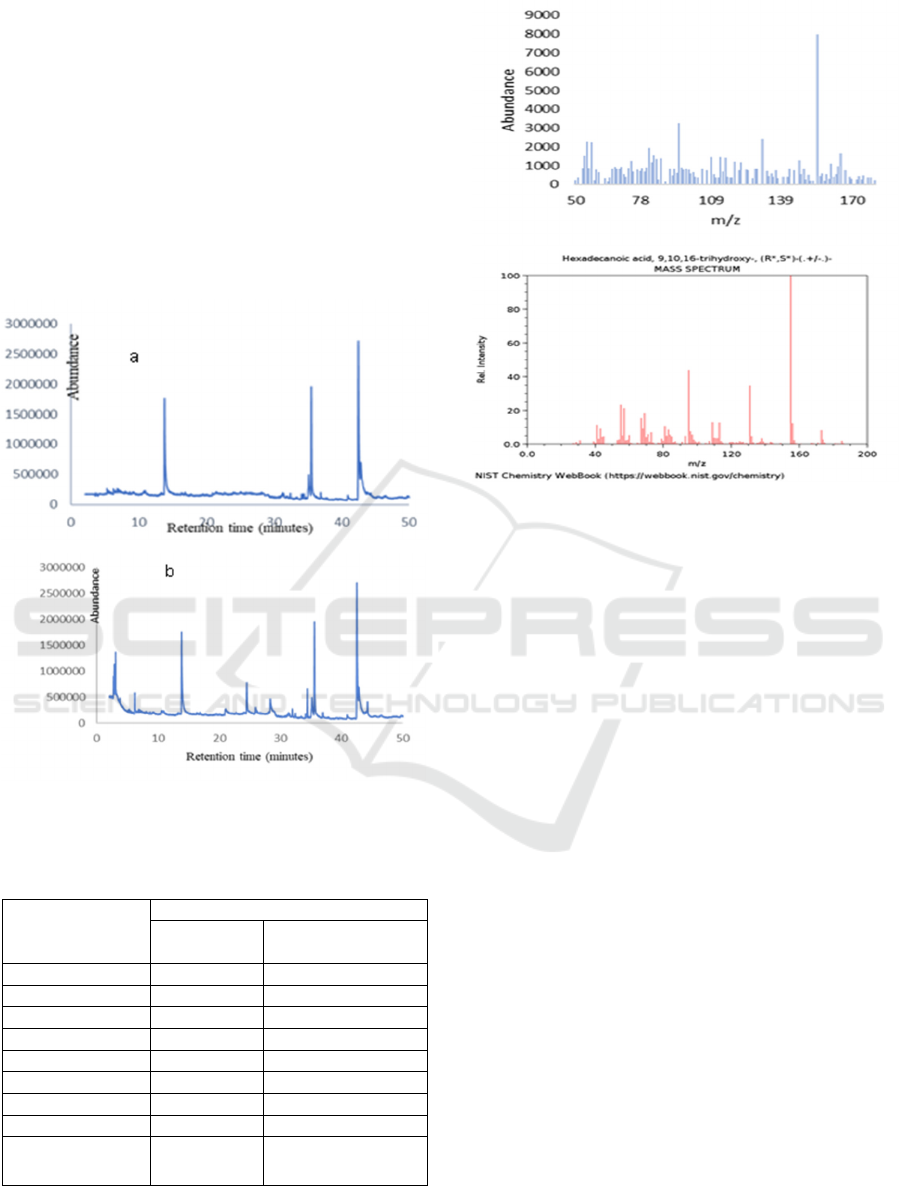

Characterization of the hydrolysis product of

seedlac and decolorized seedlac using GCMS was

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

88

shown in Figure 3. The chromatogram of decolorized

seedlac has three dominant peaks in retention time

13,87 minutes; 35,73 minutes and 42,80 minutes. The

chromatogram of seedlac has more peaks but not all

of the peaks were dominant peaks. Several peaks in

the chromatogram of seedlac indicated the impurities

of hydrolysis products. Decolorized process of

seedlac could eliminate the natural dyes which

interfere with the purification process, therefore the

chromatogram of decolorized seedlac has fewer

peaks. The aleuritic acid was suspected in retention

time 42,80 minute by comparing mass spectrum with

reference (NIST Chemistry WebBook).

Figure 3: GCMS Chromatogram of product hydrolysis a:

decolorized seedlac; b: seedlac

Tabel 2: Relative percentage area of peaks on GCMS

chromatogram

Retention time

(minutes)

Relative percentage area (%)

seedlac

hydrolysis

Decolorized

seedlac hydrolysis

3.48 2.29 -

6.23 1.76 -

13.86 13.87 20.07

24.52 5.56 -

28.38 6.31 -

34.45 3.20 -

35.16 4.44 6.83

35.58 11.31 19.43

42.51 (aleruritic

acid)

28.43 44.30

Figure 4: Mass spectrum of peak in retention time 42,80

minutes and reference

The relative percentage area of each

chromatogram peak was summarized in Table 2. The

percentage area of aleuritic acid from decolorized

seed hydrolysis (44.30%) was greater than aleuritic

acid from seedlac hydrolysis (28.43). The decolorized

process of seedlac before hydrolysis in this

experiment could improve the percentage of aleuritic

acid up to 56% (from 28.43% to 44.30%).

4 CONCLUSIONS

Characterization of seedlac hydrolysis with the

decolorized process before hydrolysis showed that

the percentage of aleuritic acid as a hydrolysis

product could be improved from 28.43 % to 44.30%.

This method could be considered in the production of

aleuritic acid from seedlac.

REFERENCES

Berbers, S. V. J. et al. (2019) ‘Historical formulations of

lake pigments and dyes derived from lac : A study of

compositional variability’, Dyes and Pigments.

Elsevier, 170(March), p. 107579. doi:

10.1016/j.dyepig.2019.107579.

Biswas, S. (2014) ‘Preparation of Environment Friendly

Composites from Effluent of Aleutitic acid Industry and

Modified Betel-Nut Fiber’,

Int.J.Curr.Res.Chem.Pharma.Sci, 1(6), pp. 50–55.

Characterization of Seedlac Hydrolysis from Kesambi (Schleicera oleosa Merr) as an Intermediate Compound for Fragrance Synthesis

89

Derry, J. (2012) ‘Investigating shellac: documenting the

process, defining the product. A study on the processing

methods of shellac, and the analysis of selected physical

and chemical characteristics’, The Institute of

Archeology, Conservation and History, Faculty of

Humanities, Master The.

Farag, Y. (2010) Characterization of Different Shellac

Types and Development of Shellac-Coated Dosage

Forms, Fakultät für Mathematik, Informatik und

Naturwissenschaften.

Farag, Y. and Leopold, C. S. (2009) ‘Physicochemical

Properties of Various Shellac Types’, Dissolution

Technologies, (May), pp. 33–39.

Heredia-Guerrero, J. A. et al. (2010) ‘Aleuritic (9,10,16-

trihydroxypalmitic) acid self-assembly on mica’,

Physical Chemistry Chemical Physics, 12(35), pp.

10423–10428. doi: 10.1039/c0cp00163e.

Nagappayya, S. K. and Gaikar, V. G. (2010) ‘Extraction of

Aleuritic Acid from Seedlac and Purification by

Reactive Adsorption on Functionalized Polymers’,

Ind.Eng.Chem.Res, 49, pp. 6547–6553.

Prasad, N. (2014) ‘Final Report of NAIP sub-project on A

Value Chain on Lac and Lac based Products for

Domestic and Export Markets’, . Indian Institute of

Natural Resins and Gums, Namkum, Ranchi.

Ravi, S., Padmanabhan, D. and Mamdapur, V. R. (2001)

‘Macrocyclic musk compounds: Synthetic approaches

to key intermediates for exaltolide, exaltone and

dilactones’, Journal of the Indian Institute of Science,

81(3), pp. 299–312.

Shearer, G. L. (1989) ‘An Evaluation of Fourier Transform

Infrared Spectroscopy for the Characterzation of

Organic Compounds in Art and Archaeology’,

(October), pp. 1–399.

Sutherland, K. and Río, J. C. (2014) ‘Characterisation and

discrimination of various types of lac resin using gas

chromatography mass spectrometry techniques with

quaternary ammonium reagents’, Journal of

Chromatography A. Elsevier B.V., 1338, pp. 149–163.

doi: 10.1016/j.chroma.2014.02.063.

Taskirawati, I. et al. (2017) ‘Peluang investasi dan strategi

pengembangan usaha budidaya kutu lak (Laccifer lacca

Kerr): studi kasus di KPH probolinggo, perum

perhutani unit II jawa timur’, Jurnal Entomologi

Indonesia, 4(1), p. 42. doi: 10.5994/jei.4.1.42.

Yaqub, A. et al. (2014) ‘Isolation and its Purification of

Laccaic Acid Dye from Stick Lac and study of its (

Colour Fastness ) Properties and Reflactance on Silk

Fabric Dyed with Heavy Metal Mordants’, Technical

Journal, University of Engineering and Technology

Taxila, 19(I), pp. 6–12.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

90